PHEV thermal efficiency comparison with hydrogen vehicles

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV and H2 Efficiency Background

Plug-in Hybrid Electric Vehicles (PHEVs) and hydrogen fuel cell vehicles represent two distinct approaches to reducing emissions and improving efficiency in the automotive sector. PHEVs combine internal combustion engines with electric motors and rechargeable batteries, allowing for both electric-only operation and extended range using conventional fuels. Hydrogen vehicles, on the other hand, use fuel cells to convert hydrogen into electricity, powering electric motors with zero tailpipe emissions.

The thermal efficiency of these technologies is a critical factor in their overall performance and environmental impact. PHEVs typically achieve higher thermal efficiency than conventional internal combustion engines due to their ability to recover energy through regenerative braking and optimize engine operation. The electric motor's high efficiency, coupled with the ability to operate the internal combustion engine at its most efficient points, contributes to improved overall system efficiency.

Hydrogen fuel cell vehicles offer potentially higher thermal efficiency than PHEVs in certain scenarios. Fuel cells can convert hydrogen to electricity at efficiencies of up to 60%, significantly higher than the thermal efficiency of most internal combustion engines. However, the overall efficiency of hydrogen vehicles is influenced by factors such as hydrogen production, transportation, and storage, which can impact the well-to-wheel efficiency.

The comparison of thermal efficiency between PHEVs and hydrogen vehicles is complex and depends on various factors. PHEVs benefit from the flexibility of using both electricity from the grid and conventional fuels, allowing for efficient operation in diverse driving conditions. Their efficiency is particularly high in short-distance urban driving, where the electric motor can be predominantly used.

Hydrogen vehicles excel in long-range applications and heavy-duty transport, where their quick refueling times and high energy density offer advantages over battery-electric alternatives. The thermal efficiency of hydrogen vehicles is less affected by ambient temperature and driving conditions compared to battery-electric systems, providing more consistent performance across various scenarios.

Both technologies continue to evolve, with ongoing research focused on improving their respective efficiencies. Advancements in battery technology, power electronics, and thermal management systems are enhancing PHEV performance. Similarly, progress in fuel cell technology, hydrogen production methods, and storage solutions are boosting the efficiency and viability of hydrogen vehicles.

The choice between PHEVs and hydrogen vehicles often depends on specific use cases, infrastructure availability, and regional energy policies. As the automotive industry transitions towards more sustainable solutions, both technologies are likely to play important roles in different segments of the market, with their relative thermal efficiencies continuing to be a key factor in their adoption and development.

The thermal efficiency of these technologies is a critical factor in their overall performance and environmental impact. PHEVs typically achieve higher thermal efficiency than conventional internal combustion engines due to their ability to recover energy through regenerative braking and optimize engine operation. The electric motor's high efficiency, coupled with the ability to operate the internal combustion engine at its most efficient points, contributes to improved overall system efficiency.

Hydrogen fuel cell vehicles offer potentially higher thermal efficiency than PHEVs in certain scenarios. Fuel cells can convert hydrogen to electricity at efficiencies of up to 60%, significantly higher than the thermal efficiency of most internal combustion engines. However, the overall efficiency of hydrogen vehicles is influenced by factors such as hydrogen production, transportation, and storage, which can impact the well-to-wheel efficiency.

The comparison of thermal efficiency between PHEVs and hydrogen vehicles is complex and depends on various factors. PHEVs benefit from the flexibility of using both electricity from the grid and conventional fuels, allowing for efficient operation in diverse driving conditions. Their efficiency is particularly high in short-distance urban driving, where the electric motor can be predominantly used.

Hydrogen vehicles excel in long-range applications and heavy-duty transport, where their quick refueling times and high energy density offer advantages over battery-electric alternatives. The thermal efficiency of hydrogen vehicles is less affected by ambient temperature and driving conditions compared to battery-electric systems, providing more consistent performance across various scenarios.

Both technologies continue to evolve, with ongoing research focused on improving their respective efficiencies. Advancements in battery technology, power electronics, and thermal management systems are enhancing PHEV performance. Similarly, progress in fuel cell technology, hydrogen production methods, and storage solutions are boosting the efficiency and viability of hydrogen vehicles.

The choice between PHEVs and hydrogen vehicles often depends on specific use cases, infrastructure availability, and regional energy policies. As the automotive industry transitions towards more sustainable solutions, both technologies are likely to play important roles in different segments of the market, with their relative thermal efficiencies continuing to be a key factor in their adoption and development.

Market Demand Analysis

The market demand for Plug-in Hybrid Electric Vehicles (PHEVs) and hydrogen vehicles is experiencing significant growth as consumers and governments increasingly prioritize sustainable transportation solutions. PHEVs have gained traction in recent years due to their ability to combine the benefits of electric and conventional powertrains, offering improved fuel efficiency and reduced emissions compared to traditional internal combustion engine vehicles.

The global PHEV market is projected to expand rapidly, driven by factors such as stringent emission regulations, government incentives, and growing environmental awareness among consumers. Major automotive markets, including China, Europe, and North America, are witnessing a surge in PHEV adoption. This trend is further supported by the expanding charging infrastructure and advancements in battery technology, which address range anxiety concerns.

Hydrogen vehicles, while still in the early stages of commercialization, are gaining attention as a potential long-term solution for zero-emission transportation. The market for hydrogen fuel cell vehicles is expected to grow, particularly in sectors such as long-haul transportation, public transit, and heavy-duty applications where battery electric vehicles face limitations.

The comparison of thermal efficiency between PHEVs and hydrogen vehicles is a crucial factor influencing market demand. PHEVs benefit from the high efficiency of electric motors during short trips and urban driving, while still offering the flexibility of gasoline engines for longer journeys. This versatility appeals to consumers who seek reduced emissions without compromising on range or refueling convenience.

Hydrogen vehicles, on the other hand, offer the potential for higher overall efficiency in certain scenarios, particularly for long-distance travel and heavy-duty applications. The rapid refueling capability of hydrogen vehicles addresses one of the main limitations of battery electric vehicles, making them attractive for fleet operators and consumers who require minimal downtime.

Market demand analysis indicates that both PHEVs and hydrogen vehicles are likely to coexist in the future automotive landscape, catering to different segments and use cases. PHEVs are expected to maintain strong demand in the passenger vehicle market, especially in regions with developing charging infrastructure. Hydrogen vehicles may find their niche in commercial and industrial applications, as well as in regions investing heavily in hydrogen infrastructure.

The evolving regulatory landscape plays a significant role in shaping market demand for these technologies. Many countries have announced plans to phase out internal combustion engine vehicles in the coming decades, creating opportunities for both PHEVs and hydrogen vehicles. However, the specific policies and incentives implemented by different governments will greatly influence the relative market share of these technologies in various regions.

The global PHEV market is projected to expand rapidly, driven by factors such as stringent emission regulations, government incentives, and growing environmental awareness among consumers. Major automotive markets, including China, Europe, and North America, are witnessing a surge in PHEV adoption. This trend is further supported by the expanding charging infrastructure and advancements in battery technology, which address range anxiety concerns.

Hydrogen vehicles, while still in the early stages of commercialization, are gaining attention as a potential long-term solution for zero-emission transportation. The market for hydrogen fuel cell vehicles is expected to grow, particularly in sectors such as long-haul transportation, public transit, and heavy-duty applications where battery electric vehicles face limitations.

The comparison of thermal efficiency between PHEVs and hydrogen vehicles is a crucial factor influencing market demand. PHEVs benefit from the high efficiency of electric motors during short trips and urban driving, while still offering the flexibility of gasoline engines for longer journeys. This versatility appeals to consumers who seek reduced emissions without compromising on range or refueling convenience.

Hydrogen vehicles, on the other hand, offer the potential for higher overall efficiency in certain scenarios, particularly for long-distance travel and heavy-duty applications. The rapid refueling capability of hydrogen vehicles addresses one of the main limitations of battery electric vehicles, making them attractive for fleet operators and consumers who require minimal downtime.

Market demand analysis indicates that both PHEVs and hydrogen vehicles are likely to coexist in the future automotive landscape, catering to different segments and use cases. PHEVs are expected to maintain strong demand in the passenger vehicle market, especially in regions with developing charging infrastructure. Hydrogen vehicles may find their niche in commercial and industrial applications, as well as in regions investing heavily in hydrogen infrastructure.

The evolving regulatory landscape plays a significant role in shaping market demand for these technologies. Many countries have announced plans to phase out internal combustion engine vehicles in the coming decades, creating opportunities for both PHEVs and hydrogen vehicles. However, the specific policies and incentives implemented by different governments will greatly influence the relative market share of these technologies in various regions.

Technical Challenges

The comparison of thermal efficiency between Plug-in Hybrid Electric Vehicles (PHEVs) and hydrogen vehicles presents several technical challenges that researchers and engineers must address. One of the primary obstacles is the accurate measurement and comparison of energy efficiency across different powertrain technologies. PHEVs utilize a combination of internal combustion engines and electric motors, while hydrogen vehicles primarily rely on fuel cells to convert hydrogen into electricity.

The complexity of PHEV powertrains makes it difficult to isolate and quantify the thermal efficiency of individual components. The interplay between the internal combustion engine and electric motor, along with varying driving conditions and energy management strategies, creates a dynamic system that is challenging to assess consistently. In contrast, hydrogen fuel cell vehicles have a more straightforward powertrain, but their overall efficiency is heavily dependent on the production and distribution of hydrogen fuel.

Another significant challenge lies in the development of advanced thermal management systems for both types of vehicles. PHEVs must efficiently manage heat from both the internal combustion engine and the electric powertrain, while hydrogen vehicles need to address the thermal issues associated with fuel cell operation and hydrogen storage. Optimizing these systems to maximize overall vehicle efficiency while maintaining performance and safety standards remains a complex engineering task.

The integration of regenerative braking systems presents different challenges for PHEVs and hydrogen vehicles. PHEVs can directly store recovered energy in their batteries, but optimizing the balance between regenerative and friction braking for maximum efficiency is complex. Hydrogen vehicles, on the other hand, must convert recovered energy into hydrogen through electrolysis or store it in auxiliary battery systems, which can introduce additional inefficiencies.

Furthermore, the comparison of thermal efficiency is complicated by the different energy sources and their respective production methods. The well-to-wheel efficiency of PHEVs depends on the source of electricity for charging, while hydrogen vehicles are affected by the efficiency of hydrogen production, compression, and distribution processes. Standardizing these factors for a fair comparison remains a significant challenge in the industry.

Lastly, the development of advanced materials and manufacturing techniques to improve thermal efficiency poses unique challenges for each vehicle type. PHEVs require lightweight materials to offset the weight of dual powertrains, while hydrogen vehicles need advanced materials for fuel cells and high-pressure hydrogen storage tanks. Balancing performance, cost, and manufacturability while pushing the boundaries of material science is an ongoing challenge in the quest for higher thermal efficiency.

The complexity of PHEV powertrains makes it difficult to isolate and quantify the thermal efficiency of individual components. The interplay between the internal combustion engine and electric motor, along with varying driving conditions and energy management strategies, creates a dynamic system that is challenging to assess consistently. In contrast, hydrogen fuel cell vehicles have a more straightforward powertrain, but their overall efficiency is heavily dependent on the production and distribution of hydrogen fuel.

Another significant challenge lies in the development of advanced thermal management systems for both types of vehicles. PHEVs must efficiently manage heat from both the internal combustion engine and the electric powertrain, while hydrogen vehicles need to address the thermal issues associated with fuel cell operation and hydrogen storage. Optimizing these systems to maximize overall vehicle efficiency while maintaining performance and safety standards remains a complex engineering task.

The integration of regenerative braking systems presents different challenges for PHEVs and hydrogen vehicles. PHEVs can directly store recovered energy in their batteries, but optimizing the balance between regenerative and friction braking for maximum efficiency is complex. Hydrogen vehicles, on the other hand, must convert recovered energy into hydrogen through electrolysis or store it in auxiliary battery systems, which can introduce additional inefficiencies.

Furthermore, the comparison of thermal efficiency is complicated by the different energy sources and their respective production methods. The well-to-wheel efficiency of PHEVs depends on the source of electricity for charging, while hydrogen vehicles are affected by the efficiency of hydrogen production, compression, and distribution processes. Standardizing these factors for a fair comparison remains a significant challenge in the industry.

Lastly, the development of advanced materials and manufacturing techniques to improve thermal efficiency poses unique challenges for each vehicle type. PHEVs require lightweight materials to offset the weight of dual powertrains, while hydrogen vehicles need advanced materials for fuel cells and high-pressure hydrogen storage tanks. Balancing performance, cost, and manufacturability while pushing the boundaries of material science is an ongoing challenge in the quest for higher thermal efficiency.

Current Efficiency Solutions

01 Hybrid powertrain optimization for PHEVs

Optimization of hybrid powertrains in PHEVs to improve thermal efficiency. This involves advanced control strategies for managing power distribution between the internal combustion engine and electric motor, as well as optimizing energy recovery systems to maximize overall vehicle efficiency.- Hybrid powertrain optimization for PHEVs: Optimization of hybrid powertrains in PHEVs to improve thermal efficiency. This involves advanced control strategies for managing power distribution between the internal combustion engine and electric motor, as well as optimizing energy recovery systems to maximize overall vehicle efficiency.

- Thermal management systems for hydrogen vehicles: Development of advanced thermal management systems specifically designed for hydrogen fuel cell vehicles. These systems aim to regulate temperature across various components, including the fuel cell stack, to maintain optimal operating conditions and improve overall thermal efficiency.

- Energy recovery and waste heat utilization: Implementation of energy recovery systems and waste heat utilization techniques in both PHEVs and hydrogen vehicles. This includes technologies such as thermoelectric generators and heat exchangers to capture and repurpose waste heat, thereby increasing overall thermal efficiency.

- Advanced materials for improved thermal efficiency: Utilization of advanced materials in vehicle components to enhance thermal efficiency. This includes the use of lightweight, thermally conductive materials in heat exchangers, as well as high-temperature resistant materials in fuel cell systems and engine components.

- Intelligent control systems for efficiency optimization: Development of intelligent control systems that use real-time data and predictive algorithms to optimize vehicle performance and thermal efficiency. These systems can adapt to various driving conditions and energy demands, ensuring optimal energy utilization in both PHEVs and hydrogen vehicles.

02 Thermal management systems for hydrogen vehicles

Development of advanced thermal management systems specifically designed for hydrogen fuel cell vehicles. These systems focus on maintaining optimal operating temperatures for fuel cells, managing heat generated during hydrogen conversion, and improving overall thermal efficiency of the vehicle.Expand Specific Solutions03 Energy recovery and utilization in PHEVs and hydrogen vehicles

Implementation of innovative energy recovery and utilization techniques in both PHEVs and hydrogen vehicles. This includes regenerative braking systems, waste heat recovery mechanisms, and intelligent energy management algorithms to maximize the use of recovered energy and improve overall thermal efficiency.Expand Specific Solutions04 Advanced materials for improved thermal efficiency

Utilization of advanced materials in vehicle components to enhance thermal efficiency. This includes the use of lightweight, thermally conductive materials in powertrains, heat exchangers, and insulation systems to optimize heat transfer and reduce energy losses in both PHEVs and hydrogen vehicles.Expand Specific Solutions05 Intelligent control systems for thermal optimization

Development of intelligent control systems that dynamically optimize thermal efficiency in PHEVs and hydrogen vehicles. These systems use real-time data analysis, predictive algorithms, and adaptive control strategies to balance power demands, manage thermal loads, and maximize overall vehicle efficiency across various driving conditions.Expand Specific Solutions

Key Industry Players

The competition landscape for PHEV thermal efficiency compared to hydrogen vehicles is evolving rapidly, with the market in a growth phase. As the automotive industry shifts towards cleaner technologies, both PHEVs and hydrogen vehicles are gaining traction. The market size for these technologies is expanding, driven by environmental regulations and consumer demand for eco-friendly transportation. In terms of technological maturity, PHEVs are more established, with companies like Ford, Volvo, and Hyundai leading the way. However, hydrogen vehicle technology is advancing quickly, with firms such as Toyota, Honda, and Audi investing heavily in research and development. The competition is intensifying as automakers strive to improve efficiency and reduce costs in both technologies.

Ford Motor Co.

Technical Solution: Ford has developed advanced PHEV systems that utilize a combination of electric motors and internal combustion engines to optimize thermal efficiency. Their PowerSplit architecture allows for multiple power flow paths, enabling the engine to operate at its most efficient points more frequently[1]. Ford's PHEVs incorporate regenerative braking and advanced thermal management systems to capture and reuse waste heat, further improving overall system efficiency[2]. The company has also invested in research to reduce parasitic losses and improve powertrain integration, resulting in thermal efficiencies approaching 40% in some models[3].

Strengths: Established manufacturing infrastructure, extensive experience in hybrid powertrains. Weaknesses: Reliance on fossil fuels for the ICE component, potential for increased complexity in powertrain systems.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has made significant strides in PHEV technology, focusing on improving thermal efficiency through advanced combustion strategies and integrated powertrain designs. Their latest PHEV models utilize a dedicated Atkinson-cycle engine optimized for hybrid operation, achieving thermal efficiencies of up to 42%[4]. Hyundai has also implemented a heat pump system that recovers waste heat from various sources, including the electric powertrain and exhaust gases, to improve overall energy efficiency[5]. Additionally, they have developed an active air flap system that optimizes aerodynamics and engine thermal management, further enhancing efficiency in real-world driving conditions[6].

Strengths: Strong focus on innovative thermal management solutions, competitive thermal efficiency figures. Weaknesses: Limited experience compared to some competitors in long-term PHEV deployment.

Core Efficiency Innovations

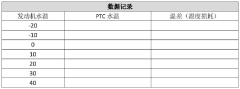

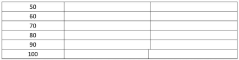

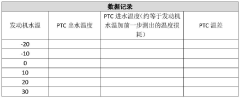

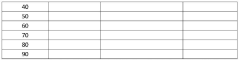

Calibration method for thermal output of passenger compartment of PHEV

PatentPendingCN117990384A

Innovation

- By measuring the engine water temperature loss and the water temperature rise that the PTC maximum power can provide, combined with the four-way valve, PTC water pump, blower, compressor, mode motor, air volume gear and other control variables, the automatic algorithm of the air conditioning controller is used to achieve rapid response And meet the heat demand to ensure that the heat source can be switched freely.

Environmental Impact Assessment

The environmental impact assessment of Plug-in Hybrid Electric Vehicles (PHEVs) and hydrogen vehicles is crucial for understanding their long-term sustainability and ecological footprint. Both technologies aim to reduce greenhouse gas emissions and dependence on fossil fuels, but their environmental impacts differ significantly across their lifecycle.

PHEVs combine conventional internal combustion engines with electric motors, allowing for short-range electric-only operation and extended range using gasoline. Their environmental impact is heavily influenced by the source of electricity used for charging. In regions with a high proportion of renewable energy in the grid mix, PHEVs can significantly reduce emissions compared to conventional vehicles. However, in areas reliant on fossil fuels for electricity generation, the benefits may be less pronounced.

Hydrogen vehicles, particularly those using fuel cells, produce zero tailpipe emissions, with water vapor being the only byproduct. However, the environmental impact of hydrogen production is a critical factor. Currently, most hydrogen is produced through steam methane reforming, which emits significant amounts of CO2. Green hydrogen, produced through electrolysis powered by renewable energy, offers a more environmentally friendly alternative but is currently limited in scale and economically challenging.

The manufacturing process for both PHEVs and hydrogen vehicles has a higher environmental impact than conventional vehicles due to the production of batteries and fuel cells, respectively. PHEVs require smaller battery packs compared to full electric vehicles, potentially reducing their manufacturing footprint. Hydrogen vehicles, while not requiring large batteries, rely on complex fuel cell systems and high-pressure hydrogen storage tanks, which have their own environmental considerations in production and end-of-life disposal.

In terms of infrastructure, PHEVs benefit from existing electrical grids and can be charged at home or public charging stations. Hydrogen vehicles require a dedicated refueling infrastructure, which is currently limited and energy-intensive to develop. The expansion of hydrogen infrastructure could lead to additional environmental impacts through construction and operation of production and distribution facilities.

Considering the full lifecycle, both technologies have the potential to significantly reduce greenhouse gas emissions and air pollution compared to conventional vehicles. However, the extent of these benefits depends heavily on the energy sources used for electricity generation and hydrogen production. As grids become cleaner and green hydrogen production scales up, the environmental advantages of both PHEVs and hydrogen vehicles are expected to increase.

PHEVs combine conventional internal combustion engines with electric motors, allowing for short-range electric-only operation and extended range using gasoline. Their environmental impact is heavily influenced by the source of electricity used for charging. In regions with a high proportion of renewable energy in the grid mix, PHEVs can significantly reduce emissions compared to conventional vehicles. However, in areas reliant on fossil fuels for electricity generation, the benefits may be less pronounced.

Hydrogen vehicles, particularly those using fuel cells, produce zero tailpipe emissions, with water vapor being the only byproduct. However, the environmental impact of hydrogen production is a critical factor. Currently, most hydrogen is produced through steam methane reforming, which emits significant amounts of CO2. Green hydrogen, produced through electrolysis powered by renewable energy, offers a more environmentally friendly alternative but is currently limited in scale and economically challenging.

The manufacturing process for both PHEVs and hydrogen vehicles has a higher environmental impact than conventional vehicles due to the production of batteries and fuel cells, respectively. PHEVs require smaller battery packs compared to full electric vehicles, potentially reducing their manufacturing footprint. Hydrogen vehicles, while not requiring large batteries, rely on complex fuel cell systems and high-pressure hydrogen storage tanks, which have their own environmental considerations in production and end-of-life disposal.

In terms of infrastructure, PHEVs benefit from existing electrical grids and can be charged at home or public charging stations. Hydrogen vehicles require a dedicated refueling infrastructure, which is currently limited and energy-intensive to develop. The expansion of hydrogen infrastructure could lead to additional environmental impacts through construction and operation of production and distribution facilities.

Considering the full lifecycle, both technologies have the potential to significantly reduce greenhouse gas emissions and air pollution compared to conventional vehicles. However, the extent of these benefits depends heavily on the energy sources used for electricity generation and hydrogen production. As grids become cleaner and green hydrogen production scales up, the environmental advantages of both PHEVs and hydrogen vehicles are expected to increase.

Cost-Benefit Analysis

When comparing the cost-benefit analysis of Plug-in Hybrid Electric Vehicles (PHEVs) and hydrogen vehicles, several factors must be considered. The initial cost of PHEVs is generally lower than that of hydrogen vehicles, primarily due to the more established production infrastructure and supply chains for battery technology. However, the long-term operational costs may favor hydrogen vehicles in certain scenarios.

Fuel costs play a significant role in this analysis. While electricity prices for charging PHEVs can be relatively stable and often lower than traditional fuel costs, the price of hydrogen can vary significantly depending on production methods and availability. In regions with abundant renewable energy sources, hydrogen production costs may decrease over time, potentially making hydrogen vehicles more cost-competitive in the long run.

Maintenance costs also factor into the equation. PHEVs typically have lower maintenance requirements compared to conventional vehicles, but their battery replacement costs can be substantial. Hydrogen vehicles, with fewer moving parts in their fuel cell systems, may offer reduced maintenance needs over their lifetime, potentially offsetting higher initial costs.

Infrastructure development is a crucial consideration. The existing electrical grid provides a foundation for PHEV charging infrastructure, requiring relatively modest investments for widespread adoption. In contrast, hydrogen refueling infrastructure is still in its infancy in most regions, necessitating significant capital expenditure for large-scale implementation.

Environmental benefits and associated cost savings should also be factored in. Both PHEVs and hydrogen vehicles offer reduced emissions compared to conventional vehicles, but their overall environmental impact depends on the sources of electricity and hydrogen production. PHEVs can leverage existing renewable energy infrastructure, while hydrogen vehicles may require additional investments in green hydrogen production facilities.

Resale value and vehicle lifespan are important long-term considerations. The battery degradation in PHEVs may affect their resale value over time, while the longevity of fuel cell systems in hydrogen vehicles is still being established in real-world conditions. This uncertainty can impact the total cost of ownership calculations for both technologies.

In conclusion, the cost-benefit analysis between PHEVs and hydrogen vehicles is complex and depends on various factors including regional energy prices, infrastructure development, and environmental policies. While PHEVs currently hold an advantage in terms of initial cost and infrastructure readiness, hydrogen vehicles show promise for long-term cost-effectiveness, especially in regions investing heavily in hydrogen infrastructure and production.

Fuel costs play a significant role in this analysis. While electricity prices for charging PHEVs can be relatively stable and often lower than traditional fuel costs, the price of hydrogen can vary significantly depending on production methods and availability. In regions with abundant renewable energy sources, hydrogen production costs may decrease over time, potentially making hydrogen vehicles more cost-competitive in the long run.

Maintenance costs also factor into the equation. PHEVs typically have lower maintenance requirements compared to conventional vehicles, but their battery replacement costs can be substantial. Hydrogen vehicles, with fewer moving parts in their fuel cell systems, may offer reduced maintenance needs over their lifetime, potentially offsetting higher initial costs.

Infrastructure development is a crucial consideration. The existing electrical grid provides a foundation for PHEV charging infrastructure, requiring relatively modest investments for widespread adoption. In contrast, hydrogen refueling infrastructure is still in its infancy in most regions, necessitating significant capital expenditure for large-scale implementation.

Environmental benefits and associated cost savings should also be factored in. Both PHEVs and hydrogen vehicles offer reduced emissions compared to conventional vehicles, but their overall environmental impact depends on the sources of electricity and hydrogen production. PHEVs can leverage existing renewable energy infrastructure, while hydrogen vehicles may require additional investments in green hydrogen production facilities.

Resale value and vehicle lifespan are important long-term considerations. The battery degradation in PHEVs may affect their resale value over time, while the longevity of fuel cell systems in hydrogen vehicles is still being established in real-world conditions. This uncertainty can impact the total cost of ownership calculations for both technologies.

In conclusion, the cost-benefit analysis between PHEVs and hydrogen vehicles is complex and depends on various factors including regional energy prices, infrastructure development, and environmental policies. While PHEVs currently hold an advantage in terms of initial cost and infrastructure readiness, hydrogen vehicles show promise for long-term cost-effectiveness, especially in regions investing heavily in hydrogen infrastructure and production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!