Nichrome Uses in High-Performance Cooking Appliances

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Evolution in Cooking Appliances

The evolution of nichrome in cooking appliances represents a significant technological advancement in the culinary industry. Initially developed in the early 20th century, nichrome, an alloy of nickel and chromium, quickly found its way into heating elements due to its exceptional properties.

In the 1920s and 1930s, nichrome began to be incorporated into basic electric stoves and ovens. These early applications utilized nichrome wire coils as heating elements, providing a more consistent and controllable heat source compared to traditional gas or wood-burning stoves. This marked the beginning of a new era in kitchen appliance technology.

The 1950s and 1960s saw a rapid expansion in the use of nichrome in a wider range of cooking appliances. During this period, manufacturers started to experiment with different nichrome alloy compositions to optimize performance. The introduction of ribbon-wound nichrome elements in toasters and grills improved heat distribution and energy efficiency.

The 1970s and 1980s brought about significant improvements in nichrome heating element design. Engineers developed more sophisticated coil configurations and began to integrate nichrome elements into ceramic and glass-ceramic cooktops. This innovation allowed for sleeker, more aesthetically pleasing appliance designs while maintaining excellent heating performance.

In the 1990s and early 2000s, the focus shifted towards enhancing the durability and longevity of nichrome elements. Manufacturers introduced protective coatings and improved insulation techniques, extending the lifespan of heating elements in high-use appliances such as commercial ovens and industrial food processing equipment.

The past two decades have seen a renewed interest in nichrome technology, driven by the demand for energy-efficient and precise cooking appliances. Advanced nichrome alloys with improved heat resistance and faster heating capabilities have been developed. These innovations have enabled the creation of high-performance cooking appliances that offer rapid heating, precise temperature control, and uniform heat distribution.

Recent developments include the integration of nichrome elements with smart technology. Modern appliances now feature nichrome heating systems that can be controlled remotely, programmed for specific cooking cycles, and even learn from user preferences to optimize performance. This fusion of traditional nichrome technology with digital innovation represents the cutting edge of cooking appliance evolution.

In the 1920s and 1930s, nichrome began to be incorporated into basic electric stoves and ovens. These early applications utilized nichrome wire coils as heating elements, providing a more consistent and controllable heat source compared to traditional gas or wood-burning stoves. This marked the beginning of a new era in kitchen appliance technology.

The 1950s and 1960s saw a rapid expansion in the use of nichrome in a wider range of cooking appliances. During this period, manufacturers started to experiment with different nichrome alloy compositions to optimize performance. The introduction of ribbon-wound nichrome elements in toasters and grills improved heat distribution and energy efficiency.

The 1970s and 1980s brought about significant improvements in nichrome heating element design. Engineers developed more sophisticated coil configurations and began to integrate nichrome elements into ceramic and glass-ceramic cooktops. This innovation allowed for sleeker, more aesthetically pleasing appliance designs while maintaining excellent heating performance.

In the 1990s and early 2000s, the focus shifted towards enhancing the durability and longevity of nichrome elements. Manufacturers introduced protective coatings and improved insulation techniques, extending the lifespan of heating elements in high-use appliances such as commercial ovens and industrial food processing equipment.

The past two decades have seen a renewed interest in nichrome technology, driven by the demand for energy-efficient and precise cooking appliances. Advanced nichrome alloys with improved heat resistance and faster heating capabilities have been developed. These innovations have enabled the creation of high-performance cooking appliances that offer rapid heating, precise temperature control, and uniform heat distribution.

Recent developments include the integration of nichrome elements with smart technology. Modern appliances now feature nichrome heating systems that can be controlled remotely, programmed for specific cooking cycles, and even learn from user preferences to optimize performance. This fusion of traditional nichrome technology with digital innovation represents the cutting edge of cooking appliance evolution.

Market Demand Analysis for High-Performance Cooking

The market demand for high-performance cooking appliances incorporating nichrome technology has shown significant growth in recent years. This trend is driven by several factors, including the increasing popularity of gourmet home cooking, the rise of smart kitchen appliances, and the growing awareness of energy efficiency among consumers.

In the residential sector, there is a strong demand for premium cooking appliances that offer precise temperature control and rapid heating capabilities. Nichrome-based heating elements in ovens, stovetops, and grills provide these features, allowing home chefs to achieve restaurant-quality results. The market for high-end kitchen appliances has expanded, with consumers willing to invest in advanced cooking technologies that enhance their culinary experiences.

The commercial foodservice industry also contributes substantially to the market demand for nichrome-based cooking appliances. Restaurants, hotels, and catering services require equipment that can withstand continuous use while maintaining consistent performance. Nichrome's durability and ability to reach high temperatures quickly make it an ideal choice for commercial kitchens, where efficiency and reliability are paramount.

Energy efficiency is another key driver of market demand. As energy costs rise and environmental concerns grow, consumers and businesses alike are seeking appliances that minimize energy consumption. Nichrome's excellent electrical resistance properties allow for efficient heat generation, making it an attractive option for manufacturers looking to develop energy-efficient cooking appliances.

The global pandemic has further accelerated the demand for high-performance cooking appliances. With more people cooking at home, there has been a surge in interest in advanced kitchen equipment that can replicate restaurant-quality meals. This trend is expected to continue even as dining out resumes, as many consumers have developed new cooking habits and skills.

In terms of market size, the global household cooking appliance market, which includes nichrome-based products, was valued at over $100 billion in 2020 and is projected to grow at a CAGR of around 6% from 2021 to 2028. The commercial cooking equipment market, where nichrome also plays a significant role, was estimated at $10 billion in 2020, with a projected CAGR of 5.5% through 2027.

Regionally, North America and Europe lead in the adoption of high-performance cooking appliances, driven by high disposable incomes and a strong culture of home cooking. However, the Asia-Pacific region is expected to see the fastest growth, fueled by rapid urbanization, increasing household incomes, and changing lifestyles in countries like China and India.

As the market for high-performance cooking appliances continues to evolve, manufacturers are focusing on integrating smart technologies with nichrome heating elements. This combination promises to deliver even greater precision and control, further driving demand among tech-savvy consumers and professional chefs alike.

In the residential sector, there is a strong demand for premium cooking appliances that offer precise temperature control and rapid heating capabilities. Nichrome-based heating elements in ovens, stovetops, and grills provide these features, allowing home chefs to achieve restaurant-quality results. The market for high-end kitchen appliances has expanded, with consumers willing to invest in advanced cooking technologies that enhance their culinary experiences.

The commercial foodservice industry also contributes substantially to the market demand for nichrome-based cooking appliances. Restaurants, hotels, and catering services require equipment that can withstand continuous use while maintaining consistent performance. Nichrome's durability and ability to reach high temperatures quickly make it an ideal choice for commercial kitchens, where efficiency and reliability are paramount.

Energy efficiency is another key driver of market demand. As energy costs rise and environmental concerns grow, consumers and businesses alike are seeking appliances that minimize energy consumption. Nichrome's excellent electrical resistance properties allow for efficient heat generation, making it an attractive option for manufacturers looking to develop energy-efficient cooking appliances.

The global pandemic has further accelerated the demand for high-performance cooking appliances. With more people cooking at home, there has been a surge in interest in advanced kitchen equipment that can replicate restaurant-quality meals. This trend is expected to continue even as dining out resumes, as many consumers have developed new cooking habits and skills.

In terms of market size, the global household cooking appliance market, which includes nichrome-based products, was valued at over $100 billion in 2020 and is projected to grow at a CAGR of around 6% from 2021 to 2028. The commercial cooking equipment market, where nichrome also plays a significant role, was estimated at $10 billion in 2020, with a projected CAGR of 5.5% through 2027.

Regionally, North America and Europe lead in the adoption of high-performance cooking appliances, driven by high disposable incomes and a strong culture of home cooking. However, the Asia-Pacific region is expected to see the fastest growth, fueled by rapid urbanization, increasing household incomes, and changing lifestyles in countries like China and India.

As the market for high-performance cooking appliances continues to evolve, manufacturers are focusing on integrating smart technologies with nichrome heating elements. This combination promises to deliver even greater precision and control, further driving demand among tech-savvy consumers and professional chefs alike.

Current Nichrome Technology and Challenges

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone in the development of high-performance cooking appliances. Its widespread use can be attributed to its excellent electrical resistance properties and ability to withstand high temperatures. In the current landscape of cooking appliance technology, nichrome continues to play a crucial role, particularly in heating elements for ovens, toasters, and electric grills.

The current state of nichrome technology in cooking appliances is characterized by its reliability and cost-effectiveness. Manufacturers have refined the production processes, allowing for consistent quality and performance across a wide range of products. The alloy's composition, typically 80% nickel and 20% chromium, provides an optimal balance between electrical resistance and durability, enabling efficient heat generation and long-term stability.

However, the industry faces several challenges in pushing the boundaries of nichrome applications. One significant hurdle is the increasing demand for faster heating times in modern cooking appliances. While nichrome performs well, there is a growing need for materials that can reach higher temperatures more quickly without compromising safety or longevity.

Another challenge lies in the pursuit of energy efficiency. As global energy consumption concerns rise, manufacturers are under pressure to develop more energy-efficient appliances. This necessitates innovations in nichrome technology to improve heat transfer and reduce power consumption without sacrificing cooking performance.

The environmental impact of nichrome production and disposal is also becoming a pressing issue. The mining and processing of nickel and chromium have significant environmental footprints, and there is a growing need for more sustainable production methods and recycling processes for nichrome components in appliances.

Durability in extreme conditions remains an ongoing challenge. While nichrome is known for its resilience, the constant exposure to high temperatures, thermal cycling, and potentially corrosive environments in cooking appliances can lead to degradation over time. Researchers are exploring ways to enhance the alloy's resistance to oxidation and thermal fatigue to extend the lifespan of heating elements.

Miniaturization trends in appliance design present another hurdle. As consumers demand more compact and versatile cooking devices, engineers must find ways to maintain or improve heating performance while reducing the size of nichrome elements. This requires advancements in alloy composition and element design to achieve higher power densities without compromising safety or reliability.

Lastly, the integration of smart technology in cooking appliances poses new challenges for nichrome applications. The need for precise temperature control and rapid response to user inputs demands innovations in how nichrome elements are designed and controlled, potentially leading to the development of more sophisticated heating systems that combine traditional nichrome technology with advanced electronic controls.

The current state of nichrome technology in cooking appliances is characterized by its reliability and cost-effectiveness. Manufacturers have refined the production processes, allowing for consistent quality and performance across a wide range of products. The alloy's composition, typically 80% nickel and 20% chromium, provides an optimal balance between electrical resistance and durability, enabling efficient heat generation and long-term stability.

However, the industry faces several challenges in pushing the boundaries of nichrome applications. One significant hurdle is the increasing demand for faster heating times in modern cooking appliances. While nichrome performs well, there is a growing need for materials that can reach higher temperatures more quickly without compromising safety or longevity.

Another challenge lies in the pursuit of energy efficiency. As global energy consumption concerns rise, manufacturers are under pressure to develop more energy-efficient appliances. This necessitates innovations in nichrome technology to improve heat transfer and reduce power consumption without sacrificing cooking performance.

The environmental impact of nichrome production and disposal is also becoming a pressing issue. The mining and processing of nickel and chromium have significant environmental footprints, and there is a growing need for more sustainable production methods and recycling processes for nichrome components in appliances.

Durability in extreme conditions remains an ongoing challenge. While nichrome is known for its resilience, the constant exposure to high temperatures, thermal cycling, and potentially corrosive environments in cooking appliances can lead to degradation over time. Researchers are exploring ways to enhance the alloy's resistance to oxidation and thermal fatigue to extend the lifespan of heating elements.

Miniaturization trends in appliance design present another hurdle. As consumers demand more compact and versatile cooking devices, engineers must find ways to maintain or improve heating performance while reducing the size of nichrome elements. This requires advancements in alloy composition and element design to achieve higher power densities without compromising safety or reliability.

Lastly, the integration of smart technology in cooking appliances poses new challenges for nichrome applications. The need for precise temperature control and rapid response to user inputs demands innovations in how nichrome elements are designed and controlled, potentially leading to the development of more sophisticated heating systems that combine traditional nichrome technology with advanced electronic controls.

Existing Nichrome Applications in Cooking

01 Composition and properties of nichrome alloys

Nichrome is an alloy primarily composed of nickel and chromium, with varying proportions depending on the specific application. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.- Composition and properties of nichrome alloys: Nichrome is an alloy primarily composed of nickel and chromium, with varying compositions for different applications. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.

- Manufacturing processes for nichrome components: Various manufacturing processes are employed to produce nichrome components, including wire drawing, thin film deposition, and powder metallurgy. These processes allow for the creation of nichrome elements in different forms such as wires, films, and powders, each suited for specific applications in electronics and heating systems.

- Applications in heating elements and resistors: Nichrome is widely used in the production of heating elements and resistors due to its high electrical resistance and heat tolerance. It is commonly found in household appliances, industrial heaters, and electronic devices where precise temperature control or electrical resistance is required.

- Use in thin film technology and sensors: Nichrome plays a crucial role in thin film technology, particularly in the fabrication of sensors and microelectronic devices. Its stability and resistance properties make it suitable for creating precise and durable thin film resistors and temperature sensors used in various industries.

- Innovations in nichrome-based materials and coatings: Recent innovations focus on improving nichrome-based materials and coatings. These advancements include developing new alloy compositions, enhancing surface properties, and creating composite materials that combine nichrome with other elements to achieve specific performance characteristics for specialized applications.

02 Manufacturing processes for nichrome components

Various manufacturing processes are employed to produce nichrome components, including wire drawing, thin film deposition, and powder metallurgy techniques. These processes are optimized to achieve desired physical and electrical properties for specific applications, such as heating elements or sensors.Expand Specific Solutions03 Applications in electronic devices and sensors

Nichrome is widely used in electronic devices and sensors due to its stable electrical properties. It is employed in the fabrication of thin-film resistors, temperature sensors, and other electronic components that require precise resistance values and temperature stability.Expand Specific Solutions04 Heating element applications

Nichrome is extensively used in heating elements for various applications, including household appliances, industrial heaters, and laboratory equipment. Its high resistance to oxidation at elevated temperatures and consistent electrical properties make it an ideal material for these applications.Expand Specific Solutions05 Surface treatment and coating techniques

Various surface treatment and coating techniques are applied to nichrome components to enhance their performance or protect them from environmental factors. These techniques may include oxidation-resistant coatings, insulation layers, or surface modifications to improve adhesion or other properties.Expand Specific Solutions

Key Players in Nichrome Manufacturing

The market for nichrome in high-performance cooking appliances is in a mature growth stage, with a steady global market size driven by increasing demand for advanced kitchen equipment. The technology is well-established, with key players like SEB SA, Hangzhou Joyoung, and Panasonic Holdings Corp. leading innovation. These companies leverage nichrome's superior heat resistance and electrical properties to enhance cooking performance and energy efficiency. The competitive landscape is characterized by continuous product improvements and diversification, with firms like Miele & Cie. KG and BSH Hausgeräte GmbH focusing on premium segments. Emerging players from China, such as Wuhan Supor Cookware, are also making significant inroads, intensifying market competition and driving technological advancements in nichrome applications for cooking appliances.

SEB SA

Technical Solution: SEB SA has developed advanced nichrome heating elements for their high-performance cooking appliances. Their technology incorporates a precision-engineered nichrome alloy composition, optimized for rapid and uniform heating. The company utilizes a proprietary coating process that enhances the durability and corrosion resistance of the nichrome elements, extending their lifespan in demanding cooking environments[1]. SEB's nichrome elements are designed with a unique serpentine pattern that maximizes surface area contact with cookware, resulting in improved heat transfer efficiency and reduced energy consumption[3]. Additionally, they have implemented advanced temperature control systems that work in tandem with the nichrome elements to provide precise and consistent cooking temperatures across various culinary applications[5].

Strengths: Rapid and uniform heating, enhanced durability, improved energy efficiency, and precise temperature control. Weaknesses: Potentially higher production costs due to proprietary processes and materials, which may impact product pricing.

Sandvik Intellectual Property AB

Technical Solution: Sandvik has developed a high-performance nichrome alloy specifically tailored for cooking appliances. Their innovative approach involves a carefully controlled composition of nickel, chromium, and trace elements to optimize electrical resistance and thermal properties[2]. The company employs advanced metallurgical techniques to create a microstructure that enhances the alloy's stability at high temperatures, reducing the risk of element failure during prolonged use[4]. Sandvik's nichrome elements are manufactured using a precision wire-drawing process that ensures consistent diameter and surface quality, critical for even heat distribution in cooking applications[6]. Furthermore, they have developed a specialized surface treatment that minimizes oxidation and extends the operational life of the heating elements in various cooking environments[8].

Strengths: Superior high-temperature stability, consistent performance, and extended operational life. Weaknesses: Potentially higher material costs compared to standard nichrome alloys, which may limit adoption in budget-friendly appliances.

Innovative Nichrome Alloy Compositions

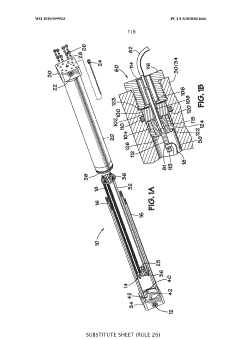

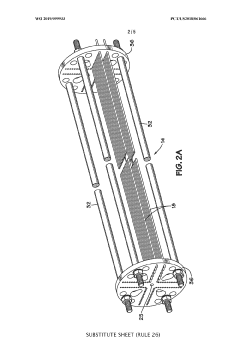

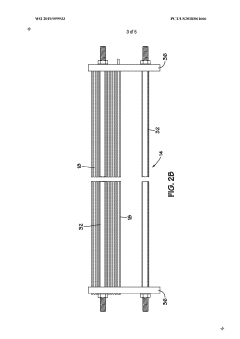

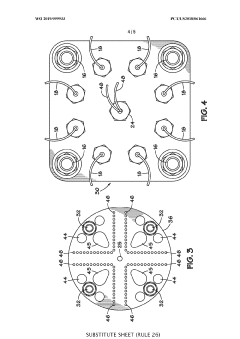

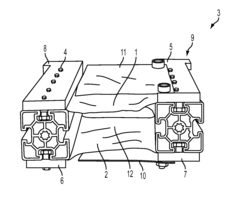

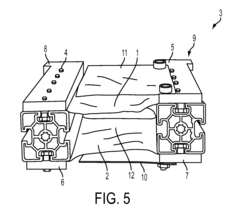

In-line electric heater for plural component materials

PatentWO2019099933A1

Innovation

- An in-line electric heater design featuring a housing with multiple electric resistance heating elements along the fluid flow path, supported by a wire loom assembly and temperature sensors, using INCONEL wires coated with Teflon for improved durability and insulation, and a power feedthrough system for secure electrical connections, enhancing heat transfer and temperature control.

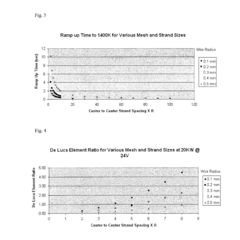

Wire mesh thermal radiative element and use in a radiative oven

PatentInactiveUS20150184867A1

Innovation

- A resistive mesh element with a calibrated De Luca Element Ratio, using nichrome wire with a specific strand diameter and spacing, operates at 24V to achieve efficient heat distribution and rapid temperature rise, allowing for quick cooking times while being cost-effective and easy to assemble.

Thermal Efficiency Optimization

Thermal efficiency optimization in high-performance cooking appliances utilizing nichrome heating elements is a critical area of focus for manufacturers and engineers. The primary goal is to maximize heat transfer from the nichrome wire to the cooking surface or food while minimizing energy losses. This optimization process involves several key strategies and considerations.

One of the primary approaches to enhancing thermal efficiency is through improved heating element design. By optimizing the geometry and configuration of nichrome wire coils, manufacturers can increase the surface area for heat transfer while maintaining or reducing power consumption. This may involve using tightly wound coils or flat ribbon designs that maximize contact with the cooking surface.

Another crucial aspect of thermal efficiency optimization is the implementation of advanced insulation materials and techniques. High-performance cooking appliances often incorporate multi-layer insulation systems that effectively trap heat within the cooking chamber. These systems may include ceramic fiber insulation, aerogels, or vacuum-insulated panels, which significantly reduce heat loss to the surrounding environment.

Heat distribution is also a key factor in thermal efficiency. Engineers focus on designing heating element layouts that provide uniform heat distribution across the cooking surface. This may involve strategic placement of multiple nichrome elements or the use of heat-spreading materials to ensure even cooking and prevent hot spots.

Advanced control systems play a vital role in optimizing thermal efficiency. Microprocessor-controlled temperature regulation allows for precise heat management, reducing energy waste from overheating or temperature fluctuations. These systems can also incorporate adaptive heating algorithms that adjust power output based on the type and quantity of food being cooked.

The integration of reflective surfaces and materials within the appliance can further enhance thermal efficiency. By strategically placing heat-reflective components, such as polished stainless steel or specialized coatings, manufacturers can redirect radiant heat back towards the cooking area, minimizing losses and improving overall energy utilization.

Thermal mass optimization is another consideration in high-performance cooking appliances. By carefully balancing the thermal mass of components, designers can achieve rapid heating and cooling cycles while maintaining temperature stability during cooking. This may involve using materials with specific heat capacities that complement the nichrome heating elements' performance characteristics.

One of the primary approaches to enhancing thermal efficiency is through improved heating element design. By optimizing the geometry and configuration of nichrome wire coils, manufacturers can increase the surface area for heat transfer while maintaining or reducing power consumption. This may involve using tightly wound coils or flat ribbon designs that maximize contact with the cooking surface.

Another crucial aspect of thermal efficiency optimization is the implementation of advanced insulation materials and techniques. High-performance cooking appliances often incorporate multi-layer insulation systems that effectively trap heat within the cooking chamber. These systems may include ceramic fiber insulation, aerogels, or vacuum-insulated panels, which significantly reduce heat loss to the surrounding environment.

Heat distribution is also a key factor in thermal efficiency. Engineers focus on designing heating element layouts that provide uniform heat distribution across the cooking surface. This may involve strategic placement of multiple nichrome elements or the use of heat-spreading materials to ensure even cooking and prevent hot spots.

Advanced control systems play a vital role in optimizing thermal efficiency. Microprocessor-controlled temperature regulation allows for precise heat management, reducing energy waste from overheating or temperature fluctuations. These systems can also incorporate adaptive heating algorithms that adjust power output based on the type and quantity of food being cooked.

The integration of reflective surfaces and materials within the appliance can further enhance thermal efficiency. By strategically placing heat-reflective components, such as polished stainless steel or specialized coatings, manufacturers can redirect radiant heat back towards the cooking area, minimizing losses and improving overall energy utilization.

Thermal mass optimization is another consideration in high-performance cooking appliances. By carefully balancing the thermal mass of components, designers can achieve rapid heating and cooling cycles while maintaining temperature stability during cooking. This may involve using materials with specific heat capacities that complement the nichrome heating elements' performance characteristics.

Safety Standards for Nichrome in Appliances

Safety standards for nichrome in cooking appliances are crucial to ensure consumer protection and product reliability. These standards encompass various aspects, including thermal management, electrical safety, and material durability. Regulatory bodies such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have established comprehensive guidelines for nichrome usage in high-performance cooking appliances.

One of the primary safety considerations is the prevention of overheating. Nichrome wires in cooking appliances must be designed to operate within specific temperature ranges to avoid potential fire hazards or damage to surrounding components. Standards typically specify maximum operating temperatures and require the implementation of thermal cut-off mechanisms to prevent excessive heat buildup.

Electrical insulation is another critical aspect of nichrome safety standards. The nichrome heating elements must be properly insulated to prevent electrical shock risks to users. This includes requirements for adequate spacing between conductive parts, use of appropriate insulating materials, and protection against moisture ingress that could compromise electrical safety.

Durability and longevity of nichrome components are also addressed in safety standards. The material must withstand repeated thermal cycling without significant degradation or risk of failure. Standards often include accelerated aging tests to simulate long-term use and ensure the nichrome elements maintain their integrity over the expected lifespan of the appliance.

Electromagnetic compatibility (EMC) is an increasingly important consideration in modern appliance design. Safety standards for nichrome in cooking appliances include requirements to minimize electromagnetic interference with other electronic devices and to ensure the appliance itself is not susceptible to external electromagnetic disturbances.

Chemical safety is another aspect covered by these standards. Nichrome elements must not release harmful substances when heated, and the materials used in conjunction with nichrome (such as insulation and support structures) must also meet strict chemical safety requirements to prevent the release of toxic fumes or particles during operation.

Manufacturing and quality control processes are also subject to safety standards. These include specifications for the purity and composition of nichrome alloys, as well as requirements for consistent production methods to ensure uniformity and reliability across all manufactured units.

Compliance with these safety standards is typically verified through rigorous testing procedures. These may include thermal imaging, electrical safety tests, durability assessments, and EMC evaluations. Certification by recognized testing laboratories is often required before a nichrome-containing cooking appliance can be marketed and sold in many jurisdictions.

One of the primary safety considerations is the prevention of overheating. Nichrome wires in cooking appliances must be designed to operate within specific temperature ranges to avoid potential fire hazards or damage to surrounding components. Standards typically specify maximum operating temperatures and require the implementation of thermal cut-off mechanisms to prevent excessive heat buildup.

Electrical insulation is another critical aspect of nichrome safety standards. The nichrome heating elements must be properly insulated to prevent electrical shock risks to users. This includes requirements for adequate spacing between conductive parts, use of appropriate insulating materials, and protection against moisture ingress that could compromise electrical safety.

Durability and longevity of nichrome components are also addressed in safety standards. The material must withstand repeated thermal cycling without significant degradation or risk of failure. Standards often include accelerated aging tests to simulate long-term use and ensure the nichrome elements maintain their integrity over the expected lifespan of the appliance.

Electromagnetic compatibility (EMC) is an increasingly important consideration in modern appliance design. Safety standards for nichrome in cooking appliances include requirements to minimize electromagnetic interference with other electronic devices and to ensure the appliance itself is not susceptible to external electromagnetic disturbances.

Chemical safety is another aspect covered by these standards. Nichrome elements must not release harmful substances when heated, and the materials used in conjunction with nichrome (such as insulation and support structures) must also meet strict chemical safety requirements to prevent the release of toxic fumes or particles during operation.

Manufacturing and quality control processes are also subject to safety standards. These include specifications for the purity and composition of nichrome alloys, as well as requirements for consistent production methods to ensure uniformity and reliability across all manufactured units.

Compliance with these safety standards is typically verified through rigorous testing procedures. These may include thermal imaging, electrical safety tests, durability assessments, and EMC evaluations. Certification by recognized testing laboratories is often required before a nichrome-containing cooking appliance can be marketed and sold in many jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!