Nichrome Wire's Benefits in Laboratory Heating Applications

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Wire Evolution

Nichrome wire, an alloy primarily composed of nickel and chromium, has undergone significant evolution since its inception in the early 20th century. The development of this material has been closely tied to advancements in electrical heating applications, particularly in laboratory settings.

In the 1905, Albert Marsh patented the first nichrome alloy, marking the beginning of its journey in heating applications. This initial composition, consisting of 80% nickel and 20% chromium, offered unprecedented resistance to oxidation at high temperatures, making it ideal for use in heating elements.

Throughout the 1920s and 1930s, researchers focused on refining the alloy's composition to enhance its performance characteristics. This period saw the introduction of various grades of nichrome, each tailored for specific applications. The addition of small amounts of other elements, such as iron and silicon, led to improvements in strength and oxidation resistance.

The 1940s and 1950s witnessed a surge in the use of nichrome wire in laboratory equipment. Its reliability and consistent performance made it the material of choice for heating mantles, hot plates, and other precision heating devices. During this time, manufacturers developed techniques to produce thinner gauge wires, allowing for more compact and efficient heating elements.

In the 1960s and 1970s, the focus shifted towards improving the longevity of nichrome wire. Researchers explored ways to minimize grain boundary oxidation, a common cause of failure in high-temperature applications. This led to the development of more advanced alloy compositions and surface treatments that significantly extended the operational life of nichrome heating elements.

The 1980s and 1990s saw the integration of nichrome wire into more sophisticated laboratory equipment. Its use in controlled atmosphere furnaces and thermal analysis instruments became widespread, thanks to its ability to maintain precise temperatures over extended periods.

Entering the 21st century, the evolution of nichrome wire has been characterized by a focus on energy efficiency and precise temperature control. Modern manufacturing techniques have allowed for the production of nichrome wires with extremely tight tolerances, ensuring consistent performance across batches. Additionally, the development of computer-controlled heating systems has leveraged the predictable resistance properties of nichrome to achieve unprecedented levels of temperature accuracy in laboratory applications.

Recent advancements have also explored the potential of nanostructured nichrome materials, aiming to further enhance heat distribution and energy efficiency. These innovations promise to extend the utility of nichrome wire in increasingly demanding laboratory heating applications, ensuring its continued relevance in scientific research and industrial processes.

In the 1905, Albert Marsh patented the first nichrome alloy, marking the beginning of its journey in heating applications. This initial composition, consisting of 80% nickel and 20% chromium, offered unprecedented resistance to oxidation at high temperatures, making it ideal for use in heating elements.

Throughout the 1920s and 1930s, researchers focused on refining the alloy's composition to enhance its performance characteristics. This period saw the introduction of various grades of nichrome, each tailored for specific applications. The addition of small amounts of other elements, such as iron and silicon, led to improvements in strength and oxidation resistance.

The 1940s and 1950s witnessed a surge in the use of nichrome wire in laboratory equipment. Its reliability and consistent performance made it the material of choice for heating mantles, hot plates, and other precision heating devices. During this time, manufacturers developed techniques to produce thinner gauge wires, allowing for more compact and efficient heating elements.

In the 1960s and 1970s, the focus shifted towards improving the longevity of nichrome wire. Researchers explored ways to minimize grain boundary oxidation, a common cause of failure in high-temperature applications. This led to the development of more advanced alloy compositions and surface treatments that significantly extended the operational life of nichrome heating elements.

The 1980s and 1990s saw the integration of nichrome wire into more sophisticated laboratory equipment. Its use in controlled atmosphere furnaces and thermal analysis instruments became widespread, thanks to its ability to maintain precise temperatures over extended periods.

Entering the 21st century, the evolution of nichrome wire has been characterized by a focus on energy efficiency and precise temperature control. Modern manufacturing techniques have allowed for the production of nichrome wires with extremely tight tolerances, ensuring consistent performance across batches. Additionally, the development of computer-controlled heating systems has leveraged the predictable resistance properties of nichrome to achieve unprecedented levels of temperature accuracy in laboratory applications.

Recent advancements have also explored the potential of nanostructured nichrome materials, aiming to further enhance heat distribution and energy efficiency. These innovations promise to extend the utility of nichrome wire in increasingly demanding laboratory heating applications, ensuring its continued relevance in scientific research and industrial processes.

Lab Heating Market Analysis

The laboratory heating market has experienced significant growth in recent years, driven by increasing demand for precise temperature control in scientific research, pharmaceutical development, and industrial applications. This market segment encompasses a wide range of heating devices, including hot plates, heating mantles, and furnaces, with nichrome wire playing a crucial role in many of these applications.

The global laboratory heating equipment market was valued at approximately $630 million in 2020 and is projected to reach $850 million by 2025, growing at a CAGR of 6.2% during the forecast period. This growth is primarily attributed to the expanding pharmaceutical and biotechnology industries, increased research and development activities, and the rising adoption of advanced laboratory technologies.

Nichrome wire, an alloy of nickel and chromium, has become a preferred heating element in many laboratory heating applications due to its unique properties. Its high electrical resistance, excellent heat resistance, and ability to withstand high temperatures make it ideal for use in precision heating equipment. The market for nichrome wire in laboratory heating applications is estimated to account for approximately 15% of the overall laboratory heating market.

Geographically, North America and Europe dominate the laboratory heating market, collectively accounting for over 60% of the global market share. This is due to the presence of well-established research institutions, pharmaceutical companies, and advanced healthcare infrastructure in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing investments in research and development, growing healthcare expenditure, and the expansion of the biotechnology sector in countries like China and India.

The laboratory heating market is characterized by intense competition, with several key players vying for market share. Major companies in this space include Thermo Fisher Scientific, Agilent Technologies, Benchmark Scientific, and IKA Works. These companies are continuously innovating to develop more efficient and precise heating solutions, often incorporating nichrome wire technology in their products.

The demand for nichrome wire in laboratory heating applications is expected to grow steadily, driven by its superior performance characteristics and reliability. As research activities become more complex and require more precise temperature control, the adoption of nichrome wire-based heating elements is likely to increase. This trend is particularly evident in applications such as DNA amplification, protein analysis, and materials testing, where accurate and consistent heating is critical for reliable results.

The global laboratory heating equipment market was valued at approximately $630 million in 2020 and is projected to reach $850 million by 2025, growing at a CAGR of 6.2% during the forecast period. This growth is primarily attributed to the expanding pharmaceutical and biotechnology industries, increased research and development activities, and the rising adoption of advanced laboratory technologies.

Nichrome wire, an alloy of nickel and chromium, has become a preferred heating element in many laboratory heating applications due to its unique properties. Its high electrical resistance, excellent heat resistance, and ability to withstand high temperatures make it ideal for use in precision heating equipment. The market for nichrome wire in laboratory heating applications is estimated to account for approximately 15% of the overall laboratory heating market.

Geographically, North America and Europe dominate the laboratory heating market, collectively accounting for over 60% of the global market share. This is due to the presence of well-established research institutions, pharmaceutical companies, and advanced healthcare infrastructure in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing investments in research and development, growing healthcare expenditure, and the expansion of the biotechnology sector in countries like China and India.

The laboratory heating market is characterized by intense competition, with several key players vying for market share. Major companies in this space include Thermo Fisher Scientific, Agilent Technologies, Benchmark Scientific, and IKA Works. These companies are continuously innovating to develop more efficient and precise heating solutions, often incorporating nichrome wire technology in their products.

The demand for nichrome wire in laboratory heating applications is expected to grow steadily, driven by its superior performance characteristics and reliability. As research activities become more complex and require more precise temperature control, the adoption of nichrome wire-based heating elements is likely to increase. This trend is particularly evident in applications such as DNA amplification, protein analysis, and materials testing, where accurate and consistent heating is critical for reliable results.

Nichrome Wire Tech Status

Nichrome wire, an alloy primarily composed of nickel and chromium, has established itself as a cornerstone in laboratory heating applications. The current technological status of nichrome wire reflects its widespread adoption and continuous refinement over decades of use.

In modern laboratories, nichrome wire is extensively utilized in various heating devices, including furnaces, hot plates, and heating mantles. Its popularity stems from its exceptional combination of properties that make it ideal for controlled heating processes. The wire's high electrical resistance allows for efficient conversion of electrical energy into heat, while its remarkable oxidation resistance at elevated temperatures ensures longevity and stability in demanding laboratory environments.

Recent advancements in nichrome wire technology have focused on enhancing its performance characteristics. Manufacturers have fine-tuned the alloy composition, typically consisting of 80% nickel and 20% chromium, to optimize its thermal and electrical properties. This refinement has resulted in nichrome wires with improved temperature uniformity and faster heating rates, crucial factors in precise laboratory experiments.

The current generation of nichrome wires boasts an impressive operating temperature range, commonly reaching up to 1200°C (2192°F). This high-temperature capability makes it suitable for a wide array of laboratory applications, from gentle warming to high-temperature synthesis reactions. Moreover, the wire's low temperature coefficient of resistance ensures consistent heat output across its operational range, a critical feature for maintaining stable experimental conditions.

Durability and reliability remain key strengths of nichrome wire in laboratory settings. Its resistance to corrosion and oxidation, even under prolonged exposure to high temperatures, translates to reduced maintenance requirements and extended service life for laboratory equipment. This durability factor has contributed significantly to the wire's continued prevalence in laboratory heating applications.

In terms of form factor, nichrome wire is available in various gauges and configurations to suit different heating requirements. Thin wires are commonly used in precision heating applications, while thicker gauges are employed in high-power heating elements. The flexibility in wire diameter and length allows for customization of heating elements to meet specific laboratory needs, from small-scale analytical instruments to large industrial furnaces.

Recent technological developments have also focused on improving the integration of nichrome wire heating elements with modern laboratory control systems. Advanced temperature controllers and power management systems now work in tandem with nichrome wire heating elements to provide precise temperature regulation and programmable heating profiles. This integration enhances the versatility and accuracy of laboratory heating processes, enabling researchers to conduct more complex and controlled experiments.

In modern laboratories, nichrome wire is extensively utilized in various heating devices, including furnaces, hot plates, and heating mantles. Its popularity stems from its exceptional combination of properties that make it ideal for controlled heating processes. The wire's high electrical resistance allows for efficient conversion of electrical energy into heat, while its remarkable oxidation resistance at elevated temperatures ensures longevity and stability in demanding laboratory environments.

Recent advancements in nichrome wire technology have focused on enhancing its performance characteristics. Manufacturers have fine-tuned the alloy composition, typically consisting of 80% nickel and 20% chromium, to optimize its thermal and electrical properties. This refinement has resulted in nichrome wires with improved temperature uniformity and faster heating rates, crucial factors in precise laboratory experiments.

The current generation of nichrome wires boasts an impressive operating temperature range, commonly reaching up to 1200°C (2192°F). This high-temperature capability makes it suitable for a wide array of laboratory applications, from gentle warming to high-temperature synthesis reactions. Moreover, the wire's low temperature coefficient of resistance ensures consistent heat output across its operational range, a critical feature for maintaining stable experimental conditions.

Durability and reliability remain key strengths of nichrome wire in laboratory settings. Its resistance to corrosion and oxidation, even under prolonged exposure to high temperatures, translates to reduced maintenance requirements and extended service life for laboratory equipment. This durability factor has contributed significantly to the wire's continued prevalence in laboratory heating applications.

In terms of form factor, nichrome wire is available in various gauges and configurations to suit different heating requirements. Thin wires are commonly used in precision heating applications, while thicker gauges are employed in high-power heating elements. The flexibility in wire diameter and length allows for customization of heating elements to meet specific laboratory needs, from small-scale analytical instruments to large industrial furnaces.

Recent technological developments have also focused on improving the integration of nichrome wire heating elements with modern laboratory control systems. Advanced temperature controllers and power management systems now work in tandem with nichrome wire heating elements to provide precise temperature regulation and programmable heating profiles. This integration enhances the versatility and accuracy of laboratory heating processes, enabling researchers to conduct more complex and controlled experiments.

Current Nichrome Solutions

01 Composition and properties of nichrome wire

Nichrome wire is an alloy primarily composed of nickel and chromium. It is known for its high electrical resistance and excellent heat resistance, making it suitable for various heating applications. The specific composition and properties of nichrome wire can be tailored to meet different requirements in terms of resistivity, temperature coefficient, and mechanical strength.- Composition and properties of nichrome wire: Nichrome wire is an alloy primarily composed of nickel and chromium. It is known for its high electrical resistance and heat resistance, making it suitable for various heating applications. The specific composition and properties of nichrome wire can be tailored to meet different requirements in terms of resistivity, temperature coefficient, and mechanical strength.

- Applications in heating elements: Nichrome wire is widely used in the manufacturing of heating elements for various devices and appliances. Its high resistance to heat and oxidation makes it ideal for use in electric heaters, toasters, hair dryers, and other heating appliances. The wire can be formed into different shapes and configurations to suit specific heating requirements.

- Use in sensors and measurement devices: Nichrome wire finds applications in sensors and measurement devices due to its stable electrical properties and temperature coefficient. It is used in thermocouples, strain gauges, and other precision instruments where accurate temperature or electrical resistance measurements are required.

- Fabrication techniques for nichrome wire: Various fabrication techniques are employed in the production of nichrome wire to achieve desired properties and dimensions. These may include drawing, annealing, and surface treatments. Advanced manufacturing methods can be used to produce ultra-fine nichrome wires or specialized shapes for specific applications.

- Innovations in nichrome wire technology: Ongoing research and development in nichrome wire technology focus on improving its performance characteristics, such as increasing its maximum operating temperature, enhancing its corrosion resistance, and developing new alloy compositions. These innovations aim to expand the range of applications for nichrome wire and improve its longevity in harsh environments.

02 Applications in heating elements

Nichrome wire is widely used in the manufacturing of heating elements for various devices and appliances. Its high resistance to oxidation at elevated temperatures and stable electrical properties make it ideal for use in electric heaters, ovens, toasters, and other heating appliances. The wire can be formed into different shapes and configurations to suit specific heating requirements.Expand Specific Solutions03 Use in electronic components

Nichrome wire finds applications in electronic components, particularly in the production of resistors and other circuit elements. Its precise electrical resistance characteristics allow for the creation of accurate and stable resistive components. The wire can be used in various forms, including wound resistors and thin-film resistors, for different electronic applications.Expand Specific Solutions04 Fabrication techniques for nichrome wire

Various fabrication techniques are employed in the production of nichrome wire to achieve desired properties and forms. These may include drawing, annealing, and surface treatment processes. Advanced manufacturing methods can be used to produce ultra-fine nichrome wires or specialized forms for specific applications, such as coiled or flattened wires.Expand Specific Solutions05 Innovations in nichrome wire technology

Ongoing research and development in nichrome wire technology focus on improving its performance characteristics and expanding its applications. This includes developing new alloy compositions, enhancing durability and lifespan, and exploring novel manufacturing techniques. Innovations also involve the integration of nichrome wire in advanced sensor technologies and specialized industrial applications.Expand Specific Solutions

Key Nichrome Manufacturers

The market for nichrome wire in laboratory heating applications is in a mature stage, with established players and steady demand. The global market size is estimated to be in the hundreds of millions of dollars annually, driven by ongoing research and development activities across various scientific fields. Technologically, nichrome wire is a well-understood and reliable solution, with incremental improvements in performance and durability. Key players like Heraeus Precious Metals and Yancheng Xinyang Electric Heating Material Co. are focusing on enhancing product quality and expanding application areas to maintain their competitive edge in this stable market.

Heraeus Precious Metals GmbH & Co. KG (New)

Technical Solution: Heraeus has developed advanced nichrome wire solutions for laboratory heating applications, leveraging their expertise in precious metals. Their nichrome wires are engineered with precise composition control, typically 80% nickel and 20% chromium, to achieve optimal resistivity and temperature coefficient of resistance. These wires exhibit excellent oxidation resistance at high temperatures, maintaining stability up to 1200°C [1]. Heraeus employs advanced drawing techniques to produce ultra-fine nichrome wires with diameters as small as 0.025 mm, enabling the creation of compact and efficient heating elements for laboratory equipment [2]. The company also offers custom alloy compositions and surface treatments to enhance specific properties such as corrosion resistance or electrical conductivity, tailoring the wire performance to specific laboratory heating requirements.

Strengths: High-quality materials, precise composition control, and customization options. Weaknesses: Potentially higher cost compared to standard nichrome wires, may require specialized handling during installation.

Yancheng Xinyang Electric Heating Material Co., Ltd.

Technical Solution: Yancheng Xinyang specializes in the production of nichrome wire for various heating applications, including laboratory use. Their manufacturing process focuses on creating uniform wire with consistent electrical properties. The company offers nichrome wire in a range of diameters, typically from 0.1 mm to 10 mm, to suit different heating requirements [3]. They utilize a controlled atmosphere during production to minimize impurities and ensure optimal oxidation resistance. Yancheng Xinyang's nichrome wire products feature a temperature coefficient of resistance of approximately 0.00013 per degree Celsius, providing stable performance across a wide temperature range [4]. The company also provides nichrome ribbon and flat wire options, offering flexibility in heating element design for laboratory equipment manufacturers.

Strengths: Wide range of product sizes, consistent quality, and competitive pricing. Weaknesses: May lack the advanced customization options of some competitors, potentially limited global distribution network.

Nichrome Innovations

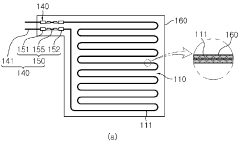

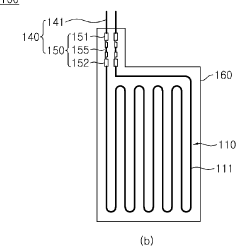

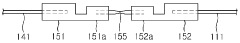

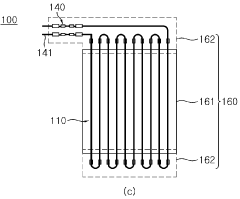

Electric heater and heat exchanger employing the same

PatentWO1985000084A1

Innovation

- A bare nichrome wire is immersed in silicone oil, which provides rapid temperature rise, excellent insulation, oxidation resistance, and durability, preventing oxidation and ensuring safety by using silicone oil with good thermal and electrical properties.

Heating device and liquid heating device comprising same

PatentWO2012134242A2

Innovation

- A heating device featuring a carbon fiber heating element shaped in columns or rows, covered with fluororesin (Teflon) for insulation, which prevents oxidation and volatilization, and includes a terminal unit connected via a bare copper wire with a fuse or bimetal cut-off mechanism for safe power connection, ensuring stable insulation even in contact with liquids.

Energy Efficiency Impact

The energy efficiency impact of nichrome wire in laboratory heating applications is significant and multifaceted. Nichrome wire, an alloy primarily composed of nickel and chromium, exhibits exceptional electrical resistance properties, making it an ideal choice for heating elements in various laboratory equipment.

One of the primary advantages of nichrome wire is its ability to rapidly reach and maintain high temperatures with minimal energy input. This characteristic is particularly beneficial in laboratory settings where precise temperature control is crucial for experimental accuracy. The wire's quick heating response allows for faster experiment setup times and reduced energy consumption during idle periods between tests.

Furthermore, nichrome wire's high melting point and resistance to oxidation at elevated temperatures contribute to its longevity and consistent performance over time. This durability translates to reduced maintenance requirements and fewer replacements, indirectly improving the overall energy efficiency of laboratory operations by minimizing downtime and replacement costs.

The wire's excellent thermal conductivity ensures uniform heat distribution across the heating surface, eliminating hot spots and cold zones that could compromise experimental results. This uniformity not only enhances the reliability of laboratory procedures but also optimizes energy utilization by ensuring that heat is evenly distributed where it is needed most.

In comparison to alternative heating methods, such as gas burners or infrared lamps, nichrome wire-based heating systems offer superior control over temperature gradients and heating rates. This precision allows researchers to fine-tune energy input based on specific experimental requirements, potentially reducing overall energy consumption in laboratory processes.

Additionally, the compact nature of nichrome wire heating elements enables the design of more energy-efficient laboratory equipment. Smaller heating units require less power to operate and can be more effectively insulated, further minimizing heat loss and improving overall system efficiency.

The integration of nichrome wire heating elements with modern digital control systems has opened up new avenues for energy optimization in laboratory settings. Advanced temperature controllers can now implement sophisticated heating algorithms, such as pulse-width modulation, to achieve precise temperature regulation while minimizing energy waste. This synergy between nichrome wire's inherent properties and smart control systems represents a significant leap forward in laboratory energy efficiency.

One of the primary advantages of nichrome wire is its ability to rapidly reach and maintain high temperatures with minimal energy input. This characteristic is particularly beneficial in laboratory settings where precise temperature control is crucial for experimental accuracy. The wire's quick heating response allows for faster experiment setup times and reduced energy consumption during idle periods between tests.

Furthermore, nichrome wire's high melting point and resistance to oxidation at elevated temperatures contribute to its longevity and consistent performance over time. This durability translates to reduced maintenance requirements and fewer replacements, indirectly improving the overall energy efficiency of laboratory operations by minimizing downtime and replacement costs.

The wire's excellent thermal conductivity ensures uniform heat distribution across the heating surface, eliminating hot spots and cold zones that could compromise experimental results. This uniformity not only enhances the reliability of laboratory procedures but also optimizes energy utilization by ensuring that heat is evenly distributed where it is needed most.

In comparison to alternative heating methods, such as gas burners or infrared lamps, nichrome wire-based heating systems offer superior control over temperature gradients and heating rates. This precision allows researchers to fine-tune energy input based on specific experimental requirements, potentially reducing overall energy consumption in laboratory processes.

Additionally, the compact nature of nichrome wire heating elements enables the design of more energy-efficient laboratory equipment. Smaller heating units require less power to operate and can be more effectively insulated, further minimizing heat loss and improving overall system efficiency.

The integration of nichrome wire heating elements with modern digital control systems has opened up new avenues for energy optimization in laboratory settings. Advanced temperature controllers can now implement sophisticated heating algorithms, such as pulse-width modulation, to achieve precise temperature regulation while minimizing energy waste. This synergy between nichrome wire's inherent properties and smart control systems represents a significant leap forward in laboratory energy efficiency.

Safety Regulations

Safety regulations play a crucial role in the use of nichrome wire for laboratory heating applications. These regulations are designed to protect laboratory personnel, equipment, and the environment from potential hazards associated with high-temperature operations.

One of the primary safety concerns when using nichrome wire is the risk of electrical shock. To mitigate this risk, laboratories must adhere to strict electrical safety standards. This includes proper insulation of the wire, regular inspection of electrical connections, and the use of ground fault circuit interrupters (GFCIs) to prevent electrical accidents.

Thermal safety is another critical aspect of nichrome wire usage. As these wires can reach extremely high temperatures, proper shielding and insulation are essential to prevent accidental burns or fires. Safety regulations often mandate the use of heat-resistant materials in the construction of heating devices and the implementation of thermal cut-off mechanisms to prevent overheating.

Fire safety regulations are particularly stringent for laboratory heating applications. Nichrome wire heating elements must be housed in fire-resistant enclosures, and laboratories are required to have appropriate fire suppression systems in place. Additionally, safety protocols often include the use of temperature-sensitive alarms and automatic shut-off systems to prevent potential fire hazards.

Ventilation requirements are also an important consideration in safety regulations. When nichrome wire is used for heating applications, it may produce fumes or vapors, especially if it comes into contact with certain materials. Proper ventilation systems must be in place to remove these potentially harmful substances from the laboratory environment.

Personal protective equipment (PPE) regulations are essential for laboratory personnel working with nichrome wire heating applications. This typically includes heat-resistant gloves, safety goggles, and flame-resistant lab coats. Training requirements are often specified in safety regulations, ensuring that all personnel are adequately prepared to handle the equipment safely and respond to potential emergencies.

Maintenance and inspection protocols form a significant part of safety regulations. Regular checks of nichrome wire heating elements, electrical systems, and safety devices are mandated to ensure ongoing safe operation. Documentation of these inspections and any maintenance activities is typically required for compliance with safety standards.

Lastly, safety regulations often address the proper disposal of nichrome wire and associated heating equipment. As these materials may contain hazardous substances or retain residual heat, specific procedures must be followed to ensure safe and environmentally responsible disposal.

One of the primary safety concerns when using nichrome wire is the risk of electrical shock. To mitigate this risk, laboratories must adhere to strict electrical safety standards. This includes proper insulation of the wire, regular inspection of electrical connections, and the use of ground fault circuit interrupters (GFCIs) to prevent electrical accidents.

Thermal safety is another critical aspect of nichrome wire usage. As these wires can reach extremely high temperatures, proper shielding and insulation are essential to prevent accidental burns or fires. Safety regulations often mandate the use of heat-resistant materials in the construction of heating devices and the implementation of thermal cut-off mechanisms to prevent overheating.

Fire safety regulations are particularly stringent for laboratory heating applications. Nichrome wire heating elements must be housed in fire-resistant enclosures, and laboratories are required to have appropriate fire suppression systems in place. Additionally, safety protocols often include the use of temperature-sensitive alarms and automatic shut-off systems to prevent potential fire hazards.

Ventilation requirements are also an important consideration in safety regulations. When nichrome wire is used for heating applications, it may produce fumes or vapors, especially if it comes into contact with certain materials. Proper ventilation systems must be in place to remove these potentially harmful substances from the laboratory environment.

Personal protective equipment (PPE) regulations are essential for laboratory personnel working with nichrome wire heating applications. This typically includes heat-resistant gloves, safety goggles, and flame-resistant lab coats. Training requirements are often specified in safety regulations, ensuring that all personnel are adequately prepared to handle the equipment safely and respond to potential emergencies.

Maintenance and inspection protocols form a significant part of safety regulations. Regular checks of nichrome wire heating elements, electrical systems, and safety devices are mandated to ensure ongoing safe operation. Documentation of these inspections and any maintenance activities is typically required for compliance with safety standards.

Lastly, safety regulations often address the proper disposal of nichrome wire and associated heating equipment. As these materials may contain hazardous substances or retain residual heat, specific procedures must be followed to ensure safe and environmentally responsible disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!