PHEV cost reduction strategies for mass adoption

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV Evolution and Targets

Plug-in Hybrid Electric Vehicles (PHEVs) have undergone significant evolution since their inception, driven by advancements in battery technology, powertrain efficiency, and manufacturing processes. The journey of PHEVs began with early models offering limited electric-only range and higher costs, gradually progressing to more capable and affordable options. This evolution has been marked by continuous improvements in battery energy density, electric motor efficiency, and integration of advanced control systems.

The primary goal in PHEV development has been to strike an optimal balance between electric range, performance, and cost-effectiveness. As the technology matured, manufacturers focused on extending electric-only range while simultaneously reducing production costs. This dual objective has been crucial in positioning PHEVs as a viable transition technology between conventional internal combustion engine vehicles and fully electric vehicles.

A key target in PHEV evolution has been the reduction of battery costs, which historically represented a significant portion of the vehicle's overall cost. Advancements in battery chemistry, particularly the shift from nickel-metal hydride to lithium-ion technologies, have played a pivotal role in this cost reduction strategy. Concurrently, improvements in battery management systems have enhanced the longevity and performance of these power sources.

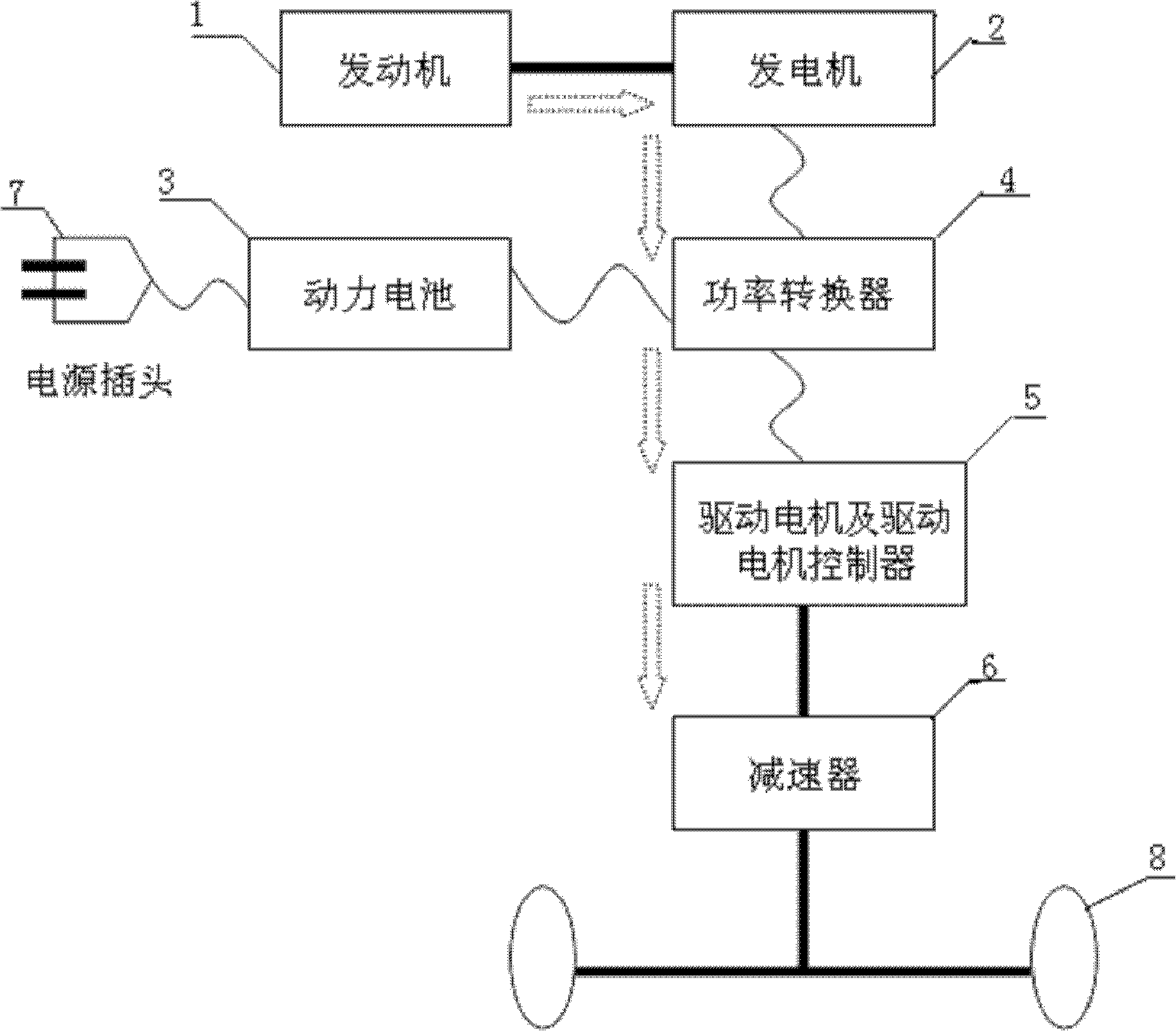

Another critical target has been the optimization of the powertrain, aiming to seamlessly integrate electric and combustion propulsion systems. This integration has focused on improving overall vehicle efficiency, reducing emissions, and enhancing the driving experience. Advanced control algorithms and power electronics have been instrumental in achieving these goals, allowing for more intelligent energy management and smoother transitions between power sources.

Manufacturing efficiency has also been a key target in PHEV evolution. Automakers have invested heavily in streamlining production processes, developing modular platforms, and increasing economies of scale. These efforts have been crucial in bringing down the overall cost of PHEVs, making them more accessible to a broader consumer base.

Looking forward, the targets for PHEV evolution continue to focus on cost reduction strategies for mass adoption. This includes further improvements in battery technology, with a focus on increasing energy density while reducing material costs. Additionally, the integration of more advanced lightweight materials in vehicle construction is expected to play a significant role in improving overall efficiency and range.

The ultimate target for PHEVs is to achieve price parity with conventional vehicles while offering superior performance and environmental benefits. This goal necessitates continued innovation in manufacturing processes, supply chain optimization, and technological advancements across all components of the PHEV system. As these targets are progressively met, PHEVs are poised to play an increasingly important role in the transition towards a more sustainable transportation ecosystem.

The primary goal in PHEV development has been to strike an optimal balance between electric range, performance, and cost-effectiveness. As the technology matured, manufacturers focused on extending electric-only range while simultaneously reducing production costs. This dual objective has been crucial in positioning PHEVs as a viable transition technology between conventional internal combustion engine vehicles and fully electric vehicles.

A key target in PHEV evolution has been the reduction of battery costs, which historically represented a significant portion of the vehicle's overall cost. Advancements in battery chemistry, particularly the shift from nickel-metal hydride to lithium-ion technologies, have played a pivotal role in this cost reduction strategy. Concurrently, improvements in battery management systems have enhanced the longevity and performance of these power sources.

Another critical target has been the optimization of the powertrain, aiming to seamlessly integrate electric and combustion propulsion systems. This integration has focused on improving overall vehicle efficiency, reducing emissions, and enhancing the driving experience. Advanced control algorithms and power electronics have been instrumental in achieving these goals, allowing for more intelligent energy management and smoother transitions between power sources.

Manufacturing efficiency has also been a key target in PHEV evolution. Automakers have invested heavily in streamlining production processes, developing modular platforms, and increasing economies of scale. These efforts have been crucial in bringing down the overall cost of PHEVs, making them more accessible to a broader consumer base.

Looking forward, the targets for PHEV evolution continue to focus on cost reduction strategies for mass adoption. This includes further improvements in battery technology, with a focus on increasing energy density while reducing material costs. Additionally, the integration of more advanced lightweight materials in vehicle construction is expected to play a significant role in improving overall efficiency and range.

The ultimate target for PHEVs is to achieve price parity with conventional vehicles while offering superior performance and environmental benefits. This goal necessitates continued innovation in manufacturing processes, supply chain optimization, and technological advancements across all components of the PHEV system. As these targets are progressively met, PHEVs are poised to play an increasingly important role in the transition towards a more sustainable transportation ecosystem.

PHEV Market Demand Analysis

The market demand for Plug-in Hybrid Electric Vehicles (PHEVs) has been steadily growing in recent years, driven by increasing environmental awareness, government incentives, and advancements in battery technology. As consumers seek more fuel-efficient and environmentally friendly transportation options, PHEVs have emerged as a compelling alternative to traditional internal combustion engine vehicles.

Global PHEV sales have shown a significant upward trend, with major automotive markets such as China, Europe, and North America leading the adoption. In 2020, despite the overall automotive industry downturn due to the COVID-19 pandemic, PHEV sales demonstrated resilience and continued growth. This trend is expected to accelerate in the coming years as more automakers introduce PHEV models across various vehicle segments.

The market potential for PHEVs is substantial, with projections indicating a compound annual growth rate (CAGR) of over 30% in the next five years. This growth is fueled by several factors, including stricter emissions regulations, improvements in charging infrastructure, and increasing consumer acceptance of electrified vehicles.

One of the key drivers of PHEV market demand is the technology's ability to address range anxiety, a common concern among potential electric vehicle buyers. PHEVs offer the flexibility of electric-only driving for short trips while providing the extended range of a conventional engine for longer journeys. This dual-powertrain approach makes PHEVs an attractive option for consumers who are not yet ready to transition to fully electric vehicles.

However, the high cost of PHEVs compared to conventional vehicles remains a significant barrier to mass adoption. The complex powertrain, advanced battery systems, and additional components contribute to higher manufacturing costs, which are often passed on to consumers. As a result, cost reduction strategies are crucial for expanding market penetration and achieving economies of scale.

Industry trends indicate that automakers are focusing on several areas to reduce PHEV costs, including battery technology improvements, powertrain optimization, and increased production efficiency. Advancements in battery chemistry and manufacturing processes are expected to drive down costs while improving energy density and overall performance.

The market demand for PHEVs is also influenced by government policies and incentives. Many countries have implemented tax credits, rebates, and other financial incentives to encourage PHEV adoption. These policies play a significant role in making PHEVs more affordable and attractive to consumers, thereby stimulating market demand.

As the automotive industry continues to evolve, the PHEV market is expected to face increasing competition from battery electric vehicles (BEVs). However, PHEVs are likely to maintain a strong market position in the medium term, particularly in regions with limited charging infrastructure or where consumers require longer driving ranges.

Global PHEV sales have shown a significant upward trend, with major automotive markets such as China, Europe, and North America leading the adoption. In 2020, despite the overall automotive industry downturn due to the COVID-19 pandemic, PHEV sales demonstrated resilience and continued growth. This trend is expected to accelerate in the coming years as more automakers introduce PHEV models across various vehicle segments.

The market potential for PHEVs is substantial, with projections indicating a compound annual growth rate (CAGR) of over 30% in the next five years. This growth is fueled by several factors, including stricter emissions regulations, improvements in charging infrastructure, and increasing consumer acceptance of electrified vehicles.

One of the key drivers of PHEV market demand is the technology's ability to address range anxiety, a common concern among potential electric vehicle buyers. PHEVs offer the flexibility of electric-only driving for short trips while providing the extended range of a conventional engine for longer journeys. This dual-powertrain approach makes PHEVs an attractive option for consumers who are not yet ready to transition to fully electric vehicles.

However, the high cost of PHEVs compared to conventional vehicles remains a significant barrier to mass adoption. The complex powertrain, advanced battery systems, and additional components contribute to higher manufacturing costs, which are often passed on to consumers. As a result, cost reduction strategies are crucial for expanding market penetration and achieving economies of scale.

Industry trends indicate that automakers are focusing on several areas to reduce PHEV costs, including battery technology improvements, powertrain optimization, and increased production efficiency. Advancements in battery chemistry and manufacturing processes are expected to drive down costs while improving energy density and overall performance.

The market demand for PHEVs is also influenced by government policies and incentives. Many countries have implemented tax credits, rebates, and other financial incentives to encourage PHEV adoption. These policies play a significant role in making PHEVs more affordable and attractive to consumers, thereby stimulating market demand.

As the automotive industry continues to evolve, the PHEV market is expected to face increasing competition from battery electric vehicles (BEVs). However, PHEVs are likely to maintain a strong market position in the medium term, particularly in regions with limited charging infrastructure or where consumers require longer driving ranges.

PHEV Cost Challenges

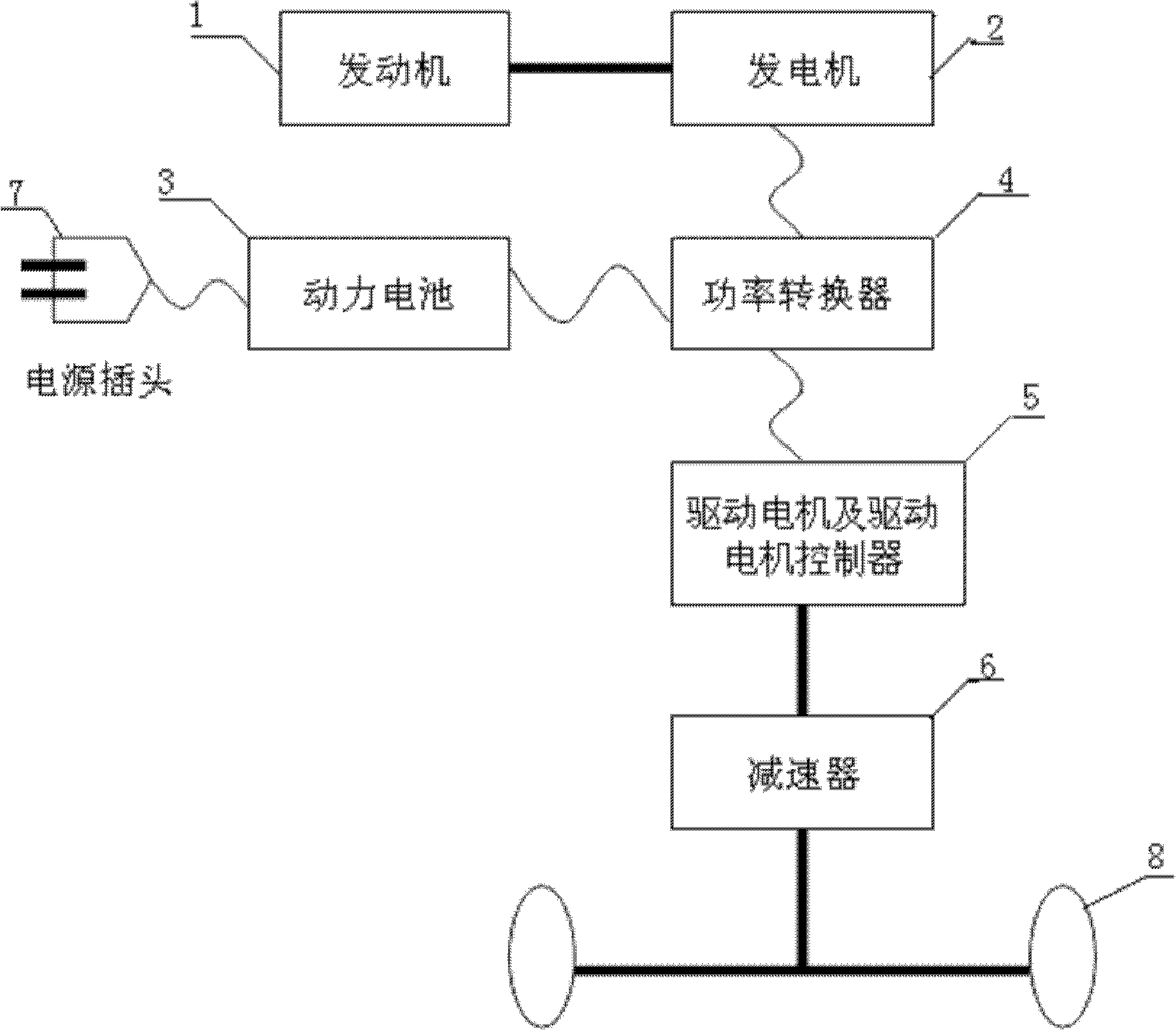

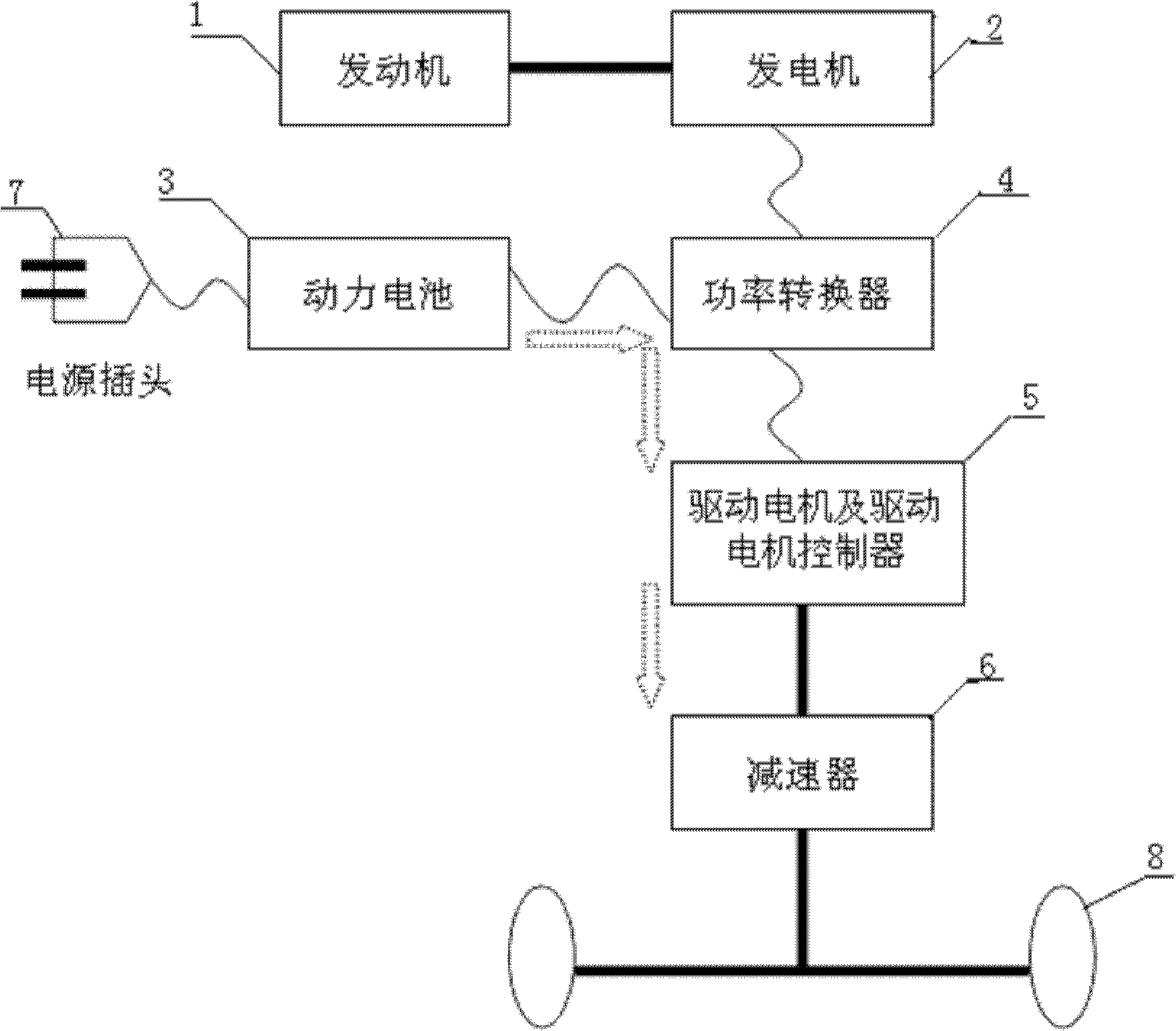

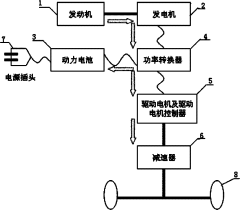

Plug-in Hybrid Electric Vehicles (PHEVs) face significant cost challenges that hinder their widespread adoption in the automotive market. The primary cost driver for PHEVs is the complex powertrain system, which combines both internal combustion engine (ICE) and electric propulsion components. This dual-system approach inherently increases manufacturing costs compared to conventional vehicles or pure electric vehicles.

Battery technology remains a major contributor to the high costs of PHEVs. Although battery prices have been declining, the need for a substantial battery pack to provide adequate electric-only range still represents a significant portion of the vehicle's overall cost. The lithium-ion batteries used in PHEVs require expensive materials and complex manufacturing processes, which drive up production expenses.

The electric drivetrain components, including the electric motor, power electronics, and thermal management systems, also add considerable costs to PHEVs. These components require specialized manufacturing processes and materials, contributing to the overall expense of the vehicle. Additionally, the integration of two separate powertrains necessitates sophisticated control systems and software, further increasing development and production costs.

Another cost challenge for PHEVs is the need for a robust charging infrastructure. While not directly part of the vehicle cost, the lack of widespread charging stations can be a deterrent for potential buyers, indirectly affecting the market demand and, consequently, the economies of scale that could help reduce production costs.

The complexity of PHEV powertrains also leads to higher maintenance costs over the vehicle's lifetime. The presence of both ICE and electric components requires specialized technicians and tools for servicing, which can increase the total cost of ownership for consumers.

Regulatory compliance and safety requirements add another layer of complexity and cost to PHEV production. Manufacturers must invest heavily in research and development to meet stringent emissions standards and safety regulations for both the electric and combustion systems, further driving up the overall cost of these vehicles.

Lastly, the current production volumes of PHEVs are relatively low compared to conventional vehicles, which prevents manufacturers from fully leveraging economies of scale. This results in higher per-unit costs, as fixed costs are spread across a smaller number of vehicles. Overcoming this challenge requires significant market growth and increased consumer adoption to justify larger production scales and associated cost reductions.

Battery technology remains a major contributor to the high costs of PHEVs. Although battery prices have been declining, the need for a substantial battery pack to provide adequate electric-only range still represents a significant portion of the vehicle's overall cost. The lithium-ion batteries used in PHEVs require expensive materials and complex manufacturing processes, which drive up production expenses.

The electric drivetrain components, including the electric motor, power electronics, and thermal management systems, also add considerable costs to PHEVs. These components require specialized manufacturing processes and materials, contributing to the overall expense of the vehicle. Additionally, the integration of two separate powertrains necessitates sophisticated control systems and software, further increasing development and production costs.

Another cost challenge for PHEVs is the need for a robust charging infrastructure. While not directly part of the vehicle cost, the lack of widespread charging stations can be a deterrent for potential buyers, indirectly affecting the market demand and, consequently, the economies of scale that could help reduce production costs.

The complexity of PHEV powertrains also leads to higher maintenance costs over the vehicle's lifetime. The presence of both ICE and electric components requires specialized technicians and tools for servicing, which can increase the total cost of ownership for consumers.

Regulatory compliance and safety requirements add another layer of complexity and cost to PHEV production. Manufacturers must invest heavily in research and development to meet stringent emissions standards and safety regulations for both the electric and combustion systems, further driving up the overall cost of these vehicles.

Lastly, the current production volumes of PHEVs are relatively low compared to conventional vehicles, which prevents manufacturers from fully leveraging economies of scale. This results in higher per-unit costs, as fixed costs are spread across a smaller number of vehicles. Overcoming this challenge requires significant market growth and increased consumer adoption to justify larger production scales and associated cost reductions.

Current Cost Reduction Methods

01 Battery cost reduction strategies

Various strategies are employed to reduce the cost of batteries in PHEVs, including improved manufacturing processes, use of alternative materials, and economies of scale. These efforts aim to decrease the overall cost of PHEVs and make them more competitive with conventional vehicles.- Battery cost reduction strategies: Various strategies are employed to reduce the cost of batteries in PHEVs, including improved manufacturing processes, use of alternative materials, and economies of scale. These efforts aim to decrease the overall cost of PHEVs and make them more competitive in the automotive market.

- Charging infrastructure optimization: Developing and optimizing charging infrastructure is crucial for reducing the operational costs of PHEVs. This includes the implementation of smart charging systems, fast-charging technologies, and the strategic placement of charging stations to improve accessibility and reduce charging times.

- Powertrain efficiency improvements: Enhancing the efficiency of PHEV powertrains through advanced control systems, regenerative braking, and optimized energy management strategies helps to reduce fuel consumption and overall operating costs. These improvements contribute to the long-term cost-effectiveness of PHEVs.

- Government incentives and policies: Various government incentives and policies, such as tax credits, subsidies, and regulations, play a significant role in reducing the upfront and operational costs of PHEVs. These measures aim to promote the adoption of PHEVs and support the transition to more sustainable transportation options.

- Vehicle-to-grid (V2G) technology integration: Incorporating V2G technology in PHEVs allows for bidirectional power flow between the vehicle and the electrical grid. This integration can potentially offset ownership costs by enabling PHEV owners to sell excess energy back to the grid during peak demand periods, creating a new revenue stream.

02 Charging infrastructure optimization

Optimizing charging infrastructure is crucial for reducing PHEV costs. This includes developing more efficient charging systems, implementing smart grid technologies, and improving the distribution of charging stations. These advancements can lead to lower operational costs for PHEV owners.Expand Specific Solutions03 Powertrain efficiency improvements

Enhancing the efficiency of PHEV powertrains through advanced control systems, improved energy management, and optimized engine-electric motor integration can significantly reduce fuel consumption and overall vehicle costs. These improvements also contribute to increased electric-only range.Expand Specific Solutions04 Government incentives and policies

Government incentives and supportive policies play a crucial role in reducing PHEV costs for consumers. These may include tax credits, subsidies, and other financial incentives that make PHEVs more affordable and encourage their adoption in the market.Expand Specific Solutions05 Manufacturing and supply chain optimization

Optimizing manufacturing processes and supply chains can significantly reduce PHEV production costs. This includes implementing lean manufacturing techniques, improving supplier relationships, and leveraging advanced technologies such as automation and 3D printing to streamline production and reduce expenses.Expand Specific Solutions

Key PHEV Manufacturers

The PHEV cost reduction strategies for mass adoption market is in a growth phase, with increasing demand for more affordable and efficient hybrid vehicles. The global PHEV market size is projected to reach significant growth in the coming years, driven by environmental regulations and consumer interest in eco-friendly transportation. Technologically, PHEVs are relatively mature but still evolving, with companies like Ford, BMW, and Volkswagen leading innovations. Ford Global Technologies LLC, Bayerische Motoren Werke AG, and International Truck Intellectual Property Co. LLC are actively developing cost-effective PHEV solutions, focusing on areas such as battery technology, powertrain efficiency, and manufacturing processes to reduce overall vehicle costs and improve performance for wider market adoption.

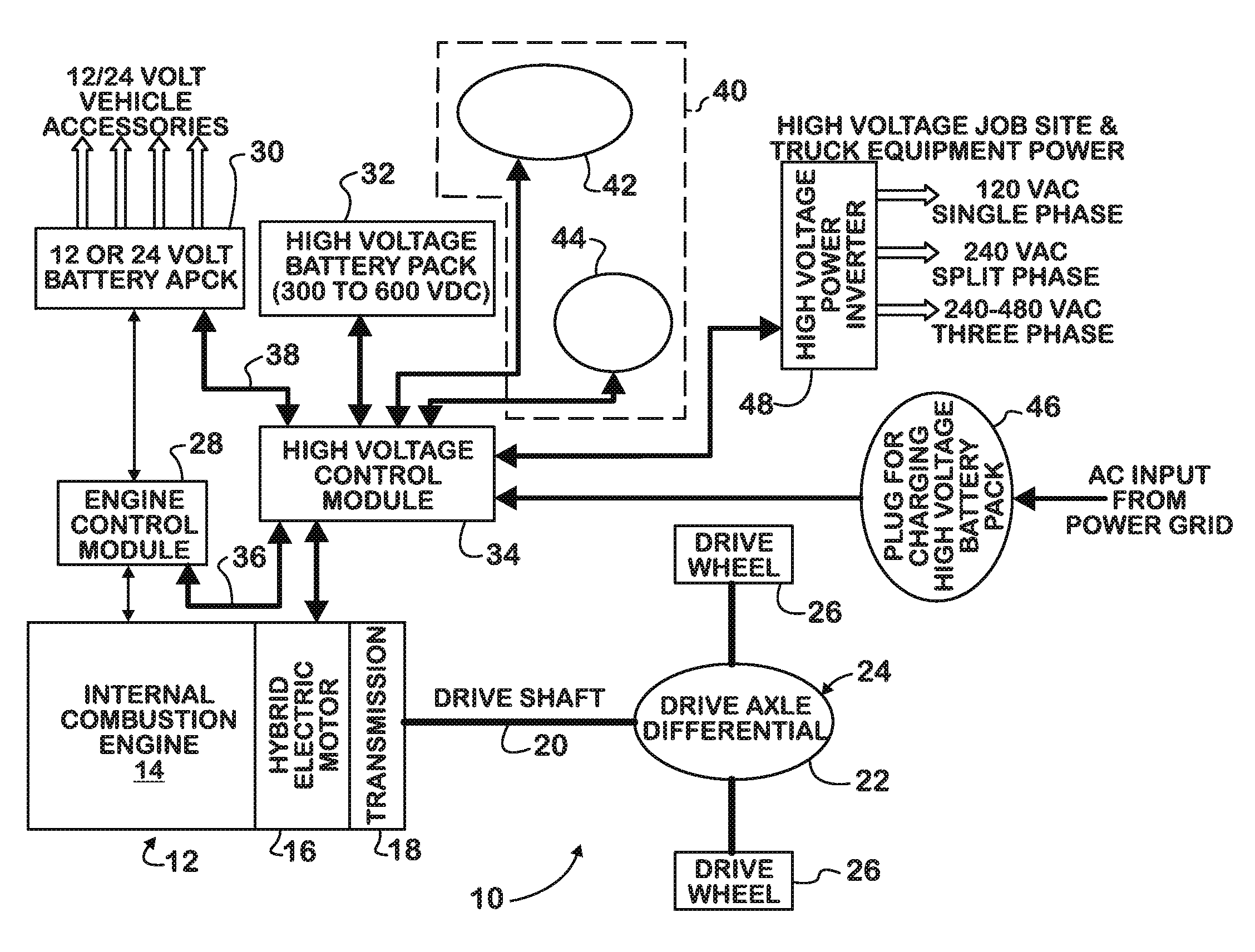

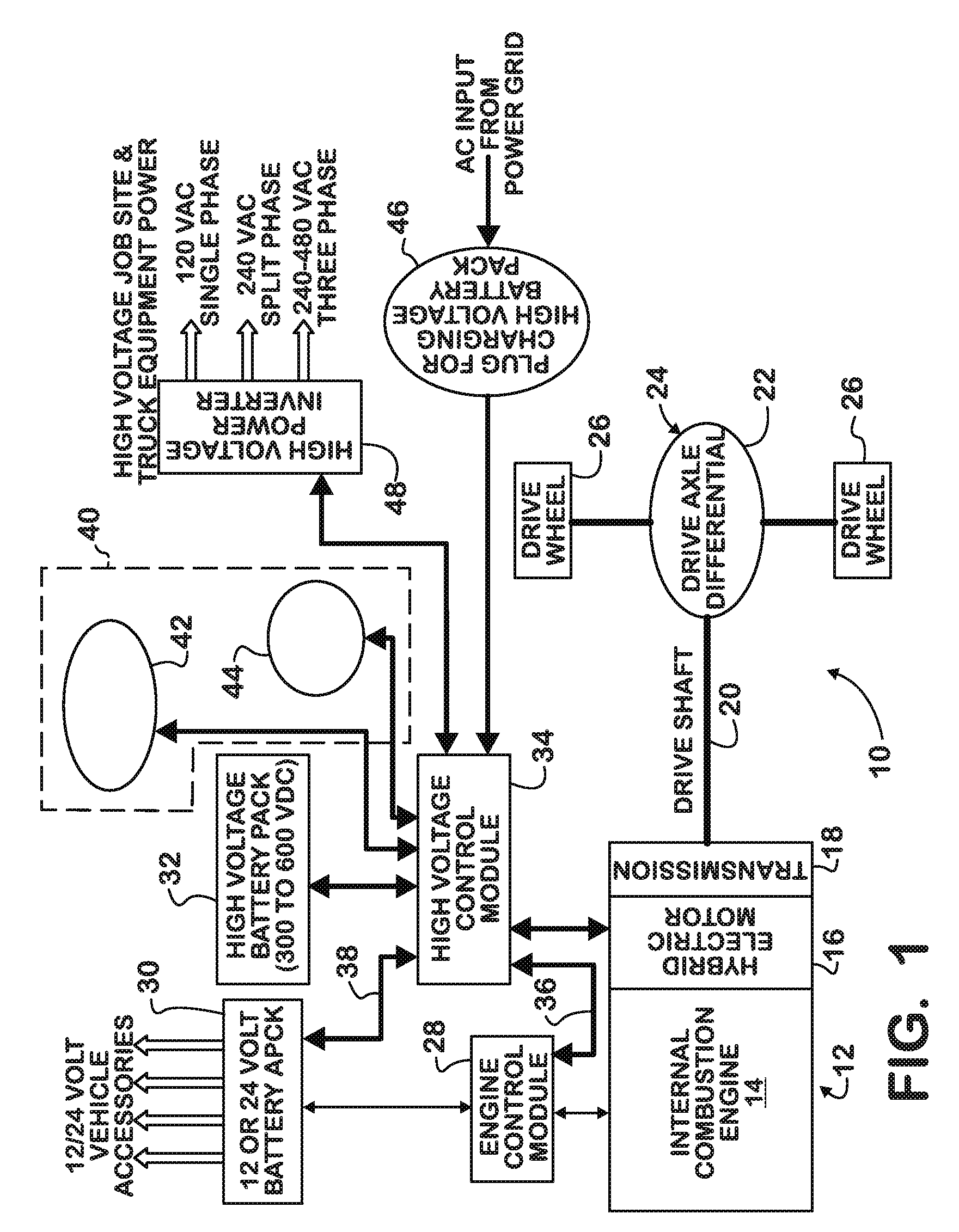

Ford Global Technologies LLC

Technical Solution: Ford's PHEV cost reduction strategy focuses on modular design and economies of scale. They have developed a flexible vehicle architecture that can accommodate both hybrid and fully electric powertrains, reducing development and production costs[1]. Ford is also investing in vertical integration of battery production, aiming to cut battery costs by 40% by 2026[2]. Their PowerSplit technology optimizes power distribution between electric and combustion engines, improving efficiency and reducing component costs[3]. Additionally, Ford is exploring the use of silicon carbide semiconductors in power electronics to increase efficiency and reduce overall system costs[4].

Strengths: Strong manufacturing capabilities, established supply chain, and economies of scale. Weaknesses: Dependence on external battery suppliers and potential challenges in rapidly adapting to new technologies.

The Regents of the University of Michigan

Technical Solution: The University of Michigan's research on PHEV cost reduction focuses on advanced control strategies and system optimization. They have developed adaptive control algorithms that optimize power distribution between electric and combustion engines, potentially reducing battery size and cost without compromising performance[13]. Their research also includes novel thermal management systems that can reduce the need for expensive cooling components in PHEVs[14]. Additionally, the university is exploring the use of artificial intelligence for predictive energy management, which could lead to smaller, more cost-effective battery packs[15]. They are also investigating the potential of vehicle-to-grid (V2G) technology to create additional value for PHEV owners, potentially offsetting initial costs[16].

Strengths: Cutting-edge research capabilities, collaboration with industry partners. Weaknesses: Longer timeline for practical implementation, reliance on industry adoption of research findings.

Core PHEV Cost-Saving Patents

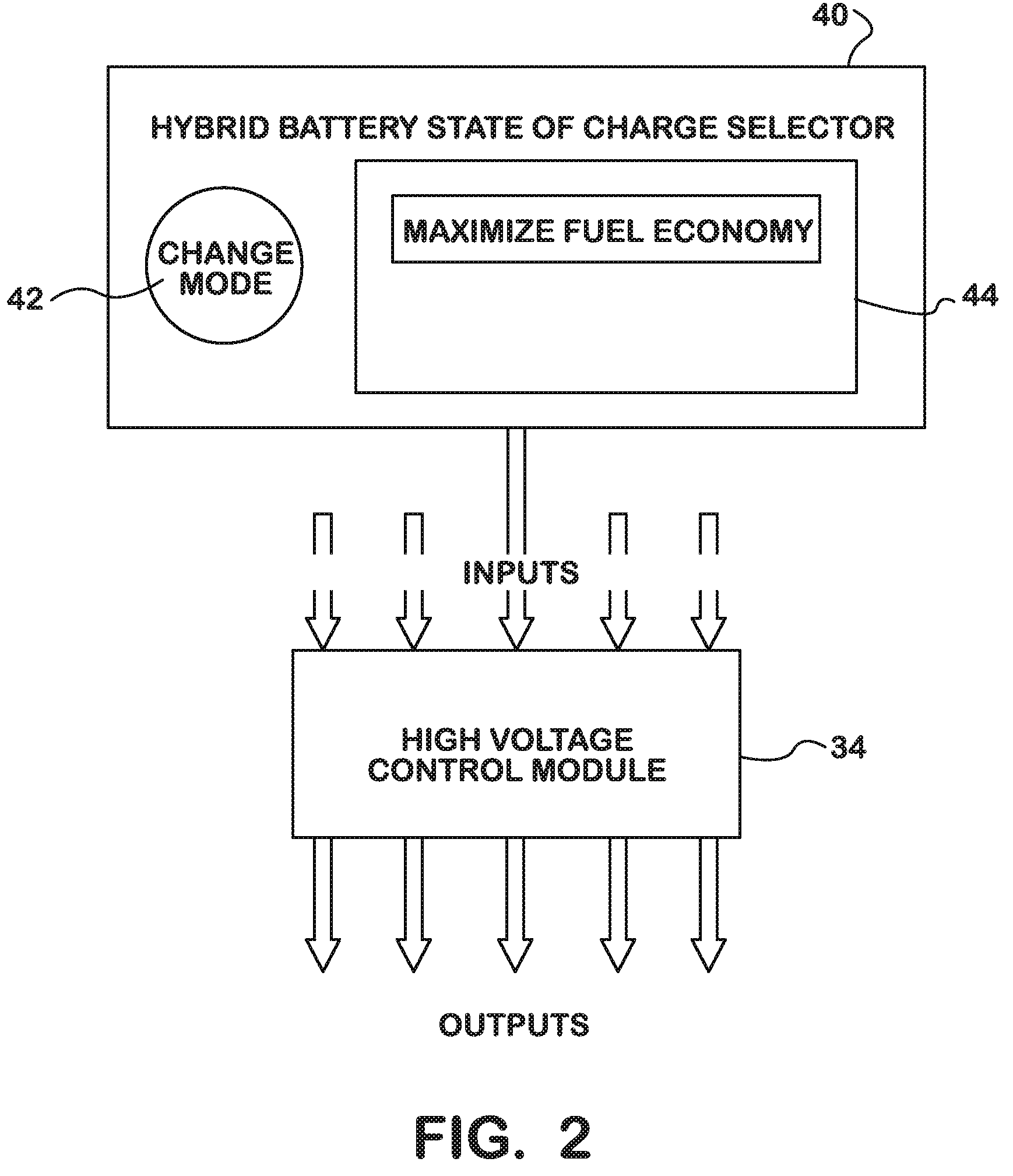

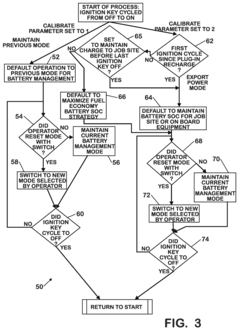

Battery pack management strategy in a hybrid electric motor vehicle

PatentInactiveUS7904217B2

Innovation

- A software algorithm in the high-voltage control module allows operators to choose between 'Maximize Fuel Economy' and 'Maintain Charge To Job Site' strategies, with options to override defaults, enabling flexible battery pack SOC management depending on calibratable parameters and specific battery chemistry and capacity.

Cost based method for optimizing external PHEV (Plug-in Hybrid Electric Vehicle) power assembly and application thereof

PatentInactiveCN102180169A

Innovation

- By establishing a cost-based optimization method, determine the variables to be optimized and construct a cost objective function equation, and use quadratic programming or matrix partitioning optimization algorithms to optimize the maximum output power of the engine, the maximum output power of the drive motor, the output power of the power battery and the capacity of the power battery pack. , to achieve the lowest cost powertrain design.

Government Incentives Impact

Government incentives play a crucial role in accelerating the mass adoption of Plug-in Hybrid Electric Vehicles (PHEVs). These incentives are designed to reduce the upfront costs for consumers and stimulate market demand, ultimately driving down production costs through economies of scale.

Financial incentives, such as tax credits and rebates, are among the most effective tools governments employ to promote PHEV adoption. In many countries, consumers can benefit from substantial tax credits when purchasing a PHEV, significantly lowering the initial cost barrier. For instance, the United States offers federal tax credits of up to $7,500 for eligible PHEVs, making them more competitive with conventional vehicles.

Non-financial incentives also contribute to PHEV cost reduction strategies. These may include preferential parking, access to high-occupancy vehicle lanes, and reduced toll fees. By enhancing the overall value proposition of PHEVs, these incentives indirectly support cost reduction efforts by increasing demand and production volumes.

Government-funded research and development initiatives are another critical aspect of PHEV cost reduction. By investing in advanced battery technologies, power electronics, and lightweight materials, governments can help accelerate technological breakthroughs that lead to more affordable PHEVs. Collaborative research programs between government agencies, academic institutions, and industry partners often yield innovative solutions that can be rapidly commercialized.

Regulatory measures, such as fuel economy standards and emissions regulations, indirectly support PHEV cost reduction by creating a favorable market environment. As automakers strive to meet increasingly stringent standards, they are incentivized to invest in PHEV technology, leading to improved manufacturing processes and reduced costs over time.

Infrastructure development is another area where government support is crucial. By investing in charging infrastructure, governments can alleviate range anxiety and make PHEVs more attractive to consumers. This increased demand can lead to higher production volumes and lower costs through economies of scale.

However, the effectiveness of government incentives in reducing PHEV costs is not without challenges. The sustainability of these programs, their impact on government budgets, and the potential for market distortions must be carefully considered. Additionally, as PHEV technology matures and becomes more cost-competitive, there is a need for governments to gradually phase out incentives to ensure a self-sustaining market.

Financial incentives, such as tax credits and rebates, are among the most effective tools governments employ to promote PHEV adoption. In many countries, consumers can benefit from substantial tax credits when purchasing a PHEV, significantly lowering the initial cost barrier. For instance, the United States offers federal tax credits of up to $7,500 for eligible PHEVs, making them more competitive with conventional vehicles.

Non-financial incentives also contribute to PHEV cost reduction strategies. These may include preferential parking, access to high-occupancy vehicle lanes, and reduced toll fees. By enhancing the overall value proposition of PHEVs, these incentives indirectly support cost reduction efforts by increasing demand and production volumes.

Government-funded research and development initiatives are another critical aspect of PHEV cost reduction. By investing in advanced battery technologies, power electronics, and lightweight materials, governments can help accelerate technological breakthroughs that lead to more affordable PHEVs. Collaborative research programs between government agencies, academic institutions, and industry partners often yield innovative solutions that can be rapidly commercialized.

Regulatory measures, such as fuel economy standards and emissions regulations, indirectly support PHEV cost reduction by creating a favorable market environment. As automakers strive to meet increasingly stringent standards, they are incentivized to invest in PHEV technology, leading to improved manufacturing processes and reduced costs over time.

Infrastructure development is another area where government support is crucial. By investing in charging infrastructure, governments can alleviate range anxiety and make PHEVs more attractive to consumers. This increased demand can lead to higher production volumes and lower costs through economies of scale.

However, the effectiveness of government incentives in reducing PHEV costs is not without challenges. The sustainability of these programs, their impact on government budgets, and the potential for market distortions must be carefully considered. Additionally, as PHEV technology matures and becomes more cost-competitive, there is a need for governments to gradually phase out incentives to ensure a self-sustaining market.

Supply Chain Optimization

Supply chain optimization plays a crucial role in reducing costs for Plug-in Hybrid Electric Vehicles (PHEVs) and promoting mass adoption. By streamlining the supply chain, manufacturers can significantly decrease production expenses and improve overall efficiency.

One key strategy is to establish long-term partnerships with suppliers. This approach allows for better negotiation of component prices and ensures a stable supply of critical parts. By fostering these relationships, PHEV manufacturers can benefit from economies of scale and reduced procurement costs.

Vertical integration is another effective method for optimizing the supply chain. By bringing certain component production in-house, companies can have greater control over quality, costs, and production timelines. This strategy has been successfully implemented by several major automakers, resulting in substantial cost savings.

Implementing just-in-time (JIT) inventory management can further reduce costs associated with storage and inventory holding. This lean manufacturing approach minimizes waste and improves cash flow by aligning production schedules with demand forecasts.

Localizing production and sourcing components from nearby suppliers can significantly reduce transportation costs and lead times. This strategy also helps mitigate risks associated with global supply chain disruptions and currency fluctuations.

Investing in advanced supply chain technologies, such as artificial intelligence and blockchain, can enhance visibility and traceability throughout the supply network. These tools enable better demand forecasting, inventory management, and risk mitigation, leading to overall cost reductions.

Standardization of components across different PHEV models can lead to economies of scale and simplified procurement processes. By using common parts across multiple vehicle platforms, manufacturers can negotiate better prices with suppliers and streamline their production lines.

Collaborative planning with suppliers and distributors can help optimize production schedules and reduce inefficiencies. By sharing demand forecasts and production plans, all parties in the supply chain can better align their operations, resulting in cost savings and improved responsiveness to market changes.

Lastly, implementing reverse logistics and circular economy principles can help recover value from end-of-life vehicles and components. Recycling and remanufacturing programs can reduce raw material costs and create additional revenue streams, contributing to overall cost reduction efforts in PHEV production.

One key strategy is to establish long-term partnerships with suppliers. This approach allows for better negotiation of component prices and ensures a stable supply of critical parts. By fostering these relationships, PHEV manufacturers can benefit from economies of scale and reduced procurement costs.

Vertical integration is another effective method for optimizing the supply chain. By bringing certain component production in-house, companies can have greater control over quality, costs, and production timelines. This strategy has been successfully implemented by several major automakers, resulting in substantial cost savings.

Implementing just-in-time (JIT) inventory management can further reduce costs associated with storage and inventory holding. This lean manufacturing approach minimizes waste and improves cash flow by aligning production schedules with demand forecasts.

Localizing production and sourcing components from nearby suppliers can significantly reduce transportation costs and lead times. This strategy also helps mitigate risks associated with global supply chain disruptions and currency fluctuations.

Investing in advanced supply chain technologies, such as artificial intelligence and blockchain, can enhance visibility and traceability throughout the supply network. These tools enable better demand forecasting, inventory management, and risk mitigation, leading to overall cost reductions.

Standardization of components across different PHEV models can lead to economies of scale and simplified procurement processes. By using common parts across multiple vehicle platforms, manufacturers can negotiate better prices with suppliers and streamline their production lines.

Collaborative planning with suppliers and distributors can help optimize production schedules and reduce inefficiencies. By sharing demand forecasts and production plans, all parties in the supply chain can better align their operations, resulting in cost savings and improved responsiveness to market changes.

Lastly, implementing reverse logistics and circular economy principles can help recover value from end-of-life vehicles and components. Recycling and remanufacturing programs can reduce raw material costs and create additional revenue streams, contributing to overall cost reduction efforts in PHEV production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!