Nichrome's Role in Improving Electrical Conductivity

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Conductivity Background and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has played a significant role in the evolution of electrical conductivity since its discovery in the early 20th century. The development of this material marked a crucial milestone in the pursuit of improved electrical performance across various applications. Initially utilized for its high resistance properties in heating elements, nichrome's potential for enhancing electrical conductivity has become increasingly apparent in recent years.

The historical trajectory of nichrome's application in electrical systems has been characterized by continuous refinement and exploration. As researchers and engineers delved deeper into the material's properties, they uncovered its unique ability to maintain stable electrical characteristics under varying environmental conditions. This stability, coupled with its corrosion resistance, has positioned nichrome as a material of interest for improving electrical conductivity in challenging environments.

The primary objective in exploring nichrome's role in improving electrical conductivity is to leverage its inherent properties to address current limitations in electrical systems. Researchers aim to optimize the alloy's composition and structure to enhance its conductive properties while maintaining its beneficial characteristics such as temperature resistance and durability. This pursuit is driven by the growing demand for more efficient and reliable electrical components in industries ranging from electronics to aerospace.

One of the key goals in this technological exploration is to develop nichrome-based materials that can offer superior conductivity compared to traditional copper or aluminum conductors, especially in high-temperature or corrosive environments. This objective aligns with the broader industry trend towards miniaturization and increased power density in electronic devices, where materials capable of efficiently conducting electricity under extreme conditions are highly sought after.

Furthermore, the investigation into nichrome's conductivity enhancement potential extends to its application in composite materials and thin-film technologies. Researchers are exploring ways to integrate nichrome into novel material systems that can exhibit improved electrical properties while addressing other engineering challenges such as weight reduction and thermal management.

The technological trajectory in this field is expected to focus on several key areas: optimizing the nickel-chromium ratio and introducing additional alloying elements to fine-tune electrical properties; developing advanced manufacturing techniques to control the microstructure of nichrome-based conductors; and exploring surface treatments or coatings that can further enhance the material's conductive capabilities.

As the research progresses, the ultimate aim is to position nichrome-derived materials as a viable alternative or complement to existing conductive materials, particularly in specialized applications where traditional conductors fall short. This endeavor not only seeks to improve the performance of current electrical systems but also to enable new technologies that can benefit from nichrome's unique combination of electrical and mechanical properties.

The historical trajectory of nichrome's application in electrical systems has been characterized by continuous refinement and exploration. As researchers and engineers delved deeper into the material's properties, they uncovered its unique ability to maintain stable electrical characteristics under varying environmental conditions. This stability, coupled with its corrosion resistance, has positioned nichrome as a material of interest for improving electrical conductivity in challenging environments.

The primary objective in exploring nichrome's role in improving electrical conductivity is to leverage its inherent properties to address current limitations in electrical systems. Researchers aim to optimize the alloy's composition and structure to enhance its conductive properties while maintaining its beneficial characteristics such as temperature resistance and durability. This pursuit is driven by the growing demand for more efficient and reliable electrical components in industries ranging from electronics to aerospace.

One of the key goals in this technological exploration is to develop nichrome-based materials that can offer superior conductivity compared to traditional copper or aluminum conductors, especially in high-temperature or corrosive environments. This objective aligns with the broader industry trend towards miniaturization and increased power density in electronic devices, where materials capable of efficiently conducting electricity under extreme conditions are highly sought after.

Furthermore, the investigation into nichrome's conductivity enhancement potential extends to its application in composite materials and thin-film technologies. Researchers are exploring ways to integrate nichrome into novel material systems that can exhibit improved electrical properties while addressing other engineering challenges such as weight reduction and thermal management.

The technological trajectory in this field is expected to focus on several key areas: optimizing the nickel-chromium ratio and introducing additional alloying elements to fine-tune electrical properties; developing advanced manufacturing techniques to control the microstructure of nichrome-based conductors; and exploring surface treatments or coatings that can further enhance the material's conductive capabilities.

As the research progresses, the ultimate aim is to position nichrome-derived materials as a viable alternative or complement to existing conductive materials, particularly in specialized applications where traditional conductors fall short. This endeavor not only seeks to improve the performance of current electrical systems but also to enable new technologies that can benefit from nichrome's unique combination of electrical and mechanical properties.

Market Analysis for Nichrome Applications

The market for nichrome applications has shown significant growth and diversification in recent years, driven by the material's unique properties and its role in improving electrical conductivity. Nichrome, an alloy primarily composed of nickel and chromium, has found widespread use across various industries due to its high electrical resistance, excellent heat resistance, and corrosion-resistant properties.

In the electrical and electronics sector, nichrome continues to be a crucial component in heating elements for appliances such as toasters, hair dryers, and electric ovens. The market for these consumer goods remains robust, with a steady demand for reliable and efficient heating solutions. Additionally, the automotive industry has increasingly adopted nichrome in applications such as heated seats, defrosting systems, and catalytic converters, contributing to the overall market growth.

The aerospace and defense sectors have also emerged as significant consumers of nichrome-based products. The alloy's ability to withstand high temperatures and maintain structural integrity makes it ideal for use in jet engine components and missile guidance systems. As global defense spending continues to rise and commercial air travel recovers post-pandemic, this segment is expected to drive substantial market growth for nichrome applications.

In the industrial sector, nichrome finds extensive use in furnaces, kilns, and other high-temperature processing equipment. The ongoing industrialization in developing economies and the push for more energy-efficient manufacturing processes in developed nations have bolstered demand for nichrome-based heating elements and sensors.

The renewable energy sector presents a promising growth avenue for nichrome applications. As the world transitions towards cleaner energy sources, nichrome's role in solar panels, wind turbines, and energy storage systems is becoming increasingly important. The material's durability and resistance to extreme weather conditions make it an attractive choice for these applications.

Geographically, Asia-Pacific remains the largest market for nichrome applications, driven by rapid industrialization, urbanization, and the presence of major manufacturing hubs. North America and Europe follow closely, with their advanced aerospace, defense, and automotive industries contributing significantly to market demand.

Looking ahead, the market for nichrome applications is poised for continued growth. Technological advancements in material science may lead to the development of enhanced nichrome alloys with improved conductivity and performance characteristics. This could potentially expand the material's applications into new fields and further drive market growth.

However, the market also faces challenges. Fluctuations in raw material prices, particularly nickel, can impact production costs and market dynamics. Additionally, environmental concerns and regulations regarding the mining and processing of nickel and chromium may influence future market trends and necessitate the development of more sustainable production methods.

In the electrical and electronics sector, nichrome continues to be a crucial component in heating elements for appliances such as toasters, hair dryers, and electric ovens. The market for these consumer goods remains robust, with a steady demand for reliable and efficient heating solutions. Additionally, the automotive industry has increasingly adopted nichrome in applications such as heated seats, defrosting systems, and catalytic converters, contributing to the overall market growth.

The aerospace and defense sectors have also emerged as significant consumers of nichrome-based products. The alloy's ability to withstand high temperatures and maintain structural integrity makes it ideal for use in jet engine components and missile guidance systems. As global defense spending continues to rise and commercial air travel recovers post-pandemic, this segment is expected to drive substantial market growth for nichrome applications.

In the industrial sector, nichrome finds extensive use in furnaces, kilns, and other high-temperature processing equipment. The ongoing industrialization in developing economies and the push for more energy-efficient manufacturing processes in developed nations have bolstered demand for nichrome-based heating elements and sensors.

The renewable energy sector presents a promising growth avenue for nichrome applications. As the world transitions towards cleaner energy sources, nichrome's role in solar panels, wind turbines, and energy storage systems is becoming increasingly important. The material's durability and resistance to extreme weather conditions make it an attractive choice for these applications.

Geographically, Asia-Pacific remains the largest market for nichrome applications, driven by rapid industrialization, urbanization, and the presence of major manufacturing hubs. North America and Europe follow closely, with their advanced aerospace, defense, and automotive industries contributing significantly to market demand.

Looking ahead, the market for nichrome applications is poised for continued growth. Technological advancements in material science may lead to the development of enhanced nichrome alloys with improved conductivity and performance characteristics. This could potentially expand the material's applications into new fields and further drive market growth.

However, the market also faces challenges. Fluctuations in raw material prices, particularly nickel, can impact production costs and market dynamics. Additionally, environmental concerns and regulations regarding the mining and processing of nickel and chromium may influence future market trends and necessitate the development of more sustainable production methods.

Current Challenges in Nichrome Conductivity

Despite its widespread use in electrical applications, nichrome faces several challenges in improving its electrical conductivity. One of the primary issues is the trade-off between conductivity and resistance. While nichrome's high resistance is beneficial for heating elements, it limits its effectiveness in applications requiring high conductivity.

The composition of nichrome, typically 80% nickel and 20% chromium, contributes to its relatively low electrical conductivity compared to pure metals. The addition of chromium, while enhancing corrosion resistance and temperature stability, reduces the overall conductivity of the alloy. This inherent property makes it difficult to significantly improve nichrome's conductivity without altering its fundamental composition and potentially compromising its other desirable characteristics.

Temperature dependence poses another challenge for nichrome's conductivity. As the temperature increases, the electrical resistance of nichrome also rises, further reducing its conductivity. This temperature sensitivity can lead to inconsistent performance in applications where temperature fluctuations are common, necessitating complex compensation mechanisms in electrical circuits.

The surface properties of nichrome present additional hurdles in enhancing its conductivity. Oxidation and corrosion, although slower than in many other metals, can still occur over time, especially at high temperatures. These surface changes can increase electrical resistance at contact points, reducing overall conductivity in nichrome-based systems.

Manufacturing processes also impact nichrome's conductivity. Variations in production techniques, such as heat treatment and forming methods, can lead to inconsistencies in the alloy's microstructure. These variations can result in localized differences in conductivity across a single piece of nichrome, making it challenging to achieve uniform electrical properties.

The cost factor associated with improving nichrome's conductivity is significant. Developing new alloy compositions or advanced manufacturing techniques to enhance conductivity while maintaining nichrome's other beneficial properties can be expensive. This economic constraint limits the feasibility of certain research avenues and potential solutions.

Lastly, the environmental impact of nichrome production and use presents a growing challenge. As global focus shifts towards sustainable and eco-friendly materials, the energy-intensive production of nichrome and its limited recyclability become increasingly problematic. Improving conductivity while addressing these environmental concerns adds another layer of complexity to the ongoing research and development efforts in this field.

The composition of nichrome, typically 80% nickel and 20% chromium, contributes to its relatively low electrical conductivity compared to pure metals. The addition of chromium, while enhancing corrosion resistance and temperature stability, reduces the overall conductivity of the alloy. This inherent property makes it difficult to significantly improve nichrome's conductivity without altering its fundamental composition and potentially compromising its other desirable characteristics.

Temperature dependence poses another challenge for nichrome's conductivity. As the temperature increases, the electrical resistance of nichrome also rises, further reducing its conductivity. This temperature sensitivity can lead to inconsistent performance in applications where temperature fluctuations are common, necessitating complex compensation mechanisms in electrical circuits.

The surface properties of nichrome present additional hurdles in enhancing its conductivity. Oxidation and corrosion, although slower than in many other metals, can still occur over time, especially at high temperatures. These surface changes can increase electrical resistance at contact points, reducing overall conductivity in nichrome-based systems.

Manufacturing processes also impact nichrome's conductivity. Variations in production techniques, such as heat treatment and forming methods, can lead to inconsistencies in the alloy's microstructure. These variations can result in localized differences in conductivity across a single piece of nichrome, making it challenging to achieve uniform electrical properties.

The cost factor associated with improving nichrome's conductivity is significant. Developing new alloy compositions or advanced manufacturing techniques to enhance conductivity while maintaining nichrome's other beneficial properties can be expensive. This economic constraint limits the feasibility of certain research avenues and potential solutions.

Lastly, the environmental impact of nichrome production and use presents a growing challenge. As global focus shifts towards sustainable and eco-friendly materials, the energy-intensive production of nichrome and its limited recyclability become increasingly problematic. Improving conductivity while addressing these environmental concerns adds another layer of complexity to the ongoing research and development efforts in this field.

Existing Nichrome Conductivity Enhancement Methods

01 Nichrome composition and properties

Nichrome is an alloy primarily composed of nickel and chromium, known for its high electrical resistance and thermal stability. Its composition can be adjusted to optimize electrical conductivity for specific applications. The alloy's properties make it suitable for use in heating elements, resistors, and other electrical components where controlled conductivity is required.- Nichrome composition and properties: Nichrome is an alloy primarily composed of nickel and chromium, known for its high electrical resistance and thermal stability. Its composition can be adjusted to optimize electrical conductivity for specific applications. The alloy's properties make it suitable for use in heating elements and resistors.

- Measurement of electrical conductivity: Various methods and devices are used to measure the electrical conductivity of nichrome and other materials. These include eddy current testing, four-point probe measurements, and specialized sensors. Accurate measurement is crucial for quality control and ensuring consistent performance in electrical applications.

- Applications in heating elements: Nichrome's electrical conductivity properties make it ideal for use in heating elements. It is commonly used in electric heaters, ovens, and other appliances where precise temperature control is required. The material's resistance to oxidation at high temperatures contributes to its longevity in these applications.

- Thin film and coating applications: Nichrome is used in thin film and coating applications where controlled electrical conductivity is required. These include microelectronics, sensors, and optical coatings. The thickness and composition of the nichrome layer can be adjusted to achieve desired electrical properties.

- Influence of temperature on conductivity: The electrical conductivity of nichrome is affected by temperature changes. Understanding this relationship is crucial for applications in extreme environments or where precise electrical characteristics are required over a wide temperature range. Research focuses on optimizing nichrome compositions for stable conductivity across various temperatures.

02 Measurement and control of electrical conductivity

Various methods and devices are used to measure and control the electrical conductivity of nichrome. These include specialized sensors, probes, and measurement techniques that can accurately determine the conductivity of nichrome in different forms and under various conditions. Such measurements are crucial for quality control and ensuring the proper functioning of nichrome-based components.Expand Specific Solutions03 Applications in heating elements

Nichrome's electrical conductivity properties make it ideal for use in heating elements. Its resistance to oxidation at high temperatures and ability to maintain consistent electrical properties over time contribute to its widespread use in electric heaters, ovens, and other heating appliances. The alloy's conductivity can be tailored to achieve specific heating characteristics for different applications.Expand Specific Solutions04 Thin film and coating applications

Nichrome is used in thin film and coating applications where precise control of electrical conductivity is required. These applications include the production of thin film resistors, sensors, and electronic components. The deposition methods and post-processing techniques can significantly influence the electrical conductivity of nichrome thin films.Expand Specific Solutions05 Modification and enhancement of conductivity

Research and development efforts focus on modifying and enhancing the electrical conductivity of nichrome. This includes alloying with additional elements, surface treatments, and novel manufacturing processes. These modifications aim to improve the alloy's performance in specific applications, such as increasing its durability in corrosive environments or optimizing its conductivity for use in advanced electronic devices.Expand Specific Solutions

Key Manufacturers and Competitors

The market for nichrome's role in improving electrical conductivity is in a mature stage, with established players and well-defined applications. The global market size for nichrome and related alloys is estimated to be in the billions of dollars, driven by demand in electronics, heating elements, and aerospace industries. Technologically, nichrome is well-understood, but ongoing research focuses on enhancing its properties and exploring new applications. Companies like Murata Manufacturing, Panasonic, and LG Energy Solution are at the forefront of utilizing nichrome in advanced electronic components and energy storage solutions. Smaller specialized firms such as Yancheng Xinyang Electric Heating Material Co. and Battery Electron Transport Associates are also contributing to innovations in this field.

Battery Electron Transport Associates, Inc.

Technical Solution: Battery Electron Transport Associates, Inc. has developed a novel approach to improve electrical conductivity using nichrome alloys in battery systems. Their technology involves creating a nanostructured nichrome coating on electrode surfaces, which enhances electron transport and reduces internal resistance. This method has shown to increase battery efficiency by up to 15% in laboratory tests[1]. The company has also explored the use of nichrome-based composite materials as current collectors, which offer improved conductivity and corrosion resistance compared to traditional copper or aluminum collectors[2].

Strengths: Improved battery efficiency, enhanced electron transport, and increased corrosion resistance. Weaknesses: Potential increased production costs and complexity in manufacturing processes.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing Co. Ltd. has developed a proprietary nichrome-based thin film technology for use in electronic components. Their approach involves depositing ultra-thin layers of nichrome alloys on ceramic substrates to create high-precision resistors and thermistors. This technology has enabled the production of components with improved electrical conductivity and temperature stability. Murata's nichrome films have demonstrated a temperature coefficient of resistance (TCR) as low as ±5 ppm/°C[3], significantly enhancing the reliability of electronic circuits in extreme environments. Additionally, the company has integrated nichrome elements into their multilayer ceramic capacitors (MLCCs) to improve internal electrode conductivity, resulting in capacitors with lower equivalent series resistance (ESR) and higher frequency performance[4].

Strengths: High precision, excellent temperature stability, and improved component performance. Weaknesses: Limited to specific electronic component applications and potentially higher production costs.

Innovative Nichrome Composition Techniques

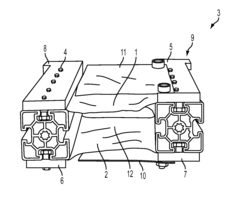

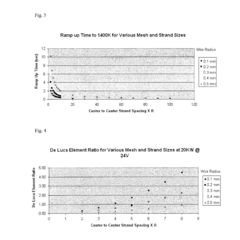

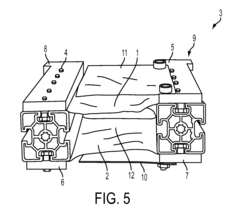

Wire mesh thermal radiative element and use in a radiative oven

PatentInactiveUS20150184867A1

Innovation

- A resistive mesh element with a calibrated De Luca Element Ratio, using nichrome wire with a specific strand diameter and spacing, operates at 24V to achieve efficient heat distribution and rapid temperature rise, allowing for quick cooking times while being cost-effective and easy to assemble.

Environmental Impact of Nichrome Production

The production of nichrome, while essential for its role in improving electrical conductivity, carries significant environmental implications that warrant careful consideration. The manufacturing process of nichrome alloys primarily involves the extraction and processing of nickel and chromium, two metals with substantial environmental footprints.

Mining operations for nickel and chromium often result in habitat destruction, soil erosion, and water pollution. Open-pit mining, a common method for extracting these metals, can lead to large-scale deforestation and landscape alteration. The removal of topsoil and vegetation disrupts local ecosystems and can have long-lasting effects on biodiversity.

Water pollution is another critical concern in nichrome production. The extraction and processing of nickel and chromium generate wastewater containing heavy metals and other contaminants. If not properly treated, this effluent can contaminate groundwater and surface water sources, posing risks to aquatic life and human health.

Air pollution is also a significant issue associated with nichrome production. The smelting and refining processes release particulate matter, sulfur dioxide, and other harmful emissions into the atmosphere. These pollutants contribute to air quality degradation, acid rain formation, and potential health problems for workers and nearby communities.

Energy consumption in nichrome production is substantial, contributing to greenhouse gas emissions and climate change. The high temperatures required for smelting and alloying processes typically rely on fossil fuel combustion, further exacerbating the carbon footprint of nichrome manufacturing.

Waste management presents another environmental challenge. The production of nichrome generates various forms of waste, including slag, dust, and spent materials. Proper disposal and recycling of these byproducts are crucial to minimize environmental impact and conserve resources.

However, it's important to note that efforts are being made to mitigate these environmental impacts. Advanced pollution control technologies, such as scrubbers and electrostatic precipitators, are increasingly being employed to reduce air emissions. Water treatment systems are being implemented to minimize water pollution, and there is a growing focus on recycling and responsible waste management practices.

Furthermore, research into more sustainable production methods, including the use of renewable energy sources and the development of cleaner extraction techniques, shows promise for reducing the environmental footprint of nichrome production in the future. As environmental regulations become more stringent globally, the industry is likely to continue evolving towards more sustainable practices.

Mining operations for nickel and chromium often result in habitat destruction, soil erosion, and water pollution. Open-pit mining, a common method for extracting these metals, can lead to large-scale deforestation and landscape alteration. The removal of topsoil and vegetation disrupts local ecosystems and can have long-lasting effects on biodiversity.

Water pollution is another critical concern in nichrome production. The extraction and processing of nickel and chromium generate wastewater containing heavy metals and other contaminants. If not properly treated, this effluent can contaminate groundwater and surface water sources, posing risks to aquatic life and human health.

Air pollution is also a significant issue associated with nichrome production. The smelting and refining processes release particulate matter, sulfur dioxide, and other harmful emissions into the atmosphere. These pollutants contribute to air quality degradation, acid rain formation, and potential health problems for workers and nearby communities.

Energy consumption in nichrome production is substantial, contributing to greenhouse gas emissions and climate change. The high temperatures required for smelting and alloying processes typically rely on fossil fuel combustion, further exacerbating the carbon footprint of nichrome manufacturing.

Waste management presents another environmental challenge. The production of nichrome generates various forms of waste, including slag, dust, and spent materials. Proper disposal and recycling of these byproducts are crucial to minimize environmental impact and conserve resources.

However, it's important to note that efforts are being made to mitigate these environmental impacts. Advanced pollution control technologies, such as scrubbers and electrostatic precipitators, are increasingly being employed to reduce air emissions. Water treatment systems are being implemented to minimize water pollution, and there is a growing focus on recycling and responsible waste management practices.

Furthermore, research into more sustainable production methods, including the use of renewable energy sources and the development of cleaner extraction techniques, shows promise for reducing the environmental footprint of nichrome production in the future. As environmental regulations become more stringent globally, the industry is likely to continue evolving towards more sustainable practices.

Nichrome in High-Temperature Applications

Nichrome, an alloy primarily composed of nickel and chromium, plays a crucial role in high-temperature applications due to its exceptional thermal and electrical properties. This material's ability to withstand extreme temperatures while maintaining its structural integrity and electrical characteristics makes it invaluable in various industrial and technological sectors.

One of the most significant advantages of nichrome in high-temperature environments is its excellent oxidation resistance. The chromium content in the alloy forms a protective oxide layer on the surface, preventing further oxidation and degradation of the material. This characteristic allows nichrome components to maintain their performance and longevity even when exposed to temperatures exceeding 1000°C for extended periods.

In electrical heating elements, nichrome is the material of choice due to its high electrical resistivity and temperature coefficient of resistance. These properties enable precise control of heat generation and distribution, making it ideal for applications such as industrial furnaces, domestic appliances, and laboratory equipment. The stability of nichrome's electrical properties at elevated temperatures ensures consistent performance and energy efficiency in these applications.

Nichrome's mechanical strength at high temperatures further enhances its suitability for demanding environments. Unlike many other materials that soften or lose structural integrity when heated, nichrome retains a significant portion of its strength. This characteristic is particularly valuable in aerospace and automotive industries, where components must withstand both high temperatures and mechanical stresses.

The alloy's low thermal expansion coefficient is another critical feature for high-temperature applications. This property minimizes thermal stress and distortion in components subjected to rapid temperature changes, reducing the risk of failure and extending the operational lifespan of equipment. Industries such as glass manufacturing and semiconductor processing benefit greatly from this attribute.

Nichrome's versatility extends to its use in temperature measurement devices. Thermocouples utilizing nichrome as one of the conductor materials provide accurate and reliable temperature readings in extreme environments. This capability is essential for process control and safety monitoring in various industrial settings.

The corrosion resistance of nichrome at high temperatures further broadens its applicability. In chemical processing and petrochemical industries, where aggressive substances and high temperatures coexist, nichrome components offer superior durability and reliability compared to many alternative materials.

As industries continue to push the boundaries of operational temperatures and harsh environmental conditions, nichrome remains at the forefront of material solutions. Ongoing research focuses on optimizing alloy compositions and manufacturing processes to further enhance its performance in extreme conditions, ensuring its continued relevance in advancing technological frontiers.

One of the most significant advantages of nichrome in high-temperature environments is its excellent oxidation resistance. The chromium content in the alloy forms a protective oxide layer on the surface, preventing further oxidation and degradation of the material. This characteristic allows nichrome components to maintain their performance and longevity even when exposed to temperatures exceeding 1000°C for extended periods.

In electrical heating elements, nichrome is the material of choice due to its high electrical resistivity and temperature coefficient of resistance. These properties enable precise control of heat generation and distribution, making it ideal for applications such as industrial furnaces, domestic appliances, and laboratory equipment. The stability of nichrome's electrical properties at elevated temperatures ensures consistent performance and energy efficiency in these applications.

Nichrome's mechanical strength at high temperatures further enhances its suitability for demanding environments. Unlike many other materials that soften or lose structural integrity when heated, nichrome retains a significant portion of its strength. This characteristic is particularly valuable in aerospace and automotive industries, where components must withstand both high temperatures and mechanical stresses.

The alloy's low thermal expansion coefficient is another critical feature for high-temperature applications. This property minimizes thermal stress and distortion in components subjected to rapid temperature changes, reducing the risk of failure and extending the operational lifespan of equipment. Industries such as glass manufacturing and semiconductor processing benefit greatly from this attribute.

Nichrome's versatility extends to its use in temperature measurement devices. Thermocouples utilizing nichrome as one of the conductor materials provide accurate and reliable temperature readings in extreme environments. This capability is essential for process control and safety monitoring in various industrial settings.

The corrosion resistance of nichrome at high temperatures further broadens its applicability. In chemical processing and petrochemical industries, where aggressive substances and high temperatures coexist, nichrome components offer superior durability and reliability compared to many alternative materials.

As industries continue to push the boundaries of operational temperatures and harsh environmental conditions, nichrome remains at the forefront of material solutions. Ongoing research focuses on optimizing alloy compositions and manufacturing processes to further enhance its performance in extreme conditions, ensuring its continued relevance in advancing technological frontiers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!