PHEV role in reducing transportation cost in logistics

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV Technology Evolution

The evolution of Plug-in Hybrid Electric Vehicle (PHEV) technology in the logistics sector has been marked by significant advancements aimed at reducing transportation costs and improving operational efficiency. This progression can be traced through several key stages, each characterized by notable technological improvements and market adoption milestones.

In the early 2000s, the first generation of PHEVs emerged, primarily focusing on passenger vehicles. These early models had limited electric-only range and were not specifically designed for logistics applications. However, they laid the groundwork for future developments by demonstrating the potential of combining electric and internal combustion engine technologies.

The second phase, occurring in the late 2000s and early 2010s, saw the introduction of PHEVs tailored for light commercial vehicles. These vehicles offered improved electric range and better fuel economy, making them more suitable for urban delivery operations. This period marked the beginning of PHEV adoption in the logistics sector, albeit on a limited scale.

The third stage, spanning the mid-2010s, witnessed a significant leap in PHEV technology for logistics. Manufacturers began developing purpose-built PHEV vans and trucks with enhanced battery capacity and more efficient powertrains. These vehicles offered extended electric-only range, making them viable for a wider range of logistics operations, including last-mile delivery and regional distribution.

From the late 2010s to the present, PHEV technology in logistics has entered a phase of rapid advancement and widespread adoption. Key developments include the integration of smart charging systems, vehicle-to-grid (V2G) capabilities, and advanced fleet management software. These innovations have not only improved the operational efficiency of PHEVs but also enabled logistics companies to optimize their energy usage and reduce overall transportation costs.

The most recent developments in PHEV technology for logistics focus on enhancing sustainability and cost-effectiveness. This includes the use of lightweight materials to improve payload capacity, the implementation of regenerative braking systems to maximize energy recovery, and the integration of artificial intelligence for route optimization and predictive maintenance.

Looking ahead, the evolution of PHEV technology in logistics is expected to continue, with a focus on increasing electric range, improving battery technology, and enhancing overall vehicle efficiency. Future developments may include the integration of autonomous driving capabilities, further reducing operational costs and improving safety in logistics operations.

In the early 2000s, the first generation of PHEVs emerged, primarily focusing on passenger vehicles. These early models had limited electric-only range and were not specifically designed for logistics applications. However, they laid the groundwork for future developments by demonstrating the potential of combining electric and internal combustion engine technologies.

The second phase, occurring in the late 2000s and early 2010s, saw the introduction of PHEVs tailored for light commercial vehicles. These vehicles offered improved electric range and better fuel economy, making them more suitable for urban delivery operations. This period marked the beginning of PHEV adoption in the logistics sector, albeit on a limited scale.

The third stage, spanning the mid-2010s, witnessed a significant leap in PHEV technology for logistics. Manufacturers began developing purpose-built PHEV vans and trucks with enhanced battery capacity and more efficient powertrains. These vehicles offered extended electric-only range, making them viable for a wider range of logistics operations, including last-mile delivery and regional distribution.

From the late 2010s to the present, PHEV technology in logistics has entered a phase of rapid advancement and widespread adoption. Key developments include the integration of smart charging systems, vehicle-to-grid (V2G) capabilities, and advanced fleet management software. These innovations have not only improved the operational efficiency of PHEVs but also enabled logistics companies to optimize their energy usage and reduce overall transportation costs.

The most recent developments in PHEV technology for logistics focus on enhancing sustainability and cost-effectiveness. This includes the use of lightweight materials to improve payload capacity, the implementation of regenerative braking systems to maximize energy recovery, and the integration of artificial intelligence for route optimization and predictive maintenance.

Looking ahead, the evolution of PHEV technology in logistics is expected to continue, with a focus on increasing electric range, improving battery technology, and enhancing overall vehicle efficiency. Future developments may include the integration of autonomous driving capabilities, further reducing operational costs and improving safety in logistics operations.

Logistics Market Demand

The logistics market has been experiencing significant growth and transformation in recent years, driven by the increasing demand for efficient and cost-effective transportation solutions. As e-commerce continues to expand and global supply chains become more complex, the need for innovative logistics solutions has become paramount. In this context, Plug-in Hybrid Electric Vehicles (PHEVs) have emerged as a promising technology to address the challenges of reducing transportation costs in the logistics sector.

The global logistics market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other industries. This growth is fueled by the rising demand for fast and reliable delivery services, particularly in the last-mile segment. As urban populations continue to grow and consumer expectations for rapid delivery intensify, logistics companies are under pressure to optimize their operations and reduce costs while maintaining service quality.

One of the key drivers of market demand in the logistics sector is the need for sustainable transportation solutions. With increasing environmental regulations and corporate sustainability goals, there is a growing emphasis on reducing carbon emissions and improving fuel efficiency in logistics operations. This trend has created a significant opportunity for PHEVs to play a crucial role in meeting these sustainability objectives while simultaneously addressing the cost challenges faced by logistics providers.

The demand for PHEVs in logistics is further bolstered by the potential for operational cost savings. As fuel prices remain volatile and constitute a significant portion of transportation expenses, logistics companies are actively seeking ways to reduce their fuel consumption and overall operating costs. PHEVs offer a compelling solution by combining the benefits of electric propulsion with the flexibility of conventional internal combustion engines, allowing for optimized fuel efficiency and reduced maintenance costs.

Moreover, the logistics market is witnessing a shift towards more flexible and adaptable transportation solutions. PHEVs align well with this trend, as they can operate in various modes depending on the specific requirements of different routes and delivery scenarios. This versatility makes PHEVs particularly attractive for logistics companies that need to navigate both urban and long-distance routes, providing a balance between electric-only operation in city centers and extended range capabilities for longer journeys.

The market demand for PHEVs in logistics is also influenced by government incentives and regulations aimed at promoting cleaner transportation. Many countries and regions have implemented policies to encourage the adoption of low-emission vehicles, including tax incentives, subsidies, and preferential access to urban areas. These measures have created a favorable environment for logistics companies to invest in PHEV technology, further driving market demand.

The global logistics market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other industries. This growth is fueled by the rising demand for fast and reliable delivery services, particularly in the last-mile segment. As urban populations continue to grow and consumer expectations for rapid delivery intensify, logistics companies are under pressure to optimize their operations and reduce costs while maintaining service quality.

One of the key drivers of market demand in the logistics sector is the need for sustainable transportation solutions. With increasing environmental regulations and corporate sustainability goals, there is a growing emphasis on reducing carbon emissions and improving fuel efficiency in logistics operations. This trend has created a significant opportunity for PHEVs to play a crucial role in meeting these sustainability objectives while simultaneously addressing the cost challenges faced by logistics providers.

The demand for PHEVs in logistics is further bolstered by the potential for operational cost savings. As fuel prices remain volatile and constitute a significant portion of transportation expenses, logistics companies are actively seeking ways to reduce their fuel consumption and overall operating costs. PHEVs offer a compelling solution by combining the benefits of electric propulsion with the flexibility of conventional internal combustion engines, allowing for optimized fuel efficiency and reduced maintenance costs.

Moreover, the logistics market is witnessing a shift towards more flexible and adaptable transportation solutions. PHEVs align well with this trend, as they can operate in various modes depending on the specific requirements of different routes and delivery scenarios. This versatility makes PHEVs particularly attractive for logistics companies that need to navigate both urban and long-distance routes, providing a balance between electric-only operation in city centers and extended range capabilities for longer journeys.

The market demand for PHEVs in logistics is also influenced by government incentives and regulations aimed at promoting cleaner transportation. Many countries and regions have implemented policies to encourage the adoption of low-emission vehicles, including tax incentives, subsidies, and preferential access to urban areas. These measures have created a favorable environment for logistics companies to invest in PHEV technology, further driving market demand.

PHEV Challenges in Logistics

The integration of Plug-in Hybrid Electric Vehicles (PHEVs) in logistics operations presents several significant challenges that need to be addressed for successful implementation. One of the primary obstacles is the high initial investment cost associated with PHEVs. While these vehicles offer long-term cost savings through reduced fuel consumption, the upfront expenses can be a deterrent for many logistics companies, especially small and medium-sized enterprises with limited capital.

Another challenge lies in the limited range of PHEVs when operating in full electric mode. This limitation can be particularly problematic for long-haul logistics operations, where vehicles need to cover extensive distances without frequent stops. The need for regular charging or switching to gasoline mode may lead to increased downtime and reduced operational efficiency, potentially offsetting some of the cost-saving benefits.

Infrastructure development poses a significant hurdle in the widespread adoption of PHEVs in logistics. The lack of adequate charging stations along transportation routes can create range anxiety and operational uncertainties. Establishing a comprehensive charging network requires substantial investment and coordination between various stakeholders, including government agencies, utility companies, and private sector entities.

The complexity of PHEV technology also presents challenges in terms of maintenance and repair. Logistics companies may need to invest in specialized training for their technicians or rely more heavily on external service providers, potentially increasing operational costs. The dual powertrain system in PHEVs also introduces additional points of failure, which could lead to higher maintenance frequencies and costs compared to traditional internal combustion engine vehicles.

Fleet management and optimization become more complex with the introduction of PHEVs. Logistics operators need to develop new strategies to balance the use of electric and gasoline modes, considering factors such as route planning, charging schedules, and load optimization. This requires sophisticated fleet management systems and may necessitate changes in existing operational procedures.

The variability in fuel prices and electricity rates adds another layer of complexity to cost management for PHEV fleets. While PHEVs offer the flexibility to switch between power sources, fluctuations in energy prices can make it challenging to accurately predict and optimize operational costs over time. This uncertainty may complicate long-term financial planning and return on investment calculations for logistics companies.

Lastly, the regulatory landscape surrounding PHEVs in logistics is still evolving. Changes in government policies, incentives, and environmental regulations can significantly impact the cost-effectiveness and operational viability of PHEV fleets. Logistics companies must stay informed about these developments and be prepared to adapt their strategies accordingly, which can be resource-intensive and create additional operational challenges.

Another challenge lies in the limited range of PHEVs when operating in full electric mode. This limitation can be particularly problematic for long-haul logistics operations, where vehicles need to cover extensive distances without frequent stops. The need for regular charging or switching to gasoline mode may lead to increased downtime and reduced operational efficiency, potentially offsetting some of the cost-saving benefits.

Infrastructure development poses a significant hurdle in the widespread adoption of PHEVs in logistics. The lack of adequate charging stations along transportation routes can create range anxiety and operational uncertainties. Establishing a comprehensive charging network requires substantial investment and coordination between various stakeholders, including government agencies, utility companies, and private sector entities.

The complexity of PHEV technology also presents challenges in terms of maintenance and repair. Logistics companies may need to invest in specialized training for their technicians or rely more heavily on external service providers, potentially increasing operational costs. The dual powertrain system in PHEVs also introduces additional points of failure, which could lead to higher maintenance frequencies and costs compared to traditional internal combustion engine vehicles.

Fleet management and optimization become more complex with the introduction of PHEVs. Logistics operators need to develop new strategies to balance the use of electric and gasoline modes, considering factors such as route planning, charging schedules, and load optimization. This requires sophisticated fleet management systems and may necessitate changes in existing operational procedures.

The variability in fuel prices and electricity rates adds another layer of complexity to cost management for PHEV fleets. While PHEVs offer the flexibility to switch between power sources, fluctuations in energy prices can make it challenging to accurately predict and optimize operational costs over time. This uncertainty may complicate long-term financial planning and return on investment calculations for logistics companies.

Lastly, the regulatory landscape surrounding PHEVs in logistics is still evolving. Changes in government policies, incentives, and environmental regulations can significantly impact the cost-effectiveness and operational viability of PHEV fleets. Logistics companies must stay informed about these developments and be prepared to adapt their strategies accordingly, which can be resource-intensive and create additional operational challenges.

Current PHEV Solutions

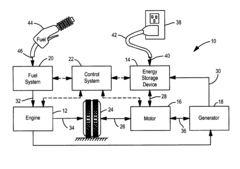

01 Energy management systems for PHEVs

Advanced energy management systems are developed to optimize the use of electric and combustion power in PHEVs. These systems aim to reduce overall transportation costs by efficiently balancing the use of battery power and fuel, considering factors such as driving conditions, route information, and energy prices.- Energy management systems for PHEVs: Advanced energy management systems are developed to optimize the use of electric and combustion power in PHEVs. These systems aim to reduce overall transportation costs by efficiently balancing the use of battery power and gasoline, considering factors such as driving conditions, route information, and energy prices.

- Charging infrastructure and cost optimization: The development of charging infrastructure plays a crucial role in reducing PHEV transportation costs. This includes the implementation of smart charging systems, strategic placement of charging stations, and the integration of renewable energy sources to minimize electricity costs for PHEV owners.

- Lightweight materials and aerodynamic design: The use of lightweight materials in PHEV construction and improvements in aerodynamic design contribute to reduced energy consumption and lower transportation costs. These advancements help to extend the electric range of PHEVs and improve overall fuel efficiency.

- Battery technology advancements: Ongoing improvements in battery technology, including increased energy density, faster charging capabilities, and longer lifespan, contribute to reducing the overall transportation costs of PHEVs. These advancements help to extend the electric range and reduce the frequency of charging, making PHEVs more cost-effective for users.

- Intelligent transportation systems for PHEVs: The integration of PHEVs with intelligent transportation systems helps to optimize routes, predict traffic conditions, and manage energy consumption more efficiently. These systems contribute to reducing transportation costs by minimizing travel time, avoiding congestion, and maximizing the use of electric power.

02 Charging infrastructure and cost optimization

Innovations in charging infrastructure and related technologies focus on reducing the cost of PHEV transportation. This includes the development of smart charging systems, improved charging station networks, and methods to optimize charging schedules based on electricity prices and vehicle usage patterns.Expand Specific Solutions03 Lightweight materials and aerodynamic design

The use of lightweight materials and aerodynamic design principles in PHEV manufacturing aims to improve fuel efficiency and reduce overall transportation costs. These innovations include the development of advanced composite materials, optimized vehicle shapes, and weight reduction strategies.Expand Specific Solutions04 Battery technology advancements

Ongoing improvements in battery technology for PHEVs focus on increasing energy density, reducing production costs, and extending battery life. These advancements contribute to lower transportation costs by improving the electric range of vehicles and reducing the frequency of battery replacements.Expand Specific Solutions05 Intelligent transportation systems for PHEVs

The development of intelligent transportation systems specifically tailored for PHEVs aims to optimize route planning, traffic management, and vehicle-to-grid integration. These systems can help reduce transportation costs by improving overall efficiency and enabling better utilization of electric power.Expand Specific Solutions

Key PHEV Manufacturers

The PHEV market in logistics transportation is in a growth phase, with increasing adoption driven by the need for cost reduction and environmental sustainability. The market size is expanding as more logistics companies seek to optimize their fleets. Technologically, PHEVs are maturing rapidly, with major players like Ford Motor Co., Nissan Motor Co., Ltd., and Jaguar Land Rover Ltd. investing heavily in R&D. These companies are developing advanced PHEV powertrains and energy management systems to enhance efficiency and reduce operational costs. The competitive landscape is intensifying, with traditional automakers and new entrants like Turntide Technologies, Inc. vying for market share through innovative solutions that promise significant reductions in transportation costs for logistics operations.

Ford Motor Co.

Technical Solution: Ford has developed a comprehensive PHEV strategy for logistics, focusing on their E-Transit van. The E-Transit PHEV combines a 2.5L Atkinson-cycle gas engine with an electric motor and battery pack, offering an estimated electric range of 126 miles[1]. For logistics applications, Ford has implemented an intelligent range management system that optimizes the use of electric and hybrid modes based on route characteristics and payload[2]. The vehicle's telematics system provides real-time data on energy consumption and route efficiency, allowing fleet managers to optimize operations and reduce costs[3]. Ford has also partnered with major logistics companies to pilot these vehicles in urban delivery scenarios, demonstrating up to 25% reduction in fuel costs compared to conventional diesel vans[4].

Strengths: Extensive experience in commercial vehicle manufacturing, established partnerships with logistics companies, and advanced telematics integration. Weaknesses: Limited battery range compared to full EVs, and potential higher upfront costs for fleet operators.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has developed a PHEV system specifically tailored for light commercial vehicles used in logistics. Their e-POWER technology, initially designed for passenger cars, has been adapted for vans and small trucks. This system uses a small gasoline engine solely to generate electricity, while the wheels are always driven by an electric motor[5]. For logistics applications, Nissan has enhanced the system with a larger battery capacity and more powerful electric motor, allowing for extended electric-only operation in urban areas. The company has also implemented an AI-driven energy management system that learns from driving patterns and route characteristics to optimize the balance between electric and hybrid modes, potentially reducing fuel consumption by up to 30% compared to conventional hybrid systems[6]. Nissan has conducted trials with several logistics companies in Japan and Europe, demonstrating significant reductions in both fuel costs and emissions[7].

Strengths: Innovative e-POWER technology, strong presence in light commercial vehicle market, and advanced AI-driven energy management. Weaknesses: Limited experience in heavy-duty commercial vehicles and potential challenges in scaling up production for global logistics market.

PHEV Efficiency Innovations

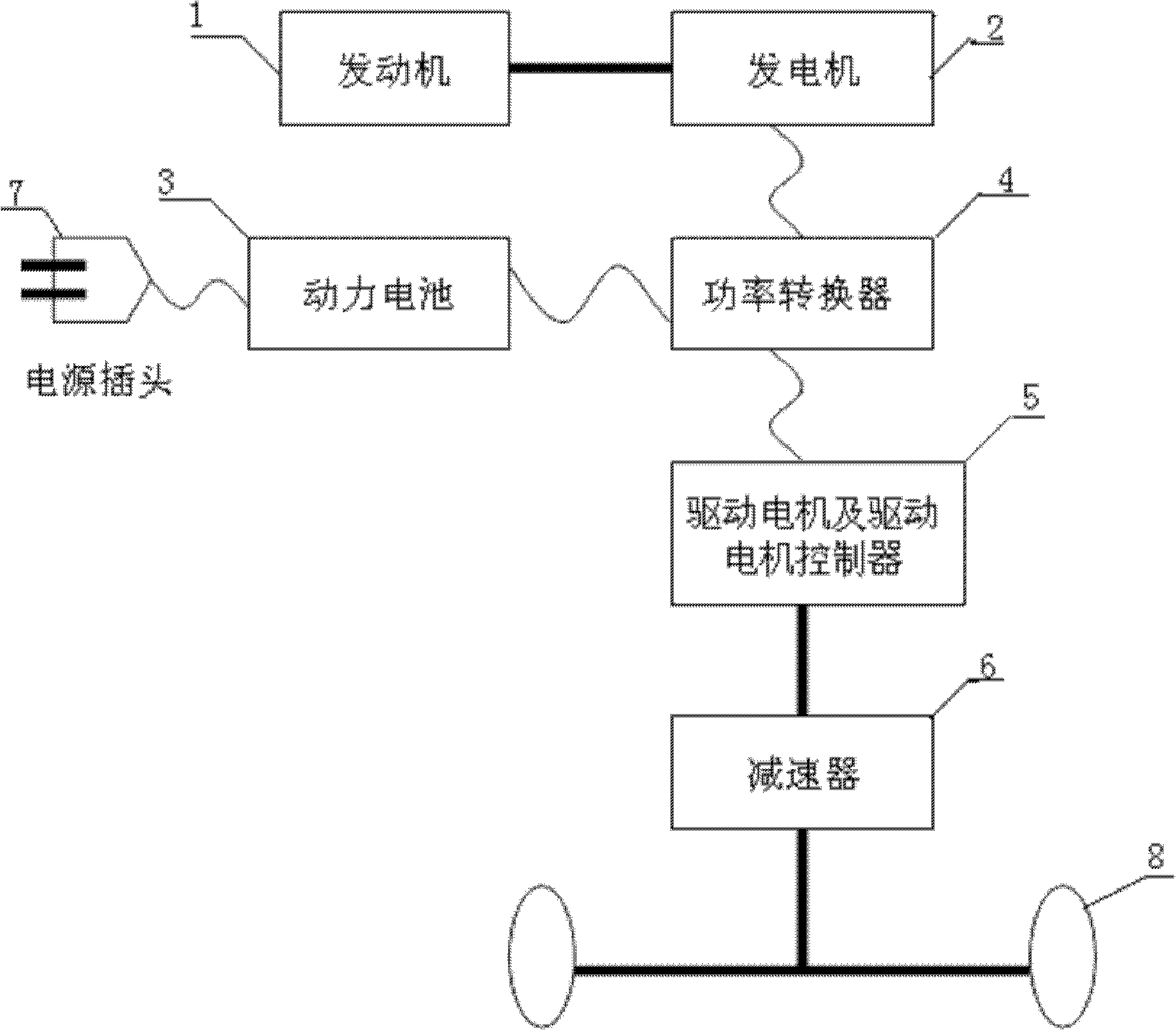

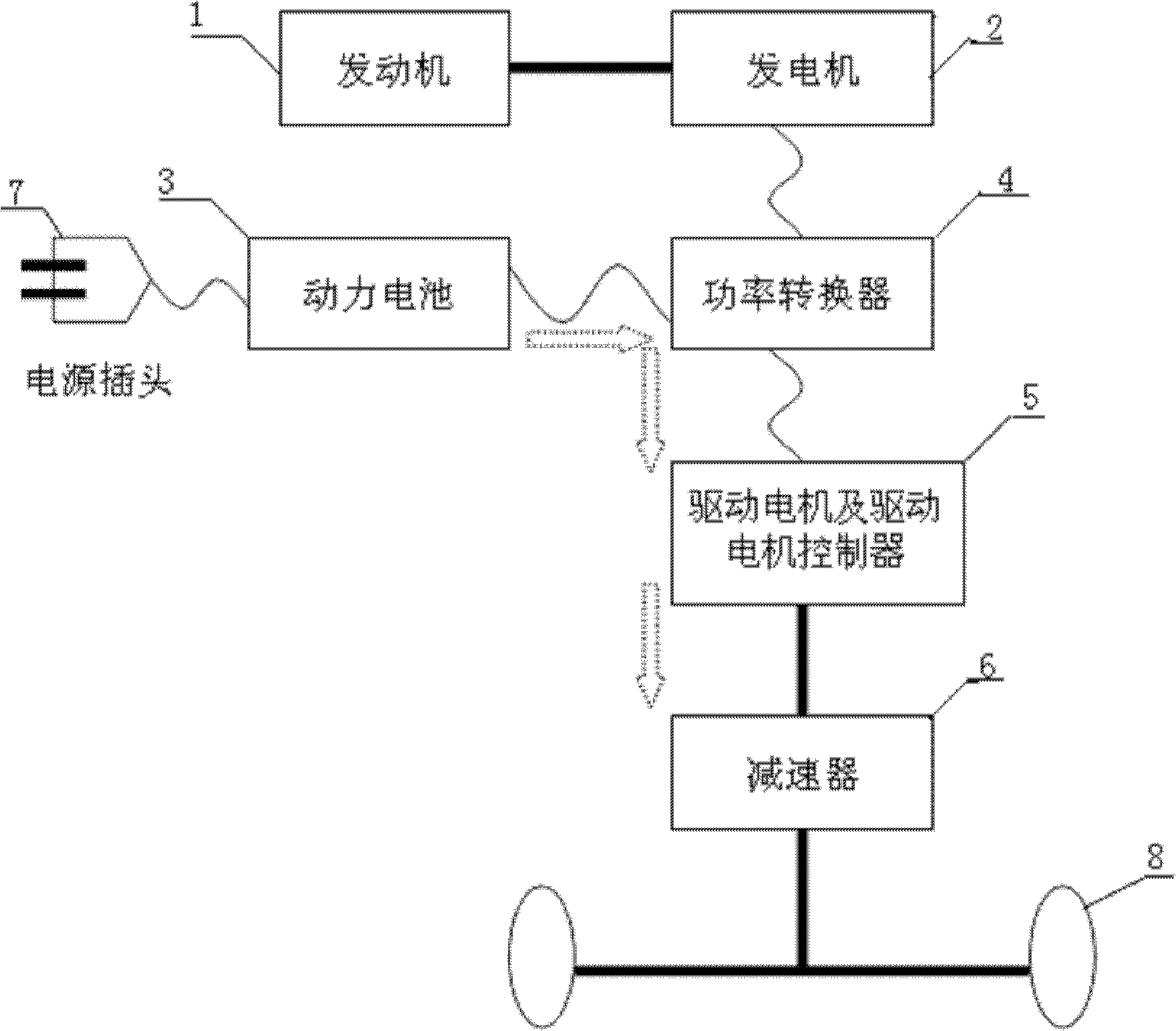

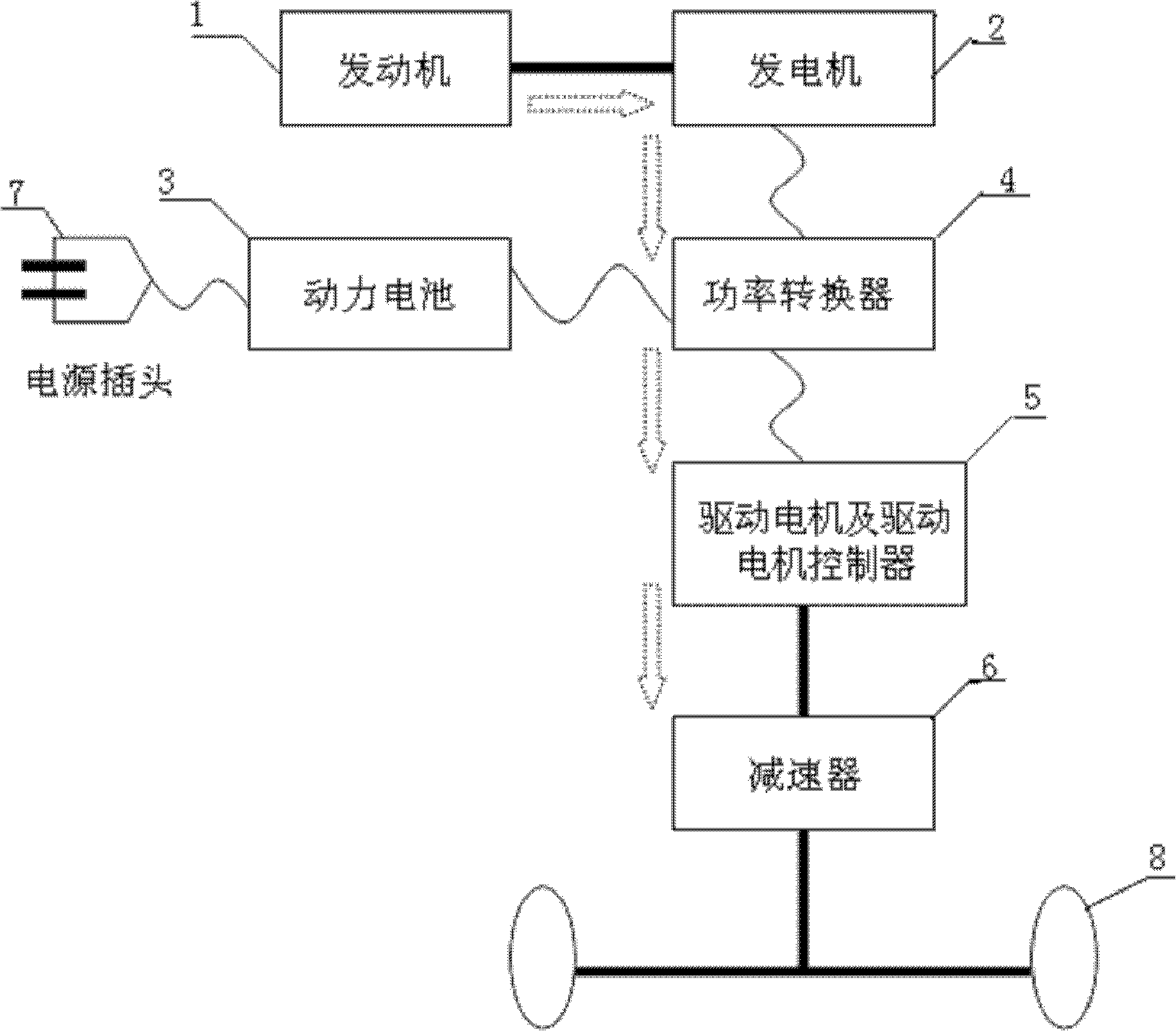

Cost based method for optimizing external PHEV (Plug-in Hybrid Electric Vehicle) power assembly and application thereof

PatentInactiveCN102180169A

Innovation

- By establishing a cost-based optimization method, determine the variables to be optimized and construct a cost objective function equation, and use quadratic programming or matrix partitioning optimization algorithms to optimize the maximum output power of the engine, the maximum output power of the drive motor, the output power of the power battery and the capacity of the power battery pack. , to achieve the lowest cost powertrain design.

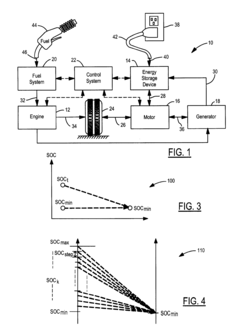

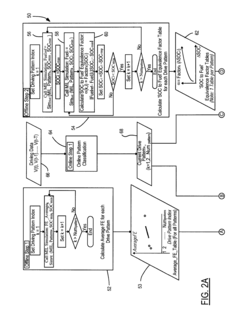

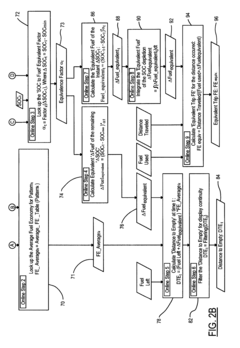

Plug-in hybrid electric vehicle and method of control for providing distance to empty and equivalent trip fuel economy information

PatentActiveUS8406948B2

Innovation

- A method for calculating DTE and equivalent Trip Fuel Economy (FE) that involves a controller determining the battery equivalent fuel amount using an equivalence factor based on SOC and driving conditions, and converting electricity consumption into fuel consumption for a unified efficiency index in miles per gallon (MPG), leveraging existing driving pattern identification and high-fidelity PHEV models to provide accurate and adaptive readouts.

TCO Analysis for Logistics

Total Cost of Ownership (TCO) analysis is a crucial tool for evaluating the economic viability of Plug-in Hybrid Electric Vehicles (PHEVs) in logistics operations. This comprehensive approach considers all costs associated with vehicle ownership and operation over its entire lifecycle, providing a more accurate picture of long-term financial implications.

For logistics companies, the TCO of PHEVs encompasses several key components. Initial purchase price is typically higher for PHEVs compared to conventional vehicles, reflecting the advanced technology and battery systems. However, this upfront cost is often offset by lower operational expenses over time.

Fuel costs represent a significant portion of the TCO for logistics vehicles. PHEVs offer substantial savings in this area due to their ability to operate on electricity for a portion of their range. The extent of these savings depends on factors such as electricity rates, fuel prices, and the proportion of electric-only miles driven.

Maintenance costs for PHEVs can be lower than those for conventional vehicles, primarily due to reduced wear on engine components and brake systems. However, the complexity of PHEV powertrains may require specialized maintenance, potentially increasing costs in some areas.

Battery replacement is a unique consideration for PHEVs. While modern batteries are designed to last the vehicle's lifetime, potential replacement costs should be factored into long-term TCO calculations.

Insurance costs for PHEVs may differ from conventional vehicles, reflecting their higher initial value and potentially lower accident rates due to advanced safety features.

Government incentives play a crucial role in PHEV TCO analysis. Tax credits, grants, and other financial incentives can significantly reduce the effective purchase price and ongoing operational costs of PHEVs for logistics companies.

Resale value is another important factor. While the PHEV market is still evolving, these vehicles often retain value well due to their fuel efficiency and advanced technology.

When conducting a TCO analysis for PHEVs in logistics, it's essential to consider the specific operational profile of the fleet. Factors such as daily mileage, route characteristics, and charging infrastructure availability significantly impact the potential cost savings.

By thoroughly examining these elements, logistics companies can make informed decisions about integrating PHEVs into their fleets. A well-executed TCO analysis not only reveals the potential for cost reduction but also helps identify the optimal scenarios for PHEV deployment in logistics operations.

For logistics companies, the TCO of PHEVs encompasses several key components. Initial purchase price is typically higher for PHEVs compared to conventional vehicles, reflecting the advanced technology and battery systems. However, this upfront cost is often offset by lower operational expenses over time.

Fuel costs represent a significant portion of the TCO for logistics vehicles. PHEVs offer substantial savings in this area due to their ability to operate on electricity for a portion of their range. The extent of these savings depends on factors such as electricity rates, fuel prices, and the proportion of electric-only miles driven.

Maintenance costs for PHEVs can be lower than those for conventional vehicles, primarily due to reduced wear on engine components and brake systems. However, the complexity of PHEV powertrains may require specialized maintenance, potentially increasing costs in some areas.

Battery replacement is a unique consideration for PHEVs. While modern batteries are designed to last the vehicle's lifetime, potential replacement costs should be factored into long-term TCO calculations.

Insurance costs for PHEVs may differ from conventional vehicles, reflecting their higher initial value and potentially lower accident rates due to advanced safety features.

Government incentives play a crucial role in PHEV TCO analysis. Tax credits, grants, and other financial incentives can significantly reduce the effective purchase price and ongoing operational costs of PHEVs for logistics companies.

Resale value is another important factor. While the PHEV market is still evolving, these vehicles often retain value well due to their fuel efficiency and advanced technology.

When conducting a TCO analysis for PHEVs in logistics, it's essential to consider the specific operational profile of the fleet. Factors such as daily mileage, route characteristics, and charging infrastructure availability significantly impact the potential cost savings.

By thoroughly examining these elements, logistics companies can make informed decisions about integrating PHEVs into their fleets. A well-executed TCO analysis not only reveals the potential for cost reduction but also helps identify the optimal scenarios for PHEV deployment in logistics operations.

Environmental Regulations

Environmental regulations play a crucial role in shaping the adoption and implementation of Plug-in Hybrid Electric Vehicles (PHEVs) in the logistics sector. These regulations are designed to reduce greenhouse gas emissions, improve air quality, and promote sustainable transportation practices. As governments worldwide intensify their efforts to combat climate change, the logistics industry faces increasing pressure to reduce its carbon footprint.

Many countries have implemented stringent emission standards for commercial vehicles, which has accelerated the adoption of cleaner technologies like PHEVs. For instance, the European Union's Euro 6 standards set strict limits on nitrogen oxides (NOx) and particulate matter emissions from diesel engines. This has prompted logistics companies to explore alternative powertrain technologies, including PHEVs, to comply with these regulations.

In urban areas, low-emission zones (LEZs) and zero-emission zones (ZEZs) are becoming more prevalent. These zones restrict or prohibit the entry of high-polluting vehicles, creating a strong incentive for logistics companies to invest in PHEVs. By utilizing electric power in these zones, PHEVs can operate with zero tailpipe emissions, ensuring compliance with local regulations and avoiding potential fines or restrictions.

Carbon pricing mechanisms, such as carbon taxes and cap-and-trade systems, are also influencing the adoption of PHEVs in logistics. These policies increase the cost of operating conventional fossil fuel vehicles, making PHEVs more economically attractive. As carbon prices rise, the total cost of ownership for PHEVs becomes increasingly competitive, further driving their adoption in the logistics sector.

Government incentives and subsidies for clean vehicles have significantly impacted the PHEV market. Many countries offer tax credits, grants, or other financial incentives for purchasing and operating PHEVs, reducing the upfront costs for logistics companies. These incentives help offset the higher initial investment required for PHEV technology, making it more accessible to a broader range of fleet operators.

Corporate sustainability goals and reporting requirements are also driving the adoption of PHEVs in logistics. As companies face pressure from stakeholders to reduce their environmental impact, many are setting ambitious targets for emissions reduction. PHEVs offer a practical solution for logistics companies to demonstrate progress towards these goals while maintaining operational flexibility.

The regulatory landscape for PHEVs in logistics is dynamic and continues to evolve. As environmental concerns grow and technology advances, it is likely that regulations will become even more stringent, further accelerating the transition to cleaner transportation solutions. Logistics companies that proactively adopt PHEV technology may gain a competitive advantage by staying ahead of regulatory requirements and positioning themselves as environmentally responsible operators in an increasingly eco-conscious market.

Many countries have implemented stringent emission standards for commercial vehicles, which has accelerated the adoption of cleaner technologies like PHEVs. For instance, the European Union's Euro 6 standards set strict limits on nitrogen oxides (NOx) and particulate matter emissions from diesel engines. This has prompted logistics companies to explore alternative powertrain technologies, including PHEVs, to comply with these regulations.

In urban areas, low-emission zones (LEZs) and zero-emission zones (ZEZs) are becoming more prevalent. These zones restrict or prohibit the entry of high-polluting vehicles, creating a strong incentive for logistics companies to invest in PHEVs. By utilizing electric power in these zones, PHEVs can operate with zero tailpipe emissions, ensuring compliance with local regulations and avoiding potential fines or restrictions.

Carbon pricing mechanisms, such as carbon taxes and cap-and-trade systems, are also influencing the adoption of PHEVs in logistics. These policies increase the cost of operating conventional fossil fuel vehicles, making PHEVs more economically attractive. As carbon prices rise, the total cost of ownership for PHEVs becomes increasingly competitive, further driving their adoption in the logistics sector.

Government incentives and subsidies for clean vehicles have significantly impacted the PHEV market. Many countries offer tax credits, grants, or other financial incentives for purchasing and operating PHEVs, reducing the upfront costs for logistics companies. These incentives help offset the higher initial investment required for PHEV technology, making it more accessible to a broader range of fleet operators.

Corporate sustainability goals and reporting requirements are also driving the adoption of PHEVs in logistics. As companies face pressure from stakeholders to reduce their environmental impact, many are setting ambitious targets for emissions reduction. PHEVs offer a practical solution for logistics companies to demonstrate progress towards these goals while maintaining operational flexibility.

The regulatory landscape for PHEVs in logistics is dynamic and continues to evolve. As environmental concerns grow and technology advances, it is likely that regulations will become even more stringent, further accelerating the transition to cleaner transportation solutions. Logistics companies that proactively adopt PHEV technology may gain a competitive advantage by staying ahead of regulatory requirements and positioning themselves as environmentally responsible operators in an increasingly eco-conscious market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!