Advanced Nichrome Types for Electrical Insulation

JUL 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Evolution and Research Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone in electrical resistance applications since its inception in the early 20th century. The evolution of nichrome has been driven by the increasing demands for improved electrical insulation and performance in various industries, including electronics, aerospace, and energy sectors.

Initially developed as a heating element material, nichrome's unique properties of high electrical resistivity and excellent oxidation resistance quickly made it indispensable in a wide range of applications. Over the decades, researchers and engineers have continuously refined the composition and manufacturing processes of nichrome to enhance its electrical insulation capabilities and overall performance.

The early stages of nichrome development focused on optimizing the nickel-chromium ratio to achieve the best balance between electrical resistance and thermal stability. As technology advanced, the inclusion of minor alloying elements such as silicon, aluminum, and iron became crucial in fine-tuning the alloy's properties for specific applications.

In recent years, the research objectives for advanced nichrome types have shifted towards addressing the challenges posed by modern electrical systems. These include the need for higher operating temperatures, improved resistance to thermal cycling, and enhanced durability in harsh environments. Additionally, the miniaturization trend in electronics has pushed for nichrome variants that can maintain their insulation properties at smaller scales and thinner layers.

One of the key research objectives in the field of advanced nichrome types is the development of nanostructured nichrome materials. These materials promise to offer superior electrical insulation properties by manipulating the alloy's microstructure at the nanoscale level. This approach aims to create more efficient barriers to electron flow while maintaining the alloy's desirable mechanical properties.

Another significant area of focus is the integration of ceramic particles or coatings with nichrome to create composite materials. These composites are designed to combine the electrical resistance of nichrome with the superior insulation properties of ceramics, potentially revolutionizing high-temperature electrical applications.

The ongoing research also aims to improve the manufacturability and cost-effectiveness of advanced nichrome types. This includes exploring new production techniques such as additive manufacturing and advanced powder metallurgy processes, which could enable the creation of complex geometries and tailored microstructures for specific insulation requirements.

As we look to the future, the research objectives for nichrome evolution are increasingly aligned with sustainability goals. This involves developing nichrome variants that are more energy-efficient in their production and application, as well as exploring recycling and reclamation processes for used nichrome components to reduce environmental impact.

Initially developed as a heating element material, nichrome's unique properties of high electrical resistivity and excellent oxidation resistance quickly made it indispensable in a wide range of applications. Over the decades, researchers and engineers have continuously refined the composition and manufacturing processes of nichrome to enhance its electrical insulation capabilities and overall performance.

The early stages of nichrome development focused on optimizing the nickel-chromium ratio to achieve the best balance between electrical resistance and thermal stability. As technology advanced, the inclusion of minor alloying elements such as silicon, aluminum, and iron became crucial in fine-tuning the alloy's properties for specific applications.

In recent years, the research objectives for advanced nichrome types have shifted towards addressing the challenges posed by modern electrical systems. These include the need for higher operating temperatures, improved resistance to thermal cycling, and enhanced durability in harsh environments. Additionally, the miniaturization trend in electronics has pushed for nichrome variants that can maintain their insulation properties at smaller scales and thinner layers.

One of the key research objectives in the field of advanced nichrome types is the development of nanostructured nichrome materials. These materials promise to offer superior electrical insulation properties by manipulating the alloy's microstructure at the nanoscale level. This approach aims to create more efficient barriers to electron flow while maintaining the alloy's desirable mechanical properties.

Another significant area of focus is the integration of ceramic particles or coatings with nichrome to create composite materials. These composites are designed to combine the electrical resistance of nichrome with the superior insulation properties of ceramics, potentially revolutionizing high-temperature electrical applications.

The ongoing research also aims to improve the manufacturability and cost-effectiveness of advanced nichrome types. This includes exploring new production techniques such as additive manufacturing and advanced powder metallurgy processes, which could enable the creation of complex geometries and tailored microstructures for specific insulation requirements.

As we look to the future, the research objectives for nichrome evolution are increasingly aligned with sustainability goals. This involves developing nichrome variants that are more energy-efficient in their production and application, as well as exploring recycling and reclamation processes for used nichrome components to reduce environmental impact.

Market Analysis for Advanced Electrical Insulation

The market for advanced electrical insulation materials, particularly those utilizing nichrome alloys, has been experiencing significant growth in recent years. This expansion is driven by the increasing demand for high-performance insulation solutions across various industries, including aerospace, automotive, electronics, and energy sectors. The global electrical insulation market is projected to reach a substantial value in the coming years, with nichrome-based materials playing a crucial role in this growth.

One of the primary factors fueling the market demand is the rapid advancement in electronic devices and electrical systems. As these technologies become more compact and powerful, the need for efficient insulation materials that can withstand higher temperatures and provide superior electrical resistance has intensified. Nichrome alloys, known for their excellent thermal and electrical properties, are well-positioned to meet these evolving requirements.

The automotive industry, in particular, has emerged as a key driver for advanced electrical insulation materials. With the shift towards electric and hybrid vehicles, there is a growing need for insulation solutions that can handle the increased electrical loads and thermal management challenges associated with these powertrains. Nichrome-based insulation materials offer the necessary performance characteristics to ensure the safety and reliability of these advanced automotive systems.

In the aerospace sector, the demand for lightweight yet highly effective insulation materials continues to rise. Nichrome alloys, with their high strength-to-weight ratio and resistance to extreme temperatures, are increasingly being adopted in aircraft electrical systems and engine components. This trend is expected to contribute significantly to the market growth of advanced nichrome-based insulation materials.

The energy sector, including power generation and distribution, represents another substantial market for advanced electrical insulation. As the world transitions towards renewable energy sources and smart grid technologies, the need for reliable insulation materials capable of withstanding high voltages and harsh environmental conditions has grown. Nichrome-based insulation solutions are well-suited to address these challenges, driving their adoption in power transmission and distribution infrastructure.

Geographically, the market for advanced electrical insulation materials shows varying patterns of growth. Developed regions such as North America and Europe continue to be significant consumers, driven by their established industrial bases and ongoing technological advancements. However, the Asia-Pacific region is emerging as the fastest-growing market, fueled by rapid industrialization, increasing investments in infrastructure development, and the expansion of manufacturing sectors in countries like China and India.

The competitive landscape of the advanced electrical insulation market is characterized by the presence of both established players and innovative startups. Major companies are investing heavily in research and development to enhance the properties of nichrome-based insulation materials, focusing on improving their thermal stability, electrical resistance, and overall performance. This ongoing innovation is expected to further expand the application scope of these materials and drive market growth in the coming years.

One of the primary factors fueling the market demand is the rapid advancement in electronic devices and electrical systems. As these technologies become more compact and powerful, the need for efficient insulation materials that can withstand higher temperatures and provide superior electrical resistance has intensified. Nichrome alloys, known for their excellent thermal and electrical properties, are well-positioned to meet these evolving requirements.

The automotive industry, in particular, has emerged as a key driver for advanced electrical insulation materials. With the shift towards electric and hybrid vehicles, there is a growing need for insulation solutions that can handle the increased electrical loads and thermal management challenges associated with these powertrains. Nichrome-based insulation materials offer the necessary performance characteristics to ensure the safety and reliability of these advanced automotive systems.

In the aerospace sector, the demand for lightweight yet highly effective insulation materials continues to rise. Nichrome alloys, with their high strength-to-weight ratio and resistance to extreme temperatures, are increasingly being adopted in aircraft electrical systems and engine components. This trend is expected to contribute significantly to the market growth of advanced nichrome-based insulation materials.

The energy sector, including power generation and distribution, represents another substantial market for advanced electrical insulation. As the world transitions towards renewable energy sources and smart grid technologies, the need for reliable insulation materials capable of withstanding high voltages and harsh environmental conditions has grown. Nichrome-based insulation solutions are well-suited to address these challenges, driving their adoption in power transmission and distribution infrastructure.

Geographically, the market for advanced electrical insulation materials shows varying patterns of growth. Developed regions such as North America and Europe continue to be significant consumers, driven by their established industrial bases and ongoing technological advancements. However, the Asia-Pacific region is emerging as the fastest-growing market, fueled by rapid industrialization, increasing investments in infrastructure development, and the expansion of manufacturing sectors in countries like China and India.

The competitive landscape of the advanced electrical insulation market is characterized by the presence of both established players and innovative startups. Major companies are investing heavily in research and development to enhance the properties of nichrome-based insulation materials, focusing on improving their thermal stability, electrical resistance, and overall performance. This ongoing innovation is expected to further expand the application scope of these materials and drive market growth in the coming years.

Current Nichrome Limitations and Challenges

Nichrome, a widely used alloy in electrical applications, faces several limitations and challenges in its current form, particularly when it comes to electrical insulation. One of the primary issues is its thermal stability at high temperatures. While nichrome exhibits excellent resistance to oxidation and corrosion, its performance can degrade when subjected to prolonged exposure to extreme heat. This limitation becomes critical in applications requiring sustained high-temperature operation, such as industrial furnaces or aerospace components.

Another significant challenge lies in the electrical resistivity of nichrome. Although its resistance to electrical current is a desirable property in many applications, it can be a drawback when higher conductivity is required. This limitation restricts its use in certain high-power electrical systems where minimal resistance is crucial for efficiency.

The mechanical properties of nichrome also present challenges, particularly in terms of ductility and formability. While the alloy is generally considered to have good workability, it can become brittle under certain conditions, especially after prolonged exposure to high temperatures. This brittleness can lead to cracking or failure in applications subject to thermal cycling or mechanical stress.

Insulation effectiveness is another area where current nichrome types face limitations. The thin oxide layer that forms on nichrome surfaces provides some degree of electrical insulation, but it may not be sufficient for applications requiring high voltage isolation. This necessitates the use of additional insulation materials, which can increase complexity and cost in electrical system designs.

The composition of nichrome also presents challenges in terms of resource availability and cost. The nickel content, which is crucial for the alloy's properties, is subject to price volatility and supply chain uncertainties. This can impact the long-term economic viability of nichrome-based solutions, especially in large-scale applications.

Environmental concerns are becoming increasingly relevant in the context of nichrome usage. The production and disposal of nichrome components can have environmental implications, particularly regarding the release of nickel compounds. This aspect is gaining importance as industries move towards more sustainable and environmentally friendly materials and processes.

Lastly, the scalability of nichrome production for advanced electrical insulation applications poses a challenge. As demand for more sophisticated electrical systems grows, particularly in emerging technologies like electric vehicles and renewable energy systems, there is a need for nichrome variants that can meet increasingly stringent performance requirements while maintaining cost-effectiveness at scale.

Another significant challenge lies in the electrical resistivity of nichrome. Although its resistance to electrical current is a desirable property in many applications, it can be a drawback when higher conductivity is required. This limitation restricts its use in certain high-power electrical systems where minimal resistance is crucial for efficiency.

The mechanical properties of nichrome also present challenges, particularly in terms of ductility and formability. While the alloy is generally considered to have good workability, it can become brittle under certain conditions, especially after prolonged exposure to high temperatures. This brittleness can lead to cracking or failure in applications subject to thermal cycling or mechanical stress.

Insulation effectiveness is another area where current nichrome types face limitations. The thin oxide layer that forms on nichrome surfaces provides some degree of electrical insulation, but it may not be sufficient for applications requiring high voltage isolation. This necessitates the use of additional insulation materials, which can increase complexity and cost in electrical system designs.

The composition of nichrome also presents challenges in terms of resource availability and cost. The nickel content, which is crucial for the alloy's properties, is subject to price volatility and supply chain uncertainties. This can impact the long-term economic viability of nichrome-based solutions, especially in large-scale applications.

Environmental concerns are becoming increasingly relevant in the context of nichrome usage. The production and disposal of nichrome components can have environmental implications, particularly regarding the release of nickel compounds. This aspect is gaining importance as industries move towards more sustainable and environmentally friendly materials and processes.

Lastly, the scalability of nichrome production for advanced electrical insulation applications poses a challenge. As demand for more sophisticated electrical systems grows, particularly in emerging technologies like electric vehicles and renewable energy systems, there is a need for nichrome variants that can meet increasingly stringent performance requirements while maintaining cost-effectiveness at scale.

Existing Nichrome Insulation Solutions

01 Advanced nichrome alloy compositions

Development of improved nichrome alloy compositions with enhanced electrical and thermal properties for use in electrical insulation applications. These advanced alloys offer better resistance to oxidation and corrosion, improved mechanical strength, and enhanced electrical conductivity.- Advanced Nichrome Alloy Compositions: Development of advanced nichrome alloy compositions with improved electrical and thermal properties for enhanced insulation performance. These alloys may include additional elements or modified ratios of nickel and chromium to optimize resistance and durability in high-temperature applications.

- Insulation Coatings for Nichrome Wires: Application of specialized insulation coatings on nichrome wires to improve electrical isolation and heat resistance. These coatings may include ceramic-based materials, polymer composites, or multi-layer structures designed to withstand high temperatures and maintain insulation integrity.

- Nichrome-based Heating Element Designs: Innovative designs for nichrome-based heating elements that incorporate advanced insulation techniques. These designs may feature unique geometries, embedded insulation layers, or composite structures to optimize heat distribution while maintaining electrical isolation.

- Nano-engineered Insulation Materials: Development of nano-engineered materials for improved electrical insulation of nichrome components. These materials may include nanoparticle-reinforced polymers, nanostructured ceramics, or graphene-based composites that offer superior insulation properties at the nanoscale.

- Smart Insulation Systems for Nichrome Applications: Integration of smart insulation systems in nichrome-based devices, incorporating sensors and adaptive materials. These systems may feature self-healing properties, temperature-responsive insulation, or real-time monitoring capabilities to ensure optimal performance and safety in various electrical applications.

02 Insulation coatings for nichrome wires

Application of specialized insulation coatings on nichrome wires to improve their electrical insulation properties. These coatings may include ceramic-based materials, polymer composites, or other advanced insulating compounds that can withstand high temperatures and provide excellent dielectric strength.Expand Specific Solutions03 Multilayer insulation systems

Development of multilayer insulation systems for nichrome elements, combining different materials to achieve superior electrical insulation and thermal management. These systems may incorporate alternating layers of insulating materials with varying properties to optimize overall performance.Expand Specific Solutions04 Nanotechnology-enhanced insulation

Integration of nanotechnology in nichrome insulation, such as the use of nanoparticles or nanostructured materials to enhance insulation properties. These advanced materials can provide improved thermal stability, increased dielectric strength, and better resistance to electrical breakdown.Expand Specific Solutions05 Smart insulation systems for nichrome components

Development of smart insulation systems for nichrome components, incorporating sensors and adaptive materials that can respond to changes in temperature, electrical load, or environmental conditions. These systems can provide real-time monitoring and adjustment of insulation properties to optimize performance and safety.Expand Specific Solutions

Key Manufacturers in Nichrome Industry

The research on advanced nichrome types for electrical insulation is in a competitive and evolving stage, with significant market potential driven by increasing demand for high-performance electrical components. The market is characterized by a mix of established players and emerging innovators, reflecting a moderate level of technological maturity. Key companies like Samsung Electronics, Siemens, and DuPont are likely leveraging their extensive R&D capabilities to develop advanced nichrome materials. Meanwhile, specialized research institutions such as the Institute of Metal Research Chinese Academy of Sciences and the National Institute for Materials Science are contributing to fundamental advancements in the field. The involvement of diverse players suggests a dynamic landscape with opportunities for breakthrough innovations in nichrome technology.

Siemens Corp.

Technical Solution: Siemens has focused on developing advanced Nichrome alloys for high-temperature electrical insulation in power generation and industrial applications. Their research has led to the creation of a new class of Nichrome-based materials with improved creep resistance and electrical properties. Siemens' approach involves precise control of grain boundary engineering and the introduction of dispersed oxide particles within the alloy matrix. This results in a more stable microstructure at elevated temperatures, crucial for maintaining insulation properties[2]. The company has reported a 15% increase in maximum operating temperature for their advanced Nichrome insulation materials compared to standard grades[4]. Additionally, Siemens has developed a proprietary coating technology that further enhances the oxidation resistance of their Nichrome alloys, extending their lifespan in corrosive environments.

Strengths: Higher operating temperatures, improved creep resistance, and enhanced oxidation protection. Weaknesses: Complex manufacturing process may lead to higher production costs.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has made significant strides in the development of advanced Nichrome-based coatings for electrical insulation. Their research focuses on creating multi-layered coating systems that combine the excellent electrical properties of Nichrome with enhanced durability and environmental resistance. PPG's approach involves the use of nano-dispersed ceramic particles within a Nichrome matrix, which has shown to improve both the electrical insulation properties and the mechanical strength of the coating[6]. The company has reported a 30% increase in dielectric strength for their advanced Nichrome coatings compared to traditional formulations[8]. Additionally, PPG has developed a novel application process that allows for more uniform and thinner coatings, resulting in improved performance in miniaturized electronic components.

Strengths: Improved dielectric strength, enhanced durability, and suitability for miniaturized components. Weaknesses: May require specialized application equipment, potentially limiting widespread adoption.

Innovative Nichrome Compositions and Properties

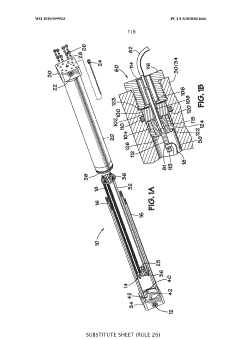

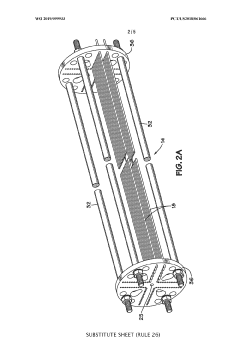

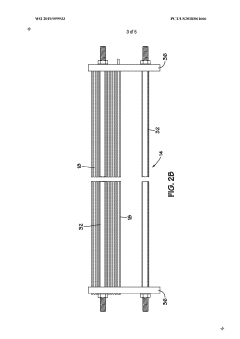

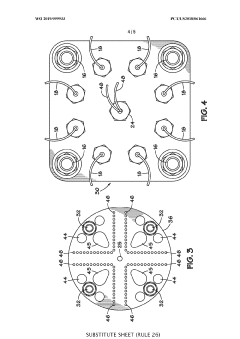

In-line electric heater for plural component materials

PatentWO2019099933A1

Innovation

- An in-line electric heater design featuring a housing with multiple electric resistance heating elements along the fluid flow path, supported by a wire loom assembly and temperature sensors, using INCONEL wires coated with Teflon for improved durability and insulation, and a power feedthrough system for secure electrical connections, enhancing heat transfer and temperature control.

COG dieletric composition for use with nickel electrodes

PatentInactiveUS8114801B2

Innovation

- A strontium-zirconate-titanate-based dielectric composition with a uniform dense microstructure, sintered in a reducing atmosphere, is used to form multilayer ceramic capacitors with base metal internal electrodes, incorporating oxides like MgO, B2O3, and MgO—CaO—Al2O3—SiO2 as sintering aids to achieve stable dielectric constants and high reliability.

Environmental Impact of Nichrome Production

The production of nichrome alloys for electrical insulation applications has significant environmental implications that warrant careful consideration. The manufacturing process involves the extraction and processing of raw materials, primarily nickel and chromium, which can lead to various environmental impacts.

Mining activities for nickel and chromium ores contribute to land degradation, habitat destruction, and potential water pollution. Open-pit mining, in particular, can result in large-scale landscape alterations and ecosystem disruptions. The extraction process often requires substantial energy inputs, contributing to greenhouse gas emissions and climate change concerns.

During the refining and alloying stages, energy-intensive processes are employed to purify the metals and create the nichrome alloy. These processes typically involve high-temperature furnaces, which consume significant amounts of fossil fuels, further adding to the carbon footprint of nichrome production. Additionally, the refining process may generate air pollutants, including particulate matter, sulfur dioxide, and nitrogen oxides, which can negatively impact local air quality.

Water usage is another critical environmental factor in nichrome production. Large volumes of water are required for cooling, cleaning, and processing throughout the manufacturing chain. This can strain local water resources, particularly in water-scarce regions. Moreover, wastewater from these processes may contain heavy metals and other contaminants, necessitating proper treatment to prevent water pollution.

The production of nichrome also generates solid waste, including slag and other byproducts. Proper management and disposal of these materials are essential to prevent soil contamination and potential leaching of hazardous substances into groundwater.

However, it is important to note that the environmental impact of nichrome production should be balanced against its benefits in electrical insulation applications. The durability and efficiency of nichrome in these applications can lead to longer-lasting and more energy-efficient electrical systems, potentially offsetting some of the environmental costs associated with its production.

To mitigate the environmental impact, manufacturers are increasingly adopting cleaner production technologies and implementing recycling programs. Advanced filtration systems and more efficient furnaces are being employed to reduce air emissions. Water recycling and treatment systems are being implemented to minimize water consumption and prevent pollution. Additionally, efforts are being made to increase the use of recycled nickel and chromium in nichrome production, which can significantly reduce the need for primary raw material extraction.

As research on advanced nichrome types for electrical insulation progresses, there is an opportunity to develop more environmentally friendly production methods and alloy compositions. This may include exploring alternative raw materials, optimizing production processes for energy efficiency, and designing nichrome alloys that require less material while maintaining or improving performance characteristics.

Mining activities for nickel and chromium ores contribute to land degradation, habitat destruction, and potential water pollution. Open-pit mining, in particular, can result in large-scale landscape alterations and ecosystem disruptions. The extraction process often requires substantial energy inputs, contributing to greenhouse gas emissions and climate change concerns.

During the refining and alloying stages, energy-intensive processes are employed to purify the metals and create the nichrome alloy. These processes typically involve high-temperature furnaces, which consume significant amounts of fossil fuels, further adding to the carbon footprint of nichrome production. Additionally, the refining process may generate air pollutants, including particulate matter, sulfur dioxide, and nitrogen oxides, which can negatively impact local air quality.

Water usage is another critical environmental factor in nichrome production. Large volumes of water are required for cooling, cleaning, and processing throughout the manufacturing chain. This can strain local water resources, particularly in water-scarce regions. Moreover, wastewater from these processes may contain heavy metals and other contaminants, necessitating proper treatment to prevent water pollution.

The production of nichrome also generates solid waste, including slag and other byproducts. Proper management and disposal of these materials are essential to prevent soil contamination and potential leaching of hazardous substances into groundwater.

However, it is important to note that the environmental impact of nichrome production should be balanced against its benefits in electrical insulation applications. The durability and efficiency of nichrome in these applications can lead to longer-lasting and more energy-efficient electrical systems, potentially offsetting some of the environmental costs associated with its production.

To mitigate the environmental impact, manufacturers are increasingly adopting cleaner production technologies and implementing recycling programs. Advanced filtration systems and more efficient furnaces are being employed to reduce air emissions. Water recycling and treatment systems are being implemented to minimize water consumption and prevent pollution. Additionally, efforts are being made to increase the use of recycled nickel and chromium in nichrome production, which can significantly reduce the need for primary raw material extraction.

As research on advanced nichrome types for electrical insulation progresses, there is an opportunity to develop more environmentally friendly production methods and alloy compositions. This may include exploring alternative raw materials, optimizing production processes for energy efficiency, and designing nichrome alloys that require less material while maintaining or improving performance characteristics.

Standardization and Quality Control Measures

Standardization and quality control measures play a crucial role in ensuring the consistency and reliability of advanced nichrome types used for electrical insulation. These measures are essential for maintaining the high performance and safety standards required in electrical applications.

The standardization process for nichrome alloys involves establishing precise specifications for chemical composition, physical properties, and manufacturing processes. International standards organizations, such as ASTM International and the International Electrotechnical Commission (IEC), have developed specific guidelines for nichrome alloys used in electrical insulation. These standards define acceptable ranges for key elements like nickel and chromium content, as well as impurity levels.

Quality control measures begin at the raw material stage, where suppliers must provide certificates of analysis for each batch of nichrome. These certificates verify the chemical composition and ensure compliance with specified standards. Advanced analytical techniques, such as X-ray fluorescence (XRF) and inductively coupled plasma mass spectrometry (ICP-MS), are employed to validate the material composition independently.

During the manufacturing process, strict quality control protocols are implemented to maintain consistency in the production of nichrome wire or ribbon. This includes continuous monitoring of key parameters such as temperature, drawing speed, and annealing conditions. Statistical process control (SPC) techniques are utilized to identify and address any deviations from the established norms promptly.

Physical and electrical property testing is a critical aspect of quality control for nichrome used in electrical insulation. Tensile strength, elongation, and electrical resistivity tests are conducted on samples from each production batch. These tests ensure that the material meets the required mechanical and electrical specifications for its intended application.

Surface finish and dimensional accuracy are also crucial factors in the performance of nichrome in electrical insulation applications. Advanced inspection techniques, such as laser micrometry and optical comparators, are used to verify the dimensional tolerances of nichrome wire or ribbon. Surface roughness measurements are performed to ensure optimal adhesion of insulation coatings.

To maintain long-term reliability, accelerated aging tests are conducted on nichrome samples. These tests simulate the environmental conditions and stresses that the material may encounter during its service life. The results of these tests help predict the long-term performance and durability of the nichrome in electrical insulation applications.

Traceability is a key component of quality control in the production of advanced nichrome types. Each batch of material is assigned a unique identifier, allowing for complete traceability from raw material to finished product. This system enables rapid identification and isolation of any potential quality issues, minimizing the impact on end-users.

The standardization process for nichrome alloys involves establishing precise specifications for chemical composition, physical properties, and manufacturing processes. International standards organizations, such as ASTM International and the International Electrotechnical Commission (IEC), have developed specific guidelines for nichrome alloys used in electrical insulation. These standards define acceptable ranges for key elements like nickel and chromium content, as well as impurity levels.

Quality control measures begin at the raw material stage, where suppliers must provide certificates of analysis for each batch of nichrome. These certificates verify the chemical composition and ensure compliance with specified standards. Advanced analytical techniques, such as X-ray fluorescence (XRF) and inductively coupled plasma mass spectrometry (ICP-MS), are employed to validate the material composition independently.

During the manufacturing process, strict quality control protocols are implemented to maintain consistency in the production of nichrome wire or ribbon. This includes continuous monitoring of key parameters such as temperature, drawing speed, and annealing conditions. Statistical process control (SPC) techniques are utilized to identify and address any deviations from the established norms promptly.

Physical and electrical property testing is a critical aspect of quality control for nichrome used in electrical insulation. Tensile strength, elongation, and electrical resistivity tests are conducted on samples from each production batch. These tests ensure that the material meets the required mechanical and electrical specifications for its intended application.

Surface finish and dimensional accuracy are also crucial factors in the performance of nichrome in electrical insulation applications. Advanced inspection techniques, such as laser micrometry and optical comparators, are used to verify the dimensional tolerances of nichrome wire or ribbon. Surface roughness measurements are performed to ensure optimal adhesion of insulation coatings.

To maintain long-term reliability, accelerated aging tests are conducted on nichrome samples. These tests simulate the environmental conditions and stresses that the material may encounter during its service life. The results of these tests help predict the long-term performance and durability of the nichrome in electrical insulation applications.

Traceability is a key component of quality control in the production of advanced nichrome types. Each batch of material is assigned a unique identifier, allowing for complete traceability from raw material to finished product. This system enables rapid identification and isolation of any potential quality issues, minimizing the impact on end-users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!