Advanced Nichrome Alloys for Industrial Furnace Systems

JUL 11, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Alloy Evolution and Objectives

Nichrome alloys have been a cornerstone of industrial furnace systems for over a century, evolving significantly since their inception in the early 1900s. Initially developed as a resistance heating element, these nickel-chromium alloys have undergone continuous refinement to meet the ever-increasing demands of high-temperature applications.

The evolution of nichrome alloys can be traced through several key stages. Early compositions focused primarily on balancing nickel and chromium content to achieve optimal electrical resistance and oxidation resistance. As industrial processes became more demanding, manufacturers began incorporating additional elements such as iron, aluminum, and silicon to enhance specific properties.

In recent decades, the development of nichrome alloys has been driven by the need for materials that can withstand even higher temperatures, more corrosive environments, and longer operational lifetimes. This has led to the creation of advanced nichrome variants with carefully controlled microstructures and precise elemental compositions.

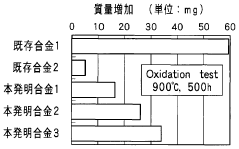

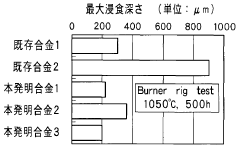

The primary objective of current research on advanced nichrome alloys for industrial furnace systems is to push the boundaries of material performance. Researchers aim to develop alloys that can operate reliably at temperatures exceeding 1300°C while maintaining excellent oxidation resistance and mechanical stability. This involves optimizing the alloy composition to achieve a delicate balance between high-temperature strength, creep resistance, and thermal stability.

Another critical objective is to enhance the longevity of nichrome components in industrial furnaces. This includes improving resistance to thermal cycling, reducing susceptibility to embrittlement, and minimizing grain growth at elevated temperatures. By extending the service life of furnace components, manufacturers can significantly reduce maintenance costs and improve overall system efficiency.

Researchers are also focusing on developing nichrome alloys with improved electrical properties. The goal is to create materials that maintain consistent resistivity over a wide temperature range, ensuring uniform heating in industrial furnaces. Additionally, efforts are being made to increase the maximum operating temperature of nichrome alloys, potentially opening up new applications in extreme environments.

Environmental considerations are becoming increasingly important in nichrome alloy development. Objectives include reducing the use of scarce or environmentally problematic elements while maintaining or improving performance characteristics. This aligns with broader industry trends towards sustainability and resource efficiency.

The evolution of nichrome alloys can be traced through several key stages. Early compositions focused primarily on balancing nickel and chromium content to achieve optimal electrical resistance and oxidation resistance. As industrial processes became more demanding, manufacturers began incorporating additional elements such as iron, aluminum, and silicon to enhance specific properties.

In recent decades, the development of nichrome alloys has been driven by the need for materials that can withstand even higher temperatures, more corrosive environments, and longer operational lifetimes. This has led to the creation of advanced nichrome variants with carefully controlled microstructures and precise elemental compositions.

The primary objective of current research on advanced nichrome alloys for industrial furnace systems is to push the boundaries of material performance. Researchers aim to develop alloys that can operate reliably at temperatures exceeding 1300°C while maintaining excellent oxidation resistance and mechanical stability. This involves optimizing the alloy composition to achieve a delicate balance between high-temperature strength, creep resistance, and thermal stability.

Another critical objective is to enhance the longevity of nichrome components in industrial furnaces. This includes improving resistance to thermal cycling, reducing susceptibility to embrittlement, and minimizing grain growth at elevated temperatures. By extending the service life of furnace components, manufacturers can significantly reduce maintenance costs and improve overall system efficiency.

Researchers are also focusing on developing nichrome alloys with improved electrical properties. The goal is to create materials that maintain consistent resistivity over a wide temperature range, ensuring uniform heating in industrial furnaces. Additionally, efforts are being made to increase the maximum operating temperature of nichrome alloys, potentially opening up new applications in extreme environments.

Environmental considerations are becoming increasingly important in nichrome alloy development. Objectives include reducing the use of scarce or environmentally problematic elements while maintaining or improving performance characteristics. This aligns with broader industry trends towards sustainability and resource efficiency.

Industrial Furnace Market Analysis

The industrial furnace market has been experiencing steady growth, driven by increasing demand across various sectors such as metallurgy, automotive, aerospace, and chemical processing. This market segment is closely tied to the overall manufacturing industry, with a particular focus on high-temperature applications that require advanced materials like nichrome alloys.

In recent years, the global industrial furnace market has shown a compound annual growth rate (CAGR) of approximately 5-6%, with projections indicating continued expansion. This growth is primarily attributed to the rising need for energy-efficient and high-performance furnace systems in emerging economies, as well as the ongoing modernization of existing facilities in developed nations.

The demand for industrial furnaces is particularly strong in regions with robust manufacturing sectors, such as Asia-Pacific, North America, and Europe. China, in particular, has emerged as a significant player in both production and consumption of industrial furnaces, driven by its expansive manufacturing base and government initiatives promoting industrial upgrading.

Within the industrial furnace market, there is a growing trend towards the adoption of advanced materials and technologies to enhance furnace performance and longevity. This is where nichrome alloys play a crucial role, offering superior heat resistance and durability in high-temperature environments. The increasing focus on energy efficiency and environmental regulations has also spurred demand for furnaces with improved thermal management and reduced emissions, further driving innovation in alloy development.

The automotive and aerospace industries are key drivers of demand for advanced industrial furnaces, as these sectors require precision heat treatment processes for manufacturing critical components. Additionally, the growing emphasis on additive manufacturing and 3D printing technologies has created new opportunities for specialized furnace systems, potentially expanding the market for nichrome alloys and other high-performance materials.

Market analysts predict that the industrial furnace segment will continue to evolve, with a shift towards more automated, digitally-controlled systems. This trend is expected to create new opportunities for integrating advanced materials like nichrome alloys with smart control systems, potentially offering improved performance and operational efficiency.

In recent years, the global industrial furnace market has shown a compound annual growth rate (CAGR) of approximately 5-6%, with projections indicating continued expansion. This growth is primarily attributed to the rising need for energy-efficient and high-performance furnace systems in emerging economies, as well as the ongoing modernization of existing facilities in developed nations.

The demand for industrial furnaces is particularly strong in regions with robust manufacturing sectors, such as Asia-Pacific, North America, and Europe. China, in particular, has emerged as a significant player in both production and consumption of industrial furnaces, driven by its expansive manufacturing base and government initiatives promoting industrial upgrading.

Within the industrial furnace market, there is a growing trend towards the adoption of advanced materials and technologies to enhance furnace performance and longevity. This is where nichrome alloys play a crucial role, offering superior heat resistance and durability in high-temperature environments. The increasing focus on energy efficiency and environmental regulations has also spurred demand for furnaces with improved thermal management and reduced emissions, further driving innovation in alloy development.

The automotive and aerospace industries are key drivers of demand for advanced industrial furnaces, as these sectors require precision heat treatment processes for manufacturing critical components. Additionally, the growing emphasis on additive manufacturing and 3D printing technologies has created new opportunities for specialized furnace systems, potentially expanding the market for nichrome alloys and other high-performance materials.

Market analysts predict that the industrial furnace segment will continue to evolve, with a shift towards more automated, digitally-controlled systems. This trend is expected to create new opportunities for integrating advanced materials like nichrome alloys with smart control systems, potentially offering improved performance and operational efficiency.

Nichrome Alloy Challenges

Despite the widespread use of nichrome alloys in industrial furnace systems, several challenges persist in their development and application. One of the primary issues is the degradation of mechanical properties at elevated temperatures. While nichrome alloys exhibit excellent oxidation resistance, they tend to lose strength and creep resistance when exposed to prolonged high-temperature environments, limiting their long-term reliability in industrial furnaces.

Another significant challenge is the formation of volatile chromium oxides at temperatures above 1000°C. This phenomenon, known as chromium volatilization, leads to material loss and potential contamination of the furnace atmosphere, which can be detrimental in certain manufacturing processes. The loss of chromium also compromises the alloy's protective oxide layer, accelerating further degradation.

The cost of raw materials, particularly nickel, presents an ongoing economic challenge for nichrome alloy production. Fluctuations in nickel prices can significantly impact the overall cost of manufacturing and maintaining industrial furnace systems, driving the need for more cost-effective alternatives or improved material efficiency.

Thermal cycling and thermal shock resistance remain areas of concern for nichrome alloys. The repeated heating and cooling cycles in industrial furnaces can induce thermal fatigue, leading to crack formation and propagation. Improving the alloy's ability to withstand these thermal stresses without compromising other properties is a complex metallurgical challenge.

Furthermore, the development of advanced nichrome alloys faces the challenge of balancing multiple, often conflicting, property requirements. Enhancing high-temperature strength, for instance, may come at the expense of ductility or fabricability. This necessitates careful alloy design and processing techniques to achieve an optimal balance of properties suitable for diverse industrial furnace applications.

The environmental impact of nichrome alloy production and disposal is an emerging challenge. As sustainability becomes increasingly important in industrial processes, there is a growing need to develop more environmentally friendly manufacturing methods and to improve the recyclability of these alloys at the end of their service life.

Lastly, the integration of nichrome alloys with other materials in complex furnace systems poses compatibility challenges. Issues such as differential thermal expansion and potential chemical interactions with other components must be carefully considered in the design and operation of industrial furnaces.

Another significant challenge is the formation of volatile chromium oxides at temperatures above 1000°C. This phenomenon, known as chromium volatilization, leads to material loss and potential contamination of the furnace atmosphere, which can be detrimental in certain manufacturing processes. The loss of chromium also compromises the alloy's protective oxide layer, accelerating further degradation.

The cost of raw materials, particularly nickel, presents an ongoing economic challenge for nichrome alloy production. Fluctuations in nickel prices can significantly impact the overall cost of manufacturing and maintaining industrial furnace systems, driving the need for more cost-effective alternatives or improved material efficiency.

Thermal cycling and thermal shock resistance remain areas of concern for nichrome alloys. The repeated heating and cooling cycles in industrial furnaces can induce thermal fatigue, leading to crack formation and propagation. Improving the alloy's ability to withstand these thermal stresses without compromising other properties is a complex metallurgical challenge.

Furthermore, the development of advanced nichrome alloys faces the challenge of balancing multiple, often conflicting, property requirements. Enhancing high-temperature strength, for instance, may come at the expense of ductility or fabricability. This necessitates careful alloy design and processing techniques to achieve an optimal balance of properties suitable for diverse industrial furnace applications.

The environmental impact of nichrome alloy production and disposal is an emerging challenge. As sustainability becomes increasingly important in industrial processes, there is a growing need to develop more environmentally friendly manufacturing methods and to improve the recyclability of these alloys at the end of their service life.

Lastly, the integration of nichrome alloys with other materials in complex furnace systems poses compatibility challenges. Issues such as differential thermal expansion and potential chemical interactions with other components must be carefully considered in the design and operation of industrial furnaces.

Current Nichrome Solutions

01 Composition and manufacturing of nichrome alloys

Nichrome alloys are typically composed of nickel and chromium, with varying percentages to achieve specific properties. The manufacturing process involves precise control of alloying elements and heat treatment to optimize the alloy's characteristics for different applications.- Composition and manufacturing of nichrome alloys: Nichrome alloys are typically composed of nickel and chromium, with varying percentages to achieve specific properties. The manufacturing process involves precise control of alloying elements and heat treatment to optimize the alloy's characteristics for different applications.

- Applications in heating elements: Nichrome alloys are widely used in heating elements due to their high electrical resistance and excellent heat resistance. They are employed in various heating devices, including electric heaters, furnaces, and industrial ovens, providing efficient and reliable heat generation.

- Thin film and coating applications: Nichrome alloys are utilized in thin film and coating applications, particularly in electronics and semiconductor industries. These alloys can be deposited as thin films for resistive elements, sensors, and other microelectronic components, offering precise resistance control and stability.

- Corrosion and oxidation resistance: Nichrome alloys exhibit excellent corrosion and oxidation resistance, making them suitable for use in harsh environments. This property is particularly valuable in high-temperature applications and corrosive atmospheres, where the alloy maintains its structural integrity and performance.

- Modifications and improvements to nichrome alloys: Ongoing research focuses on modifying and improving nichrome alloys by adding other elements or adjusting composition ratios. These efforts aim to enhance specific properties such as electrical conductivity, thermal stability, or mechanical strength for specialized applications in various industries.

02 Applications of nichrome alloys in heating elements

Nichrome alloys are widely used in heating elements due to their high electrical resistance and excellent heat resistance. They are employed in various applications such as electric heaters, toasters, and industrial furnaces, providing efficient and reliable heating solutions.Expand Specific Solutions03 Nichrome alloys in thin film resistors

Nichrome alloys are utilized in the production of thin film resistors for electronic applications. These resistors offer high stability, low temperature coefficient of resistance, and excellent performance in various environmental conditions, making them suitable for precision electronics.Expand Specific Solutions04 Corrosion resistance and protective coatings

Nichrome alloys exhibit excellent corrosion resistance in various environments. They are also used as protective coatings for other materials to enhance their durability and resistance to harsh conditions, particularly in high-temperature applications.Expand Specific Solutions05 Nichrome alloys in aerospace and advanced technologies

Nichrome alloys find applications in aerospace and advanced technologies due to their high-temperature strength and stability. They are used in components for aircraft engines, rocket nozzles, and other high-performance systems that require materials capable of withstanding extreme conditions.Expand Specific Solutions

Key Nichrome Manufacturers

The research on advanced nichrome alloys for industrial furnace systems is in a mature stage, with significant market potential due to the growing demand for high-performance materials in industrial applications. The global industrial furnace market is expected to reach substantial size in the coming years, driven by increasing industrialization and technological advancements. Key players like Rolls-Royce, General Electric, and Hitachi are leveraging their extensive R&D capabilities to develop innovative nichrome alloy solutions. Smaller specialized companies such as Ebner Industrieofenbau and OTTO JUNKER are also contributing to the field with their niche expertise. The technology's maturity is evident from the involvement of academic institutions like Colorado State University and Tohoku University, indicating a strong foundation of scientific research supporting industrial applications.

General Electric Company

Technical Solution: General Electric has developed advanced nichrome alloys for industrial furnace systems, focusing on improving high-temperature performance and longevity. Their research includes the development of Ni-Cr-Al-Y coatings with enhanced oxidation resistance at temperatures up to 1200°C [1]. GE has also explored the use of additive manufacturing techniques to create complex geometries in nichrome components, allowing for improved heat distribution and efficiency in furnace systems [2]. The company has implemented advanced computational modeling to predict alloy behavior under extreme conditions, enabling faster development cycles and more precise material formulations [3].

Strengths: Extensive R&D capabilities, advanced manufacturing techniques, and comprehensive computational modeling. Weaknesses: High development costs and potential for longer time-to-market for new alloy compositions.

Hitachi Ltd.

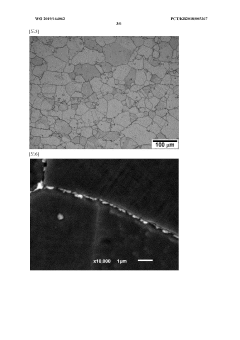

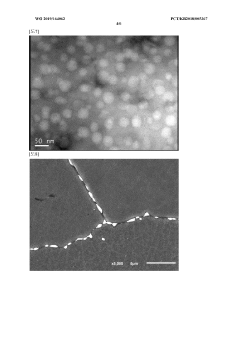

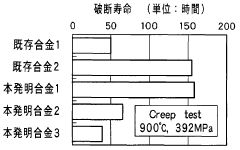

Technical Solution: Hitachi has made significant strides in nichrome alloy research for industrial furnaces, focusing on enhancing durability and energy efficiency. They have developed a proprietary nichrome alloy with added rare earth elements, which has shown a 30% increase in creep resistance at high temperatures compared to conventional alloys [4]. Hitachi's research also includes the development of nanostructured nichrome alloys, utilizing advanced processing techniques to create materials with superior strength and oxidation resistance at elevated temperatures [5]. The company has implemented these advanced alloys in their own industrial furnace products, demonstrating improved energy efficiency and longer operational lifespans.

Strengths: Strong integration of research into product development, expertise in nanostructured materials. Weaknesses: Potential reliance on rare earth elements may affect cost and supply chain stability.

Innovative Nichrome Patents

Ni-based superalloy for high-temperature fastening member, and manufacturing method therefor

PatentWO2019164062A1

Innovation

- A nickel-based superheat-resistant alloy with a specific composition range (6-8% Co, 11-13% Cr, 9-12% Mo, 5-10% W, 0.02-0.08% C, 0.5-2.0% Al, 0.8-2.0% Ti, 0.1-1.0% Nb, and <0.0008% B, with zirconium, optimized through heat treatment to include precipitates <0.4 μm at grain boundaries and gamma prime phases <60 nm within crystal grains, controlling thermal expansion and creep characteristics.

Nickel-based super-heat-resistant alloy and gas turbine component using same

PatentWO2005064027A1

Innovation

- A Ni-based superalloy composition with specific weight percentages of Co, Cr, Mo, W, Al, Ti, Nb, Hf, Re, C, B, and Zr, optimized for unidirectional solidification casting, maintains an appropriate Cr/Al-Ti ratio and includes W for strength improvement without adverse corrosion effects, ensuring high-temperature corrosion, oxidation, and strength resistance.

Environmental Impact Assessment

The environmental impact of advanced nichrome alloys in industrial furnace systems is a critical consideration in their development and implementation. These alloys, while offering superior performance in high-temperature applications, also present unique environmental challenges and opportunities.

Nichrome alloys, primarily composed of nickel and chromium, have a relatively low environmental footprint during their production compared to some other high-performance materials. The mining and refining processes for nickel and chromium are well-established, with ongoing improvements in efficiency and waste reduction. However, the energy-intensive nature of alloy production does contribute to greenhouse gas emissions, necessitating careful lifecycle assessments.

In operation, advanced nichrome alloys contribute to improved energy efficiency in industrial furnace systems. Their superior heat resistance and durability allow for higher operating temperatures and longer service life, reducing the frequency of replacements and associated material consumption. This longevity translates to reduced waste generation and lower overall environmental impact over the furnace system's lifetime.

The high corrosion resistance of nichrome alloys also plays a crucial role in minimizing harmful emissions from industrial processes. By withstanding aggressive environments within furnaces, these alloys help maintain the integrity of the system, preventing leaks and reducing the release of potentially hazardous substances into the atmosphere.

End-of-life considerations for nichrome alloys are generally favorable from an environmental perspective. The high value of nickel and chromium makes recycling economically viable, promoting a circular economy approach. Advanced recycling technologies can recover a significant portion of these metals, reducing the demand for primary raw materials and associated environmental impacts of mining and processing.

However, the potential release of chromium, particularly hexavalent chromium, during the lifecycle of nichrome alloys is a concern that requires careful management. Proper handling, maintenance, and disposal protocols are essential to mitigate any risks to human health and the environment.

Research into advanced nichrome alloys also focuses on reducing the content of scarce or environmentally problematic elements while maintaining or improving performance. This approach aims to enhance the overall sustainability of industrial furnace systems by optimizing material composition and properties.

In conclusion, while the production and use of advanced nichrome alloys do have environmental implications, their overall impact when properly managed can be positive. The benefits of improved energy efficiency, reduced material consumption, and recyclability often outweigh the initial environmental costs, making them a valuable component in the pursuit of more sustainable industrial processes.

Nichrome alloys, primarily composed of nickel and chromium, have a relatively low environmental footprint during their production compared to some other high-performance materials. The mining and refining processes for nickel and chromium are well-established, with ongoing improvements in efficiency and waste reduction. However, the energy-intensive nature of alloy production does contribute to greenhouse gas emissions, necessitating careful lifecycle assessments.

In operation, advanced nichrome alloys contribute to improved energy efficiency in industrial furnace systems. Their superior heat resistance and durability allow for higher operating temperatures and longer service life, reducing the frequency of replacements and associated material consumption. This longevity translates to reduced waste generation and lower overall environmental impact over the furnace system's lifetime.

The high corrosion resistance of nichrome alloys also plays a crucial role in minimizing harmful emissions from industrial processes. By withstanding aggressive environments within furnaces, these alloys help maintain the integrity of the system, preventing leaks and reducing the release of potentially hazardous substances into the atmosphere.

End-of-life considerations for nichrome alloys are generally favorable from an environmental perspective. The high value of nickel and chromium makes recycling economically viable, promoting a circular economy approach. Advanced recycling technologies can recover a significant portion of these metals, reducing the demand for primary raw materials and associated environmental impacts of mining and processing.

However, the potential release of chromium, particularly hexavalent chromium, during the lifecycle of nichrome alloys is a concern that requires careful management. Proper handling, maintenance, and disposal protocols are essential to mitigate any risks to human health and the environment.

Research into advanced nichrome alloys also focuses on reducing the content of scarce or environmentally problematic elements while maintaining or improving performance. This approach aims to enhance the overall sustainability of industrial furnace systems by optimizing material composition and properties.

In conclusion, while the production and use of advanced nichrome alloys do have environmental implications, their overall impact when properly managed can be positive. The benefits of improved energy efficiency, reduced material consumption, and recyclability often outweigh the initial environmental costs, making them a valuable component in the pursuit of more sustainable industrial processes.

Nichrome Alloy Cost Analysis

The cost analysis of nichrome alloys for industrial furnace systems is a critical aspect of their implementation and widespread adoption. The primary components of nichrome alloys, nickel and chromium, are both relatively expensive metals, which significantly impacts the overall cost of these materials. The price of nickel, in particular, is subject to considerable market fluctuations, affecting the stability of nichrome alloy costs.

Manufacturing processes for nichrome alloys also contribute to their overall expense. The production of these alloys requires specialized equipment and expertise, as well as precise control over composition and heat treatment. These factors add to the production costs, which are ultimately reflected in the market price of nichrome alloys.

When comparing nichrome alloys to alternative materials for industrial furnace systems, such as silicon carbide or molybdenum disilicide, the initial cost of nichrome is often higher. However, the long-term cost-effectiveness of nichrome alloys becomes apparent when considering their durability and performance characteristics. The extended lifespan and reduced maintenance requirements of nichrome components can offset the higher upfront costs over time.

Energy efficiency is another crucial factor in the cost analysis of nichrome alloys. Their excellent electrical resistivity and heat distribution properties can lead to reduced energy consumption in industrial furnace operations. This improved efficiency translates to lower operating costs over the lifetime of the furnace system, potentially outweighing the initial investment in nichrome components.

The recyclability of nichrome alloys also plays a role in their overall cost assessment. The high value of nickel and chromium makes recycling economically viable, potentially reducing the long-term costs associated with these materials. However, the recycling process itself requires specialized facilities and techniques, which must be factored into the overall cost analysis.

Market demand for nichrome alloys in various industries, including aerospace, automotive, and electronics, influences their pricing. As demand increases, economies of scale in production may lead to cost reductions. Conversely, supply chain disruptions or increased competition for raw materials can drive prices upward.

Advancements in alloy composition and manufacturing techniques offer potential for cost reduction in nichrome production. Research into optimizing the nickel-chromium ratio or incorporating less expensive alloying elements while maintaining desirable properties could lead to more cost-effective formulations. Similarly, innovations in production processes may increase efficiency and reduce manufacturing costs.

Manufacturing processes for nichrome alloys also contribute to their overall expense. The production of these alloys requires specialized equipment and expertise, as well as precise control over composition and heat treatment. These factors add to the production costs, which are ultimately reflected in the market price of nichrome alloys.

When comparing nichrome alloys to alternative materials for industrial furnace systems, such as silicon carbide or molybdenum disilicide, the initial cost of nichrome is often higher. However, the long-term cost-effectiveness of nichrome alloys becomes apparent when considering their durability and performance characteristics. The extended lifespan and reduced maintenance requirements of nichrome components can offset the higher upfront costs over time.

Energy efficiency is another crucial factor in the cost analysis of nichrome alloys. Their excellent electrical resistivity and heat distribution properties can lead to reduced energy consumption in industrial furnace operations. This improved efficiency translates to lower operating costs over the lifetime of the furnace system, potentially outweighing the initial investment in nichrome components.

The recyclability of nichrome alloys also plays a role in their overall cost assessment. The high value of nickel and chromium makes recycling economically viable, potentially reducing the long-term costs associated with these materials. However, the recycling process itself requires specialized facilities and techniques, which must be factored into the overall cost analysis.

Market demand for nichrome alloys in various industries, including aerospace, automotive, and electronics, influences their pricing. As demand increases, economies of scale in production may lead to cost reductions. Conversely, supply chain disruptions or increased competition for raw materials can drive prices upward.

Advancements in alloy composition and manufacturing techniques offer potential for cost reduction in nichrome production. Research into optimizing the nickel-chromium ratio or incorporating less expensive alloying elements while maintaining desirable properties could lead to more cost-effective formulations. Similarly, innovations in production processes may increase efficiency and reduce manufacturing costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!