Real-time Monitoring of Building Integrity through Piezoelectrics

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Sensing for Structural Health Monitoring

Piezoelectric sensing has emerged as a promising technology for structural health monitoring (SHM) in buildings and infrastructure. This approach leverages the unique properties of piezoelectric materials, which generate an electrical charge when subjected to mechanical stress. By strategically placing piezoelectric sensors throughout a structure, engineers can continuously monitor its integrity and detect potential issues before they escalate into critical problems.

The development of piezoelectric sensing for SHM has been driven by the increasing need for real-time, accurate, and cost-effective monitoring solutions. Traditional methods of structural assessment often rely on periodic visual inspections or localized sensor deployments, which can be time-consuming, labor-intensive, and may miss subtle changes in structural behavior. Piezoelectric sensing offers a more comprehensive and dynamic approach to monitoring.

One of the key advantages of piezoelectric sensors is their ability to function both as actuators and sensors. This dual capability allows for active sensing techniques, where controlled vibrations are introduced into the structure and the resulting responses are measured. By analyzing these responses, engineers can detect changes in structural properties that may indicate damage or deterioration.

Recent advancements in piezoelectric materials and sensor design have significantly improved the sensitivity and reliability of these systems. High-performance piezoelectric ceramics and polymers have been developed, offering enhanced electromechanical coupling and durability. Additionally, innovative sensor configurations, such as piezoelectric wafer active sensors (PWAS) and interdigitated transducers, have expanded the range of applications and improved signal quality.

The integration of piezoelectric sensing with advanced data processing and analysis techniques has further enhanced its effectiveness for SHM. Machine learning algorithms and artificial intelligence are increasingly being employed to interpret the vast amounts of data generated by these sensor networks. These tools can identify patterns and anomalies that may be indicative of structural issues, enabling more accurate and timely assessments of building integrity.

As the technology continues to mature, researchers are exploring new frontiers in piezoelectric sensing for SHM. This includes the development of self-powered sensor networks that harvest energy from ambient vibrations, as well as the integration of piezoelectric sensors with other sensing modalities for more comprehensive structural monitoring. The goal is to create intelligent, autonomous monitoring systems that can provide continuous, real-time insights into the health and performance of buildings and infrastructure.

The development of piezoelectric sensing for SHM has been driven by the increasing need for real-time, accurate, and cost-effective monitoring solutions. Traditional methods of structural assessment often rely on periodic visual inspections or localized sensor deployments, which can be time-consuming, labor-intensive, and may miss subtle changes in structural behavior. Piezoelectric sensing offers a more comprehensive and dynamic approach to monitoring.

One of the key advantages of piezoelectric sensors is their ability to function both as actuators and sensors. This dual capability allows for active sensing techniques, where controlled vibrations are introduced into the structure and the resulting responses are measured. By analyzing these responses, engineers can detect changes in structural properties that may indicate damage or deterioration.

Recent advancements in piezoelectric materials and sensor design have significantly improved the sensitivity and reliability of these systems. High-performance piezoelectric ceramics and polymers have been developed, offering enhanced electromechanical coupling and durability. Additionally, innovative sensor configurations, such as piezoelectric wafer active sensors (PWAS) and interdigitated transducers, have expanded the range of applications and improved signal quality.

The integration of piezoelectric sensing with advanced data processing and analysis techniques has further enhanced its effectiveness for SHM. Machine learning algorithms and artificial intelligence are increasingly being employed to interpret the vast amounts of data generated by these sensor networks. These tools can identify patterns and anomalies that may be indicative of structural issues, enabling more accurate and timely assessments of building integrity.

As the technology continues to mature, researchers are exploring new frontiers in piezoelectric sensing for SHM. This includes the development of self-powered sensor networks that harvest energy from ambient vibrations, as well as the integration of piezoelectric sensors with other sensing modalities for more comprehensive structural monitoring. The goal is to create intelligent, autonomous monitoring systems that can provide continuous, real-time insights into the health and performance of buildings and infrastructure.

Market Analysis for Smart Building Technologies

The smart building technologies market is experiencing rapid growth, driven by increasing demand for energy efficiency, sustainability, and enhanced occupant comfort. Real-time monitoring of building integrity through piezoelectrics is a key component of this market, offering innovative solutions for structural health monitoring and predictive maintenance.

The global smart building market is projected to reach significant value in the coming years, with a compound annual growth rate (CAGR) exceeding 10%. This growth is fueled by factors such as urbanization, government initiatives for green buildings, and the need for cost-effective building management solutions. The integration of piezoelectric sensors for real-time structural monitoring is expected to contribute substantially to this market expansion.

Within the smart building ecosystem, the structural health monitoring segment, which includes piezoelectric-based solutions, is gaining traction. This technology addresses critical needs in building safety, maintenance optimization, and long-term cost reduction. The market for structural health monitoring systems in smart buildings is anticipated to grow at a CAGR of over 15% in the forecast period.

Geographically, North America and Europe are leading the adoption of smart building technologies, including piezoelectric monitoring systems. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid urbanization and increasing investments in smart city projects.

The demand for real-time building integrity monitoring is particularly strong in high-rise buildings, critical infrastructure, and historical structures. These sectors recognize the value of continuous monitoring in preventing catastrophic failures and optimizing maintenance schedules. Additionally, the insurance industry is showing interest in buildings equipped with such monitoring systems, potentially offering reduced premiums for properties with advanced structural health monitoring capabilities.

Challenges in the market include the initial high cost of implementation, the need for skilled personnel to interpret data, and concerns about data privacy and security. However, these challenges are gradually being addressed through technological advancements and the development of more user-friendly, integrated solutions.

The COVID-19 pandemic has further accelerated the adoption of smart building technologies, with an increased focus on touchless operations and remote monitoring capabilities. This trend is expected to continue, driving further innovation and market growth in the piezoelectric monitoring sector.

As sustainability becomes a key focus for building owners and operators, the ability of piezoelectric monitoring systems to contribute to energy efficiency and predictive maintenance aligns well with market demands. This technology not only enhances building safety but also supports green building initiatives by optimizing resource usage and extending the lifespan of structures.

The global smart building market is projected to reach significant value in the coming years, with a compound annual growth rate (CAGR) exceeding 10%. This growth is fueled by factors such as urbanization, government initiatives for green buildings, and the need for cost-effective building management solutions. The integration of piezoelectric sensors for real-time structural monitoring is expected to contribute substantially to this market expansion.

Within the smart building ecosystem, the structural health monitoring segment, which includes piezoelectric-based solutions, is gaining traction. This technology addresses critical needs in building safety, maintenance optimization, and long-term cost reduction. The market for structural health monitoring systems in smart buildings is anticipated to grow at a CAGR of over 15% in the forecast period.

Geographically, North America and Europe are leading the adoption of smart building technologies, including piezoelectric monitoring systems. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid urbanization and increasing investments in smart city projects.

The demand for real-time building integrity monitoring is particularly strong in high-rise buildings, critical infrastructure, and historical structures. These sectors recognize the value of continuous monitoring in preventing catastrophic failures and optimizing maintenance schedules. Additionally, the insurance industry is showing interest in buildings equipped with such monitoring systems, potentially offering reduced premiums for properties with advanced structural health monitoring capabilities.

Challenges in the market include the initial high cost of implementation, the need for skilled personnel to interpret data, and concerns about data privacy and security. However, these challenges are gradually being addressed through technological advancements and the development of more user-friendly, integrated solutions.

The COVID-19 pandemic has further accelerated the adoption of smart building technologies, with an increased focus on touchless operations and remote monitoring capabilities. This trend is expected to continue, driving further innovation and market growth in the piezoelectric monitoring sector.

As sustainability becomes a key focus for building owners and operators, the ability of piezoelectric monitoring systems to contribute to energy efficiency and predictive maintenance aligns well with market demands. This technology not only enhances building safety but also supports green building initiatives by optimizing resource usage and extending the lifespan of structures.

Current Challenges in Real-time Structural Monitoring

Real-time structural monitoring faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the complexity of integrating piezoelectric sensors into existing structures without compromising their integrity. The installation process often requires careful planning and execution to ensure that the sensors are placed in optimal locations for data collection while minimizing any potential weakening of the structure.

Data management and processing present another major challenge. The continuous stream of data from multiple sensors across a building generates an enormous volume of information. This big data scenario necessitates robust storage systems and advanced analytics capabilities to process and interpret the data in real-time. The sheer quantity of data can overwhelm traditional monitoring systems, leading to delays in analysis and potential missed warning signs.

The reliability and durability of piezoelectric sensors in harsh environmental conditions pose additional concerns. Structures are exposed to various weather conditions, temperature fluctuations, and mechanical stresses. Ensuring that the sensors remain functional and accurate over extended periods without frequent maintenance or replacement is crucial for the long-term viability of real-time monitoring systems.

Power supply and energy efficiency are critical factors that need addressing. While piezoelectric materials can generate small amounts of electricity, powering an entire network of sensors and their associated data transmission systems requires careful energy management. Developing low-power sensors and efficient energy harvesting techniques is essential to create self-sustaining monitoring systems.

The interpretation of sensor data and the development of accurate predictive models remain challenging. Structural behavior is complex and influenced by numerous factors. Creating algorithms that can reliably distinguish between normal structural movements and potentially dangerous deformations requires sophisticated modeling and machine learning techniques. False alarms or missed detections can have serious consequences, making the refinement of these models a critical ongoing challenge.

Standardization and interoperability issues also hinder the widespread adoption of real-time monitoring systems. Different manufacturers may use proprietary technologies and data formats, making it difficult to integrate various components into a cohesive system. Establishing industry-wide standards for sensor communication protocols and data formats is necessary to ensure compatibility and facilitate the development of comprehensive monitoring solutions.

Lastly, the cost-effectiveness of implementing and maintaining real-time monitoring systems remains a significant barrier for many building owners and operators. The initial investment in sensors, data processing infrastructure, and specialized software can be substantial. Demonstrating a clear return on investment through improved safety, reduced maintenance costs, and extended structural lifespan is crucial for wider adoption of these technologies.

Data management and processing present another major challenge. The continuous stream of data from multiple sensors across a building generates an enormous volume of information. This big data scenario necessitates robust storage systems and advanced analytics capabilities to process and interpret the data in real-time. The sheer quantity of data can overwhelm traditional monitoring systems, leading to delays in analysis and potential missed warning signs.

The reliability and durability of piezoelectric sensors in harsh environmental conditions pose additional concerns. Structures are exposed to various weather conditions, temperature fluctuations, and mechanical stresses. Ensuring that the sensors remain functional and accurate over extended periods without frequent maintenance or replacement is crucial for the long-term viability of real-time monitoring systems.

Power supply and energy efficiency are critical factors that need addressing. While piezoelectric materials can generate small amounts of electricity, powering an entire network of sensors and their associated data transmission systems requires careful energy management. Developing low-power sensors and efficient energy harvesting techniques is essential to create self-sustaining monitoring systems.

The interpretation of sensor data and the development of accurate predictive models remain challenging. Structural behavior is complex and influenced by numerous factors. Creating algorithms that can reliably distinguish between normal structural movements and potentially dangerous deformations requires sophisticated modeling and machine learning techniques. False alarms or missed detections can have serious consequences, making the refinement of these models a critical ongoing challenge.

Standardization and interoperability issues also hinder the widespread adoption of real-time monitoring systems. Different manufacturers may use proprietary technologies and data formats, making it difficult to integrate various components into a cohesive system. Establishing industry-wide standards for sensor communication protocols and data formats is necessary to ensure compatibility and facilitate the development of comprehensive monitoring solutions.

Lastly, the cost-effectiveness of implementing and maintaining real-time monitoring systems remains a significant barrier for many building owners and operators. The initial investment in sensors, data processing infrastructure, and specialized software can be substantial. Demonstrating a clear return on investment through improved safety, reduced maintenance costs, and extended structural lifespan is crucial for wider adoption of these technologies.

Existing Piezoelectric-based Monitoring Solutions

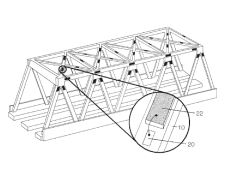

01 Piezoelectric sensors for structural health monitoring

Piezoelectric sensors are used to monitor the integrity of buildings and structures. These sensors can detect vibrations, stress, and strain in real-time, providing valuable data on the structural health of a building. By analyzing the data from these sensors, engineers can identify potential issues and take preventive measures to maintain building integrity.- Piezoelectric sensors for structural health monitoring: Piezoelectric sensors are used to monitor the integrity of buildings and structures. These sensors can detect vibrations, stress, and strain in real-time, providing valuable data on the structural health of a building. This technology allows for early detection of potential issues and helps in maintaining the overall integrity of the structure.

- Integration of piezoelectric materials in building components: Piezoelectric materials are incorporated into various building components such as walls, floors, and foundations. This integration allows for continuous monitoring of the building's structural integrity and can also be used for energy harvesting purposes. The piezoelectric elements can generate electrical signals in response to mechanical stress, providing valuable data on the building's condition.

- Data analysis and interpretation for building integrity assessment: Advanced algorithms and data analysis techniques are employed to interpret the signals from piezoelectric sensors. These methods help in assessing the structural health of buildings, identifying potential weaknesses, and predicting maintenance needs. Machine learning and artificial intelligence are often used to process the large amounts of data generated by piezoelectric monitoring systems.

- Wireless sensor networks for building monitoring: Wireless sensor networks utilizing piezoelectric technology are deployed throughout buildings to monitor structural integrity. These networks allow for real-time data collection and transmission, enabling remote monitoring and analysis of building health. The wireless nature of these systems makes them easy to install and maintain, especially in existing structures.

- Piezoelectric-based early warning systems for structural failures: Early warning systems based on piezoelectric sensors are developed to detect and alert about potential structural failures in buildings. These systems can identify subtle changes in building behavior that may indicate impending issues, allowing for proactive maintenance and potentially preventing catastrophic failures. The systems often include alert mechanisms to notify building managers or safety personnel of detected anomalies.

02 Integration of piezoelectric materials in building components

Piezoelectric materials can be integrated into various building components such as walls, floors, and beams. This integration allows for continuous monitoring of the building's structural integrity. The piezoelectric elements can generate electrical signals in response to mechanical stress, providing real-time data on the building's condition and potential weaknesses.Expand Specific Solutions03 Data analysis and interpretation for building integrity assessment

Advanced data analysis techniques are employed to interpret the signals from piezoelectric sensors in buildings. These methods can include machine learning algorithms, pattern recognition, and statistical analysis to identify trends and anomalies in the building's structural behavior. This analysis helps in predicting potential failures and optimizing maintenance schedules.Expand Specific Solutions04 Wireless sensor networks for large-scale building monitoring

Wireless sensor networks utilizing piezoelectric technology are developed for monitoring large-scale buildings and infrastructure. These networks allow for comprehensive coverage of the entire structure, with multiple sensors communicating data to a central system. This approach enables efficient monitoring of complex structures and early detection of potential integrity issues.Expand Specific Solutions05 Energy harvesting from building vibrations for self-powered monitoring

Piezoelectric materials are used to harvest energy from natural building vibrations. This energy can power the monitoring sensors and wireless communication systems, creating self-sustaining monitoring networks. This approach reduces the need for external power sources and enables long-term, maintenance-free operation of building integrity monitoring systems.Expand Specific Solutions

Key Players in Piezoelectric Sensor Industry

The real-time monitoring of building integrity through piezoelectrics is an emerging field in structural health monitoring, currently in its early development stage. The market size is growing, driven by increasing concerns about infrastructure safety and the need for proactive maintenance. While the technology shows promise, its maturity level varies across applications. Leading players like University of Houston, Airbus Group, and Tsinghua University are advancing research, while companies such as DuPont and Robert Bosch GmbH are exploring commercial applications. The involvement of diverse institutions, from academia to industry giants, indicates a competitive landscape with significant potential for innovation and market expansion in the coming years.

University of Houston

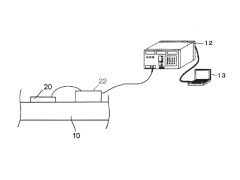

Technical Solution: The University of Houston has developed an advanced piezoelectric-based system for real-time monitoring of building integrity. Their approach utilizes a network of piezoelectric sensors strategically placed throughout the building structure. These sensors detect minute changes in stress and strain, converting mechanical energy into electrical signals. The system employs machine learning algorithms to analyze the data in real-time, identifying patterns that may indicate structural weaknesses or potential failures. Additionally, they have integrated wireless communication technology to enable remote monitoring and alert systems[1][3]. The university has also pioneered the use of flexible piezoelectric materials that can be easily retrofitted to existing structures, enhancing the system's adaptability[5].

Strengths: Highly sensitive detection of structural changes, real-time data analysis, and remote monitoring capabilities. Weaknesses: May require significant initial investment for installation and calibration in large structures.

Airbus Group Ltd.

Technical Solution: Airbus Group has adapted its aerospace expertise to develop a cutting-edge piezoelectric monitoring system for building integrity. Their technology incorporates ultra-thin piezoelectric films embedded within composite materials used in building construction. These films act as both sensors and energy harvesters, powering the monitoring system itself. Airbus's system utilizes advanced signal processing techniques to filter out environmental noise and focus on critical structural data. They have also implemented a predictive maintenance model that uses historical data and AI to forecast potential structural issues before they become critical[2][4]. The system is designed to be particularly effective in high-rise buildings and structures subject to extreme weather conditions.

Strengths: Self-powered system, advanced noise filtering, and predictive maintenance capabilities. Weaknesses: May be more costly to implement in existing buildings due to the need for specialized materials.

Innovations in Piezoelectric Materials and Sensors

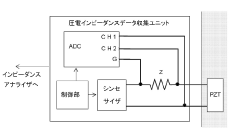

Integrity evaluation system of structure using piezoelectric impedance measurement method and integrity evaluation method of structure

PatentInactiveJP2007085733A

Innovation

- Introduce new evaluation indices such as waveform shift amount ΔS, waveform amplitude change amount ε, waveform center-of-gravity change amount ΔH, and frequency center-of-gravity change amount ΔG, which are used in conjunction with conventional indices like peak frequency shift amount ΔF and peak amplitude ratio change rate δ, to provide frequency-independent soundness and damage evaluation.

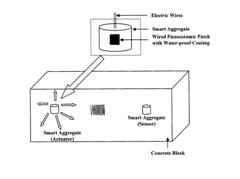

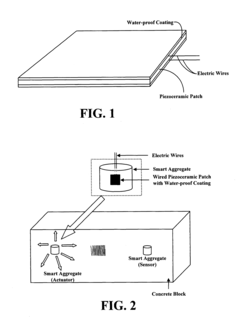

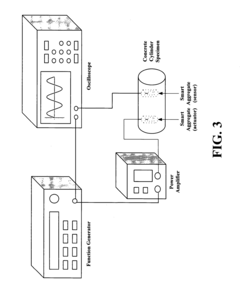

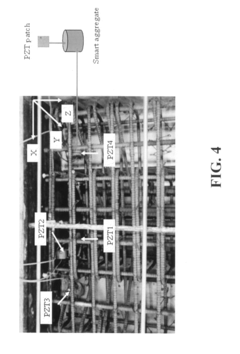

Piezoceramic-based smart aggregate for unified performance monitoring of concrete structures

PatentActiveUS7987728B2

Innovation

- A piezoelectric smart aggregate is embedded in concrete structures to monitor early-age strength and detect cracks and damage using piezoceramic transducers coated with waterproof insulating layers, allowing for non-destructive, in-situ health monitoring of concrete structures throughout their lifetime.

Regulatory Framework for Structural Safety Systems

The regulatory framework for structural safety systems plays a crucial role in ensuring the effective implementation and operation of real-time monitoring technologies, such as piezoelectric-based building integrity monitoring systems. As these advanced technologies become more prevalent in the construction industry, governments and regulatory bodies are developing comprehensive guidelines and standards to govern their use.

At the international level, organizations like the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are working to establish global standards for structural health monitoring systems. These standards aim to provide a unified approach to the design, installation, and operation of monitoring technologies, including piezoelectric sensors for real-time building integrity assessment.

In the United States, the National Institute of Standards and Technology (NIST) has been at the forefront of developing guidelines for structural health monitoring systems. Their recommendations cover various aspects, including sensor placement, data acquisition, and interpretation of results. Additionally, the American Society of Civil Engineers (ASCE) has published standards and best practices for implementing structural health monitoring systems in buildings and infrastructure.

The European Union has also made significant strides in this area, with the European Committee for Standardization (CEN) developing standards for structural health monitoring systems. These standards address issues such as sensor reliability, data management, and integration with existing building management systems.

Many countries have incorporated these international and regional standards into their national building codes and regulations. For instance, Japan, known for its advanced earthquake-resistant building technologies, has specific regulations governing the use of real-time monitoring systems in high-rise buildings and critical infrastructure.

As the technology evolves, regulatory frameworks are adapting to address new challenges and opportunities. For example, recent regulations have begun to focus on data privacy and cybersecurity concerns associated with the collection and transmission of building integrity data. These regulations aim to protect sensitive information while ensuring that the benefits of real-time monitoring can be fully realized.

Furthermore, some jurisdictions are now requiring the implementation of structural health monitoring systems in certain types of buildings or structures, particularly those deemed critical or high-risk. This trend is likely to continue as the technology becomes more cost-effective and its benefits become more widely recognized.

In conclusion, the regulatory framework for structural safety systems, including real-time monitoring through piezoelectrics, is a dynamic and evolving field. As technology advances and our understanding of building performance improves, we can expect these regulations to become increasingly sophisticated, ensuring that structural health monitoring systems contribute effectively to building safety and resilience.

At the international level, organizations like the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are working to establish global standards for structural health monitoring systems. These standards aim to provide a unified approach to the design, installation, and operation of monitoring technologies, including piezoelectric sensors for real-time building integrity assessment.

In the United States, the National Institute of Standards and Technology (NIST) has been at the forefront of developing guidelines for structural health monitoring systems. Their recommendations cover various aspects, including sensor placement, data acquisition, and interpretation of results. Additionally, the American Society of Civil Engineers (ASCE) has published standards and best practices for implementing structural health monitoring systems in buildings and infrastructure.

The European Union has also made significant strides in this area, with the European Committee for Standardization (CEN) developing standards for structural health monitoring systems. These standards address issues such as sensor reliability, data management, and integration with existing building management systems.

Many countries have incorporated these international and regional standards into their national building codes and regulations. For instance, Japan, known for its advanced earthquake-resistant building technologies, has specific regulations governing the use of real-time monitoring systems in high-rise buildings and critical infrastructure.

As the technology evolves, regulatory frameworks are adapting to address new challenges and opportunities. For example, recent regulations have begun to focus on data privacy and cybersecurity concerns associated with the collection and transmission of building integrity data. These regulations aim to protect sensitive information while ensuring that the benefits of real-time monitoring can be fully realized.

Furthermore, some jurisdictions are now requiring the implementation of structural health monitoring systems in certain types of buildings or structures, particularly those deemed critical or high-risk. This trend is likely to continue as the technology becomes more cost-effective and its benefits become more widely recognized.

In conclusion, the regulatory framework for structural safety systems, including real-time monitoring through piezoelectrics, is a dynamic and evolving field. As technology advances and our understanding of building performance improves, we can expect these regulations to become increasingly sophisticated, ensuring that structural health monitoring systems contribute effectively to building safety and resilience.

Energy Harvesting Potential of Piezoelectric Sensors

Piezoelectric sensors have shown significant potential in energy harvesting applications, particularly in the context of real-time monitoring of building integrity. These sensors can convert mechanical stress or vibrations into electrical energy, offering a sustainable power source for monitoring systems. The energy harvesting capability of piezoelectric sensors is particularly advantageous in scenarios where traditional power sources are impractical or costly to implement.

In building monitoring applications, piezoelectric sensors can be strategically placed at key structural points to capture vibrations and movements. These vibrations, caused by factors such as wind, traffic, or seismic activity, can be converted into electrical energy. This harvested energy can then be used to power the sensors themselves, as well as other low-power electronic components in the monitoring system, creating a self-sustaining network of sensors.

The amount of energy that can be harvested depends on several factors, including the frequency and amplitude of vibrations, the size and efficiency of the piezoelectric material, and the overall design of the energy harvesting system. In typical building environments, the energy output may range from microwatts to milliwatts, which is sufficient for powering wireless sensor nodes and data transmission systems.

Recent advancements in piezoelectric materials and energy harvesting circuits have significantly improved the efficiency of these systems. Novel piezoelectric materials with higher coupling coefficients and improved durability have been developed, enhancing the overall energy conversion efficiency. Additionally, sophisticated power management circuits have been designed to optimize the energy extraction and storage processes, ensuring maximum utilization of the harvested energy.

The integration of energy harvesting capabilities with piezoelectric sensors offers several advantages for building integrity monitoring. It reduces or eliminates the need for battery replacements, lowering maintenance costs and environmental impact. This self-powering feature also allows for the deployment of sensors in hard-to-reach or hazardous locations within buildings, expanding the coverage and effectiveness of monitoring systems.

Furthermore, the energy harvesting potential of piezoelectric sensors aligns well with the growing trend towards smart and sustainable buildings. By providing a renewable energy source for monitoring systems, these sensors contribute to reducing the overall energy consumption of buildings while enhancing their safety and operational efficiency.

In building monitoring applications, piezoelectric sensors can be strategically placed at key structural points to capture vibrations and movements. These vibrations, caused by factors such as wind, traffic, or seismic activity, can be converted into electrical energy. This harvested energy can then be used to power the sensors themselves, as well as other low-power electronic components in the monitoring system, creating a self-sustaining network of sensors.

The amount of energy that can be harvested depends on several factors, including the frequency and amplitude of vibrations, the size and efficiency of the piezoelectric material, and the overall design of the energy harvesting system. In typical building environments, the energy output may range from microwatts to milliwatts, which is sufficient for powering wireless sensor nodes and data transmission systems.

Recent advancements in piezoelectric materials and energy harvesting circuits have significantly improved the efficiency of these systems. Novel piezoelectric materials with higher coupling coefficients and improved durability have been developed, enhancing the overall energy conversion efficiency. Additionally, sophisticated power management circuits have been designed to optimize the energy extraction and storage processes, ensuring maximum utilization of the harvested energy.

The integration of energy harvesting capabilities with piezoelectric sensors offers several advantages for building integrity monitoring. It reduces or eliminates the need for battery replacements, lowering maintenance costs and environmental impact. This self-powering feature also allows for the deployment of sensors in hard-to-reach or hazardous locations within buildings, expanding the coverage and effectiveness of monitoring systems.

Furthermore, the energy harvesting potential of piezoelectric sensors aligns well with the growing trend towards smart and sustainable buildings. By providing a renewable energy source for monitoring systems, these sensors contribute to reducing the overall energy consumption of buildings while enhancing their safety and operational efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!