Prototype Development: From Lab Bench To Field Trials

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Prototype Evolution and Development Goals

The evolution of prototype development represents a critical journey from conceptual design to practical implementation. Historically, prototyping has transformed from rudimentary physical models to sophisticated digital-physical hybrid systems that incorporate advanced materials and technologies. This evolution has been accelerated by the integration of rapid prototyping technologies, computer-aided design tools, and simulation capabilities that allow for faster iteration cycles and more accurate predictions of real-world performance.

The primary goal of modern prototype development is to establish a seamless transition pathway from laboratory concepts to field-tested solutions. This involves creating prototypes that not only demonstrate technical feasibility but also address practical considerations such as manufacturability, scalability, and user experience. The development process aims to identify and mitigate potential issues early, reducing costly modifications during later stages of product development.

Current prototype development methodologies emphasize iterative approaches, where each version builds upon lessons learned from previous iterations. This spiral development model allows for continuous refinement based on empirical data and stakeholder feedback. The integration of agile principles into hardware development has further enhanced this process, enabling more responsive adaptation to changing requirements and emerging constraints.

A significant trend in prototype evolution is the increasing focus on modular architectures that allow for component-level testing and validation. This approach enables parallel development tracks and more efficient resource allocation, as different subsystems can be optimized independently before integration. Additionally, the adoption of digital twins—virtual replicas of physical prototypes—has enabled more comprehensive testing scenarios without the expense of multiple physical builds.

The development goals for modern prototyping extend beyond mere technical validation to include early-stage user testing, regulatory compliance assessment, and supply chain validation. Prototypes now serve as platforms for cross-functional collaboration, bringing together engineering, design, manufacturing, and marketing perspectives to ensure holistic product development.

Environmental considerations have also become integral to prototype development goals, with increasing emphasis on sustainable materials, energy-efficient operation, and end-of-life recyclability. These factors are now evaluated during early prototype stages rather than being addressed as afterthoughts in final product design.

The convergence of digital tools and physical prototyping has created new opportunities for distributed development teams to collaborate effectively across geographic boundaries. Cloud-based design platforms, remote monitoring capabilities, and standardized testing protocols enable consistent evaluation methodologies regardless of where prototype testing occurs, facilitating global product development strategies while maintaining coherent design integrity.

The primary goal of modern prototype development is to establish a seamless transition pathway from laboratory concepts to field-tested solutions. This involves creating prototypes that not only demonstrate technical feasibility but also address practical considerations such as manufacturability, scalability, and user experience. The development process aims to identify and mitigate potential issues early, reducing costly modifications during later stages of product development.

Current prototype development methodologies emphasize iterative approaches, where each version builds upon lessons learned from previous iterations. This spiral development model allows for continuous refinement based on empirical data and stakeholder feedback. The integration of agile principles into hardware development has further enhanced this process, enabling more responsive adaptation to changing requirements and emerging constraints.

A significant trend in prototype evolution is the increasing focus on modular architectures that allow for component-level testing and validation. This approach enables parallel development tracks and more efficient resource allocation, as different subsystems can be optimized independently before integration. Additionally, the adoption of digital twins—virtual replicas of physical prototypes—has enabled more comprehensive testing scenarios without the expense of multiple physical builds.

The development goals for modern prototyping extend beyond mere technical validation to include early-stage user testing, regulatory compliance assessment, and supply chain validation. Prototypes now serve as platforms for cross-functional collaboration, bringing together engineering, design, manufacturing, and marketing perspectives to ensure holistic product development.

Environmental considerations have also become integral to prototype development goals, with increasing emphasis on sustainable materials, energy-efficient operation, and end-of-life recyclability. These factors are now evaluated during early prototype stages rather than being addressed as afterthoughts in final product design.

The convergence of digital tools and physical prototyping has created new opportunities for distributed development teams to collaborate effectively across geographic boundaries. Cloud-based design platforms, remote monitoring capabilities, and standardized testing protocols enable consistent evaluation methodologies regardless of where prototype testing occurs, facilitating global product development strategies while maintaining coherent design integrity.

Market Requirements Analysis for Field-Ready Prototypes

The transition from laboratory prototypes to field-ready products represents a critical phase in technology commercialization. Market analysis reveals that approximately 70% of innovations fail during this transition due to misalignment with actual market requirements. Field-ready prototypes must address specific market demands that laboratory versions often overlook, including durability, user interface simplicity, regulatory compliance, and cost-effectiveness at scale.

Current market trends indicate growing demand for rapid prototype-to-field transitions across multiple sectors. In healthcare, medical device manufacturers require field prototypes that can withstand rigorous clinical testing environments while maintaining precision. The industrial automation sector seeks prototypes capable of operating in harsh conditions with minimal maintenance requirements. Consumer electronics companies prioritize field prototypes that demonstrate both technical functionality and aesthetic appeal to potential users.

Market research indicates that successful field-ready prototypes typically incorporate feedback from three key stakeholder groups: end-users, regulatory bodies, and manufacturing partners. End-users consistently emphasize the importance of intuitive interfaces, reliability under varied conditions, and clear value proposition over existing solutions. Regulatory stakeholders focus on compliance documentation and safety verification during field trials. Manufacturing partners prioritize design features that facilitate efficient production scaling.

Geographic market requirements vary significantly, with North American markets emphasizing regulatory compliance and liability protection, European markets focusing on sustainability and energy efficiency, and emerging markets prioritizing cost-effectiveness and adaptability to infrastructure limitations. These regional variations necessitate customized field testing protocols to validate prototype performance across diverse operating environments.

Time-to-market pressures continue to intensify across industries, with companies seeking to reduce prototype-to-commercial timelines by 30-40% compared to historical standards. This acceleration requires field prototypes that can simultaneously validate technical performance, manufacturing feasibility, and market acceptance. Companies achieving this integration gain significant competitive advantage through earlier market entry and reduced development costs.

Cost considerations remain paramount, with market analysis showing willingness to invest in robust field prototypes that reduce downstream commercialization risks. Organizations increasingly view comprehensive field testing as insurance against costly post-launch modifications or recalls. The most successful prototype development programs allocate 15-20% of total development budgets specifically to field testing phases, recognizing this investment as critical to commercial success.

Current market trends indicate growing demand for rapid prototype-to-field transitions across multiple sectors. In healthcare, medical device manufacturers require field prototypes that can withstand rigorous clinical testing environments while maintaining precision. The industrial automation sector seeks prototypes capable of operating in harsh conditions with minimal maintenance requirements. Consumer electronics companies prioritize field prototypes that demonstrate both technical functionality and aesthetic appeal to potential users.

Market research indicates that successful field-ready prototypes typically incorporate feedback from three key stakeholder groups: end-users, regulatory bodies, and manufacturing partners. End-users consistently emphasize the importance of intuitive interfaces, reliability under varied conditions, and clear value proposition over existing solutions. Regulatory stakeholders focus on compliance documentation and safety verification during field trials. Manufacturing partners prioritize design features that facilitate efficient production scaling.

Geographic market requirements vary significantly, with North American markets emphasizing regulatory compliance and liability protection, European markets focusing on sustainability and energy efficiency, and emerging markets prioritizing cost-effectiveness and adaptability to infrastructure limitations. These regional variations necessitate customized field testing protocols to validate prototype performance across diverse operating environments.

Time-to-market pressures continue to intensify across industries, with companies seeking to reduce prototype-to-commercial timelines by 30-40% compared to historical standards. This acceleration requires field prototypes that can simultaneously validate technical performance, manufacturing feasibility, and market acceptance. Companies achieving this integration gain significant competitive advantage through earlier market entry and reduced development costs.

Cost considerations remain paramount, with market analysis showing willingness to invest in robust field prototypes that reduce downstream commercialization risks. Organizations increasingly view comprehensive field testing as insurance against costly post-launch modifications or recalls. The most successful prototype development programs allocate 15-20% of total development budgets specifically to field testing phases, recognizing this investment as critical to commercial success.

Technical Barriers in Prototype-to-Field Transition

The transition from laboratory prototype to field-ready product represents one of the most challenging phases in technology development. This critical stage encounters numerous technical barriers that often impede successful commercialization. The primary challenge lies in scaling production from controlled laboratory conditions to industrial manufacturing processes while maintaining performance consistency. Laboratory prototypes typically benefit from meticulous assembly and ideal testing environments that cannot be replicated in mass production settings.

Material compatibility issues frequently emerge during this transition. Materials that perform adequately in laboratory prototypes may exhibit unexpected degradation, incompatibility, or performance variations when subjected to real-world environmental conditions. These issues necessitate substantial reformulation or redesign, adding significant delays to development timelines.

Reliability and durability requirements present another substantial barrier. Laboratory prototypes rarely undergo the rigorous testing necessary to ensure long-term performance under varied field conditions. The development of accelerated life testing protocols becomes essential yet remains challenging to correlate with actual field performance, particularly for novel technologies without established testing standards.

Integration challenges with existing systems and infrastructure often emerge only during field trials. Laboratory prototypes typically operate as standalone units, whereas field deployment requires seamless integration with established systems, compliance with industry standards, and interoperability with legacy equipment. These requirements frequently necessitate significant redesign of initially promising prototypes.

Cost optimization represents a persistent barrier throughout the transition process. Laboratory prototypes prioritize functionality over cost-effectiveness, utilizing expensive components or complex manufacturing processes that prove economically unfeasible at scale. The engineering challenge of maintaining performance while reducing production costs requires substantial redesign efforts and material substitutions.

Regulatory compliance introduces additional complexity, particularly in highly regulated industries such as healthcare, transportation, and energy. Laboratory prototypes rarely address the full spectrum of safety, environmental, and performance standards required for commercial deployment. The certification process often reveals technical deficiencies that necessitate further development iterations.

User experience considerations frequently emerge as significant barriers during field trials. Laboratory prototypes designed by technical experts may lack intuitive interfaces or fail to account for varied user capabilities and operational environments. Addressing these human factors often requires substantial redesign beyond mere technical functionality.

The knowledge transfer between research and production teams presents a final critical barrier. Documentation practices suitable for laboratory work frequently prove insufficient for manufacturing teams, resulting in implementation gaps and performance inconsistencies that undermine the transition process.

Material compatibility issues frequently emerge during this transition. Materials that perform adequately in laboratory prototypes may exhibit unexpected degradation, incompatibility, or performance variations when subjected to real-world environmental conditions. These issues necessitate substantial reformulation or redesign, adding significant delays to development timelines.

Reliability and durability requirements present another substantial barrier. Laboratory prototypes rarely undergo the rigorous testing necessary to ensure long-term performance under varied field conditions. The development of accelerated life testing protocols becomes essential yet remains challenging to correlate with actual field performance, particularly for novel technologies without established testing standards.

Integration challenges with existing systems and infrastructure often emerge only during field trials. Laboratory prototypes typically operate as standalone units, whereas field deployment requires seamless integration with established systems, compliance with industry standards, and interoperability with legacy equipment. These requirements frequently necessitate significant redesign of initially promising prototypes.

Cost optimization represents a persistent barrier throughout the transition process. Laboratory prototypes prioritize functionality over cost-effectiveness, utilizing expensive components or complex manufacturing processes that prove economically unfeasible at scale. The engineering challenge of maintaining performance while reducing production costs requires substantial redesign efforts and material substitutions.

Regulatory compliance introduces additional complexity, particularly in highly regulated industries such as healthcare, transportation, and energy. Laboratory prototypes rarely address the full spectrum of safety, environmental, and performance standards required for commercial deployment. The certification process often reveals technical deficiencies that necessitate further development iterations.

User experience considerations frequently emerge as significant barriers during field trials. Laboratory prototypes designed by technical experts may lack intuitive interfaces or fail to account for varied user capabilities and operational environments. Addressing these human factors often requires substantial redesign beyond mere technical functionality.

The knowledge transfer between research and production teams presents a final critical barrier. Documentation practices suitable for laboratory work frequently prove insufficient for manufacturing teams, resulting in implementation gaps and performance inconsistencies that undermine the transition process.

Current Methodologies for Prototype Field Testing

01 Iterative prototype development methodologies

Iterative approaches to prototype development involve creating successive versions of a product, with each iteration incorporating feedback and improvements. This methodology allows for continuous refinement of the design based on testing results and user feedback. The process typically includes planning, designing, implementing, testing, and evaluating phases that repeat until the final product meets all requirements. This approach reduces risks by identifying issues early in the development cycle.- Iterative prototype development methodologies: Iterative approaches to prototype development involve creating successive versions of a product, with each iteration incorporating feedback and improvements from the previous version. This methodology allows for continuous refinement of the design based on testing and evaluation. The process typically includes planning, designing, implementing, testing, and refining phases that are repeated until the final product meets the desired specifications and requirements.

- Software prototype development frameworks: Specialized frameworks for software prototype development streamline the creation of functional software models. These frameworks provide tools, libraries, and methodologies that accelerate the development process by offering pre-built components and standardized approaches. They enable developers to quickly create working prototypes that demonstrate key functionalities, allowing for early validation of concepts before committing to full-scale development.

- Hardware prototype development systems: Systems specifically designed for hardware prototype development facilitate the creation of physical product models. These systems include tools for design, simulation, fabrication, and testing of hardware components. They often incorporate rapid prototyping technologies such as 3D printing, CNC machining, or modular assembly platforms that enable quick iteration of physical designs and validation of mechanical, electrical, or structural properties.

- Collaborative prototype development environments: Collaborative environments for prototype development enable multiple stakeholders to participate in the creation process simultaneously. These platforms provide tools for sharing designs, collecting feedback, tracking changes, and managing version control across distributed teams. They facilitate communication between designers, engineers, product managers, and end-users, ensuring that diverse perspectives are incorporated into the prototype development process.

- AI-assisted prototype development tools: Emerging tools leverage artificial intelligence to enhance the prototype development process. These technologies can automatically generate design alternatives, predict performance characteristics, identify potential issues, and optimize prototypes based on specified parameters. AI-assisted tools accelerate the development cycle by automating repetitive tasks, suggesting improvements, and helping developers explore a wider range of design possibilities than would be feasible through manual methods alone.

02 Software prototype development frameworks

Specialized frameworks for software prototype development streamline the creation of functional models before full-scale implementation. These frameworks provide tools and methodologies for rapid development of software prototypes, enabling developers to validate concepts, test user interfaces, and verify functionality. The process often includes requirement analysis, design modeling, prototype coding, and validation phases, with emphasis on code reusability and modular architecture to accelerate development cycles.Expand Specific Solutions03 Hardware prototype development systems

Systems specifically designed for hardware prototype development facilitate the creation of physical product models. These systems integrate design tools, simulation capabilities, and fabrication processes to create functional hardware prototypes. The development process typically involves conceptual design, component selection, circuit design, physical layout, assembly, and testing phases. Advanced systems may incorporate rapid prototyping technologies such as 3D printing to accelerate the creation of physical models.Expand Specific Solutions04 Collaborative prototype development platforms

Collaborative platforms enable multiple stakeholders to participate in the prototype development process simultaneously. These platforms provide shared workspaces, version control, and communication tools that facilitate cooperation between designers, engineers, and other team members regardless of their physical location. The collaborative approach enhances the development process by incorporating diverse perspectives, reducing communication barriers, and accelerating decision-making through real-time feedback and iteration.Expand Specific Solutions05 Automated prototype testing and validation methods

Automated methods for testing and validating prototypes ensure that developed models meet specified requirements and performance criteria. These methods incorporate automated test scripts, simulation environments, and performance analysis tools to evaluate prototype functionality under various conditions. The validation process typically includes functional testing, performance testing, usability assessment, and compliance verification. Automation reduces the time and resources required for comprehensive testing while improving the consistency and reliability of test results.Expand Specific Solutions

Leading Organizations in Prototype Commercialization

The prototype development landscape from lab bench to field trials is currently in a growth phase, with an estimated market size of $15-20 billion annually. The industry is characterized by a mix of established players and emerging innovators across multiple sectors. Companies like Robert Bosch GmbH, Texas Instruments, and Microsoft lead with mature development pipelines and extensive field testing capabilities, while research institutions such as MIT contribute cutting-edge innovations. The technical maturity varies significantly across sectors, with automotive (Nissan, AVL List) and industrial automation (Schaeffler, Thales) demonstrating advanced capabilities. Defense contractors and medical technology firms (Cincinnati Children's Hospital) are rapidly advancing their prototype-to-field methodologies, creating a competitive ecosystem that balances established processes with emerging agile development approaches.

Robert Bosch GmbH

Technical Solution: Bosch employs a comprehensive prototype development methodology that bridges laboratory research with field implementation through their "Fast Track Prototyping" framework. This approach integrates rapid prototyping technologies with simulation tools to accelerate the transition from concept to field-ready solutions. Their methodology includes virtual validation environments where digital twins of physical prototypes are tested under simulated real-world conditions before physical prototyping begins. Bosch's hardware-in-the-loop (HIL) testing platforms allow for component testing in simulated environments, reducing development cycles by approximately 30%. Their modular prototype architecture enables parallel development of subsystems, with standardized interfaces facilitating integration. Field trials are conducted using their "Graduated Deployment" strategy, where prototypes are incrementally exposed to increasingly complex real-world scenarios, with telemetry systems collecting performance data for continuous refinement.

Strengths: Bosch's extensive global testing facilities and established relationships with industry partners enable comprehensive field trials across diverse environments. Their integrated development ecosystem allows seamless transition between virtual and physical prototyping. Weaknesses: The high investment required for their comprehensive approach may be prohibitive for smaller projects, and their highly structured methodology can sometimes reduce flexibility for radical innovation.

AVL List GmbH

Technical Solution: AVL has developed a sophisticated prototype development framework specifically tailored for powertrain and vehicle technologies called "Integrated and Open Development Platform" (IODP). This platform bridges laboratory research and field implementation through a systematic approach that combines virtual simulation with physical testing. AVL's methodology incorporates model-based systems engineering (MBSE) principles to create digital representations of systems before physical prototyping begins. Their X-in-the-Loop approach enables continuous validation throughout the development process, with components tested in increasingly complex environments. AVL's prototype development includes advanced rapid prototyping facilities that can produce functional components within 48 hours, significantly reducing iteration cycles. Their field trial methodology employs instrumented test vehicles equipped with comprehensive data acquisition systems that can capture over 1,000 parameters simultaneously, providing rich datasets for performance analysis and optimization.

Strengths: AVL's specialized expertise in powertrain and vehicle technologies provides deep domain knowledge for prototype development in these areas. Their extensive testing infrastructure includes climate chambers, altitude simulation, and proving grounds that enable comprehensive validation under diverse conditions. Weaknesses: Their solutions are primarily optimized for automotive applications, potentially limiting transferability to other industries. The sophisticated tools and methodologies require significant expertise to utilize effectively.

Key Technical Innovations in Prototype Scaling

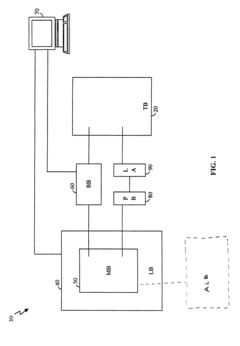

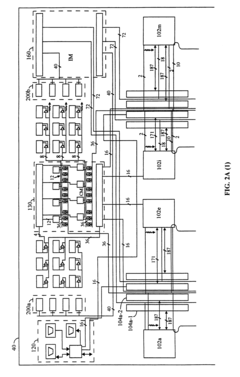

Prototype development system and method

PatentInactiveUS6618842B2

Innovation

- A prototype development system combining a logic board with re-programmable integrated circuits and a mezzanine board with dedicated interconnect structures, allowing for rapid reconfiguration and modification by re-fabricating the mezzanine board.

Risk Management Strategies for Field Trials

Field trials represent a critical transition phase in prototype development, where theoretical concepts and laboratory successes face real-world conditions. Effective risk management during this phase is essential for protecting investments, ensuring data validity, and maintaining stakeholder confidence. A comprehensive risk management framework for field trials should begin with systematic risk identification through cross-functional team assessments, historical data analysis, and structured brainstorming sessions.

Risk categorization provides organizational clarity, typically dividing concerns into technical risks (equipment failures, performance inconsistencies), environmental risks (weather conditions, terrain challenges), regulatory risks (compliance issues, permit delays), and operational risks (logistics failures, resource constraints). Each identified risk must undergo quantitative assessment using probability-impact matrices to prioritize mitigation efforts effectively.

Preventive strategies form the first line of defense in risk management. These include redundant systems implementation for critical components, comprehensive training programs for field personnel, and detailed contingency planning. Environmental monitoring systems can provide early warnings of changing conditions that might affect trial outcomes, while regular equipment maintenance protocols reduce the likelihood of technical failures.

Responsive measures must be established for when preventive strategies prove insufficient. These include clear escalation procedures with defined thresholds for intervention, rapid response teams with specialized expertise, and adaptive testing protocols that can accommodate unexpected field conditions. Documentation systems should capture not only successes but also failures and near-misses to inform future risk assessments.

Stakeholder communication represents a frequently overlooked aspect of field trial risk management. Regular updates to investors, regulatory bodies, and internal teams help manage expectations and maintain confidence even when challenges arise. Transparency about potential risks and mitigation strategies builds credibility and demonstrates professional foresight.

Financial risk management tools such as staged funding releases tied to milestone achievements, insurance coverage for specific field trial risks, and contingency budgets for unexpected challenges provide fiscal protection. These mechanisms ensure that financial resources remain available throughout the trial period despite unforeseen complications.

Post-trial analysis completes the risk management cycle, with structured debriefing sessions, comprehensive documentation of risk events and responses, and integration of lessons learned into future trial designs. This continuous improvement approach ensures that risk management strategies evolve alongside technological advancements and changing field conditions.

Risk categorization provides organizational clarity, typically dividing concerns into technical risks (equipment failures, performance inconsistencies), environmental risks (weather conditions, terrain challenges), regulatory risks (compliance issues, permit delays), and operational risks (logistics failures, resource constraints). Each identified risk must undergo quantitative assessment using probability-impact matrices to prioritize mitigation efforts effectively.

Preventive strategies form the first line of defense in risk management. These include redundant systems implementation for critical components, comprehensive training programs for field personnel, and detailed contingency planning. Environmental monitoring systems can provide early warnings of changing conditions that might affect trial outcomes, while regular equipment maintenance protocols reduce the likelihood of technical failures.

Responsive measures must be established for when preventive strategies prove insufficient. These include clear escalation procedures with defined thresholds for intervention, rapid response teams with specialized expertise, and adaptive testing protocols that can accommodate unexpected field conditions. Documentation systems should capture not only successes but also failures and near-misses to inform future risk assessments.

Stakeholder communication represents a frequently overlooked aspect of field trial risk management. Regular updates to investors, regulatory bodies, and internal teams help manage expectations and maintain confidence even when challenges arise. Transparency about potential risks and mitigation strategies builds credibility and demonstrates professional foresight.

Financial risk management tools such as staged funding releases tied to milestone achievements, insurance coverage for specific field trial risks, and contingency budgets for unexpected challenges provide fiscal protection. These mechanisms ensure that financial resources remain available throughout the trial period despite unforeseen complications.

Post-trial analysis completes the risk management cycle, with structured debriefing sessions, comprehensive documentation of risk events and responses, and integration of lessons learned into future trial designs. This continuous improvement approach ensures that risk management strategies evolve alongside technological advancements and changing field conditions.

Sustainability Considerations in Prototype Development

Sustainability has emerged as a critical dimension in the prototype development journey from laboratory to field trials. The integration of sustainable practices throughout the development lifecycle not only addresses environmental concerns but also enhances economic viability and social acceptance of new technologies. When transitioning prototypes from controlled laboratory environments to real-world applications, developers must consider the environmental footprint of materials, manufacturing processes, and operational requirements.

Material selection represents a fundamental sustainability consideration, with biodegradable, recyclable, or renewable materials increasingly preferred over traditional options. The environmental impact assessment of these materials must account for extraction methods, processing requirements, and end-of-life scenarios. For instance, bioplastics derived from agricultural waste may offer significant carbon footprint reductions compared to petroleum-based alternatives, though their performance characteristics must be rigorously evaluated during prototype testing.

Energy efficiency constitutes another crucial sustainability factor in prototype development. Field trials should incorporate measurements of energy consumption under various operational conditions, enabling developers to optimize power requirements before commercial deployment. The integration of renewable energy sources, such as solar panels or kinetic energy harvesters, can further enhance sustainability profiles, particularly for prototypes intended for remote or off-grid applications.

Lifecycle analysis methodologies provide valuable frameworks for quantifying environmental impacts across the entire prototype development process. These assessments typically examine resource consumption, emissions, waste generation, and potential for circular economy integration. By conducting preliminary lifecycle analyses during early development stages, teams can identify and address sustainability concerns before significant resources are committed to field trials.

Regulatory compliance regarding environmental standards varies significantly across regions and industries, necessitating thorough understanding of applicable requirements. Forward-thinking prototype developers increasingly adopt standards that exceed minimum regulatory thresholds, anticipating more stringent future requirements and positioning their innovations advantageously in environmentally conscious markets.

Social sustainability dimensions, including community engagement and ethical considerations, have gained prominence in prototype development. Field trials offer valuable opportunities to gather stakeholder feedback regarding sustainability perceptions and expectations. This input can inform design refinements that align technological capabilities with societal values and needs, ultimately enhancing market acceptance and adoption rates.

Economic sustainability remains fundamental to successful prototype commercialization. Sustainable design choices often yield long-term cost benefits through reduced resource consumption, lower waste management expenses, and enhanced brand reputation. The challenge lies in balancing immediate development costs against these future advantages, requiring sophisticated financial modeling and strategic decision-making throughout the prototype development process.

Material selection represents a fundamental sustainability consideration, with biodegradable, recyclable, or renewable materials increasingly preferred over traditional options. The environmental impact assessment of these materials must account for extraction methods, processing requirements, and end-of-life scenarios. For instance, bioplastics derived from agricultural waste may offer significant carbon footprint reductions compared to petroleum-based alternatives, though their performance characteristics must be rigorously evaluated during prototype testing.

Energy efficiency constitutes another crucial sustainability factor in prototype development. Field trials should incorporate measurements of energy consumption under various operational conditions, enabling developers to optimize power requirements before commercial deployment. The integration of renewable energy sources, such as solar panels or kinetic energy harvesters, can further enhance sustainability profiles, particularly for prototypes intended for remote or off-grid applications.

Lifecycle analysis methodologies provide valuable frameworks for quantifying environmental impacts across the entire prototype development process. These assessments typically examine resource consumption, emissions, waste generation, and potential for circular economy integration. By conducting preliminary lifecycle analyses during early development stages, teams can identify and address sustainability concerns before significant resources are committed to field trials.

Regulatory compliance regarding environmental standards varies significantly across regions and industries, necessitating thorough understanding of applicable requirements. Forward-thinking prototype developers increasingly adopt standards that exceed minimum regulatory thresholds, anticipating more stringent future requirements and positioning their innovations advantageously in environmentally conscious markets.

Social sustainability dimensions, including community engagement and ethical considerations, have gained prominence in prototype development. Field trials offer valuable opportunities to gather stakeholder feedback regarding sustainability perceptions and expectations. This input can inform design refinements that align technological capabilities with societal values and needs, ultimately enhancing market acceptance and adoption rates.

Economic sustainability remains fundamental to successful prototype commercialization. Sustainable design choices often yield long-term cost benefits through reduced resource consumption, lower waste management expenses, and enhanced brand reputation. The challenge lies in balancing immediate development costs against these future advantages, requiring sophisticated financial modeling and strategic decision-making throughout the prototype development process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!