Nichrome Technology: Enhancing Thermal Imaging Devices

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Tech Evolution

Nichrome technology has undergone significant evolution in its application to thermal imaging devices. The journey began in the mid-20th century when nichrome, an alloy of nickel and chromium, was first recognized for its excellent electrical resistance and heat-generating properties. Initially used primarily in heating elements, its potential for thermal imaging was not immediately apparent.

The 1960s marked a turning point as researchers began exploring nichrome's capabilities in infrared detection. Early experiments focused on using thin nichrome films as bolometers, devices that measure electromagnetic radiation through heating effects. These rudimentary sensors laid the groundwork for more sophisticated thermal imaging applications.

By the 1970s, nichrome-based microbolometer arrays emerged, representing a significant leap forward. These arrays allowed for the creation of two-dimensional thermal images, albeit with limited resolution and sensitivity. The technology continued to improve through the 1980s, with advancements in fabrication techniques leading to more uniform and reliable nichrome films.

The 1990s saw a revolution in thermal imaging with the development of uncooled microbolometer focal plane arrays (FPAs) using vanadium oxide (VOx) and amorphous silicon (a-Si) as sensing materials. While these materials initially overshadowed nichrome, researchers continued to refine nichrome-based sensors, recognizing their potential for cost-effective, robust thermal imaging solutions.

In the early 2000s, a resurgence of interest in nichrome for thermal imaging occurred. Improved deposition techniques and microfabrication processes allowed for the creation of ultra-thin nichrome films with enhanced thermal sensitivity. This led to the development of high-performance nichrome-based microbolometers that could compete with VOx and a-Si alternatives in certain applications.

The past decade has seen further refinements in nichrome technology for thermal imaging. Advanced material engineering has resulted in nichrome alloys with optimized thermal properties, while innovations in MEMS (Micro-Electro-Mechanical Systems) have enabled the integration of nichrome sensors into compact, low-power devices. These developments have expanded the application of nichrome-based thermal imaging into fields such as automotive safety, building inspection, and personal electronics.

Looking ahead, the evolution of nichrome technology in thermal imaging devices continues to focus on improving sensitivity, reducing power consumption, and enhancing integration capabilities. Researchers are exploring nanostructured nichrome materials and hybrid sensing elements that combine nichrome with other materials to push the boundaries of thermal imaging performance. As the demand for affordable, high-quality thermal imaging grows across various industries, nichrome technology remains a promising avenue for innovation and advancement in this field.

The 1960s marked a turning point as researchers began exploring nichrome's capabilities in infrared detection. Early experiments focused on using thin nichrome films as bolometers, devices that measure electromagnetic radiation through heating effects. These rudimentary sensors laid the groundwork for more sophisticated thermal imaging applications.

By the 1970s, nichrome-based microbolometer arrays emerged, representing a significant leap forward. These arrays allowed for the creation of two-dimensional thermal images, albeit with limited resolution and sensitivity. The technology continued to improve through the 1980s, with advancements in fabrication techniques leading to more uniform and reliable nichrome films.

The 1990s saw a revolution in thermal imaging with the development of uncooled microbolometer focal plane arrays (FPAs) using vanadium oxide (VOx) and amorphous silicon (a-Si) as sensing materials. While these materials initially overshadowed nichrome, researchers continued to refine nichrome-based sensors, recognizing their potential for cost-effective, robust thermal imaging solutions.

In the early 2000s, a resurgence of interest in nichrome for thermal imaging occurred. Improved deposition techniques and microfabrication processes allowed for the creation of ultra-thin nichrome films with enhanced thermal sensitivity. This led to the development of high-performance nichrome-based microbolometers that could compete with VOx and a-Si alternatives in certain applications.

The past decade has seen further refinements in nichrome technology for thermal imaging. Advanced material engineering has resulted in nichrome alloys with optimized thermal properties, while innovations in MEMS (Micro-Electro-Mechanical Systems) have enabled the integration of nichrome sensors into compact, low-power devices. These developments have expanded the application of nichrome-based thermal imaging into fields such as automotive safety, building inspection, and personal electronics.

Looking ahead, the evolution of nichrome technology in thermal imaging devices continues to focus on improving sensitivity, reducing power consumption, and enhancing integration capabilities. Researchers are exploring nanostructured nichrome materials and hybrid sensing elements that combine nichrome with other materials to push the boundaries of thermal imaging performance. As the demand for affordable, high-quality thermal imaging grows across various industries, nichrome technology remains a promising avenue for innovation and advancement in this field.

Thermal Imaging Market

The thermal imaging market has experienced significant growth in recent years, driven by increasing demand across various sectors including military and defense, industrial applications, and consumer electronics. This technology, which detects and visualizes heat signatures, has become increasingly accessible and versatile, leading to a broader range of applications and market opportunities.

In the military and defense sector, thermal imaging devices play a crucial role in surveillance, target acquisition, and night vision capabilities. The need for enhanced situational awareness and improved operational effectiveness in low-light conditions continues to drive demand in this segment. Additionally, the integration of thermal imaging technology with other advanced systems, such as unmanned aerial vehicles (UAVs) and artificial intelligence, is further expanding its utility and market potential.

The industrial sector has also embraced thermal imaging technology for a wide array of applications. Predictive maintenance in manufacturing facilities, energy audits in buildings, and fault detection in electrical systems are just a few examples of how thermal imaging is being utilized to improve efficiency and reduce costs. The growing emphasis on energy conservation and workplace safety has further accelerated the adoption of thermal imaging solutions in industrial settings.

In the consumer market, thermal imaging has found applications in smartphones, automotive systems, and home security devices. The integration of thermal sensors in smartphones has opened up new possibilities for augmented reality applications and improved camera functionality. In the automotive industry, thermal imaging is being used for advanced driver assistance systems (ADAS) to enhance night driving safety and pedestrian detection.

The healthcare sector has emerged as a promising new market for thermal imaging, particularly in the wake of the global pandemic. Temperature screening applications have seen a surge in demand, and there is growing interest in using thermal imaging for early detection of various medical conditions.

Geographically, North America and Europe have traditionally been the largest markets for thermal imaging technology, primarily due to their advanced military and industrial sectors. However, the Asia-Pacific region is experiencing the fastest growth, driven by increasing industrialization, rising security concerns, and growing adoption of advanced technologies in countries like China, Japan, and South Korea.

Looking ahead, the thermal imaging market is expected to continue its growth trajectory, fueled by ongoing technological advancements, decreasing costs of thermal sensors, and expanding applications across various industries. The development of more compact, higher-resolution, and more affordable thermal imaging devices is likely to further broaden the market appeal and drive adoption in both established and emerging sectors.

In the military and defense sector, thermal imaging devices play a crucial role in surveillance, target acquisition, and night vision capabilities. The need for enhanced situational awareness and improved operational effectiveness in low-light conditions continues to drive demand in this segment. Additionally, the integration of thermal imaging technology with other advanced systems, such as unmanned aerial vehicles (UAVs) and artificial intelligence, is further expanding its utility and market potential.

The industrial sector has also embraced thermal imaging technology for a wide array of applications. Predictive maintenance in manufacturing facilities, energy audits in buildings, and fault detection in electrical systems are just a few examples of how thermal imaging is being utilized to improve efficiency and reduce costs. The growing emphasis on energy conservation and workplace safety has further accelerated the adoption of thermal imaging solutions in industrial settings.

In the consumer market, thermal imaging has found applications in smartphones, automotive systems, and home security devices. The integration of thermal sensors in smartphones has opened up new possibilities for augmented reality applications and improved camera functionality. In the automotive industry, thermal imaging is being used for advanced driver assistance systems (ADAS) to enhance night driving safety and pedestrian detection.

The healthcare sector has emerged as a promising new market for thermal imaging, particularly in the wake of the global pandemic. Temperature screening applications have seen a surge in demand, and there is growing interest in using thermal imaging for early detection of various medical conditions.

Geographically, North America and Europe have traditionally been the largest markets for thermal imaging technology, primarily due to their advanced military and industrial sectors. However, the Asia-Pacific region is experiencing the fastest growth, driven by increasing industrialization, rising security concerns, and growing adoption of advanced technologies in countries like China, Japan, and South Korea.

Looking ahead, the thermal imaging market is expected to continue its growth trajectory, fueled by ongoing technological advancements, decreasing costs of thermal sensors, and expanding applications across various industries. The development of more compact, higher-resolution, and more affordable thermal imaging devices is likely to further broaden the market appeal and drive adoption in both established and emerging sectors.

Nichrome Challenges

Despite the widespread use of nichrome in thermal imaging devices, several challenges persist in maximizing its potential for enhancing thermal sensitivity and image quality. One of the primary obstacles is the inherent trade-off between thermal sensitivity and response time. While thinner nichrome films offer faster response times, they often sacrifice thermal sensitivity, making it difficult to achieve optimal performance in both aspects simultaneously.

Another significant challenge lies in the uniformity of nichrome deposition across large sensor arrays. Inconsistencies in film thickness or composition can lead to non-uniform thermal responses, resulting in image artifacts and reduced overall image quality. This issue becomes particularly pronounced as manufacturers strive to increase the resolution and size of thermal imaging sensors.

The long-term stability of nichrome films under repeated thermal cycling poses another hurdle. Over time, the electrical and thermal properties of nichrome can degrade due to oxidation, interdiffusion with substrate materials, or structural changes. This degradation can lead to drift in sensor calibration and reduced device longevity, necessitating frequent recalibration or replacement.

Thermal management within the device itself presents a complex challenge. As nichrome elements generate heat during operation, efficient heat dissipation becomes crucial to prevent thermal crosstalk between adjacent pixels and maintain accurate temperature readings. This issue is exacerbated in compact or high-density sensor designs where space for thermal management solutions is limited.

The integration of nichrome with other materials and components in the thermal imaging system also presents difficulties. Ensuring good adhesion to substrates, compatibility with passivation layers, and effective electrical connections without compromising thermal performance requires careful material selection and process optimization.

Furthermore, the cost-effectiveness of nichrome-based solutions in comparison to emerging alternative materials remains a concern. While nichrome offers reliability and well-established manufacturing processes, newer materials may promise superior performance characteristics, challenging the continued dominance of nichrome in certain applications.

Lastly, environmental concerns and regulations regarding the use of certain metals in electronic devices may impact the future viability of nichrome in some markets. Developing eco-friendly alternatives or improving the recyclability of nichrome-based components is becoming increasingly important for long-term sustainability in the thermal imaging industry.

Another significant challenge lies in the uniformity of nichrome deposition across large sensor arrays. Inconsistencies in film thickness or composition can lead to non-uniform thermal responses, resulting in image artifacts and reduced overall image quality. This issue becomes particularly pronounced as manufacturers strive to increase the resolution and size of thermal imaging sensors.

The long-term stability of nichrome films under repeated thermal cycling poses another hurdle. Over time, the electrical and thermal properties of nichrome can degrade due to oxidation, interdiffusion with substrate materials, or structural changes. This degradation can lead to drift in sensor calibration and reduced device longevity, necessitating frequent recalibration or replacement.

Thermal management within the device itself presents a complex challenge. As nichrome elements generate heat during operation, efficient heat dissipation becomes crucial to prevent thermal crosstalk between adjacent pixels and maintain accurate temperature readings. This issue is exacerbated in compact or high-density sensor designs where space for thermal management solutions is limited.

The integration of nichrome with other materials and components in the thermal imaging system also presents difficulties. Ensuring good adhesion to substrates, compatibility with passivation layers, and effective electrical connections without compromising thermal performance requires careful material selection and process optimization.

Furthermore, the cost-effectiveness of nichrome-based solutions in comparison to emerging alternative materials remains a concern. While nichrome offers reliability and well-established manufacturing processes, newer materials may promise superior performance characteristics, challenging the continued dominance of nichrome in certain applications.

Lastly, environmental concerns and regulations regarding the use of certain metals in electronic devices may impact the future viability of nichrome in some markets. Developing eco-friendly alternatives or improving the recyclability of nichrome-based components is becoming increasingly important for long-term sustainability in the thermal imaging industry.

Current Nichrome Apps

01 Nichrome-based thermal imaging sensors

Nichrome alloy is used in the development of thermal imaging sensors due to its high electrical resistance and temperature stability. These sensors can detect infrared radiation and convert it into electrical signals, enabling the creation of thermal images. The technology is applied in various fields including surveillance, medical diagnostics, and industrial inspections.- Nichrome-based thermal imaging sensors: Nichrome alloy is used in thermal imaging sensors due to its high electrical resistance and temperature coefficient. These sensors can detect minute temperature changes, enabling high-resolution thermal imaging for various applications including surveillance, medical diagnostics, and industrial monitoring.

- Thermal imaging display technologies: Advanced display technologies are developed to visualize thermal imaging data effectively. These include high-contrast screens, color mapping techniques, and real-time image processing algorithms to enhance the clarity and interpretability of thermal images for end-users.

- Integration of thermal imaging in smart devices: Thermal imaging capabilities are being integrated into smartphones, tablets, and other portable devices. This integration allows for widespread access to thermal imaging technology, enabling applications in home energy audits, personal health monitoring, and outdoor recreation.

- Thermal imaging for autonomous vehicles: Thermal imaging systems are being developed for use in autonomous vehicles to enhance their sensing capabilities. These systems can detect pedestrians, animals, and other vehicles in low-light conditions or adverse weather, improving overall safety and navigation.

- AI-enhanced thermal image processing: Artificial intelligence and machine learning algorithms are being applied to thermal image processing. These technologies improve image quality, automate object detection and classification, and enable predictive maintenance applications in industrial settings.

02 Thermal imaging display systems

Advanced display systems are developed to visualize thermal imaging data effectively. These systems may incorporate specialized screens, image processing algorithms, and user interfaces to present thermal information in a clear and interpretable manner. The technology aims to enhance the usability and accuracy of thermal imaging in various applications.Expand Specific Solutions03 Calibration and image quality improvement

Techniques for calibrating thermal imaging devices and improving image quality are developed. These may include methods for reducing noise, enhancing contrast, and correcting for environmental factors that can affect thermal measurements. The goal is to produce more accurate and reliable thermal images across different operating conditions.Expand Specific Solutions04 Integration with other imaging technologies

Thermal imaging is integrated with other imaging technologies such as visible light cameras or multispectral sensors. This fusion of different imaging modalities allows for more comprehensive analysis and interpretation of scenes, enhancing the overall capabilities of imaging systems in various applications.Expand Specific Solutions05 Miniaturization and portability

Efforts are made to miniaturize thermal imaging technology, making it more portable and suitable for integration into handheld devices or wearable technology. This includes the development of smaller sensors, more efficient power management systems, and compact optics, enabling wider adoption of thermal imaging in consumer and professional applications.Expand Specific Solutions

Key Industry Players

The thermal imaging devices market, driven by advancements in Nichrome Technology, is experiencing rapid growth and increasing competition. The industry is in a mature stage, with established players like FLIR Systems AB and Seek Thermal, Inc. leading innovation. Market size is expanding due to rising demand in sectors such as defense, healthcare, and industrial applications. Technologically, the field is advancing quickly, with companies like Canon, Inc., Samsung Electronics Co., Ltd., and BAE Systems pushing boundaries in sensor technology and image processing. Emerging players like RadiaBeam Technologies LLC are introducing novel solutions, intensifying competition. The market's technological maturity is evident in the diverse applications and continuous improvements in resolution, sensitivity, and integration capabilities offered by key players.

FLIR Systems AB

Technical Solution: FLIR Systems AB has developed advanced Nichrome Technology for enhancing thermal imaging devices. Their approach involves using nichrome as a key component in microbolometer focal plane arrays (FPAs), which are the heart of modern thermal cameras. The nichrome thin film acts as both the infrared absorber and the temperature-sensitive resistor, allowing for highly sensitive thermal detection[1]. FLIR has optimized the deposition process of nichrome to achieve uniform and stable thin films, resulting in improved thermal sensitivity and image quality. They have also implemented advanced readout integrated circuits (ROICs) that work in tandem with the nichrome-based detectors to reduce noise and increase dynamic range[3]. Furthermore, FLIR has developed proprietary image processing algorithms that leverage the unique properties of nichrome-based sensors to enhance contrast and detail in thermal images[5].

Strengths: High sensitivity, fast response time, and excellent uniformity across the sensor array. Weaknesses: Potential for higher power consumption compared to some alternative materials, and sensitivity to temperature fluctuations in the operating environment.

Aselsan Elektronik Sanayi ve Ticaret AS

Technical Solution: Aselsan has innovated in Nichrome Technology for thermal imaging by developing a unique sandwich structure for their microbolometer pixels. This structure consists of a nichrome absorber layer sandwiched between two silicon nitride layers, which enhances thermal isolation and improves sensitivity[2]. They have also implemented a proprietary vacuum packaging technique that reduces thermal conductivity and increases the detector's performance. Aselsan's approach includes the use of advanced MEMS (Micro-Electro-Mechanical Systems) fabrication techniques to create suspended microbridge structures with nichrome elements, optimizing thermal isolation[4]. Additionally, they have developed custom readout circuits that are specifically tailored to the characteristics of their nichrome-based detectors, allowing for better noise reduction and dynamic range expansion[6].

Strengths: Excellent thermal isolation, high sensitivity, and robust design suitable for harsh environments. Weaknesses: Potentially higher manufacturing costs due to complex structure and specialized packaging requirements.

Nichrome Innovations

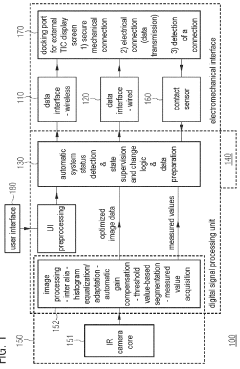

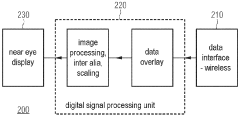

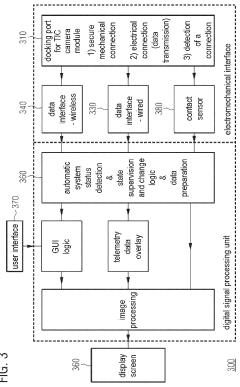

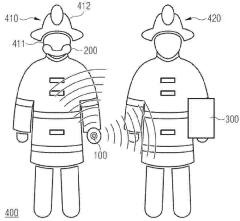

Thermal imaging camera and thermal imaging camera systems

PatentActiveGB2570777A

Innovation

- A thermal imaging camera system with a detachable fastening device for protective clothing, featuring both wireless and wired interfaces for image transmission, allowing the camera to be worn, carried, or shared with others, and enabling power-saving, reliable data output via a wired connection.

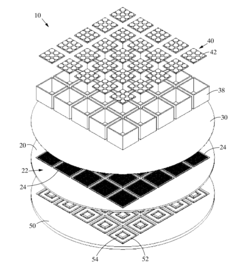

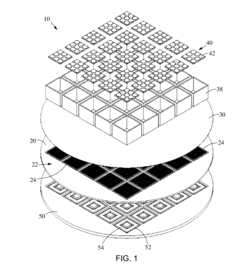

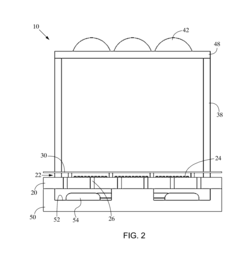

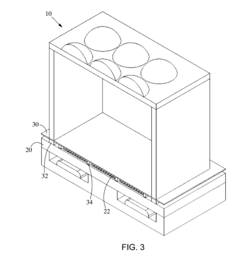

Thermal Imaging Device

PatentInactiveUS20160380014A1

Innovation

- A thermal imaging device design featuring a focal plane array enclosed in a vacuum with a thin silicon lid substrate and a micro-lens array, using support structures and fusion bonding to reduce thickness and cost, along with chalcogenide glass lenses for reduced material expense and improved manufacturing efficiency.

Regulatory Framework

The regulatory framework surrounding thermal imaging devices, particularly those utilizing Nichrome technology, is complex and multifaceted. These regulations are designed to ensure the safe and responsible use of such devices while protecting national security interests and individual privacy rights.

In the United States, the primary regulatory body overseeing thermal imaging technology is the Department of Commerce's Bureau of Industry and Security (BIS). The BIS enforces export control regulations, including those related to thermal imaging devices, under the Export Administration Regulations (EAR). These regulations classify certain thermal imaging technologies as "dual-use" items, potentially having both civilian and military applications, and may require export licenses for international sales or transfers.

The Federal Aviation Administration (FAA) has also implemented regulations concerning the use of thermal imaging devices in unmanned aerial vehicles (UAVs) or drones. These rules aim to balance the benefits of thermal imaging technology in areas such as search and rescue operations with potential privacy concerns and airspace safety issues.

On a global scale, the Wassenaar Arrangement on Export Controls for Conventional Arms and Dual-Use Goods and Technologies plays a crucial role in harmonizing export control policies among participating countries. This international agreement impacts the transfer of thermal imaging technologies across borders, requiring member states to implement controls on specified items, including certain thermal imaging devices.

In the European Union, the EU Dual-Use Regulation (Regulation (EU) 2021/821) governs the export of dual-use items, including thermal imaging technologies. This regulation establishes a common EU regime for the control of exports, brokering, technical assistance, transit, and transfer of dual-use items.

Privacy regulations also significantly impact the use of thermal imaging devices. In many jurisdictions, laws such as the General Data Protection Regulation (GDPR) in the EU and various state-level privacy laws in the US may apply to data collected through thermal imaging, especially when such data can be linked to identifiable individuals.

Industry standards and certifications also form an important part of the regulatory landscape. Organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) have developed standards related to thermal imaging devices, covering aspects such as performance specifications, testing methods, and calibration procedures.

As Nichrome technology continues to enhance thermal imaging devices, manufacturers and users must navigate this complex regulatory environment. Compliance with these regulations is crucial not only for legal reasons but also to ensure public trust and acceptance of this powerful technology. As the capabilities of thermal imaging devices advance, it is likely that regulatory frameworks will evolve to address new challenges and applications, necessitating ongoing vigilance and adaptation from industry stakeholders.

In the United States, the primary regulatory body overseeing thermal imaging technology is the Department of Commerce's Bureau of Industry and Security (BIS). The BIS enforces export control regulations, including those related to thermal imaging devices, under the Export Administration Regulations (EAR). These regulations classify certain thermal imaging technologies as "dual-use" items, potentially having both civilian and military applications, and may require export licenses for international sales or transfers.

The Federal Aviation Administration (FAA) has also implemented regulations concerning the use of thermal imaging devices in unmanned aerial vehicles (UAVs) or drones. These rules aim to balance the benefits of thermal imaging technology in areas such as search and rescue operations with potential privacy concerns and airspace safety issues.

On a global scale, the Wassenaar Arrangement on Export Controls for Conventional Arms and Dual-Use Goods and Technologies plays a crucial role in harmonizing export control policies among participating countries. This international agreement impacts the transfer of thermal imaging technologies across borders, requiring member states to implement controls on specified items, including certain thermal imaging devices.

In the European Union, the EU Dual-Use Regulation (Regulation (EU) 2021/821) governs the export of dual-use items, including thermal imaging technologies. This regulation establishes a common EU regime for the control of exports, brokering, technical assistance, transit, and transfer of dual-use items.

Privacy regulations also significantly impact the use of thermal imaging devices. In many jurisdictions, laws such as the General Data Protection Regulation (GDPR) in the EU and various state-level privacy laws in the US may apply to data collected through thermal imaging, especially when such data can be linked to identifiable individuals.

Industry standards and certifications also form an important part of the regulatory landscape. Organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) have developed standards related to thermal imaging devices, covering aspects such as performance specifications, testing methods, and calibration procedures.

As Nichrome technology continues to enhance thermal imaging devices, manufacturers and users must navigate this complex regulatory environment. Compliance with these regulations is crucial not only for legal reasons but also to ensure public trust and acceptance of this powerful technology. As the capabilities of thermal imaging devices advance, it is likely that regulatory frameworks will evolve to address new challenges and applications, necessitating ongoing vigilance and adaptation from industry stakeholders.

Environmental Impact

The environmental impact of nichrome technology in thermal imaging devices is a crucial consideration in the development and deployment of these systems. As thermal imaging devices become more prevalent in various industries, their potential effects on the environment must be carefully evaluated and mitigated.

One of the primary environmental concerns associated with nichrome-based thermal imaging devices is energy consumption. These devices require a constant supply of electricity to maintain the nichrome elements at the necessary temperature for optimal performance. This increased energy demand can contribute to higher carbon emissions if the power source is not renewable. However, advancements in nichrome technology have led to more energy-efficient designs, reducing the overall power consumption and environmental footprint of these devices.

The manufacturing process of nichrome components for thermal imaging devices also has environmental implications. The production of nichrome alloys involves mining and processing nickel and chromium, which can have significant environmental impacts if not managed responsibly. Sustainable mining practices and efficient production techniques are essential to minimize the ecological footprint of nichrome manufacturing.

Another environmental consideration is the disposal and recycling of thermal imaging devices containing nichrome elements. As these devices reach the end of their lifecycle, proper disposal methods are crucial to prevent the release of potentially harmful materials into the environment. Implementing effective recycling programs can help recover valuable materials from decommissioned devices, reducing waste and conserving resources.

The use of nichrome technology in thermal imaging devices can also have indirect positive environmental impacts. These devices are often employed in energy audits and building inspections, helping to identify heat loss and improve energy efficiency in structures. This application can lead to reduced energy consumption and lower greenhouse gas emissions in the long term.

In the field of environmental monitoring, thermal imaging devices with nichrome technology play a vital role in detecting and tracking wildlife, assessing vegetation health, and monitoring industrial emissions. These applications contribute to better environmental management and conservation efforts, potentially offsetting some of the environmental costs associated with the technology's production and use.

As the technology continues to evolve, researchers and manufacturers are exploring more environmentally friendly alternatives to traditional nichrome elements. This includes the development of bio-based materials and the use of recycled components in thermal imaging devices. These innovations aim to reduce the environmental impact of the technology while maintaining or improving its performance characteristics.

One of the primary environmental concerns associated with nichrome-based thermal imaging devices is energy consumption. These devices require a constant supply of electricity to maintain the nichrome elements at the necessary temperature for optimal performance. This increased energy demand can contribute to higher carbon emissions if the power source is not renewable. However, advancements in nichrome technology have led to more energy-efficient designs, reducing the overall power consumption and environmental footprint of these devices.

The manufacturing process of nichrome components for thermal imaging devices also has environmental implications. The production of nichrome alloys involves mining and processing nickel and chromium, which can have significant environmental impacts if not managed responsibly. Sustainable mining practices and efficient production techniques are essential to minimize the ecological footprint of nichrome manufacturing.

Another environmental consideration is the disposal and recycling of thermal imaging devices containing nichrome elements. As these devices reach the end of their lifecycle, proper disposal methods are crucial to prevent the release of potentially harmful materials into the environment. Implementing effective recycling programs can help recover valuable materials from decommissioned devices, reducing waste and conserving resources.

The use of nichrome technology in thermal imaging devices can also have indirect positive environmental impacts. These devices are often employed in energy audits and building inspections, helping to identify heat loss and improve energy efficiency in structures. This application can lead to reduced energy consumption and lower greenhouse gas emissions in the long term.

In the field of environmental monitoring, thermal imaging devices with nichrome technology play a vital role in detecting and tracking wildlife, assessing vegetation health, and monitoring industrial emissions. These applications contribute to better environmental management and conservation efforts, potentially offsetting some of the environmental costs associated with the technology's production and use.

As the technology continues to evolve, researchers and manufacturers are exploring more environmentally friendly alternatives to traditional nichrome elements. This includes the development of bio-based materials and the use of recycled components in thermal imaging devices. These innovations aim to reduce the environmental impact of the technology while maintaining or improving its performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!