High Performance Nichrome Wire for Advanced Electronics

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Wire Evolution and Objectives

Nichrome wire, an alloy primarily composed of nickel and chromium, has been a cornerstone in the field of electronics for over a century. Its evolution has been driven by the ever-increasing demands of advanced electronic applications, particularly in areas requiring high-performance resistive elements. The journey of nichrome wire began in the early 1900s when it was first developed as a heating element, but its potential in electronics was quickly recognized.

The primary objective in the research of high-performance nichrome wire for advanced electronics is to enhance its electrical and thermal properties while maintaining or improving its durability and reliability. This involves optimizing the alloy composition, refining manufacturing processes, and exploring novel structural designs at the micro and nano scales.

One of the key evolutionary trends in nichrome wire development has been the fine-tuning of its nickel-chromium ratio. While the traditional 80/20 composition (80% nickel, 20% chromium) has been widely used, researchers have been experimenting with varying ratios and introducing additional elements to achieve specific performance characteristics. These efforts aim to strike a balance between electrical resistivity, temperature coefficient of resistance, and oxidation resistance.

Another significant aspect of nichrome wire evolution is the advancement in manufacturing techniques. From early methods of drawing and annealing, the industry has progressed to more sophisticated processes such as precision controlled atmosphere melting, rapid solidification, and advanced heat treatment protocols. These improvements have led to more consistent wire properties and the ability to produce ultra-fine gauge wires suitable for miniaturized electronic components.

The objectives of current research in high-performance nichrome wire are multifaceted. Firstly, there is a push towards increasing the maximum operating temperature of the wire without compromising its stability or lifespan. This is crucial for applications in high-power electronics and extreme environment sensors. Secondly, researchers are focusing on enhancing the wire's resistance to oxidation and corrosion, which is essential for long-term reliability in diverse operating conditions.

Furthermore, the miniaturization trend in electronics has set new goals for nichrome wire development. The aim is to produce wires with extremely small diameters while maintaining uniform electrical properties and mechanical strength. This objective is particularly challenging as it requires overcoming the limitations of traditional manufacturing methods and exploring new approaches such as nanoscale fabrication techniques.

Lastly, an emerging objective in nichrome wire research is the integration of smart functionalities. This includes developing wires with self-diagnostic capabilities, such as the ability to detect and report stress or temperature anomalies. Such advancements could revolutionize the reliability and maintenance aspects of electronic systems, especially in critical applications like aerospace and medical devices.

The primary objective in the research of high-performance nichrome wire for advanced electronics is to enhance its electrical and thermal properties while maintaining or improving its durability and reliability. This involves optimizing the alloy composition, refining manufacturing processes, and exploring novel structural designs at the micro and nano scales.

One of the key evolutionary trends in nichrome wire development has been the fine-tuning of its nickel-chromium ratio. While the traditional 80/20 composition (80% nickel, 20% chromium) has been widely used, researchers have been experimenting with varying ratios and introducing additional elements to achieve specific performance characteristics. These efforts aim to strike a balance between electrical resistivity, temperature coefficient of resistance, and oxidation resistance.

Another significant aspect of nichrome wire evolution is the advancement in manufacturing techniques. From early methods of drawing and annealing, the industry has progressed to more sophisticated processes such as precision controlled atmosphere melting, rapid solidification, and advanced heat treatment protocols. These improvements have led to more consistent wire properties and the ability to produce ultra-fine gauge wires suitable for miniaturized electronic components.

The objectives of current research in high-performance nichrome wire are multifaceted. Firstly, there is a push towards increasing the maximum operating temperature of the wire without compromising its stability or lifespan. This is crucial for applications in high-power electronics and extreme environment sensors. Secondly, researchers are focusing on enhancing the wire's resistance to oxidation and corrosion, which is essential for long-term reliability in diverse operating conditions.

Furthermore, the miniaturization trend in electronics has set new goals for nichrome wire development. The aim is to produce wires with extremely small diameters while maintaining uniform electrical properties and mechanical strength. This objective is particularly challenging as it requires overcoming the limitations of traditional manufacturing methods and exploring new approaches such as nanoscale fabrication techniques.

Lastly, an emerging objective in nichrome wire research is the integration of smart functionalities. This includes developing wires with self-diagnostic capabilities, such as the ability to detect and report stress or temperature anomalies. Such advancements could revolutionize the reliability and maintenance aspects of electronic systems, especially in critical applications like aerospace and medical devices.

Electronics Market Demand Analysis

The global electronics market has been experiencing significant growth, driven by the increasing demand for advanced electronic devices across various sectors. The market for high-performance nichrome wire, a critical component in many electronic applications, is closely tied to this overall trend. As consumer electronics, automotive systems, and industrial equipment become more sophisticated, the need for reliable and efficient heating elements and resistors has surged.

In the consumer electronics segment, the demand for nichrome wire is particularly strong. Smartphones, tablets, and wearable devices require miniaturized components that can withstand high temperatures and provide precise resistance control. The growing popularity of smart home devices, such as thermostats and appliances, also contributes to the increased demand for high-quality nichrome wire.

The automotive industry represents another significant market for advanced nichrome wire. With the rise of electric and hybrid vehicles, there is a growing need for efficient heating systems and sensors that can operate in harsh environments. Nichrome wire is used in various automotive applications, including seat heaters, defrosting systems, and engine management sensors.

In the industrial sector, the demand for high-performance nichrome wire is driven by the need for reliable heating elements in manufacturing processes, laboratory equipment, and aerospace applications. The wire's ability to maintain stable resistance at high temperatures makes it invaluable in these demanding environments.

The medical device industry is also a key driver of demand for advanced nichrome wire. Surgical instruments, diagnostic equipment, and therapeutic devices often require precise temperature control and resistance properties, which nichrome wire can provide.

Market analysts project that the global nichrome wire market will continue to grow at a steady pace in the coming years. This growth is attributed to the increasing adoption of electronic devices across various industries and the ongoing technological advancements in electronics manufacturing.

However, the market also faces challenges. The volatility in raw material prices, particularly nickel and chromium, can impact the production costs and pricing of nichrome wire. Additionally, environmental regulations regarding the use of certain metals in electronic components may influence market dynamics.

Despite these challenges, the overall outlook for the high-performance nichrome wire market remains positive. The continuous innovation in electronic devices and the expansion of emerging technologies such as Internet of Things (IoT) and 5G networks are expected to create new opportunities for nichrome wire applications, further driving market growth.

In the consumer electronics segment, the demand for nichrome wire is particularly strong. Smartphones, tablets, and wearable devices require miniaturized components that can withstand high temperatures and provide precise resistance control. The growing popularity of smart home devices, such as thermostats and appliances, also contributes to the increased demand for high-quality nichrome wire.

The automotive industry represents another significant market for advanced nichrome wire. With the rise of electric and hybrid vehicles, there is a growing need for efficient heating systems and sensors that can operate in harsh environments. Nichrome wire is used in various automotive applications, including seat heaters, defrosting systems, and engine management sensors.

In the industrial sector, the demand for high-performance nichrome wire is driven by the need for reliable heating elements in manufacturing processes, laboratory equipment, and aerospace applications. The wire's ability to maintain stable resistance at high temperatures makes it invaluable in these demanding environments.

The medical device industry is also a key driver of demand for advanced nichrome wire. Surgical instruments, diagnostic equipment, and therapeutic devices often require precise temperature control and resistance properties, which nichrome wire can provide.

Market analysts project that the global nichrome wire market will continue to grow at a steady pace in the coming years. This growth is attributed to the increasing adoption of electronic devices across various industries and the ongoing technological advancements in electronics manufacturing.

However, the market also faces challenges. The volatility in raw material prices, particularly nickel and chromium, can impact the production costs and pricing of nichrome wire. Additionally, environmental regulations regarding the use of certain metals in electronic components may influence market dynamics.

Despite these challenges, the overall outlook for the high-performance nichrome wire market remains positive. The continuous innovation in electronic devices and the expansion of emerging technologies such as Internet of Things (IoT) and 5G networks are expected to create new opportunities for nichrome wire applications, further driving market growth.

Nichrome Wire Tech Challenges

Nichrome wire, a crucial component in advanced electronics, faces several significant technical challenges that hinder its optimal performance and widespread adoption. One of the primary issues is the trade-off between electrical resistance and thermal stability. As the demand for higher power density in electronic devices increases, nichrome wires are required to handle greater current loads while maintaining their structural integrity at elevated temperatures.

The composition of nichrome alloys presents another challenge. While the typical 80/20 nickel-chromium ratio offers good overall performance, fine-tuning this composition to achieve specific electrical and thermal properties for diverse applications remains complex. Slight variations in the alloy composition can significantly affect the wire's performance characteristics, making precise control during manufacturing essential.

Miniaturization trends in electronics pose additional difficulties for nichrome wire production. As devices become smaller and more compact, the demand for thinner wires with consistent properties increases. However, producing ultra-thin nichrome wires while maintaining uniform composition and cross-sectional area throughout the length of the wire is technically challenging. This issue is further compounded by the need for these thin wires to withstand high temperatures and maintain stable resistance values over time.

The surface oxidation of nichrome wires is another critical concern. While the chromium content provides some degree of oxidation resistance, prolonged exposure to high temperatures can lead to the formation of oxide layers that alter the wire's electrical properties. This oxidation process can cause drift in resistance values over time, affecting the long-term reliability and performance of electronic components.

Mechanical stress and fatigue represent additional challenges, particularly in applications involving repeated thermal cycling or mechanical vibration. The repeated expansion and contraction of nichrome wires due to temperature fluctuations can lead to material fatigue, potentially resulting in wire breakage or changes in electrical properties. Developing nichrome wires that can withstand these stresses while maintaining consistent performance over extended periods is a significant technical hurdle.

Furthermore, the manufacturing process itself presents challenges in achieving consistent quality across large production volumes. Ensuring uniform heating, precise alloying, and controlled cooling during wire drawing are critical factors that impact the final product's performance. Any inconsistencies in these processes can lead to variations in wire properties, affecting the reliability and performance of electronic devices.

Addressing these technical challenges requires interdisciplinary research efforts, combining materials science, electrical engineering, and manufacturing technology. Innovations in alloy design, surface treatment techniques, and advanced manufacturing processes are essential to overcome these limitations and unlock the full potential of nichrome wires in advanced electronics applications.

The composition of nichrome alloys presents another challenge. While the typical 80/20 nickel-chromium ratio offers good overall performance, fine-tuning this composition to achieve specific electrical and thermal properties for diverse applications remains complex. Slight variations in the alloy composition can significantly affect the wire's performance characteristics, making precise control during manufacturing essential.

Miniaturization trends in electronics pose additional difficulties for nichrome wire production. As devices become smaller and more compact, the demand for thinner wires with consistent properties increases. However, producing ultra-thin nichrome wires while maintaining uniform composition and cross-sectional area throughout the length of the wire is technically challenging. This issue is further compounded by the need for these thin wires to withstand high temperatures and maintain stable resistance values over time.

The surface oxidation of nichrome wires is another critical concern. While the chromium content provides some degree of oxidation resistance, prolonged exposure to high temperatures can lead to the formation of oxide layers that alter the wire's electrical properties. This oxidation process can cause drift in resistance values over time, affecting the long-term reliability and performance of electronic components.

Mechanical stress and fatigue represent additional challenges, particularly in applications involving repeated thermal cycling or mechanical vibration. The repeated expansion and contraction of nichrome wires due to temperature fluctuations can lead to material fatigue, potentially resulting in wire breakage or changes in electrical properties. Developing nichrome wires that can withstand these stresses while maintaining consistent performance over extended periods is a significant technical hurdle.

Furthermore, the manufacturing process itself presents challenges in achieving consistent quality across large production volumes. Ensuring uniform heating, precise alloying, and controlled cooling during wire drawing are critical factors that impact the final product's performance. Any inconsistencies in these processes can lead to variations in wire properties, affecting the reliability and performance of electronic devices.

Addressing these technical challenges requires interdisciplinary research efforts, combining materials science, electrical engineering, and manufacturing technology. Innovations in alloy design, surface treatment techniques, and advanced manufacturing processes are essential to overcome these limitations and unlock the full potential of nichrome wires in advanced electronics applications.

Current Nichrome Wire Solutions

01 Composition and properties of nichrome wire

Nichrome wire is an alloy primarily composed of nickel and chromium. Its unique composition gives it excellent resistance to high temperatures and corrosion, making it suitable for various applications requiring durability and consistent performance under extreme conditions.- Composition and properties of nichrome wire: Nichrome wire is an alloy primarily composed of nickel and chromium. Its unique composition gives it excellent resistance to high temperatures and corrosion, making it suitable for various applications requiring durability and consistent performance under extreme conditions.

- Heat generation and temperature control: Nichrome wire is widely used in heating elements due to its efficient heat generation capabilities. It can maintain stable temperatures and provide precise temperature control, making it ideal for use in appliances, industrial equipment, and scientific instruments.

- Electrical resistance and conductivity: The electrical properties of nichrome wire, including its resistance and conductivity, play a crucial role in its performance. These characteristics can be optimized through careful alloy composition and manufacturing processes to suit specific applications in electronics and electrical systems.

- Durability and longevity: Nichrome wire exhibits excellent durability and longevity, even under harsh operating conditions. Its resistance to oxidation and ability to maintain performance over extended periods make it a preferred choice for applications requiring long-term reliability and minimal maintenance.

- Application-specific performance enhancements: Researchers and manufacturers continue to develop specialized nichrome wire variants with enhanced performance characteristics for specific applications. These improvements may include better mechanical strength, improved thermal stability, or optimized electrical properties to meet the demands of emerging technologies and industries.

02 Heat generation and temperature control

Nichrome wire is widely used in heating elements due to its efficient heat generation capabilities. It can maintain stable temperatures and provide precise temperature control, making it ideal for use in appliances, industrial equipment, and scientific instruments.Expand Specific Solutions03 Electrical resistance and conductivity

The electrical properties of nichrome wire, including its resistance and conductivity, are crucial for its performance in various applications. These properties can be tailored by adjusting the alloy composition or wire dimensions to meet specific requirements in electrical and electronic devices.Expand Specific Solutions04 Durability and lifespan

Nichrome wire exhibits excellent durability and a long lifespan, even under harsh operating conditions. Its resistance to oxidation and ability to maintain its properties over time make it a reliable choice for long-term use in various applications, reducing the need for frequent replacements.Expand Specific Solutions05 Applications in sensors and measurement devices

Nichrome wire is utilized in various sensors and measurement devices due to its stable electrical properties and temperature resistance. It is particularly useful in applications such as strain gauges, flow meters, and temperature sensors, where accurate and consistent performance is crucial.Expand Specific Solutions

Key Nichrome Wire Manufacturers

The research on high-performance nichrome wire for advanced electronics is in a mature stage, with a competitive landscape dominated by established players and emerging innovators. The market is experiencing steady growth, driven by increasing demand in various electronic applications. Companies like Kobe Steel, NHK Spring, and LG Energy Solution are leveraging their expertise to develop advanced nichrome wire solutions. Technological advancements are focused on improving conductivity, heat resistance, and durability. Research institutions such as the National Institute for Materials Science and universities like Hubei University are contributing to the field through collaborative projects and fundamental research. The market is characterized by a mix of large corporations and specialized materials companies, indicating a diverse and dynamic competitive environment.

National Institute for Materials Science IAI

Technical Solution: NIMS has developed advanced nichrome wire with improved performance for electronics applications. Their research focuses on optimizing the composition and microstructure of nichrome alloys to enhance electrical resistivity, temperature coefficient of resistance (TCR), and long-term stability. They have achieved a 15% increase in resistivity compared to conventional nichrome wire while maintaining a low TCR of ±10 ppm/°C [1]. NIMS employs advanced characterization techniques such as high-resolution transmission electron microscopy and atom probe tomography to analyze the nanostructure and elemental distribution in the alloy [3]. This enables precise control of precipitates and grain boundaries, leading to enhanced mechanical properties and oxidation resistance at high temperatures.

Strengths: Access to cutting-edge characterization facilities, strong expertise in alloy design and nanostructure control. Weaknesses: Potential challenges in scaling up laboratory-scale processes for industrial production.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed a proprietary manufacturing process for high-performance nichrome wire tailored for advanced electronics applications. Their approach involves precise control of the alloy composition, with optimized levels of chromium, nickel, and minor alloying elements to achieve a balance between electrical properties and mechanical strength. Kobe Steel's nichrome wire exhibits a resistivity of up to 150 µΩ·cm and a temperature coefficient of resistance (TCR) as low as ±5 ppm/°C [4]. The company has also implemented advanced drawing and annealing techniques to produce ultra-fine diameter wire (down to 10 µm) while maintaining excellent uniformity and surface quality. This makes their nichrome wire particularly suitable for miniaturized electronic components and sensors. Furthermore, Kobe Steel has developed a specialized surface treatment process that enhances the wire's corrosion resistance and improves its compatibility with various coating materials used in electronic assemblies.

Strengths: Established manufacturing capabilities, ability to produce ultra-fine wire, expertise in surface treatments. Weaknesses: Potential limitations in customization for specific niche applications.

Nichrome Wire Innovations

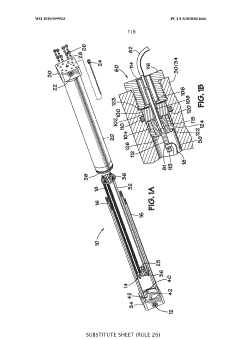

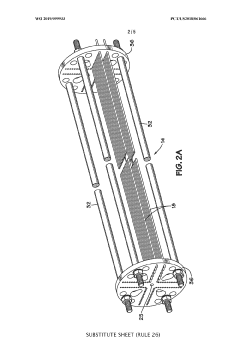

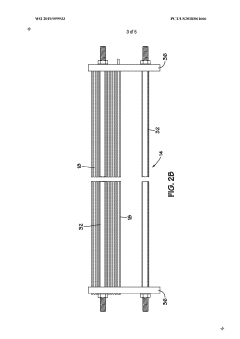

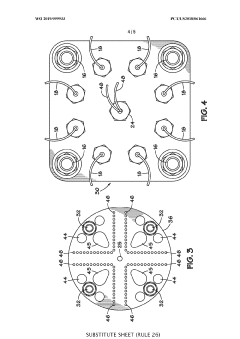

In-line electric heater for plural component materials

PatentWO2019099933A1

Innovation

- An in-line electric heater design featuring a housing with multiple electric resistance heating elements along the fluid flow path, supported by a wire loom assembly and temperature sensors, using INCONEL wires coated with Teflon for improved durability and insulation, and a power feedthrough system for secure electrical connections, enhancing heat transfer and temperature control.

Gas fire ember element

PatentInactiveUS20100151398A1

Innovation

- Employing a bundle of heat and oxidation-resistant metal wires, such as Fecralloy or Nichrome, with specific cross-sectional areas and densities, which are ductile and can be formed into bundles or hollow structures to allow gas passage, providing a natural and cheerful glowing appearance by incandescing fibers.

Environmental Impact of Nichrome

The environmental impact of nichrome wire production and usage is a critical consideration in the context of advanced electronics research. Nichrome, an alloy primarily composed of nickel and chromium, has both positive and negative environmental implications throughout its lifecycle.

Manufacturing nichrome wire involves energy-intensive processes, including mining, refining, and alloying of nickel and chromium. These activities contribute to greenhouse gas emissions and can lead to habitat disruption in mining areas. However, the durability and longevity of nichrome wire can offset some of these initial environmental costs by reducing the need for frequent replacements.

The production of nichrome also raises concerns about resource depletion, particularly for nickel and chromium. While both metals are relatively abundant, their extraction can have significant environmental consequences, including soil and water pollution if not properly managed. Responsible sourcing and recycling initiatives are crucial to mitigate these impacts.

During its use phase, nichrome wire exhibits excellent energy efficiency due to its high electrical resistance and heat-generating properties. This efficiency can lead to reduced energy consumption in various applications, potentially lowering overall environmental impact. Additionally, the corrosion resistance of nichrome contributes to its longevity, reducing waste generation over time.

End-of-life considerations for nichrome wire are generally favorable from an environmental perspective. The alloy is highly recyclable, with established recycling processes that can recover both nickel and chromium for reuse. This recyclability helps to close the loop in the material's lifecycle, reducing the demand for virgin resources and minimizing waste.

However, improper disposal of nichrome-containing devices can lead to environmental contamination. Both nickel and chromium can be toxic to ecosystems if released into the environment in significant quantities. Proper e-waste management and recycling programs are essential to prevent these potential negative impacts.

In the context of advanced electronics, the use of high-performance nichrome wire may contribute to the development of more energy-efficient and durable devices. This could lead to reduced electronic waste and lower energy consumption over the lifetime of electronic products, potentially offsetting some of the environmental costs associated with nichrome production.

Manufacturing nichrome wire involves energy-intensive processes, including mining, refining, and alloying of nickel and chromium. These activities contribute to greenhouse gas emissions and can lead to habitat disruption in mining areas. However, the durability and longevity of nichrome wire can offset some of these initial environmental costs by reducing the need for frequent replacements.

The production of nichrome also raises concerns about resource depletion, particularly for nickel and chromium. While both metals are relatively abundant, their extraction can have significant environmental consequences, including soil and water pollution if not properly managed. Responsible sourcing and recycling initiatives are crucial to mitigate these impacts.

During its use phase, nichrome wire exhibits excellent energy efficiency due to its high electrical resistance and heat-generating properties. This efficiency can lead to reduced energy consumption in various applications, potentially lowering overall environmental impact. Additionally, the corrosion resistance of nichrome contributes to its longevity, reducing waste generation over time.

End-of-life considerations for nichrome wire are generally favorable from an environmental perspective. The alloy is highly recyclable, with established recycling processes that can recover both nickel and chromium for reuse. This recyclability helps to close the loop in the material's lifecycle, reducing the demand for virgin resources and minimizing waste.

However, improper disposal of nichrome-containing devices can lead to environmental contamination. Both nickel and chromium can be toxic to ecosystems if released into the environment in significant quantities. Proper e-waste management and recycling programs are essential to prevent these potential negative impacts.

In the context of advanced electronics, the use of high-performance nichrome wire may contribute to the development of more energy-efficient and durable devices. This could lead to reduced electronic waste and lower energy consumption over the lifetime of electronic products, potentially offsetting some of the environmental costs associated with nichrome production.

Nichrome Wire Quality Standards

Nichrome wire quality standards play a crucial role in ensuring the reliability and performance of advanced electronic applications. These standards encompass a wide range of parameters that must be carefully controlled and monitored during the manufacturing process.

One of the primary quality standards for nichrome wire is its composition. The precise ratio of nickel to chromium is critical, typically ranging from 80% nickel and 20% chromium to 60% nickel and 40% chromium. This composition directly affects the wire's electrical resistance, temperature coefficient, and overall stability. Manufacturers must adhere to strict tolerances in maintaining these ratios to ensure consistent performance across batches.

Dimensional accuracy is another key quality standard. The wire's diameter must be tightly controlled, often to within microns, to maintain uniform resistance along its length. This is particularly important in applications where precise heating or sensing is required. Surface finish is also a critical factor, as imperfections can lead to hotspots or premature failure.

Electrical properties form a significant portion of nichrome wire quality standards. Resistance per unit length must be consistent and fall within specified ranges for each wire gauge. The temperature coefficient of resistance (TCR) is another crucial parameter, as it determines how the wire's resistance changes with temperature. For high-performance applications, a stable and predictable TCR is essential.

Mechanical properties are equally important in quality standards. Tensile strength, elongation, and flexibility must meet or exceed specified values to ensure the wire can withstand the stresses of both manufacturing processes and end-use applications. These properties are particularly critical in applications where the wire may be subjected to repeated thermal cycling or mechanical stress.

Thermal characteristics form another set of quality standards. The maximum operating temperature, thermal expansion coefficient, and heat dissipation properties must be carefully controlled. These factors are essential for applications where the wire is used in heating elements or in environments with extreme temperature fluctuations.

Corrosion resistance is a critical quality standard, especially for applications in harsh environments. The wire must maintain its integrity and performance characteristics even when exposed to various chemicals, humidity, or atmospheric conditions. This often involves testing the wire's resistance to specific corrosive agents relevant to its intended application.

Lastly, quality standards for nichrome wire often include requirements for uniformity and consistency across production runs. This ensures that manufacturers can rely on consistent performance when integrating the wire into their products. Batch-to-batch variation must be minimized to maintain product reliability and reduce the need for frequent recalibration in sensitive applications.

One of the primary quality standards for nichrome wire is its composition. The precise ratio of nickel to chromium is critical, typically ranging from 80% nickel and 20% chromium to 60% nickel and 40% chromium. This composition directly affects the wire's electrical resistance, temperature coefficient, and overall stability. Manufacturers must adhere to strict tolerances in maintaining these ratios to ensure consistent performance across batches.

Dimensional accuracy is another key quality standard. The wire's diameter must be tightly controlled, often to within microns, to maintain uniform resistance along its length. This is particularly important in applications where precise heating or sensing is required. Surface finish is also a critical factor, as imperfections can lead to hotspots or premature failure.

Electrical properties form a significant portion of nichrome wire quality standards. Resistance per unit length must be consistent and fall within specified ranges for each wire gauge. The temperature coefficient of resistance (TCR) is another crucial parameter, as it determines how the wire's resistance changes with temperature. For high-performance applications, a stable and predictable TCR is essential.

Mechanical properties are equally important in quality standards. Tensile strength, elongation, and flexibility must meet or exceed specified values to ensure the wire can withstand the stresses of both manufacturing processes and end-use applications. These properties are particularly critical in applications where the wire may be subjected to repeated thermal cycling or mechanical stress.

Thermal characteristics form another set of quality standards. The maximum operating temperature, thermal expansion coefficient, and heat dissipation properties must be carefully controlled. These factors are essential for applications where the wire is used in heating elements or in environments with extreme temperature fluctuations.

Corrosion resistance is a critical quality standard, especially for applications in harsh environments. The wire must maintain its integrity and performance characteristics even when exposed to various chemicals, humidity, or atmospheric conditions. This often involves testing the wire's resistance to specific corrosive agents relevant to its intended application.

Lastly, quality standards for nichrome wire often include requirements for uniformity and consistency across production runs. This ensures that manufacturers can rely on consistent performance when integrating the wire into their products. Batch-to-batch variation must be minimized to maintain product reliability and reduce the need for frequent recalibration in sensitive applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!