Reliability of PHEV under extreme weather conditions

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV Reliability Goals

The reliability of Plug-in Hybrid Electric Vehicles (PHEVs) under extreme weather conditions is a critical aspect of their overall performance and market acceptance. As the automotive industry continues to shift towards electrification, ensuring that PHEVs can operate efficiently and dependably in various climatic conditions becomes paramount. The primary goal is to develop PHEVs that maintain their operational integrity, safety, and performance across a wide range of temperatures and weather phenomena.

One of the key reliability goals for PHEVs is to optimize battery performance in extreme temperatures. Cold weather can significantly reduce battery capacity and increase internal resistance, leading to decreased range and power output. Conversely, high temperatures can accelerate battery degradation and pose safety risks. Engineers aim to develop advanced thermal management systems that can maintain optimal battery temperature, regardless of external conditions.

Another crucial objective is to enhance the durability of PHEV components exposed to harsh weather elements. This includes improving the resilience of electrical connectors, seals, and insulation materials against moisture, ice, and corrosive substances. The goal is to prevent water ingress, electrical shorts, and degradation of critical components, ensuring long-term reliability even in challenging environments.

Improving the overall energy efficiency of PHEVs in extreme weather is also a primary focus. This involves optimizing the powertrain control strategies to balance the use of electric and combustion power sources effectively. The aim is to maintain fuel economy and electric range even when additional energy is required for cabin heating or cooling, which can significantly impact vehicle performance in extreme temperatures.

Ensuring consistent charging performance across various weather conditions is another critical reliability goal. Engineers strive to develop charging systems that can operate efficiently in both cold and hot climates, addressing issues such as reduced charging speeds in low temperatures and potential overheating during fast charging in high-temperature environments.

Safety remains paramount, and a key reliability goal is to maintain and enhance safety systems' functionality in extreme weather. This includes ensuring the effectiveness of traction control, stability systems, and regenerative braking across icy, wet, or extremely hot road conditions. Additionally, the reliability of sensors and electronic control units critical for advanced driver assistance systems (ADAS) must be guaranteed under all weather conditions.

Lastly, PHEVs must demonstrate long-term durability and maintain their performance characteristics over their entire lifecycle, regardless of the climate in which they operate. This involves extensive testing and validation processes to simulate years of operation under various extreme weather scenarios, ensuring that the vehicles can withstand repeated exposure to challenging conditions without significant degradation in performance or reliability.

One of the key reliability goals for PHEVs is to optimize battery performance in extreme temperatures. Cold weather can significantly reduce battery capacity and increase internal resistance, leading to decreased range and power output. Conversely, high temperatures can accelerate battery degradation and pose safety risks. Engineers aim to develop advanced thermal management systems that can maintain optimal battery temperature, regardless of external conditions.

Another crucial objective is to enhance the durability of PHEV components exposed to harsh weather elements. This includes improving the resilience of electrical connectors, seals, and insulation materials against moisture, ice, and corrosive substances. The goal is to prevent water ingress, electrical shorts, and degradation of critical components, ensuring long-term reliability even in challenging environments.

Improving the overall energy efficiency of PHEVs in extreme weather is also a primary focus. This involves optimizing the powertrain control strategies to balance the use of electric and combustion power sources effectively. The aim is to maintain fuel economy and electric range even when additional energy is required for cabin heating or cooling, which can significantly impact vehicle performance in extreme temperatures.

Ensuring consistent charging performance across various weather conditions is another critical reliability goal. Engineers strive to develop charging systems that can operate efficiently in both cold and hot climates, addressing issues such as reduced charging speeds in low temperatures and potential overheating during fast charging in high-temperature environments.

Safety remains paramount, and a key reliability goal is to maintain and enhance safety systems' functionality in extreme weather. This includes ensuring the effectiveness of traction control, stability systems, and regenerative braking across icy, wet, or extremely hot road conditions. Additionally, the reliability of sensors and electronic control units critical for advanced driver assistance systems (ADAS) must be guaranteed under all weather conditions.

Lastly, PHEVs must demonstrate long-term durability and maintain their performance characteristics over their entire lifecycle, regardless of the climate in which they operate. This involves extensive testing and validation processes to simulate years of operation under various extreme weather scenarios, ensuring that the vehicles can withstand repeated exposure to challenging conditions without significant degradation in performance or reliability.

Market Analysis for PHEV

The market for Plug-in Hybrid Electric Vehicles (PHEVs) has shown significant growth in recent years, driven by increasing environmental awareness, government incentives, and advancements in battery technology. However, the reliability of PHEVs under extreme weather conditions remains a critical factor influencing consumer adoption and market expansion.

In regions with harsh winters or scorching summers, the performance and reliability of PHEVs can be significantly impacted. Cold temperatures can reduce battery efficiency and range, while extreme heat can lead to accelerated battery degradation. These challenges have created a distinct market segment for PHEVs with enhanced weather resilience, particularly in areas prone to extreme climate conditions.

Consumer demand for PHEVs that maintain consistent performance across various weather conditions has been steadily increasing. This trend is especially pronounced in countries with diverse climates, such as the United States, Canada, and parts of Europe. Market research indicates that potential PHEV buyers in these regions prioritize all-weather reliability as a key factor in their purchasing decisions.

The global PHEV market is expected to continue its growth trajectory, with a particular focus on models that address extreme weather challenges. Automotive manufacturers are responding to this demand by investing in research and development to improve battery performance and thermal management systems. This has led to the emergence of new market opportunities for suppliers specializing in advanced climate control technologies for electric powertrains.

Fleet operators, particularly in regions with extreme weather patterns, represent a significant market segment for weather-resilient PHEVs. These customers require vehicles that can maintain operational efficiency and reliability regardless of environmental conditions. As a result, there is growing demand for PHEVs with robust weather adaptation features in sectors such as logistics, public transportation, and utility services.

The market analysis also reveals a correlation between consumer confidence in PHEV reliability and overall market penetration. Regions where manufacturers have successfully demonstrated the all-weather capabilities of their PHEV models have seen higher adoption rates and customer satisfaction. This underscores the importance of addressing extreme weather reliability as a key factor in expanding market share and fostering long-term growth in the PHEV sector.

As governments worldwide continue to push for electrification of transportation, the market for PHEVs with enhanced weather resilience is expected to expand further. Regulatory bodies are increasingly incorporating all-weather performance standards into their emissions and efficiency requirements, creating additional market drivers for improved PHEV reliability under extreme conditions.

In regions with harsh winters or scorching summers, the performance and reliability of PHEVs can be significantly impacted. Cold temperatures can reduce battery efficiency and range, while extreme heat can lead to accelerated battery degradation. These challenges have created a distinct market segment for PHEVs with enhanced weather resilience, particularly in areas prone to extreme climate conditions.

Consumer demand for PHEVs that maintain consistent performance across various weather conditions has been steadily increasing. This trend is especially pronounced in countries with diverse climates, such as the United States, Canada, and parts of Europe. Market research indicates that potential PHEV buyers in these regions prioritize all-weather reliability as a key factor in their purchasing decisions.

The global PHEV market is expected to continue its growth trajectory, with a particular focus on models that address extreme weather challenges. Automotive manufacturers are responding to this demand by investing in research and development to improve battery performance and thermal management systems. This has led to the emergence of new market opportunities for suppliers specializing in advanced climate control technologies for electric powertrains.

Fleet operators, particularly in regions with extreme weather patterns, represent a significant market segment for weather-resilient PHEVs. These customers require vehicles that can maintain operational efficiency and reliability regardless of environmental conditions. As a result, there is growing demand for PHEVs with robust weather adaptation features in sectors such as logistics, public transportation, and utility services.

The market analysis also reveals a correlation between consumer confidence in PHEV reliability and overall market penetration. Regions where manufacturers have successfully demonstrated the all-weather capabilities of their PHEV models have seen higher adoption rates and customer satisfaction. This underscores the importance of addressing extreme weather reliability as a key factor in expanding market share and fostering long-term growth in the PHEV sector.

As governments worldwide continue to push for electrification of transportation, the market for PHEVs with enhanced weather resilience is expected to expand further. Regulatory bodies are increasingly incorporating all-weather performance standards into their emissions and efficiency requirements, creating additional market drivers for improved PHEV reliability under extreme conditions.

PHEV Challenges in Extreme Weather

Plug-in Hybrid Electric Vehicles (PHEVs) face significant challenges when operating in extreme weather conditions, which can substantially impact their reliability and performance. These conditions, ranging from severe cold to intense heat, pose unique problems that require innovative solutions to ensure optimal functionality.

In extremely cold environments, PHEVs experience reduced battery efficiency and capacity. The chemical reactions within lithium-ion batteries slow down, leading to diminished power output and shorter electric-only driving ranges. This issue is compounded by the increased energy demand for cabin heating, which further drains the battery. Cold temperatures also affect the regenerative braking system, reducing its effectiveness and limiting energy recovery.

Conversely, in extremely hot conditions, PHEVs face different but equally challenging issues. High temperatures can accelerate battery degradation, potentially shortening the overall lifespan of the vehicle's power system. Thermal management becomes crucial, as overheating can lead to reduced performance and, in severe cases, safety concerns. The air conditioning system places additional strain on the battery, further compromising the electric range.

Extreme weather also impacts the internal combustion engine (ICE) component of PHEVs. In cold weather, engine oil thickens, increasing friction and reducing efficiency. Starting the engine in sub-zero temperatures can be problematic, potentially leading to increased wear and tear. In hot weather, the engine may be prone to overheating, especially when frequently switching between electric and ICE modes.

The charging infrastructure for PHEVs is another area affected by extreme weather. In cold climates, charging times can increase significantly, and the charging efficiency may decrease. Ice and snow accumulation on charging ports can pose safety risks and impede charging processes. In hot climates, rapid charging may be limited to prevent battery overheating, potentially inconveniencing users during long trips.

These challenges necessitate advanced engineering solutions. Improved battery thermal management systems are essential for maintaining optimal battery temperature in both hot and cold extremes. Enhanced insulation for battery packs and the development of more weather-resistant materials for critical components can mitigate some of these issues. Smart energy management systems that can adapt to extreme conditions by optimizing power distribution between the electric motor and ICE are also crucial.

Furthermore, the development of more robust charging infrastructure capable of operating efficiently in diverse weather conditions is vital. This includes weatherproofed charging stations and intelligent charging systems that can adjust charging rates based on ambient temperature and battery conditions.

In extremely cold environments, PHEVs experience reduced battery efficiency and capacity. The chemical reactions within lithium-ion batteries slow down, leading to diminished power output and shorter electric-only driving ranges. This issue is compounded by the increased energy demand for cabin heating, which further drains the battery. Cold temperatures also affect the regenerative braking system, reducing its effectiveness and limiting energy recovery.

Conversely, in extremely hot conditions, PHEVs face different but equally challenging issues. High temperatures can accelerate battery degradation, potentially shortening the overall lifespan of the vehicle's power system. Thermal management becomes crucial, as overheating can lead to reduced performance and, in severe cases, safety concerns. The air conditioning system places additional strain on the battery, further compromising the electric range.

Extreme weather also impacts the internal combustion engine (ICE) component of PHEVs. In cold weather, engine oil thickens, increasing friction and reducing efficiency. Starting the engine in sub-zero temperatures can be problematic, potentially leading to increased wear and tear. In hot weather, the engine may be prone to overheating, especially when frequently switching between electric and ICE modes.

The charging infrastructure for PHEVs is another area affected by extreme weather. In cold climates, charging times can increase significantly, and the charging efficiency may decrease. Ice and snow accumulation on charging ports can pose safety risks and impede charging processes. In hot climates, rapid charging may be limited to prevent battery overheating, potentially inconveniencing users during long trips.

These challenges necessitate advanced engineering solutions. Improved battery thermal management systems are essential for maintaining optimal battery temperature in both hot and cold extremes. Enhanced insulation for battery packs and the development of more weather-resistant materials for critical components can mitigate some of these issues. Smart energy management systems that can adapt to extreme conditions by optimizing power distribution between the electric motor and ICE are also crucial.

Furthermore, the development of more robust charging infrastructure capable of operating efficiently in diverse weather conditions is vital. This includes weatherproofed charging stations and intelligent charging systems that can adjust charging rates based on ambient temperature and battery conditions.

Current PHEV Weather Solutions

01 Battery management and monitoring systems

Advanced battery management and monitoring systems are crucial for PHEV reliability. These systems optimize battery performance, monitor state of charge, and ensure proper thermal management. They also help in predicting and preventing potential battery failures, thus enhancing the overall reliability of the vehicle.- Battery management and monitoring systems: Advanced battery management and monitoring systems are crucial for PHEV reliability. These systems optimize battery performance, monitor state of charge, and ensure proper thermal management. They also help in predicting potential issues and extending battery life, which is essential for long-term PHEV reliability.

- Hybrid powertrain control strategies: Sophisticated control strategies for hybrid powertrains are key to PHEV reliability. These strategies manage the interaction between the electric motor and internal combustion engine, optimizing power distribution, fuel efficiency, and overall vehicle performance. Advanced algorithms ensure smooth transitions between power sources and reduce wear on components.

- Regenerative braking systems: Efficient regenerative braking systems contribute significantly to PHEV reliability. These systems recover kinetic energy during deceleration and braking, converting it into electrical energy to recharge the battery. Well-designed regenerative braking systems reduce wear on conventional brake components and extend the vehicle's electric range.

- Thermal management of electric components: Effective thermal management of electric components is essential for PHEV reliability. This includes cooling systems for the battery pack, electric motor, and power electronics. Proper thermal management prevents overheating, extends component lifespan, and ensures consistent performance across various operating conditions.

- Diagnostic and prognostic systems: Advanced diagnostic and prognostic systems play a crucial role in maintaining PHEV reliability. These systems continuously monitor vehicle components, detect potential issues early, and provide predictive maintenance alerts. They help prevent unexpected failures, optimize maintenance schedules, and ensure the long-term reliability of PHEVs.

02 Powertrain control and optimization

Efficient powertrain control and optimization strategies are essential for PHEV reliability. These include advanced algorithms for seamless switching between electric and combustion modes, optimizing energy distribution, and adapting to various driving conditions. Such systems contribute to improved fuel efficiency and reduced wear on components.Expand Specific Solutions03 Diagnostic and fault detection systems

Sophisticated diagnostic and fault detection systems play a vital role in PHEV reliability. These systems continuously monitor various components, detect potential issues early, and provide timely alerts for maintenance. They help prevent major breakdowns and ensure the longevity of the vehicle's critical systems.Expand Specific Solutions04 Thermal management and cooling systems

Effective thermal management and cooling systems are crucial for maintaining PHEV reliability. These systems regulate the temperature of batteries, electric motors, and other critical components to prevent overheating and ensure optimal performance. Proper thermal management contributes to extended battery life and overall vehicle reliability.Expand Specific Solutions05 Regenerative braking and energy recovery

Advanced regenerative braking and energy recovery systems contribute to PHEV reliability by reducing wear on conventional braking components and maximizing energy efficiency. These systems capture and store kinetic energy during deceleration, which can be used to recharge the battery and extend the vehicle's electric range.Expand Specific Solutions

Key PHEV Manufacturers

The reliability of Plug-in Hybrid Electric Vehicles (PHEVs) under extreme weather conditions is a critical issue in the evolving automotive industry. The market is in a growth phase, with increasing adoption of PHEVs globally. Major players like Ford, Hyundai, Kia, and Audi are investing heavily in PHEV technology, indicating a competitive landscape. The market size is expanding, driven by environmental concerns and government incentives. However, the technology's maturity varies, with established automakers and new entrants like Chery and Great Wall Motor working to improve PHEV performance in challenging climates. Companies such as Johnson Controls and Panasonic are focusing on battery technology advancements to enhance PHEV reliability in extreme conditions, demonstrating the industry's commitment to overcoming this technical challenge.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced thermal management system for PHEVs to enhance reliability in extreme weather conditions. This system incorporates a heat pump for efficient cabin heating and battery temperature regulation. The company has also implemented a pre-conditioning feature that allows the vehicle to warm up or cool down while still connected to the charging station, reducing strain on the battery during initial operation[1]. Additionally, Ford has introduced a smart energy management system that optimizes power distribution between the electric motor and internal combustion engine based on weather conditions and driving patterns[3]. This system includes adaptive regenerative braking that adjusts its intensity according to road conditions, improving energy recovery in various weather scenarios.

Strengths: Comprehensive thermal management, energy-efficient pre-conditioning, and adaptive power distribution. Weaknesses: Potential increased system complexity and cost.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has implemented a multi-pronged approach to enhance PHEV reliability in extreme weather. Their system includes an advanced battery thermal management system that uses liquid cooling and heating to maintain optimal battery temperature across a wide range of ambient conditions[2]. Hyundai has also developed a predictive energy management system that uses real-time weather data and route information to optimize the use of electric and gasoline power[4]. The company's PHEVs feature a heat pump system that efficiently extracts heat from ambient air and electrical components to warm the cabin and battery, significantly reducing energy consumption in cold weather[5]. Furthermore, Hyundai has incorporated a winter mode that pre-heats the battery and adjusts power delivery to ensure consistent performance in freezing temperatures.

Strengths: Efficient battery thermal management, predictive energy optimization, and dedicated winter mode. Weaknesses: Potential for increased vehicle weight due to additional thermal management components.

PHEV Extreme Weather Patents

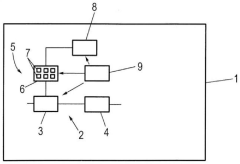

Motor vehicle and method for operating cooling device

PatentActiveCN114448174A

Innovation

- Separate the power electronic device from the first cooling cycle system, place it in the second cooling cycle system, use a lower coolant temperature than the first cooling cycle system for cooling, and use the cooling cycle system of the power battery to cool the power Electronics, reducing coolant usage and system complexity.

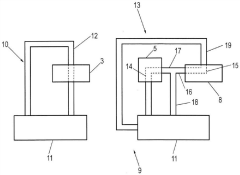

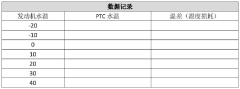

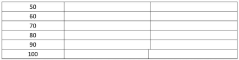

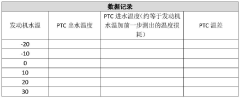

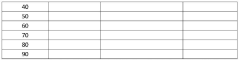

Calibration method for thermal output of passenger compartment of PHEV

PatentPendingCN117990384A

Innovation

- By measuring the engine water temperature loss and the water temperature rise that the PTC maximum power can provide, combined with the four-way valve, PTC water pump, blower, compressor, mode motor, air volume gear and other control variables, the automatic algorithm of the air conditioning controller is used to achieve rapid response And meet the heat demand to ensure that the heat source can be switched freely.

Environmental Impact of PHEV

The environmental impact of Plug-in Hybrid Electric Vehicles (PHEVs) is a crucial consideration in the broader context of sustainable transportation. PHEVs offer a promising solution to reduce greenhouse gas emissions and dependence on fossil fuels, particularly in urban environments where short-distance trips are common.

One of the primary environmental benefits of PHEVs is their ability to operate in all-electric mode for short distances, effectively eliminating tailpipe emissions during these periods. This feature is particularly valuable in densely populated urban areas, where air quality is a significant concern. By reducing local air pollution, PHEVs contribute to improved public health outcomes and decreased environmental degradation in cities.

However, the overall environmental impact of PHEVs is complex and depends on various factors, including the source of electricity used for charging. In regions where electricity is primarily generated from renewable sources such as solar, wind, or hydroelectric power, PHEVs can significantly reduce carbon emissions compared to conventional vehicles. Conversely, in areas heavily reliant on coal or other fossil fuels for electricity generation, the environmental benefits of PHEVs may be less pronounced.

The production and disposal of PHEV batteries also present environmental challenges. The mining and processing of materials like lithium, cobalt, and nickel for battery production can have significant environmental impacts, including habitat destruction and water pollution. Additionally, the energy-intensive manufacturing process of batteries contributes to the overall carbon footprint of PHEVs.

To address these concerns, ongoing research and development efforts are focused on improving battery technology, enhancing recycling processes, and developing more sustainable sourcing practices for battery materials. These advancements aim to reduce the lifecycle environmental impact of PHEVs and make them an even more attractive option for environmentally conscious consumers.

The environmental benefits of PHEVs extend beyond emissions reduction. By reducing dependence on petroleum-based fuels, PHEVs contribute to energy security and help mitigate the environmental risks associated with oil extraction and transportation. Furthermore, the integration of PHEVs into smart grid systems can potentially support the broader adoption of renewable energy sources by providing grid stabilization and energy storage capabilities.

In conclusion, while PHEVs offer significant environmental advantages over conventional vehicles, particularly in terms of reducing urban air pollution and greenhouse gas emissions, their overall environmental impact is nuanced and dependent on various factors. Continued technological advancements and the transition to cleaner electricity sources will be crucial in maximizing the environmental benefits of PHEVs in the future.

One of the primary environmental benefits of PHEVs is their ability to operate in all-electric mode for short distances, effectively eliminating tailpipe emissions during these periods. This feature is particularly valuable in densely populated urban areas, where air quality is a significant concern. By reducing local air pollution, PHEVs contribute to improved public health outcomes and decreased environmental degradation in cities.

However, the overall environmental impact of PHEVs is complex and depends on various factors, including the source of electricity used for charging. In regions where electricity is primarily generated from renewable sources such as solar, wind, or hydroelectric power, PHEVs can significantly reduce carbon emissions compared to conventional vehicles. Conversely, in areas heavily reliant on coal or other fossil fuels for electricity generation, the environmental benefits of PHEVs may be less pronounced.

The production and disposal of PHEV batteries also present environmental challenges. The mining and processing of materials like lithium, cobalt, and nickel for battery production can have significant environmental impacts, including habitat destruction and water pollution. Additionally, the energy-intensive manufacturing process of batteries contributes to the overall carbon footprint of PHEVs.

To address these concerns, ongoing research and development efforts are focused on improving battery technology, enhancing recycling processes, and developing more sustainable sourcing practices for battery materials. These advancements aim to reduce the lifecycle environmental impact of PHEVs and make them an even more attractive option for environmentally conscious consumers.

The environmental benefits of PHEVs extend beyond emissions reduction. By reducing dependence on petroleum-based fuels, PHEVs contribute to energy security and help mitigate the environmental risks associated with oil extraction and transportation. Furthermore, the integration of PHEVs into smart grid systems can potentially support the broader adoption of renewable energy sources by providing grid stabilization and energy storage capabilities.

In conclusion, while PHEVs offer significant environmental advantages over conventional vehicles, particularly in terms of reducing urban air pollution and greenhouse gas emissions, their overall environmental impact is nuanced and dependent on various factors. Continued technological advancements and the transition to cleaner electricity sources will be crucial in maximizing the environmental benefits of PHEVs in the future.

PHEV Safety Regulations

Safety regulations for Plug-in Hybrid Electric Vehicles (PHEVs) play a crucial role in ensuring the reliability and performance of these vehicles under extreme weather conditions. These regulations are designed to address the unique challenges posed by the combination of electric and conventional powertrains in PHEVs, particularly when exposed to harsh environmental factors.

One of the primary concerns addressed by PHEV safety regulations is the protection of high-voltage electrical systems from moisture and temperature extremes. Manufacturers are required to implement robust insulation and sealing measures to prevent water ingress and condensation, which could lead to short circuits or electrical failures. Additionally, regulations mandate the use of temperature-resistant materials and cooling systems to maintain optimal operating conditions for battery packs and power electronics.

Battery safety is another critical aspect covered by PHEV regulations. Extreme temperatures can significantly impact battery performance and longevity. Safety standards require manufacturers to implement advanced battery management systems that monitor and control cell temperatures, preventing overheating or excessive cooling. These systems must be capable of adjusting charging and discharging rates based on ambient conditions to maintain battery health and prevent thermal runaway.

PHEV safety regulations also address the mechanical integrity of the vehicle under extreme weather conditions. This includes requirements for enhanced structural reinforcement to withstand increased stress from thermal expansion and contraction. Manufacturers must demonstrate that critical components, such as battery enclosures and high-voltage cabling, can withstand rapid temperature changes without compromising their protective functions.

Regulations pertaining to PHEV safety systems, such as regenerative braking and traction control, are designed to ensure reliable operation in adverse weather. These systems must be able to adapt to varying road conditions, including icy or snow-covered surfaces, to maintain vehicle stability and control. Manufacturers are required to conduct extensive testing in simulated extreme weather conditions to validate the performance of these safety-critical systems.

Furthermore, PHEV safety regulations mandate the implementation of fail-safe mechanisms and redundant systems to ensure vehicle operability in the event of component failure due to extreme weather. This includes backup power systems, emergency shut-off procedures, and fault detection algorithms capable of identifying weather-related malfunctions.

In recognition of the potential for extreme weather to affect emergency response situations, PHEV safety regulations also address vehicle design features that facilitate safe rescue operations. This includes clear labeling of high-voltage components, easily accessible emergency disconnect switches, and reinforced passenger compartments designed to maintain integrity in severe weather-related accidents.

One of the primary concerns addressed by PHEV safety regulations is the protection of high-voltage electrical systems from moisture and temperature extremes. Manufacturers are required to implement robust insulation and sealing measures to prevent water ingress and condensation, which could lead to short circuits or electrical failures. Additionally, regulations mandate the use of temperature-resistant materials and cooling systems to maintain optimal operating conditions for battery packs and power electronics.

Battery safety is another critical aspect covered by PHEV regulations. Extreme temperatures can significantly impact battery performance and longevity. Safety standards require manufacturers to implement advanced battery management systems that monitor and control cell temperatures, preventing overheating or excessive cooling. These systems must be capable of adjusting charging and discharging rates based on ambient conditions to maintain battery health and prevent thermal runaway.

PHEV safety regulations also address the mechanical integrity of the vehicle under extreme weather conditions. This includes requirements for enhanced structural reinforcement to withstand increased stress from thermal expansion and contraction. Manufacturers must demonstrate that critical components, such as battery enclosures and high-voltage cabling, can withstand rapid temperature changes without compromising their protective functions.

Regulations pertaining to PHEV safety systems, such as regenerative braking and traction control, are designed to ensure reliable operation in adverse weather. These systems must be able to adapt to varying road conditions, including icy or snow-covered surfaces, to maintain vehicle stability and control. Manufacturers are required to conduct extensive testing in simulated extreme weather conditions to validate the performance of these safety-critical systems.

Furthermore, PHEV safety regulations mandate the implementation of fail-safe mechanisms and redundant systems to ensure vehicle operability in the event of component failure due to extreme weather. This includes backup power systems, emergency shut-off procedures, and fault detection algorithms capable of identifying weather-related malfunctions.

In recognition of the potential for extreme weather to affect emergency response situations, PHEV safety regulations also address vehicle design features that facilitate safe rescue operations. This includes clear labeling of high-voltage components, easily accessible emergency disconnect switches, and reinforced passenger compartments designed to maintain integrity in severe weather-related accidents.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!