Thermal Management Of PV Receivers Under High-Flux Illumination

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PV Receiver Thermal Management Background and Objectives

Photovoltaic (PV) receivers operating under high-flux illumination represent a critical component in concentrated photovoltaic (CPV) systems, which have emerged as a promising technology for efficient solar energy conversion. The evolution of PV receivers has been marked by significant technological advancements since the 1970s, progressing from simple silicon-based cells to sophisticated multi-junction designs capable of achieving conversion efficiencies exceeding 40% under concentrated sunlight.

The fundamental challenge in high-flux PV systems stems from the thermal management requirements that arise when solar radiation is concentrated at levels ranging from 100 to 1000 suns or higher. This concentration, while beneficial for increasing electrical output per unit area of semiconductor material, introduces substantial thermal loads that must be effectively managed to maintain optimal cell performance and prevent degradation.

Historical trends indicate a continuous push toward higher concentration ratios to improve economic viability, with corresponding advances in thermal management solutions. Early systems relied primarily on passive cooling techniques, while contemporary designs incorporate sophisticated active cooling mechanisms including microchannels, heat pipes, and phase-change materials to handle heat fluxes that can exceed 100 W/cm².

The primary technical objective in this domain is to develop thermal management solutions that can maintain PV cell temperatures below critical thresholds (typically 80-100°C for silicon-based cells and 150-170°C for multi-junction cells) while operating under high-flux conditions. This temperature control is essential as conversion efficiency decreases approximately 0.25-0.5% per degree Celsius increase above optimal operating temperatures.

Secondary objectives include minimizing parasitic power consumption of cooling systems, ensuring uniform temperature distribution across the receiver to prevent thermal stress and hot spots, and developing solutions that remain cost-effective at commercial scale. The integration of thermal management with electrical design considerations presents additional challenges, particularly regarding electrical isolation and interconnection reliability under thermal cycling.

Recent technological trajectories point toward hybrid approaches that combine multiple cooling mechanisms and increasingly sophisticated thermal interface materials. The development of these solutions is driven by the broader industry goal of achieving levelized cost of electricity (LCOE) parity with conventional generation technologies, which requires both high efficiency and long-term reliability under extreme operating conditions.

The convergence of advanced materials science, computational fluid dynamics modeling, and precision manufacturing techniques has accelerated innovation in this field, with particular emphasis on solutions that can be deployed in diverse geographical and climatic conditions. This technological evolution continues to push the boundaries of what is possible in solar energy conversion, with thermal management remaining a critical enabler for next-generation high-concentration photovoltaic systems.

The fundamental challenge in high-flux PV systems stems from the thermal management requirements that arise when solar radiation is concentrated at levels ranging from 100 to 1000 suns or higher. This concentration, while beneficial for increasing electrical output per unit area of semiconductor material, introduces substantial thermal loads that must be effectively managed to maintain optimal cell performance and prevent degradation.

Historical trends indicate a continuous push toward higher concentration ratios to improve economic viability, with corresponding advances in thermal management solutions. Early systems relied primarily on passive cooling techniques, while contemporary designs incorporate sophisticated active cooling mechanisms including microchannels, heat pipes, and phase-change materials to handle heat fluxes that can exceed 100 W/cm².

The primary technical objective in this domain is to develop thermal management solutions that can maintain PV cell temperatures below critical thresholds (typically 80-100°C for silicon-based cells and 150-170°C for multi-junction cells) while operating under high-flux conditions. This temperature control is essential as conversion efficiency decreases approximately 0.25-0.5% per degree Celsius increase above optimal operating temperatures.

Secondary objectives include minimizing parasitic power consumption of cooling systems, ensuring uniform temperature distribution across the receiver to prevent thermal stress and hot spots, and developing solutions that remain cost-effective at commercial scale. The integration of thermal management with electrical design considerations presents additional challenges, particularly regarding electrical isolation and interconnection reliability under thermal cycling.

Recent technological trajectories point toward hybrid approaches that combine multiple cooling mechanisms and increasingly sophisticated thermal interface materials. The development of these solutions is driven by the broader industry goal of achieving levelized cost of electricity (LCOE) parity with conventional generation technologies, which requires both high efficiency and long-term reliability under extreme operating conditions.

The convergence of advanced materials science, computational fluid dynamics modeling, and precision manufacturing techniques has accelerated innovation in this field, with particular emphasis on solutions that can be deployed in diverse geographical and climatic conditions. This technological evolution continues to push the boundaries of what is possible in solar energy conversion, with thermal management remaining a critical enabler for next-generation high-concentration photovoltaic systems.

Market Analysis for High-Flux PV Applications

The high-flux photovoltaic (PV) market represents a specialized but rapidly growing segment within the broader solar energy industry. Concentrated photovoltaic (CPV) systems, which utilize optical elements to focus sunlight onto small, high-efficiency PV cells, constitute the primary application area for high-flux PV receivers. The global CPV market was valued at approximately $372 million in 2022 and is projected to grow at a compound annual growth rate of 12.3% through 2030, driven by increasing demand for higher efficiency solar solutions.

The market for high-flux PV applications can be segmented into utility-scale power generation, industrial applications, and specialized deployments such as space power systems. Utility-scale installations currently dominate the market share, accounting for over 60% of deployments, particularly in regions with high direct normal irradiance (DNI) such as the southwestern United States, Spain, Australia, and parts of the Middle East and North Africa.

Industrial applications represent the fastest-growing segment, with a projected growth rate of 15.7% annually. This includes manufacturing facilities seeking to reduce carbon footprints while maintaining high energy density requirements, and process heat applications where the thermal management capabilities of high-flux systems provide dual benefits of electricity and heat generation.

Market drivers for high-flux PV technologies include increasing pressure for renewable energy adoption, rising efficiency requirements, and the growing economic viability of concentrated solar technologies. The levelized cost of electricity (LCOE) for high-flux PV systems has decreased by approximately 38% over the past decade, making these systems increasingly competitive with conventional PV in high-DNI regions.

Key market challenges include the significant initial capital expenditure, which remains 30-40% higher than conventional PV systems, and the technical complexity of thermal management systems that are essential for maintaining cell efficiency and longevity under concentrated illumination. The market has responded with increased R&D investment, which grew from $89 million in 2018 to $143 million in 2022, focused specifically on thermal management solutions.

Customer requirements are evolving toward integrated systems that maximize both electrical and thermal energy capture. End-users increasingly demand solutions with simplified maintenance requirements, longer operational lifetimes (25+ years), and enhanced reliability under variable environmental conditions. This has created market opportunities for advanced thermal management technologies that can maintain optimal operating temperatures while minimizing system complexity and cost.

The market for high-flux PV applications can be segmented into utility-scale power generation, industrial applications, and specialized deployments such as space power systems. Utility-scale installations currently dominate the market share, accounting for over 60% of deployments, particularly in regions with high direct normal irradiance (DNI) such as the southwestern United States, Spain, Australia, and parts of the Middle East and North Africa.

Industrial applications represent the fastest-growing segment, with a projected growth rate of 15.7% annually. This includes manufacturing facilities seeking to reduce carbon footprints while maintaining high energy density requirements, and process heat applications where the thermal management capabilities of high-flux systems provide dual benefits of electricity and heat generation.

Market drivers for high-flux PV technologies include increasing pressure for renewable energy adoption, rising efficiency requirements, and the growing economic viability of concentrated solar technologies. The levelized cost of electricity (LCOE) for high-flux PV systems has decreased by approximately 38% over the past decade, making these systems increasingly competitive with conventional PV in high-DNI regions.

Key market challenges include the significant initial capital expenditure, which remains 30-40% higher than conventional PV systems, and the technical complexity of thermal management systems that are essential for maintaining cell efficiency and longevity under concentrated illumination. The market has responded with increased R&D investment, which grew from $89 million in 2018 to $143 million in 2022, focused specifically on thermal management solutions.

Customer requirements are evolving toward integrated systems that maximize both electrical and thermal energy capture. End-users increasingly demand solutions with simplified maintenance requirements, longer operational lifetimes (25+ years), and enhanced reliability under variable environmental conditions. This has created market opportunities for advanced thermal management technologies that can maintain optimal operating temperatures while minimizing system complexity and cost.

Current Thermal Management Challenges in Concentrated PV

Concentrated Photovoltaic (CPV) systems face significant thermal management challenges due to the high flux illumination conditions they operate under. These systems typically concentrate sunlight by factors of 300-1000 times onto small receiver areas, generating substantial thermal loads that must be effectively managed. Current CPV receivers experience operating temperatures that can exceed 80-100°C under normal conditions, significantly reducing cell efficiency and accelerating degradation mechanisms.

The primary challenge stems from the fundamental nature of photovoltaic conversion - only a portion of incident solar energy (typically 25-40% for multi-junction cells) is converted to electricity, while the remainder is transformed into heat. This heat flux can reach 30-50 W/cm², creating thermal gradients that induce mechanical stress and potential failure modes in the receiver assembly.

Material interface issues present another critical challenge. The thermal expansion coefficient mismatch between different materials in the receiver stack (semiconductor, substrate, heat spreader, and heat sink) creates stress concentrations during thermal cycling. These stresses can lead to delamination, cracking, or solder joint failures, particularly at the cell-to-substrate interface where heat transfer is most critical.

Heat dissipation pathways in current designs often rely on passive cooling techniques that become inadequate at high concentration ratios. The thermal resistance between the cell junction and ambient environment creates bottlenecks that limit heat extraction rates. This is particularly problematic in densely packed receiver arrays where mutual heating effects compound the thermal management challenge.

Spatial non-uniformity of illumination creates localized hot spots that can exceed the average temperature by 15-30°C. These temperature gradients not only reduce overall efficiency but create reliability concerns as thermally-induced degradation accelerates exponentially with temperature according to Arrhenius relationships.

Current cooling technologies face practical limitations in field deployment. Active cooling systems using liquid circulation require pumping power that parasitically reduces system efficiency, while also introducing reliability concerns related to leakage, corrosion, and maintenance. Passive approaches using heat sinks and thermal spreaders struggle to maintain acceptable temperatures at high concentration ratios without becoming prohibitively large or expensive.

Cost-effectiveness remains a persistent challenge, as thermal management solutions must balance performance with economic viability. Advanced cooling technologies like microchannel heat sinks, phase change materials, or jet impingement cooling show promising thermal performance but often at costs that undermine the economic proposition of CPV systems in competitive energy markets.

The primary challenge stems from the fundamental nature of photovoltaic conversion - only a portion of incident solar energy (typically 25-40% for multi-junction cells) is converted to electricity, while the remainder is transformed into heat. This heat flux can reach 30-50 W/cm², creating thermal gradients that induce mechanical stress and potential failure modes in the receiver assembly.

Material interface issues present another critical challenge. The thermal expansion coefficient mismatch between different materials in the receiver stack (semiconductor, substrate, heat spreader, and heat sink) creates stress concentrations during thermal cycling. These stresses can lead to delamination, cracking, or solder joint failures, particularly at the cell-to-substrate interface where heat transfer is most critical.

Heat dissipation pathways in current designs often rely on passive cooling techniques that become inadequate at high concentration ratios. The thermal resistance between the cell junction and ambient environment creates bottlenecks that limit heat extraction rates. This is particularly problematic in densely packed receiver arrays where mutual heating effects compound the thermal management challenge.

Spatial non-uniformity of illumination creates localized hot spots that can exceed the average temperature by 15-30°C. These temperature gradients not only reduce overall efficiency but create reliability concerns as thermally-induced degradation accelerates exponentially with temperature according to Arrhenius relationships.

Current cooling technologies face practical limitations in field deployment. Active cooling systems using liquid circulation require pumping power that parasitically reduces system efficiency, while also introducing reliability concerns related to leakage, corrosion, and maintenance. Passive approaches using heat sinks and thermal spreaders struggle to maintain acceptable temperatures at high concentration ratios without becoming prohibitively large or expensive.

Cost-effectiveness remains a persistent challenge, as thermal management solutions must balance performance with economic viability. Advanced cooling technologies like microchannel heat sinks, phase change materials, or jet impingement cooling show promising thermal performance but often at costs that undermine the economic proposition of CPV systems in competitive energy markets.

State-of-the-Art Cooling Techniques for High-Flux PV

01 Heat dissipation systems for PV receivers

Various heat dissipation systems are employed in photovoltaic receivers to manage thermal loads and maintain optimal operating temperatures. These systems include heat sinks, cooling fins, and specialized thermal management structures that efficiently transfer heat away from critical components. Advanced designs incorporate passive cooling mechanisms that require no additional energy input, improving overall system efficiency while preventing performance degradation due to overheating.- Heat dissipation systems for PV receivers: Various heat dissipation systems are employed in photovoltaic receivers to manage thermal loads and maintain optimal operating temperatures. These systems include heat sinks, cooling fins, and specialized thermal interfaces that efficiently transfer heat away from critical components. Advanced designs incorporate passive cooling mechanisms that require no external power, improving overall system efficiency while preventing performance degradation due to overheating.

- Active cooling technologies for PV systems: Active cooling technologies utilize powered mechanisms to regulate temperature in photovoltaic receivers. These include liquid cooling systems that circulate coolants through channels or heat exchangers, forced air cooling using fans or blowers, and thermoelectric cooling devices. These active systems provide precise temperature control and can handle high heat loads, particularly beneficial for concentrated photovoltaic systems where heat generation is significant.

- Thermal management materials and coatings: Specialized materials and coatings play a crucial role in PV receiver thermal management. These include high thermal conductivity materials that efficiently transfer heat, selective absorber coatings that optimize solar absorption while minimizing heat retention, and phase change materials that absorb excess heat during peak operation. Advanced ceramic and composite materials with tailored thermal properties help maintain temperature stability across varying environmental conditions.

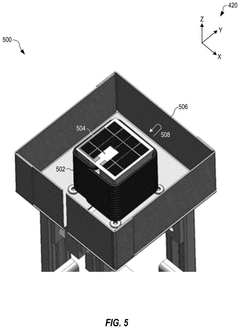

- Integrated thermal management designs: Integrated approaches to thermal management incorporate multiple cooling strategies within the PV receiver design. These holistic solutions combine structural elements with thermal functionality, such as receiver tubes with built-in cooling channels, integrated heat pipe systems, and multi-layered receiver designs with thermal barriers. Such integrated approaches optimize space utilization while providing effective temperature regulation throughout the system.

- Smart thermal management systems: Advanced PV receiver thermal management incorporates smart systems with sensors, controllers, and adaptive cooling mechanisms. These intelligent systems monitor temperature distributions in real-time, adjusting cooling parameters based on operating conditions and environmental factors. Some designs include predictive algorithms that anticipate thermal loads and preemptively adjust cooling capacity, maximizing energy production efficiency while preventing thermal damage to sensitive components.

02 Active cooling technologies for PV systems

Active cooling technologies utilize powered mechanisms to regulate temperature in photovoltaic receivers. These include liquid cooling systems, forced air circulation, and thermoelectric cooling devices that actively remove heat from PV components. Such systems can maintain optimal operating temperatures even under high solar concentration or in extreme ambient conditions, significantly improving energy conversion efficiency and extending the operational lifespan of PV receivers.Expand Specific Solutions03 Thermal interface materials and heat transfer enhancement

Specialized thermal interface materials are used to improve heat transfer between PV components and cooling systems. These materials include high thermal conductivity compounds, phase change materials, and advanced composites that minimize thermal resistance at component interfaces. By enhancing thermal contact and heat spreading, these materials ensure efficient temperature management across the entire PV receiver assembly, reducing hotspots and thermal stress.Expand Specific Solutions04 Integrated thermal management designs for concentrated PV

Concentrated photovoltaic systems require specialized integrated thermal management approaches due to their high heat flux densities. These designs incorporate multiple cooling strategies working in concert, such as hybrid passive-active systems, multi-layer thermal management structures, and receiver geometries optimized for heat dissipation. Such integrated approaches balance thermal performance with system complexity and cost considerations while maintaining high electrical output efficiency.Expand Specific Solutions05 Smart thermal management systems with monitoring and control

Advanced PV receiver thermal management incorporates smart monitoring and control systems that dynamically adjust cooling parameters based on operating conditions. These systems utilize temperature sensors, predictive algorithms, and automated control mechanisms to optimize thermal performance while minimizing energy consumption. By responding to changing environmental conditions and system demands, smart thermal management ensures consistent PV performance while maximizing overall system efficiency and reliability.Expand Specific Solutions

Leading Companies in PV Thermal Solutions

The thermal management of PV receivers under high-flux illumination market is currently in a growth phase, with increasing demand driven by concentrated solar power applications. The global market size is expanding rapidly as renewable energy adoption accelerates, estimated to reach significant scale by 2030. Technologically, the field shows varying maturity levels across different approaches. Leading companies like Abengoa Solar New Technologies and Synhelion SA have developed advanced solar thermal solutions, while research institutions such as CNRS and CEA contribute fundamental innovations. Major industrial players including Eni SpA, TotalEnergies, and Mitsubishi Heavy Industries are investing in commercialization efforts. Universities like Southeast University and Nanjing Tech University are advancing novel cooling techniques, while technology companies such as Samsung Electronics and Enphase Energy focus on system integration and efficiency improvements.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed sophisticated thermal management solutions for high-flux PV receivers based on micro-fluidic cooling technologies. Their approach utilizes multi-layered micro-channel heat sinks directly bonded to the back surface of PV cells, creating minimal thermal resistance between heat source and coolant. CEA's technology employs advanced computational fluid dynamics modeling to optimize channel geometries for uniform temperature distribution across the PV receiver surface, even under non-uniform illumination conditions typical in concentrating photovoltaic systems. The system incorporates specialized dielectric cooling fluids with enhanced thermal properties that maintain electrical isolation while providing excellent heat transfer characteristics[5][6]. CEA has also pioneered phase-change cooling techniques that utilize the latent heat of vaporization to achieve high heat flux removal (>100 W/cm²) while maintaining relatively low temperature gradients across the PV receiver. Their research includes development of nanofluid coolants with suspended nanoparticles that enhance thermal conductivity and heat transfer coefficients compared to conventional coolants.

Strengths: Extremely high heat flux removal capability; minimal temperature gradients across PV receiver surface; advanced modeling capabilities for system optimization. Weaknesses: Manufacturing complexity of micro-channel structures increases production costs; potential for channel clogging in long-term operation; higher pumping power requirements compared to simpler cooling approaches.

Abengoa Solar New Technologies SA

Technical Solution: Abengoa Solar has pioneered thermal management solutions for high-flux PV receivers in concentrated solar power (CSP) applications. Their proprietary technology combines active and passive cooling strategies, featuring a dual-fluid heat transfer system where primary coolant circuits extract heat directly from PV cells while secondary circuits manage heat distribution. The company has developed specialized heat sink designs with optimized fin geometries that enhance convective heat transfer while maintaining structural integrity under thermal cycling conditions. Abengoa's thermal management system incorporates selective optical coatings that reduce parasitic absorption of non-convertible wavelengths, thereby decreasing thermal loading on PV receivers[2]. Their integrated approach includes thermal expansion management systems that prevent mechanical stress during rapid temperature fluctuations, which is particularly important for maintaining the integrity of multi-junction cells operating under concentration ratios of 500-1000 suns.

Strengths: Extensive field experience with large-scale commercial deployments; integrated approach that addresses both thermal and mechanical challenges; proven reliability in harsh environmental conditions. Weaknesses: Higher initial capital costs compared to simpler cooling solutions; system complexity requires specialized maintenance expertise; performance may degrade in regions with limited water resources for cooling.

Critical Patents in PV Thermal Management

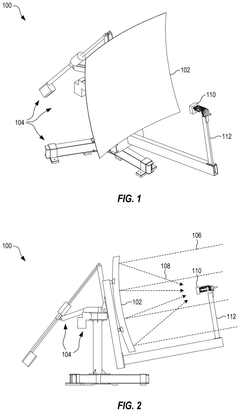

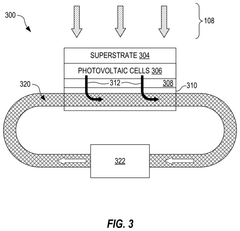

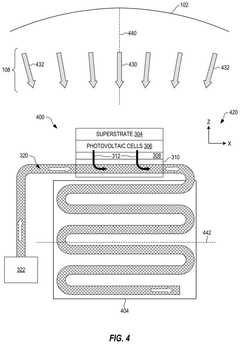

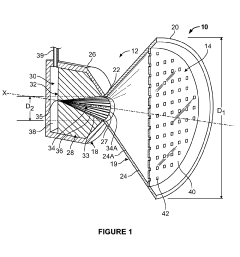

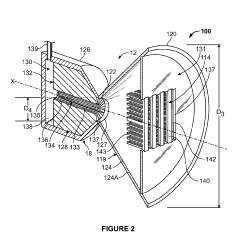

Hybrid receiver for concentrated photovoltaic-thermal power systems, and associated methods

PatentPendingUS20240339964A1

Innovation

- A hybrid concentrator photovoltaic-thermal (CPVT) system that integrates a CPV module with a thermal module acting as both a thermal receiver and a cooling system, using the same heat transfer fluid to absorb waste heat from PV cells and generate thermal power, thereby increasing efficiency by utilizing waste heat for high-temperature process applications.

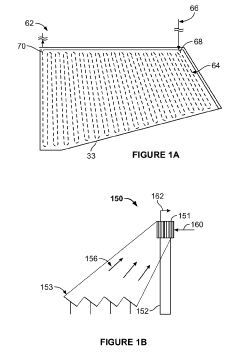

Solar receivers and methods for capturing solar energy

PatentActiveUS20190326852A1

Innovation

- A solar receiver system that integrates a thermal receiver with a photovoltaic receiver, allowing concentrated solar energy to be used for both electricity generation and heat absorption, with the photovoltaic receiver being designed to minimize heat losses through air cooling and radiative heat reduction.

Material Advancements for Heat Dissipation

Material advancements represent a critical frontier in addressing thermal management challenges for PV receivers under high-flux illumination. Recent developments in nanomaterials have shown exceptional promise, particularly carbon-based materials like graphene and carbon nanotubes which demonstrate thermal conductivity values exceeding 3000 W/m·K—significantly surpassing traditional copper (400 W/m·K) and aluminum (237 W/m·K) heat sinks.

Phase change materials (PCMs) have emerged as another innovative solution, absorbing excess heat through latent heat storage during phase transitions. Advanced metallic PCMs incorporating nanoparticles have achieved thermal conductivity improvements of 25-40% compared to their base materials, while maintaining high energy storage densities of 200-300 kJ/kg.

Ceramic-metal composites (cermets) represent a hybrid approach gaining traction in high-temperature PV applications. These materials combine the thermal stability of ceramics with the conductivity of metals, creating composites capable of withstanding temperatures above 800°C while maintaining structural integrity and heat transfer capabilities.

Microstructured surfaces have demonstrated remarkable enhancements in heat dissipation efficiency. Engineered microporous coatings with optimized pore distributions have shown increases in effective surface area by factors of 5-10, significantly improving convective heat transfer coefficients by 30-60% compared to flat surfaces.

Diamond-based materials, though expensive, offer unparalleled thermal conductivity (up to 2200 W/m·K) and are increasingly viable for concentrated PV systems where performance justifies cost. Synthetic diamond films as thin as 10-20 μm can provide substantial thermal management benefits when strategically integrated into receiver designs.

Polymer-based nanocomposites represent a cost-effective alternative, incorporating high-conductivity fillers like boron nitride or aluminum oxide into lightweight polymer matrices. Recent formulations have achieved thermal conductivities of 5-10 W/m·K—an order of magnitude improvement over standard polymers—while maintaining processing advantages and reduced weight.

Aerogel-based insulation materials are revolutionizing selective thermal management, with thermal conductivities as low as 0.015 W/m·K. These ultralight materials enable precise thermal isolation of sensitive components while directing heat flow through designated pathways, optimizing overall system thermal performance.

The integration of these advanced materials into PV receiver designs requires careful consideration of thermal expansion coefficients, long-term stability under cyclic thermal loading, and cost-effective manufacturing processes. Multi-material approaches that strategically combine these innovations are showing the most promise for next-generation high-flux PV thermal management solutions.

Phase change materials (PCMs) have emerged as another innovative solution, absorbing excess heat through latent heat storage during phase transitions. Advanced metallic PCMs incorporating nanoparticles have achieved thermal conductivity improvements of 25-40% compared to their base materials, while maintaining high energy storage densities of 200-300 kJ/kg.

Ceramic-metal composites (cermets) represent a hybrid approach gaining traction in high-temperature PV applications. These materials combine the thermal stability of ceramics with the conductivity of metals, creating composites capable of withstanding temperatures above 800°C while maintaining structural integrity and heat transfer capabilities.

Microstructured surfaces have demonstrated remarkable enhancements in heat dissipation efficiency. Engineered microporous coatings with optimized pore distributions have shown increases in effective surface area by factors of 5-10, significantly improving convective heat transfer coefficients by 30-60% compared to flat surfaces.

Diamond-based materials, though expensive, offer unparalleled thermal conductivity (up to 2200 W/m·K) and are increasingly viable for concentrated PV systems where performance justifies cost. Synthetic diamond films as thin as 10-20 μm can provide substantial thermal management benefits when strategically integrated into receiver designs.

Polymer-based nanocomposites represent a cost-effective alternative, incorporating high-conductivity fillers like boron nitride or aluminum oxide into lightweight polymer matrices. Recent formulations have achieved thermal conductivities of 5-10 W/m·K—an order of magnitude improvement over standard polymers—while maintaining processing advantages and reduced weight.

Aerogel-based insulation materials are revolutionizing selective thermal management, with thermal conductivities as low as 0.015 W/m·K. These ultralight materials enable precise thermal isolation of sensitive components while directing heat flow through designated pathways, optimizing overall system thermal performance.

The integration of these advanced materials into PV receiver designs requires careful consideration of thermal expansion coefficients, long-term stability under cyclic thermal loading, and cost-effective manufacturing processes. Multi-material approaches that strategically combine these innovations are showing the most promise for next-generation high-flux PV thermal management solutions.

Energy Efficiency and Sustainability Considerations

The energy efficiency of PV receivers under high-flux illumination represents a critical factor in the overall sustainability of concentrated photovoltaic (CPV) systems. As these systems operate under intense solar concentration, the thermal management strategies employed directly impact both energy conversion efficiency and long-term environmental sustainability.

Effective thermal management solutions contribute significantly to energy efficiency by maintaining optimal operating temperatures for PV cells. Research indicates that for every 1°C increase above optimal temperature, silicon-based PV cells experience approximately 0.4-0.5% efficiency loss. Under high-flux conditions where temperatures can exceed 100°C without proper cooling, this represents substantial energy conversion losses that compromise system performance.

From a sustainability perspective, the cooling methods employed must be evaluated across their complete lifecycle. Water-based cooling systems offer excellent thermal performance but raise concerns regarding water consumption in often water-scarce regions where solar installations are typically located. Passive cooling approaches utilizing phase-change materials present more sustainable alternatives, though they currently demonstrate lower thermal efficiency compared to active systems.

The embodied energy in thermal management components must also be considered within the sustainability framework. Advanced heat sink designs utilizing aluminum or copper offer superior thermal conductivity but carry significant carbon footprints from material extraction and manufacturing processes. Emerging alternatives using carbon-based nanomaterials show promise for reducing embodied energy while maintaining thermal performance.

Energy recovery systems represent a frontier in improving overall system sustainability. Hybrid PV-thermal (PVT) systems that capture and utilize waste heat for secondary applications can increase total system efficiency from approximately 20% (electrical only) to over 60% (combined thermal and electrical). This approach transforms thermal management from a necessary burden into a value-added component of the energy system.

The durability of thermal management solutions directly impacts sustainability through system longevity. Materials and components must withstand thermal cycling and environmental exposure for 20+ years to match PV panel lifespans. Premature degradation of thermal management systems not only reduces energy efficiency but also increases waste generation and replacement resource requirements.

Ultimately, the most sustainable thermal management approaches balance immediate performance needs with long-term environmental considerations, creating systems that maximize energy harvest while minimizing resource consumption throughout their operational lifetime.

Effective thermal management solutions contribute significantly to energy efficiency by maintaining optimal operating temperatures for PV cells. Research indicates that for every 1°C increase above optimal temperature, silicon-based PV cells experience approximately 0.4-0.5% efficiency loss. Under high-flux conditions where temperatures can exceed 100°C without proper cooling, this represents substantial energy conversion losses that compromise system performance.

From a sustainability perspective, the cooling methods employed must be evaluated across their complete lifecycle. Water-based cooling systems offer excellent thermal performance but raise concerns regarding water consumption in often water-scarce regions where solar installations are typically located. Passive cooling approaches utilizing phase-change materials present more sustainable alternatives, though they currently demonstrate lower thermal efficiency compared to active systems.

The embodied energy in thermal management components must also be considered within the sustainability framework. Advanced heat sink designs utilizing aluminum or copper offer superior thermal conductivity but carry significant carbon footprints from material extraction and manufacturing processes. Emerging alternatives using carbon-based nanomaterials show promise for reducing embodied energy while maintaining thermal performance.

Energy recovery systems represent a frontier in improving overall system sustainability. Hybrid PV-thermal (PVT) systems that capture and utilize waste heat for secondary applications can increase total system efficiency from approximately 20% (electrical only) to over 60% (combined thermal and electrical). This approach transforms thermal management from a necessary burden into a value-added component of the energy system.

The durability of thermal management solutions directly impacts sustainability through system longevity. Materials and components must withstand thermal cycling and environmental exposure for 20+ years to match PV panel lifespans. Premature degradation of thermal management systems not only reduces energy efficiency but also increases waste generation and replacement resource requirements.

Ultimately, the most sustainable thermal management approaches balance immediate performance needs with long-term environmental considerations, creating systems that maximize energy harvest while minimizing resource consumption throughout their operational lifetime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!