Enhancing Durability of Nichrome Heating Elements

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Heating Elements: Background and Objectives

Nichrome heating elements have been a cornerstone of electrical heating technology for over a century. Developed in the early 1900s, these alloy-based resistive elements quickly became the standard for a wide range of heating applications due to their excellent combination of high resistivity and oxidation resistance. The evolution of nichrome technology has been driven by the ever-increasing demands for higher performance, longer lifespan, and improved energy efficiency in various industries.

The primary objective of enhancing the durability of nichrome heating elements is to address the persistent challenges faced in high-temperature applications. As these elements are subjected to extreme thermal cycling and corrosive environments, their longevity becomes a critical factor in determining the overall efficiency and cost-effectiveness of heating systems. Improving durability not only extends the operational life of heating devices but also reduces maintenance costs and downtime in industrial processes.

The technological trajectory of nichrome heating elements has seen significant advancements in alloy composition and manufacturing techniques. Early nichrome alloys consisted primarily of nickel and chromium, but modern variants incorporate additional elements such as iron, aluminum, and silicon to enhance specific properties. These modifications aim to improve oxidation resistance, increase mechanical strength, and optimize electrical characteristics across a broader temperature range.

Recent research efforts have focused on nano-engineering approaches to further enhance the durability of nichrome elements. By manipulating the microstructure of the alloy at the nanoscale, researchers aim to create more resilient materials that can withstand higher temperatures and more aggressive environments. This includes the development of nanocomposite coatings and the integration of ceramic nanoparticles within the alloy matrix to reinforce its structure.

The market demand for more durable nichrome heating elements is driven by several factors, including the push for energy efficiency, the expansion of high-temperature industrial processes, and the growing adoption of electric heating in various sectors. As global energy policies shift towards electrification and decarbonization, the role of efficient and long-lasting heating elements becomes increasingly crucial in achieving sustainability goals.

Looking ahead, the technological objectives for nichrome heating elements include not only enhancing durability but also improving their overall performance characteristics. This encompasses goals such as increasing the maximum operating temperature, reducing power consumption, and developing smart heating elements with integrated sensors for precise temperature control and predictive maintenance. The pursuit of these objectives is expected to open new avenues for innovation and drive the next generation of heating technologies across diverse applications.

The primary objective of enhancing the durability of nichrome heating elements is to address the persistent challenges faced in high-temperature applications. As these elements are subjected to extreme thermal cycling and corrosive environments, their longevity becomes a critical factor in determining the overall efficiency and cost-effectiveness of heating systems. Improving durability not only extends the operational life of heating devices but also reduces maintenance costs and downtime in industrial processes.

The technological trajectory of nichrome heating elements has seen significant advancements in alloy composition and manufacturing techniques. Early nichrome alloys consisted primarily of nickel and chromium, but modern variants incorporate additional elements such as iron, aluminum, and silicon to enhance specific properties. These modifications aim to improve oxidation resistance, increase mechanical strength, and optimize electrical characteristics across a broader temperature range.

Recent research efforts have focused on nano-engineering approaches to further enhance the durability of nichrome elements. By manipulating the microstructure of the alloy at the nanoscale, researchers aim to create more resilient materials that can withstand higher temperatures and more aggressive environments. This includes the development of nanocomposite coatings and the integration of ceramic nanoparticles within the alloy matrix to reinforce its structure.

The market demand for more durable nichrome heating elements is driven by several factors, including the push for energy efficiency, the expansion of high-temperature industrial processes, and the growing adoption of electric heating in various sectors. As global energy policies shift towards electrification and decarbonization, the role of efficient and long-lasting heating elements becomes increasingly crucial in achieving sustainability goals.

Looking ahead, the technological objectives for nichrome heating elements include not only enhancing durability but also improving their overall performance characteristics. This encompasses goals such as increasing the maximum operating temperature, reducing power consumption, and developing smart heating elements with integrated sensors for precise temperature control and predictive maintenance. The pursuit of these objectives is expected to open new avenues for innovation and drive the next generation of heating technologies across diverse applications.

Market Analysis for Durable Heating Solutions

The market for durable heating solutions, particularly those utilizing nichrome heating elements, has shown significant growth in recent years. This trend is driven by increasing demand across various industries, including automotive, aerospace, appliances, and industrial manufacturing. The global market for heating elements is projected to reach $39.3 billion by 2026, with nichrome-based solutions accounting for a substantial portion of this market.

The automotive sector represents a key driver for durable heating solutions, as electric vehicles require efficient and long-lasting heating systems for cabin comfort and battery temperature management. The aerospace industry also demands high-performance heating elements for de-icing systems and environmental control. In the appliance market, consumers are increasingly seeking energy-efficient and long-lasting heating solutions for products such as ovens, water heaters, and hair dryers.

Industrial applications, including process heating, material testing, and semiconductor manufacturing, require heating elements that can withstand extreme temperatures and harsh environments. This sector is experiencing steady growth, with a particular emphasis on precision temperature control and energy efficiency.

The market is characterized by a growing focus on sustainability and energy efficiency. Manufacturers are developing nichrome heating elements with improved durability to reduce replacement frequency and minimize waste. This aligns with global initiatives to reduce carbon footprints and promote circular economy principles.

Geographically, Asia-Pacific is emerging as the fastest-growing market for durable heating solutions, driven by rapid industrialization and increasing adoption of electric vehicles in countries like China and India. North America and Europe continue to be significant markets, with a strong focus on technological advancements and stringent energy efficiency regulations.

The competitive landscape is marked by both established players and innovative startups. Key market players are investing heavily in research and development to enhance the durability and performance of nichrome heating elements. Collaborations between material scientists and heating element manufacturers are becoming more common, aiming to develop advanced alloys and coating technologies.

Customer preferences are shifting towards smart heating solutions that offer precise control, remote monitoring, and integration with IoT systems. This trend is creating new opportunities for value-added services and differentiation in the market.

In conclusion, the market for durable heating solutions, particularly those based on enhanced nichrome heating elements, shows strong growth potential. The industry's focus on durability, energy efficiency, and technological integration aligns well with broader economic and environmental trends, positioning it for sustained growth in the coming years.

The automotive sector represents a key driver for durable heating solutions, as electric vehicles require efficient and long-lasting heating systems for cabin comfort and battery temperature management. The aerospace industry also demands high-performance heating elements for de-icing systems and environmental control. In the appliance market, consumers are increasingly seeking energy-efficient and long-lasting heating solutions for products such as ovens, water heaters, and hair dryers.

Industrial applications, including process heating, material testing, and semiconductor manufacturing, require heating elements that can withstand extreme temperatures and harsh environments. This sector is experiencing steady growth, with a particular emphasis on precision temperature control and energy efficiency.

The market is characterized by a growing focus on sustainability and energy efficiency. Manufacturers are developing nichrome heating elements with improved durability to reduce replacement frequency and minimize waste. This aligns with global initiatives to reduce carbon footprints and promote circular economy principles.

Geographically, Asia-Pacific is emerging as the fastest-growing market for durable heating solutions, driven by rapid industrialization and increasing adoption of electric vehicles in countries like China and India. North America and Europe continue to be significant markets, with a strong focus on technological advancements and stringent energy efficiency regulations.

The competitive landscape is marked by both established players and innovative startups. Key market players are investing heavily in research and development to enhance the durability and performance of nichrome heating elements. Collaborations between material scientists and heating element manufacturers are becoming more common, aiming to develop advanced alloys and coating technologies.

Customer preferences are shifting towards smart heating solutions that offer precise control, remote monitoring, and integration with IoT systems. This trend is creating new opportunities for value-added services and differentiation in the market.

In conclusion, the market for durable heating solutions, particularly those based on enhanced nichrome heating elements, shows strong growth potential. The industry's focus on durability, energy efficiency, and technological integration aligns well with broader economic and environmental trends, positioning it for sustained growth in the coming years.

Current Challenges in Nichrome Element Longevity

Despite the widespread use of nichrome heating elements in various applications, several challenges persist in enhancing their longevity. One of the primary issues is oxidation, which occurs when nichrome elements are exposed to high temperatures in the presence of oxygen. This process leads to the formation of a brittle oxide layer on the surface, gradually reducing the element's efficiency and lifespan.

Thermal fatigue is another significant challenge faced by nichrome heating elements. Repeated heating and cooling cycles cause expansion and contraction of the material, leading to microscopic cracks and eventual failure. This issue is particularly prevalent in applications that require frequent on-off cycling, such as in household appliances or industrial processes with intermittent heating requirements.

Corrosion resistance is a critical factor affecting the durability of nichrome elements, especially in environments with aggressive chemicals or high humidity. While nichrome generally exhibits good corrosion resistance, prolonged exposure to certain substances can still lead to degradation and reduced performance over time.

The formation of hot spots is a persistent problem in nichrome heating elements. These localized areas of higher temperature can occur due to uneven current distribution or manufacturing defects, leading to accelerated degradation and potential failure at these points. Addressing this issue requires improvements in element design and manufacturing processes.

Mechanical stress is another challenge that impacts the longevity of nichrome elements. Vibrations, physical impacts, and thermal expansion can cause deformation or breakage of the elements, particularly in applications where they are subjected to frequent movement or harsh operating conditions.

The purity and composition of the nichrome alloy itself can also affect element durability. Impurities or variations in the nickel-chromium ratio can lead to inconsistent performance and reduced lifespan. Maintaining strict quality control in the production of nichrome wire is essential for ensuring consistent and long-lasting heating elements.

Lastly, the interface between the nichrome element and its electrical connections presents a challenge. Poor connections can lead to increased resistance, localized heating, and premature failure. Improving the design and materials used in these connections is crucial for enhancing overall element durability.

Thermal fatigue is another significant challenge faced by nichrome heating elements. Repeated heating and cooling cycles cause expansion and contraction of the material, leading to microscopic cracks and eventual failure. This issue is particularly prevalent in applications that require frequent on-off cycling, such as in household appliances or industrial processes with intermittent heating requirements.

Corrosion resistance is a critical factor affecting the durability of nichrome elements, especially in environments with aggressive chemicals or high humidity. While nichrome generally exhibits good corrosion resistance, prolonged exposure to certain substances can still lead to degradation and reduced performance over time.

The formation of hot spots is a persistent problem in nichrome heating elements. These localized areas of higher temperature can occur due to uneven current distribution or manufacturing defects, leading to accelerated degradation and potential failure at these points. Addressing this issue requires improvements in element design and manufacturing processes.

Mechanical stress is another challenge that impacts the longevity of nichrome elements. Vibrations, physical impacts, and thermal expansion can cause deformation or breakage of the elements, particularly in applications where they are subjected to frequent movement or harsh operating conditions.

The purity and composition of the nichrome alloy itself can also affect element durability. Impurities or variations in the nickel-chromium ratio can lead to inconsistent performance and reduced lifespan. Maintaining strict quality control in the production of nichrome wire is essential for ensuring consistent and long-lasting heating elements.

Lastly, the interface between the nichrome element and its electrical connections presents a challenge. Poor connections can lead to increased resistance, localized heating, and premature failure. Improving the design and materials used in these connections is crucial for enhancing overall element durability.

Existing Durability Enhancement Techniques

01 Composition and structure of nichrome heating elements

Nichrome heating elements are typically composed of nickel and chromium alloys. The specific composition and structure of these elements can significantly impact their durability. Factors such as the ratio of nickel to chromium, the addition of other alloying elements, and the manufacturing process can all contribute to improved durability and longevity of the heating elements.- Composition and structure of nichrome heating elements: Nichrome heating elements are typically composed of nickel and chromium alloys. The specific composition and structure of these elements can significantly impact their durability. Factors such as the ratio of nickel to chromium, the addition of other alloying elements, and the manufacturing process can all contribute to improved durability and longevity of the heating elements.

- Protective coatings for nichrome heating elements: Applying protective coatings to nichrome heating elements can enhance their durability and resistance to oxidation and corrosion. These coatings may include ceramic materials, metal oxides, or other heat-resistant compounds that form a barrier between the heating element and its environment, thereby extending its lifespan and maintaining performance over time.

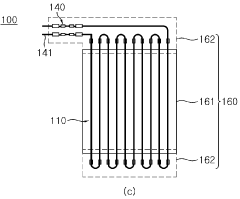

- Design optimization for improved durability: The design of nichrome heating elements plays a crucial role in their durability. Factors such as element thickness, coil spacing, and overall geometry can be optimized to distribute heat more evenly, reduce hot spots, and minimize thermal stress. These design considerations can significantly extend the lifespan of the heating elements and improve their overall performance.

- Environmental control and protection measures: Implementing environmental control and protection measures can greatly enhance the durability of nichrome heating elements. This may include controlling the atmosphere in which the elements operate, using protective enclosures, or implementing temperature regulation systems. By minimizing exposure to harmful conditions such as moisture, corrosive gases, or extreme temperature fluctuations, the lifespan of the heating elements can be significantly extended.

- Advanced manufacturing techniques: Employing advanced manufacturing techniques can improve the durability of nichrome heating elements. These may include precision forming methods, advanced welding techniques, or novel heat treatment processes. Such techniques can enhance the structural integrity of the elements, improve their resistance to thermal cycling, and reduce defects that could lead to premature failure.

02 Protective coatings for nichrome heating elements

Applying protective coatings to nichrome heating elements can enhance their durability and resistance to oxidation and corrosion. These coatings may include ceramic materials, metal oxides, or other heat-resistant compounds that form a barrier between the heating element and its environment, thereby extending its lifespan and maintaining performance over time.Expand Specific Solutions03 Design optimization for improved durability

The design of nichrome heating elements plays a crucial role in their durability. Optimizing factors such as element thickness, coil spacing, and overall geometry can help distribute heat more evenly, reduce hot spots, and minimize thermal stress. These design improvements can significantly extend the lifespan of the heating elements and enhance their overall performance.Expand Specific Solutions04 Environmental control and protection measures

Implementing environmental control and protection measures can greatly improve the durability of nichrome heating elements. This may include controlling the atmosphere surrounding the elements, using protective enclosures, or implementing temperature regulation systems. By minimizing exposure to harmful conditions such as moisture, corrosive gases, or extreme temperature fluctuations, the lifespan of the heating elements can be significantly extended.Expand Specific Solutions05 Advanced manufacturing techniques

Employing advanced manufacturing techniques can enhance the durability of nichrome heating elements. These may include precision forming methods, advanced welding techniques, or novel heat treatment processes. Such techniques can improve the structural integrity of the elements, reduce defects, and enhance their overall resistance to wear and degradation over time.Expand Specific Solutions

Key Players in Heating Element Manufacturing

The research on enhancing durability of nichrome heating elements is in a mature stage, with a competitive landscape dominated by established players. The market size is substantial, driven by applications in various industries including aerospace, automotive, and electronics. Companies like BASF Corp., Kyocera Corp., and Shin-Etsu Chemical Co., Ltd. are at the forefront of innovation, leveraging their extensive R&D capabilities. Emerging players such as Xi'an Thermal Power Research Institute and Yancheng Xinyang Electric Heating Material Co., Ltd. are also contributing to technological advancements. The industry is characterized by ongoing efforts to improve material properties, with a focus on enhancing heat resistance and longevity of nichrome elements.

Kyocera Corp.

Technical Solution: Kyocera has leveraged its expertise in ceramics to develop hybrid nichrome-ceramic heating elements with enhanced durability. Their approach involves creating a protective ceramic coating that is chemically bonded to the nichrome core, providing superior oxidation resistance and thermal shock resistance. Kyocera's research has shown that these hybrid elements can operate at higher temperatures for longer periods compared to traditional nichrome elements, with some tests demonstrating a 60% increase in lifespan under extreme conditions [9]. The company has also developed advanced manufacturing techniques, including precision laser sintering, to ensure uniform coating thickness and optimal adhesion between the ceramic and metal layers [10].

Strengths: Strong expertise in ceramic technologies, advanced manufacturing capabilities, and a diverse product portfolio. Weaknesses: Higher production costs associated with the hybrid element technology.

Yancheng Xinyang Electric Heating Material Co., Ltd.

Technical Solution: Yancheng Xinyang has focused on enhancing nichrome heating element durability through microstructure optimization and innovative manufacturing processes. They have developed a proprietary grain refinement technique that increases the element's resistance to thermal fatigue. This process involves controlled cooling rates and mechanical working to achieve a fine-grained structure that improves the material's overall strength and ductility [4]. The company has also implemented advanced quality control measures, including real-time monitoring of element composition and performance testing under simulated extreme conditions, to ensure consistent durability improvements across their product range [6].

Strengths: Specialized focus on heating elements, cost-effective manufacturing processes, and strong quality control measures. Weaknesses: Limited global presence compared to larger competitors.

Innovative Materials and Coatings for Nichrome

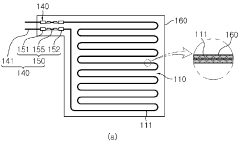

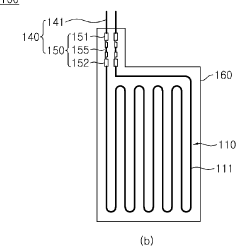

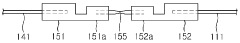

Electric heater and heat exchanger employing the same

PatentWO1985000084A1

Innovation

- A bare nichrome wire is immersed in silicone oil, which provides rapid temperature rise, excellent insulation, oxidation resistance, and durability, preventing oxidation and ensuring safety by using silicone oil with good thermal and electrical properties.

Heating device and liquid heating device comprising same

PatentWO2012134242A2

Innovation

- A heating device featuring a carbon fiber heating element shaped in columns or rows, covered with fluororesin (Teflon) for insulation, which prevents oxidation and volatilization, and includes a terminal unit connected via a bare copper wire with a fuse or bimetal cut-off mechanism for safe power connection, ensuring stable insulation even in contact with liquids.

Environmental Impact of Durable Heating Elements

The environmental impact of durable heating elements, particularly those made from nichrome, is a critical consideration in the pursuit of sustainable technology. As research on enhancing the durability of nichrome heating elements progresses, it is essential to evaluate the potential environmental benefits and drawbacks associated with these advancements.

Improved durability in heating elements can significantly reduce waste generation and resource consumption. Longer-lasting nichrome elements mean fewer replacements are needed over time, resulting in decreased manufacturing demands and reduced disposal of spent components. This reduction in material turnover can lead to lower energy consumption and greenhouse gas emissions associated with production processes, transportation, and end-of-life management.

Furthermore, durable heating elements contribute to the overall longevity of appliances and industrial equipment. This extended lifespan of products containing nichrome elements can help mitigate the environmental burden of electronic waste, which is a growing concern globally. By reducing the frequency of appliance replacements, the demand for raw materials and energy-intensive manufacturing processes can be curtailed, leading to a smaller ecological footprint.

However, the environmental impact of enhancing nichrome heating element durability is not without potential drawbacks. The development of more resilient materials may involve the use of additional alloying elements or surface treatments, which could introduce new environmental challenges. These may include increased mining activities for rare elements or the use of potentially harmful chemicals in manufacturing processes. It is crucial to carefully assess the life cycle impacts of these enhanced materials to ensure that the environmental benefits outweigh any new risks introduced.

Energy efficiency is another important factor to consider. While durable heating elements may last longer, it is essential to ensure that their performance does not degrade over time, potentially leading to increased energy consumption. Research should focus on maintaining or improving energy efficiency alongside durability enhancements to maximize the environmental benefits.

The recyclability of durable nichrome heating elements is also a key consideration. As these components are designed to last longer, it is important to develop effective recycling processes that can recover valuable materials at the end of their extended life cycle. This approach can help close the loop in material usage and further reduce the environmental impact of heating element production and disposal.

In conclusion, the environmental impact of durable nichrome heating elements is multifaceted. While the potential for waste reduction and resource conservation is significant, careful consideration must be given to the entire life cycle of these enhanced components. Balancing durability improvements with energy efficiency, recyclability, and responsible material sourcing will be crucial in maximizing the positive environmental outcomes of this technological advancement.

Improved durability in heating elements can significantly reduce waste generation and resource consumption. Longer-lasting nichrome elements mean fewer replacements are needed over time, resulting in decreased manufacturing demands and reduced disposal of spent components. This reduction in material turnover can lead to lower energy consumption and greenhouse gas emissions associated with production processes, transportation, and end-of-life management.

Furthermore, durable heating elements contribute to the overall longevity of appliances and industrial equipment. This extended lifespan of products containing nichrome elements can help mitigate the environmental burden of electronic waste, which is a growing concern globally. By reducing the frequency of appliance replacements, the demand for raw materials and energy-intensive manufacturing processes can be curtailed, leading to a smaller ecological footprint.

However, the environmental impact of enhancing nichrome heating element durability is not without potential drawbacks. The development of more resilient materials may involve the use of additional alloying elements or surface treatments, which could introduce new environmental challenges. These may include increased mining activities for rare elements or the use of potentially harmful chemicals in manufacturing processes. It is crucial to carefully assess the life cycle impacts of these enhanced materials to ensure that the environmental benefits outweigh any new risks introduced.

Energy efficiency is another important factor to consider. While durable heating elements may last longer, it is essential to ensure that their performance does not degrade over time, potentially leading to increased energy consumption. Research should focus on maintaining or improving energy efficiency alongside durability enhancements to maximize the environmental benefits.

The recyclability of durable nichrome heating elements is also a key consideration. As these components are designed to last longer, it is important to develop effective recycling processes that can recover valuable materials at the end of their extended life cycle. This approach can help close the loop in material usage and further reduce the environmental impact of heating element production and disposal.

In conclusion, the environmental impact of durable nichrome heating elements is multifaceted. While the potential for waste reduction and resource conservation is significant, careful consideration must be given to the entire life cycle of these enhanced components. Balancing durability improvements with energy efficiency, recyclability, and responsible material sourcing will be crucial in maximizing the positive environmental outcomes of this technological advancement.

Cost-Benefit Analysis of Enhanced Durability

Enhancing the durability of nichrome heating elements presents a complex cost-benefit scenario that requires careful analysis. The initial investment in research and development, as well as the potential increase in production costs, must be weighed against the long-term benefits of improved product performance and customer satisfaction.

From a cost perspective, developing more durable nichrome heating elements may involve significant upfront expenses. These costs include research into new alloy compositions, testing of various coating materials, and optimization of manufacturing processes. Additionally, the implementation of new production techniques or the use of higher-quality materials may increase the per-unit cost of heating elements.

However, the benefits of enhanced durability can be substantial. Longer-lasting heating elements reduce the frequency of replacements, leading to decreased maintenance costs for end-users. This improved reliability can result in higher customer satisfaction and potentially increased market share. For industrial applications, where downtime is costly, more durable heating elements can significantly reduce operational expenses and improve overall efficiency.

The environmental impact should also be considered in this analysis. More durable heating elements contribute to sustainability efforts by reducing waste and conserving resources. This aligns with growing consumer and regulatory demands for environmentally responsible products, potentially opening new market opportunities and enhancing brand reputation.

From a competitive standpoint, offering heating elements with superior durability can be a key differentiator in the market. This advantage may justify premium pricing, potentially offsetting the higher production costs and increasing profit margins. Moreover, the reputation gained from producing high-quality, long-lasting products can lead to increased brand loyalty and recurring sales.

It's important to note that the cost-benefit ratio may vary depending on the specific application of the heating elements. In high-temperature industrial settings, where elements are subjected to extreme stress, the benefits of enhanced durability are likely to be more pronounced compared to lower-temperature consumer applications.

In conclusion, while enhancing the durability of nichrome heating elements may incur higher initial costs, the long-term benefits in terms of customer satisfaction, reduced maintenance, environmental sustainability, and market differentiation present a compelling case for investment. A thorough market analysis and pilot studies would be crucial to quantify these benefits and determine the optimal level of durability enhancement for different market segments.

From a cost perspective, developing more durable nichrome heating elements may involve significant upfront expenses. These costs include research into new alloy compositions, testing of various coating materials, and optimization of manufacturing processes. Additionally, the implementation of new production techniques or the use of higher-quality materials may increase the per-unit cost of heating elements.

However, the benefits of enhanced durability can be substantial. Longer-lasting heating elements reduce the frequency of replacements, leading to decreased maintenance costs for end-users. This improved reliability can result in higher customer satisfaction and potentially increased market share. For industrial applications, where downtime is costly, more durable heating elements can significantly reduce operational expenses and improve overall efficiency.

The environmental impact should also be considered in this analysis. More durable heating elements contribute to sustainability efforts by reducing waste and conserving resources. This aligns with growing consumer and regulatory demands for environmentally responsible products, potentially opening new market opportunities and enhancing brand reputation.

From a competitive standpoint, offering heating elements with superior durability can be a key differentiator in the market. This advantage may justify premium pricing, potentially offsetting the higher production costs and increasing profit margins. Moreover, the reputation gained from producing high-quality, long-lasting products can lead to increased brand loyalty and recurring sales.

It's important to note that the cost-benefit ratio may vary depending on the specific application of the heating elements. In high-temperature industrial settings, where elements are subjected to extreme stress, the benefits of enhanced durability are likely to be more pronounced compared to lower-temperature consumer applications.

In conclusion, while enhancing the durability of nichrome heating elements may incur higher initial costs, the long-term benefits in terms of customer satisfaction, reduced maintenance, environmental sustainability, and market differentiation present a compelling case for investment. A thorough market analysis and pilot studies would be crucial to quantify these benefits and determine the optimal level of durability enhancement for different market segments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!