Flexible Piezoelectric Patch Design for Health Sensors

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Piezo Patch Background and Objectives

Flexible piezoelectric patches have emerged as a promising technology for health sensors, offering a unique combination of flexibility, sensitivity, and energy harvesting capabilities. The development of these patches traces back to the discovery of the piezoelectric effect in certain materials, which generate an electric charge in response to applied mechanical stress. Over the years, researchers have made significant strides in enhancing the performance and applicability of piezoelectric materials in wearable health monitoring devices.

The evolution of flexible piezoelectric patches has been driven by the growing demand for non-invasive, continuous health monitoring solutions. As healthcare systems worldwide face increasing pressure from aging populations and the rise of chronic diseases, there is a pressing need for innovative technologies that can provide real-time, accurate health data outside of traditional clinical settings. Flexible piezoelectric patches address this need by offering a comfortable, unobtrusive means of monitoring various physiological parameters.

Recent advancements in materials science and nanofabrication techniques have accelerated the development of highly sensitive and conformable piezoelectric patches. These innovations have enabled the creation of ultra-thin, stretchable sensors that can be seamlessly integrated into clothing or applied directly to the skin. The ability to harvest energy from body movements has also opened up new possibilities for self-powered health monitoring devices, potentially eliminating the need for frequent battery replacements.

The primary objective of research in flexible piezoelectric patch design for health sensors is to optimize the balance between sensitivity, flexibility, and durability. This involves exploring novel materials and composite structures that can enhance the piezoelectric response while maintaining mechanical compliance. Additionally, researchers aim to develop advanced manufacturing techniques that enable large-scale production of these patches at a reasonable cost, making them accessible for widespread adoption in healthcare applications.

Another crucial goal is to expand the range of health parameters that can be monitored using piezoelectric patches. While current applications focus primarily on measuring physical movements and vital signs, ongoing research seeks to extend their capabilities to include biochemical sensing and more complex physiological measurements. This expansion of functionality could potentially revolutionize personal health monitoring and preventive care strategies.

As the field progresses, there is also a growing emphasis on developing integrated systems that combine flexible piezoelectric patches with data processing and wireless communication technologies. The ultimate aim is to create comprehensive health monitoring platforms that can provide actionable insights to both users and healthcare providers, facilitating early detection of health issues and personalized treatment approaches.

The evolution of flexible piezoelectric patches has been driven by the growing demand for non-invasive, continuous health monitoring solutions. As healthcare systems worldwide face increasing pressure from aging populations and the rise of chronic diseases, there is a pressing need for innovative technologies that can provide real-time, accurate health data outside of traditional clinical settings. Flexible piezoelectric patches address this need by offering a comfortable, unobtrusive means of monitoring various physiological parameters.

Recent advancements in materials science and nanofabrication techniques have accelerated the development of highly sensitive and conformable piezoelectric patches. These innovations have enabled the creation of ultra-thin, stretchable sensors that can be seamlessly integrated into clothing or applied directly to the skin. The ability to harvest energy from body movements has also opened up new possibilities for self-powered health monitoring devices, potentially eliminating the need for frequent battery replacements.

The primary objective of research in flexible piezoelectric patch design for health sensors is to optimize the balance between sensitivity, flexibility, and durability. This involves exploring novel materials and composite structures that can enhance the piezoelectric response while maintaining mechanical compliance. Additionally, researchers aim to develop advanced manufacturing techniques that enable large-scale production of these patches at a reasonable cost, making them accessible for widespread adoption in healthcare applications.

Another crucial goal is to expand the range of health parameters that can be monitored using piezoelectric patches. While current applications focus primarily on measuring physical movements and vital signs, ongoing research seeks to extend their capabilities to include biochemical sensing and more complex physiological measurements. This expansion of functionality could potentially revolutionize personal health monitoring and preventive care strategies.

As the field progresses, there is also a growing emphasis on developing integrated systems that combine flexible piezoelectric patches with data processing and wireless communication technologies. The ultimate aim is to create comprehensive health monitoring platforms that can provide actionable insights to both users and healthcare providers, facilitating early detection of health issues and personalized treatment approaches.

Health Sensor Market Analysis

The health sensor market has experienced significant growth in recent years, driven by increasing health awareness, aging populations, and advancements in wearable technology. The global health sensor market was valued at $36.5 billion in 2021 and is projected to reach $96.8 billion by 2028, growing at a CAGR of 17.2% during the forecast period. This robust growth is attributed to the rising prevalence of chronic diseases, the need for remote patient monitoring, and the integration of artificial intelligence and IoT in healthcare devices.

Flexible piezoelectric patches for health sensors represent a promising segment within this market. These patches offer advantages such as non-invasive monitoring, real-time data collection, and improved patient comfort. The demand for such sensors is particularly strong in applications like continuous vital sign monitoring, physical activity tracking, and early disease detection.

The market for flexible piezoelectric health sensors is segmented based on application areas, including cardiovascular monitoring, respiratory monitoring, sleep analysis, and physical activity tracking. Cardiovascular monitoring holds the largest market share due to the high prevalence of heart diseases and the need for continuous ECG monitoring. The respiratory monitoring segment is expected to witness the fastest growth, driven by the increasing incidence of respiratory disorders and the COVID-19 pandemic's impact on respiratory health awareness.

Geographically, North America dominates the health sensor market, followed by Europe and Asia-Pacific. The United States, in particular, leads in adopting innovative health monitoring technologies due to its advanced healthcare infrastructure and high healthcare expenditure. However, the Asia-Pacific region is expected to exhibit the highest growth rate, fueled by improving healthcare systems, rising disposable incomes, and increasing awareness of preventive healthcare in countries like China and India.

Key market players in the flexible piezoelectric health sensor space include established medical device manufacturers, emerging startups, and technology giants entering the healthcare sector. These companies are focusing on developing miniaturized, energy-efficient sensors with improved accuracy and reliability. Collaborations between sensor manufacturers, healthcare providers, and software developers are becoming increasingly common to create integrated health monitoring solutions.

The market faces challenges such as data privacy concerns, regulatory hurdles, and the need for clinical validation of sensor accuracy. However, ongoing technological advancements, increasing healthcare digitization, and the shift towards personalized medicine are expected to drive continued growth in the flexible piezoelectric health sensor market.

Flexible piezoelectric patches for health sensors represent a promising segment within this market. These patches offer advantages such as non-invasive monitoring, real-time data collection, and improved patient comfort. The demand for such sensors is particularly strong in applications like continuous vital sign monitoring, physical activity tracking, and early disease detection.

The market for flexible piezoelectric health sensors is segmented based on application areas, including cardiovascular monitoring, respiratory monitoring, sleep analysis, and physical activity tracking. Cardiovascular monitoring holds the largest market share due to the high prevalence of heart diseases and the need for continuous ECG monitoring. The respiratory monitoring segment is expected to witness the fastest growth, driven by the increasing incidence of respiratory disorders and the COVID-19 pandemic's impact on respiratory health awareness.

Geographically, North America dominates the health sensor market, followed by Europe and Asia-Pacific. The United States, in particular, leads in adopting innovative health monitoring technologies due to its advanced healthcare infrastructure and high healthcare expenditure. However, the Asia-Pacific region is expected to exhibit the highest growth rate, fueled by improving healthcare systems, rising disposable incomes, and increasing awareness of preventive healthcare in countries like China and India.

Key market players in the flexible piezoelectric health sensor space include established medical device manufacturers, emerging startups, and technology giants entering the healthcare sector. These companies are focusing on developing miniaturized, energy-efficient sensors with improved accuracy and reliability. Collaborations between sensor manufacturers, healthcare providers, and software developers are becoming increasingly common to create integrated health monitoring solutions.

The market faces challenges such as data privacy concerns, regulatory hurdles, and the need for clinical validation of sensor accuracy. However, ongoing technological advancements, increasing healthcare digitization, and the shift towards personalized medicine are expected to drive continued growth in the flexible piezoelectric health sensor market.

Flexible Piezo Tech Challenges

The development of flexible piezoelectric patches for health sensors faces several significant technical challenges that researchers and engineers must overcome to realize their full potential in wearable and implantable medical devices. One of the primary obstacles is achieving a balance between flexibility and performance. While flexibility is crucial for conforming to the human body's contours, it often comes at the cost of reduced piezoelectric efficiency.

Material selection and optimization present another major hurdle. Conventional piezoelectric materials like lead zirconate titanate (PZT) are rigid and brittle, making them unsuitable for flexible applications. Researchers are exploring alternative materials such as polyvinylidene fluoride (PVDF) and its copolymers, but these often exhibit lower piezoelectric coefficients compared to ceramic counterparts.

The integration of flexible piezoelectric patches with other electronic components poses significant challenges. Creating reliable and durable connections between the flexible patch and rigid electronic elements like microprocessors and power management circuits requires innovative interface designs and manufacturing techniques.

Durability and long-term stability are critical concerns for health sensor applications. Flexible piezoelectric patches must withstand repeated bending, stretching, and exposure to bodily fluids without degradation in performance. Developing robust encapsulation methods and protective layers that do not compromise flexibility or sensitivity is an ongoing challenge.

Miniaturization of the entire sensor system, including the piezoelectric patch, associated electronics, and power sources, remains a significant technical hurdle. Reducing the overall size while maintaining functionality is crucial for user comfort and widespread adoption of wearable health sensors.

Energy harvesting and power management present unique challenges in flexible piezoelectric systems. Maximizing the energy conversion efficiency from mechanical deformation to electrical output, while operating at the low frequencies typical of human body movements, requires sophisticated circuit designs and energy storage solutions.

Biocompatibility and safety considerations add another layer of complexity to the development of flexible piezoelectric patches for health sensors. Ensuring that all materials used are non-toxic, non-irritating, and do not trigger immune responses is paramount, especially for long-term use or implantable applications.

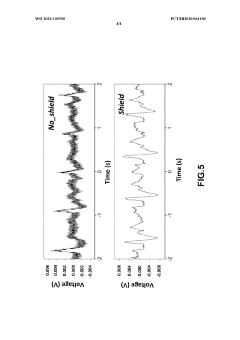

Signal processing and noise reduction in flexible piezoelectric sensors pose significant technical challenges. The low-amplitude signals generated by body movements must be accurately detected and processed amidst various sources of noise and interference, necessitating advanced signal conditioning and data analysis algorithms.

Material selection and optimization present another major hurdle. Conventional piezoelectric materials like lead zirconate titanate (PZT) are rigid and brittle, making them unsuitable for flexible applications. Researchers are exploring alternative materials such as polyvinylidene fluoride (PVDF) and its copolymers, but these often exhibit lower piezoelectric coefficients compared to ceramic counterparts.

The integration of flexible piezoelectric patches with other electronic components poses significant challenges. Creating reliable and durable connections between the flexible patch and rigid electronic elements like microprocessors and power management circuits requires innovative interface designs and manufacturing techniques.

Durability and long-term stability are critical concerns for health sensor applications. Flexible piezoelectric patches must withstand repeated bending, stretching, and exposure to bodily fluids without degradation in performance. Developing robust encapsulation methods and protective layers that do not compromise flexibility or sensitivity is an ongoing challenge.

Miniaturization of the entire sensor system, including the piezoelectric patch, associated electronics, and power sources, remains a significant technical hurdle. Reducing the overall size while maintaining functionality is crucial for user comfort and widespread adoption of wearable health sensors.

Energy harvesting and power management present unique challenges in flexible piezoelectric systems. Maximizing the energy conversion efficiency from mechanical deformation to electrical output, while operating at the low frequencies typical of human body movements, requires sophisticated circuit designs and energy storage solutions.

Biocompatibility and safety considerations add another layer of complexity to the development of flexible piezoelectric patches for health sensors. Ensuring that all materials used are non-toxic, non-irritating, and do not trigger immune responses is paramount, especially for long-term use or implantable applications.

Signal processing and noise reduction in flexible piezoelectric sensors pose significant technical challenges. The low-amplitude signals generated by body movements must be accurately detected and processed amidst various sources of noise and interference, necessitating advanced signal conditioning and data analysis algorithms.

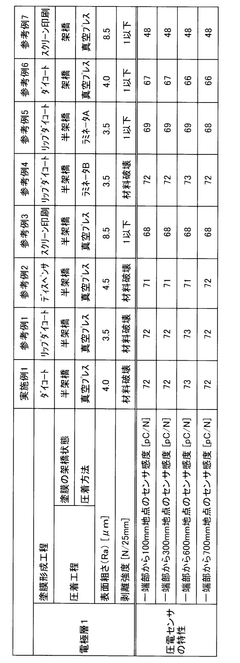

Current Flexible Piezo Patch Designs

01 Flexible piezoelectric materials

Development of flexible piezoelectric materials that can be used in patches. These materials maintain their piezoelectric properties while being bendable and conformable to various surfaces. This includes the use of polymers, composites, and thin films that exhibit both flexibility and piezoelectric behavior.- Flexible piezoelectric materials: Flexible piezoelectric materials are used to create patches that can conform to various surfaces. These materials, such as polyvinylidene fluoride (PVDF) or its copolymers, exhibit both piezoelectric properties and flexibility, making them ideal for wearable or bendable applications. The flexibility allows for better contact with the target surface, improving energy harvesting or sensing capabilities.

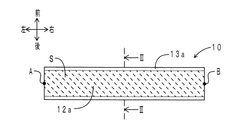

- Substrate and electrode design: The flexibility of piezoelectric patches is enhanced through careful design of substrates and electrodes. Flexible substrates, such as polyimide or silicone, are used as a base. Stretchable or serpentine-patterned electrodes are employed to maintain electrical connectivity during bending or stretching. This design approach allows the patch to conform to complex surfaces while maintaining functionality.

- Composite structures: Composite structures are developed to improve the flexibility and performance of piezoelectric patches. These may include combinations of piezoelectric materials with elastic polymers, nanofibers, or other flexible materials. The composite approach allows for tailoring of mechanical properties while maintaining or enhancing piezoelectric performance, resulting in patches that can withstand repeated bending or stretching.

- Encapsulation techniques: Various encapsulation techniques are employed to protect the flexible piezoelectric elements while maintaining overall patch flexibility. Soft, elastic encapsulants or thin-film encapsulation methods are used to shield the active components from environmental factors and mechanical stress. These techniques help to extend the lifespan of the flexible patches and ensure consistent performance under various conditions.

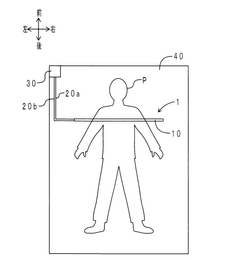

- Application-specific designs: Flexible piezoelectric patches are designed with specific applications in mind, such as wearable health monitoring devices, energy harvesting systems, or tactile sensors. The flexibility requirements are tailored to the intended use, considering factors like body movement, surface curvature, or dynamic environments. This application-specific approach optimizes the balance between flexibility and functionality for each use case.

02 Substrate and electrode design

Innovative designs for flexible substrates and electrodes that allow the piezoelectric patch to bend and stretch without losing functionality. This involves the use of stretchable electrodes, serpentine patterns, and mesh structures to enhance overall flexibility while maintaining electrical connectivity.Expand Specific Solutions03 Encapsulation techniques

Development of flexible encapsulation methods to protect the piezoelectric elements while preserving the patch's flexibility. This includes the use of soft polymers, elastomers, and thin-film encapsulation techniques that provide environmental protection without compromising the patch's ability to conform to curved surfaces.Expand Specific Solutions04 Integration with wearable devices

Techniques for integrating flexible piezoelectric patches into wearable devices and smart textiles. This involves developing methods to seamlessly incorporate the patches into clothing, accessories, or medical devices while maintaining comfort and flexibility for the user.Expand Specific Solutions05 Optimization of patch geometry

Research into optimal geometries and structures for flexible piezoelectric patches to maximize both flexibility and energy harvesting or sensing capabilities. This includes the development of multi-layer structures, patterned designs, and micro-structured surfaces that enhance the patch's performance while maintaining its flexibility.Expand Specific Solutions

Key Players in Flexible Electronics

The research on flexible piezoelectric patch design for health sensors is in a rapidly evolving phase, characterized by growing market potential and advancing technological maturity. The global market for wearable health sensors is expanding, driven by increasing demand for remote patient monitoring and personalized healthcare solutions. Companies like Sumitomo Riko Co. Ltd., Abbott Diabetes Care, Inc., and Baxter International, Inc. are at the forefront of developing innovative flexible sensor technologies. Academic institutions such as Zhejiang University and Northwestern Polytechnical University are contributing significantly to research advancements. The collaboration between industry leaders and research institutions is accelerating the development of more sophisticated, reliable, and user-friendly flexible piezoelectric patches for health monitoring applications.

Zhejiang University

Technical Solution: Zhejiang University has developed a flexible piezoelectric patch design for health sensors using PVDF (polyvinylidene fluoride) nanofibers. Their approach involves electrospinning PVDF nanofibers to create a highly sensitive and flexible piezoelectric material. The nanofiber structure enhances the piezoelectric response due to its high surface area and aligned molecular chains. The researchers have demonstrated the application of these patches in wearable health monitoring devices, capable of detecting subtle physiological signals such as heartbeat and respiration[1][3]. The patches are fabricated using a low-cost, scalable process and can be easily integrated into various wearable form factors.

Strengths: High sensitivity, flexibility, and durability. Scalable production process. Weaknesses: May require additional protective layers for long-term use in harsh environments.

Abbott Diabetes Care, Inc.

Technical Solution: Abbott Diabetes Care has developed a flexible piezoelectric patch design for continuous glucose monitoring (CGM) systems. Their approach integrates a thin, flexible piezoelectric material into a wearable patch that can detect minute changes in interstitial fluid glucose levels. The piezoelectric element generates electrical signals in response to mechanical deformations caused by glucose-induced osmotic pressure changes. This design allows for non-invasive, real-time glucose monitoring without the need for frequent finger pricks[2][5]. The patch incorporates advanced signal processing algorithms to filter out noise and improve accuracy. Abbott's system also includes wireless connectivity for data transmission to smartphones or other devices for easy monitoring and analysis.

Strengths: Non-invasive, continuous monitoring. Improved patient comfort and compliance. Weaknesses: May be affected by external factors like temperature and skin moisture.

Innovative Piezo Sensing Technologies

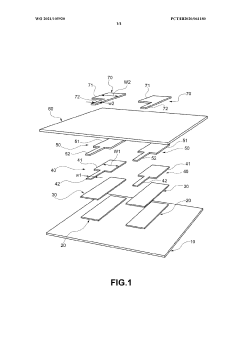

Flexible piezoelectric sensor with integrated electromagnetic shield

PatentWO2021105920A1

Innovation

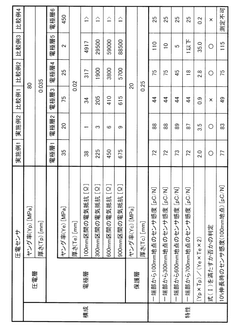

- A flexible piezoelectric sensor design incorporating a thin metal shielding layer short-circuited to the bottom electrode, integrated within the manufacturing process using standard microfabrication techniques, ensuring effective electromagnetic shielding without compromising mechanical properties.

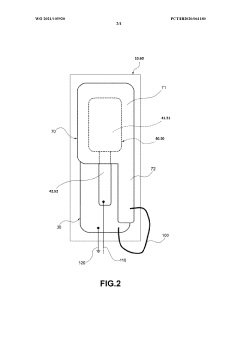

Piezoelectric sensor and method for manufacturing same

PatentWO2020157999A1

Innovation

- A flexible piezoelectric sensor design featuring a piezoelectric layer with elastomer and piezoelectric particles, and an electrode layer made of elastomer with flaky conductive material, oriented to maintain high conductivity and flexibility, even when elongated, by aligning flaky conductive materials in the length direction and pressure bonding with the piezoelectric layer before crosslinking.

Biocompatibility and Safety Standards

The development of flexible piezoelectric patches for health sensors necessitates rigorous adherence to biocompatibility and safety standards to ensure their suitability for direct contact with human skin. These standards are crucial for minimizing potential adverse reactions and ensuring long-term user safety.

Biocompatibility standards for flexible piezoelectric patches primarily focus on material selection and surface properties. ISO 10993 series, particularly ISO 10993-1, provides a comprehensive framework for evaluating the biological safety of medical devices. For piezoelectric patches, emphasis is placed on cytotoxicity (ISO 10993-5), skin irritation and sensitization (ISO 10993-10), and systemic toxicity (ISO 10993-11) tests.

Materials commonly used in flexible piezoelectric patches, such as polyvinylidene fluoride (PVDF) and its copolymers, must undergo thorough biocompatibility assessments. These evaluations typically include in vitro cell culture studies and in vivo animal testing to assess potential cytotoxicity, allergic responses, and long-term tissue compatibility.

Safety standards for wearable health sensors extend beyond biocompatibility to encompass electrical safety, electromagnetic compatibility (EMC), and data security. IEC 60601-1 provides general requirements for basic safety and essential performance of medical electrical equipment, which is applicable to piezoelectric patch-based health sensors.

Electromagnetic compatibility is a critical consideration, given the potential for interference with other medical devices. IEC 60601-1-2 outlines EMC requirements for medical devices, ensuring that piezoelectric patches do not emit harmful electromagnetic radiation or interfere with nearby electronic equipment.

Data security and privacy standards, such as the Health Insurance Portability and Accountability Act (HIPAA) in the United States, must be considered in the design of data transmission and storage systems associated with piezoelectric patch sensors. These standards ensure the protection of sensitive health information collected by the sensors.

Durability and reliability standards are also crucial for flexible piezoelectric patches. ISO 13485, which specifies requirements for quality management systems in medical devices, provides a framework for ensuring consistent production of safe and effective sensors. This includes considerations for mechanical stress, environmental factors, and long-term stability of the piezoelectric materials.

As wearable health technology advances, regulatory bodies are continually updating standards to address emerging challenges. Researchers and manufacturers must stay abreast of these evolving requirements to ensure compliance and maintain public trust in flexible piezoelectric patch technology for health monitoring applications.

Biocompatibility standards for flexible piezoelectric patches primarily focus on material selection and surface properties. ISO 10993 series, particularly ISO 10993-1, provides a comprehensive framework for evaluating the biological safety of medical devices. For piezoelectric patches, emphasis is placed on cytotoxicity (ISO 10993-5), skin irritation and sensitization (ISO 10993-10), and systemic toxicity (ISO 10993-11) tests.

Materials commonly used in flexible piezoelectric patches, such as polyvinylidene fluoride (PVDF) and its copolymers, must undergo thorough biocompatibility assessments. These evaluations typically include in vitro cell culture studies and in vivo animal testing to assess potential cytotoxicity, allergic responses, and long-term tissue compatibility.

Safety standards for wearable health sensors extend beyond biocompatibility to encompass electrical safety, electromagnetic compatibility (EMC), and data security. IEC 60601-1 provides general requirements for basic safety and essential performance of medical electrical equipment, which is applicable to piezoelectric patch-based health sensors.

Electromagnetic compatibility is a critical consideration, given the potential for interference with other medical devices. IEC 60601-1-2 outlines EMC requirements for medical devices, ensuring that piezoelectric patches do not emit harmful electromagnetic radiation or interfere with nearby electronic equipment.

Data security and privacy standards, such as the Health Insurance Portability and Accountability Act (HIPAA) in the United States, must be considered in the design of data transmission and storage systems associated with piezoelectric patch sensors. These standards ensure the protection of sensitive health information collected by the sensors.

Durability and reliability standards are also crucial for flexible piezoelectric patches. ISO 13485, which specifies requirements for quality management systems in medical devices, provides a framework for ensuring consistent production of safe and effective sensors. This includes considerations for mechanical stress, environmental factors, and long-term stability of the piezoelectric materials.

As wearable health technology advances, regulatory bodies are continually updating standards to address emerging challenges. Researchers and manufacturers must stay abreast of these evolving requirements to ensure compliance and maintain public trust in flexible piezoelectric patch technology for health monitoring applications.

Energy Harvesting Potential

Flexible piezoelectric patches for health sensors offer significant potential for energy harvesting, addressing the critical need for sustainable power sources in wearable and implantable medical devices. These patches can convert mechanical energy from body movements, vibrations, and pressure changes into electrical energy, providing a continuous and renewable power supply for health monitoring systems.

The energy harvesting capabilities of piezoelectric patches are particularly advantageous in the context of health sensors due to their ability to operate in diverse physiological environments. By harnessing energy from natural body processes such as breathing, heartbeats, and muscle movements, these patches can potentially eliminate or significantly reduce the need for battery replacements in long-term health monitoring devices.

Recent advancements in materials science and nanofabrication techniques have led to the development of highly efficient piezoelectric materials with enhanced flexibility and durability. These improvements have resulted in piezoelectric patches that can conform to complex body contours while maintaining optimal energy conversion efficiency. The integration of these patches with health sensors creates a symbiotic system where the sensor's power requirements are met through the continuous harvesting of ambient mechanical energy.

The energy harvesting potential of flexible piezoelectric patches extends beyond mere power generation. These patches can also serve as self-powered sensors, capable of detecting and measuring physiological parameters based on the electrical signals generated from mechanical stimuli. This dual functionality opens up new possibilities for minimally invasive, long-term health monitoring solutions.

Furthermore, the scalability of piezoelectric patch technology allows for its application in a wide range of health sensing devices, from small wearable patches to larger implantable systems. This versatility enables the development of energy-autonomous health sensors for various medical applications, including continuous glucose monitoring, cardiac activity tracking, and motion analysis for rehabilitation purposes.

However, challenges remain in maximizing the energy harvesting potential of these patches. Ongoing research focuses on optimizing the piezoelectric material composition, improving the energy conversion efficiency, and developing more effective energy storage and management systems. Additionally, efforts are being made to enhance the biocompatibility and long-term stability of these patches to ensure their suitability for prolonged use in health monitoring applications.

As the field progresses, the integration of flexible piezoelectric patches with other energy harvesting technologies, such as thermoelectric generators and photovoltaic cells, holds promise for creating hybrid systems capable of harvesting energy from multiple sources. This multi-modal approach could significantly enhance the overall energy harvesting potential and reliability of health sensor systems, paving the way for truly self-sustaining wearable and implantable medical devices.

The energy harvesting capabilities of piezoelectric patches are particularly advantageous in the context of health sensors due to their ability to operate in diverse physiological environments. By harnessing energy from natural body processes such as breathing, heartbeats, and muscle movements, these patches can potentially eliminate or significantly reduce the need for battery replacements in long-term health monitoring devices.

Recent advancements in materials science and nanofabrication techniques have led to the development of highly efficient piezoelectric materials with enhanced flexibility and durability. These improvements have resulted in piezoelectric patches that can conform to complex body contours while maintaining optimal energy conversion efficiency. The integration of these patches with health sensors creates a symbiotic system where the sensor's power requirements are met through the continuous harvesting of ambient mechanical energy.

The energy harvesting potential of flexible piezoelectric patches extends beyond mere power generation. These patches can also serve as self-powered sensors, capable of detecting and measuring physiological parameters based on the electrical signals generated from mechanical stimuli. This dual functionality opens up new possibilities for minimally invasive, long-term health monitoring solutions.

Furthermore, the scalability of piezoelectric patch technology allows for its application in a wide range of health sensing devices, from small wearable patches to larger implantable systems. This versatility enables the development of energy-autonomous health sensors for various medical applications, including continuous glucose monitoring, cardiac activity tracking, and motion analysis for rehabilitation purposes.

However, challenges remain in maximizing the energy harvesting potential of these patches. Ongoing research focuses on optimizing the piezoelectric material composition, improving the energy conversion efficiency, and developing more effective energy storage and management systems. Additionally, efforts are being made to enhance the biocompatibility and long-term stability of these patches to ensure their suitability for prolonged use in health monitoring applications.

As the field progresses, the integration of flexible piezoelectric patches with other energy harvesting technologies, such as thermoelectric generators and photovoltaic cells, holds promise for creating hybrid systems capable of harvesting energy from multiple sources. This multi-modal approach could significantly enhance the overall energy harvesting potential and reliability of health sensor systems, paving the way for truly self-sustaining wearable and implantable medical devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!