Improving The Wear Resistance Of Turbine Engines

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Wear Resistance Technology Background

Turbine engines are widely used in various industries, including aviation, power generation, and marine applications. However, the wear resistance of turbine engines is a critical issue that affects their performance, efficiency, and lifespan. The primary objective of this research is to explore innovative solutions for improving the wear resistance of turbine engines, thereby enhancing their durability and reliability.

This section will delve into the technological background and goals related to wear resistance in turbine engines. It will provide an overview of the historical development and evolution of wear-resistant materials and coatings used in turbine engines. Additionally, it will outline the specific targets and desired outcomes for enhancing wear resistance, such as extending component life, reducing maintenance costs, and improving overall engine performance.

This section will delve into the technological background and goals related to wear resistance in turbine engines. It will provide an overview of the historical development and evolution of wear-resistant materials and coatings used in turbine engines. Additionally, it will outline the specific targets and desired outcomes for enhancing wear resistance, such as extending component life, reducing maintenance costs, and improving overall engine performance.

Turbine Engine Wear Resistance Market Demand

- Market Demand Overview

Turbine engines are widely used in aviation, power generation, and other industries, creating a substantial market demand for wear-resistant components. - Aviation Industry

The aviation industry is a major driver for turbine engine wear resistance technology due to the harsh operating conditions and stringent safety requirements. - Power Generation

Turbines used in power plants require wear-resistant components to ensure reliable and efficient operation over extended periods. - Industrial Applications

Various industrial processes, such as oil and gas, manufacturing, and marine applications, rely on turbine engines and demand wear-resistant solutions. - Emerging Markets

The growing adoption of turbine engines in emerging markets, particularly in Asia and the Middle East, is expected to further increase the demand for wear resistance technologies.

Current Turbine Engine Wear Resistance Challenges

- Material Degradation

Turbine engines operate in extreme conditions, exposing components to high temperatures, pressures, and corrosive environments, leading to material degradation and wear. - Erosion and Corrosion

Hot gas flow carries abrasive particles that cause erosion, while combustion byproducts and environmental factors contribute to corrosion, compromising component integrity. - Thermal Fatigue

Cyclic heating and cooling during engine operation induces thermal stresses, causing fatigue cracking and failure of critical components. - Clearance Control

Maintaining optimal clearances between rotating and stationary parts is crucial for efficiency, but wear can lead to increased clearances and performance losses. - Coating Degradation

Protective coatings used to enhance wear resistance can degrade over time, reducing their effectiveness and requiring reapplication or replacement.

Existing Turbine Engine Wear Resistance Solutions

01 Wear-resistant Coatings

Various coatings like ceramics, metal alloys, or composites can be applied to turbine components using techniques such as thermal spraying, chemical vapor deposition, or physical vapor deposition. These coatings act as a protective barrier against erosion, corrosion, and high-temperature oxidation, extending the service life of the components.- Wear-resistant Coatings: Various coatings like ceramics, metal alloys, or composites can be applied to turbine components using techniques such as thermal spraying, chemical vapor deposition, or physical vapor deposition. These coatings act as protective barriers against erosion, corrosion, and high-temperature oxidation, extending the service life of the components.

- Optimized Blade Design: Turbine blade design can be optimized for wear resistance by using advanced materials like single-crystal superalloys or ceramic matrix composites, which have superior strength and resistance to high temperatures and erosion. Additionally, optimizing blade geometry and surface finish can reduce stress concentrations and minimize erosion and corrosion effects.

- Thermal Barrier Coatings: Thermal barrier coatings (TBCs), typically made of ceramic materials like yttria-stabilized zirconia, can be applied to turbine components to provide insulation from high temperatures and protect against oxidation and hot corrosion. TBCs can significantly improve the durability and service life of turbine components.

- Surface Treatments: Various surface treatments like shot peening, nitriding, carburizing, laser shock peening, or low plasticity burnishing can be applied to turbine components to enhance their wear resistance. These treatments introduce compressive residual stresses, increase surface hardness, improve surface finish, and reduce crack initiation and propagation.

- Wear-resistant Materials: Advanced materials with inherent wear resistance, such as nickel-based superalloys, cobalt-based superalloys, or intermetallic compounds like titanium aluminides or nickel aluminides, can be used in the manufacture of turbine components. These materials exhibit high strength, creep resistance, and oxidation resistance at elevated temperatures.

02 Optimized Blade Design

Turbine blade design can be optimized for wear resistance by using advanced materials like single-crystal superalloys or ceramic matrix composites, which have superior strength and resistance to high temperatures and erosion. Additionally, optimizing blade geometry and surface finish can reduce stress concentrations and minimize erosion and corrosion effects.Expand Specific Solutions03 Thermal Barrier Coatings

Thermal barrier coatings (TBCs), typically made of ceramic materials like yttria-stabilized zirconia, can be applied to turbine components to provide insulation and reduce the temperature experienced by the underlying metal substrate. TBCs can significantly improve the durability and service life of turbine components.Expand Specific Solutions04 Surface Treatments

Various surface treatments like shot peening, nitriding, carburizing, or surface texturing/patterning can be applied to turbine components to enhance their wear resistance. These treatments improve surface hardness, fatigue strength, and modify surface topography to reduce erosion and wear effects.Expand Specific Solutions05 Wear-resistant Materials

Advanced materials like nickel-based superalloys, titanium alloys, or ceramic matrix composites can be used for turbine components exposed to high temperatures, erosion, and corrosion. These materials have superior mechanical properties and resistance to degradation under harsh operating conditions.Expand Specific Solutions

Key Players in Turbine Engine Wear Resistance

The research on improving the wear resistance of turbine engines is crucial in the aerospace and power generation industries. The market for turbine engines is substantial, driven by growing air travel and energy demands. Major players like United Technologies Corp., RTX Corp., SNECMA SA, Honeywell International Technologies Ltd., and General Electric Company lead the way with mature technologies. However, continuous innovation is necessary to meet performance and efficiency requirements. Universities and research institutes also contribute to advancing this technology.

United Technologies Corp.

Technical Solution: United Technologies (now part of RTX Corp.) has developed advanced coatings and materials for turbine engines to improve wear resistance and durability, including thermal barrier coatings, erosion-resistant coatings, and specialized surface treatments.

Strengths: Extensive experience, strong R&D capabilities, and broad portfolio. Weaknesses: Potential challenges in technology integration and supply chain management.

RTX Corp.

Technical Solution: RTX (formerly Raytheon Technologies) has developed advanced materials and coatings for turbine engines, including ceramic matrix composites (CMCs) and thermal barrier coatings, to improve wear resistance, thermal protection, and overall engine performance.

Strengths: Extensive experience, strong R&D capabilities, and broad portfolio. Weaknesses: Potential challenges in technology integration and supply chain management.

Core Turbine Engine Wear Resistance Technologies

Wear-resistant coating

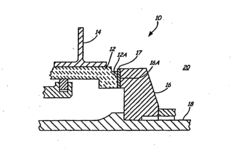

PatentActiveEP1852520B1

Innovation

- The invention provides a durable wear-resistant coating specifically designed for gas turbine engine components to protect them from wear and tear caused by high friction and temperature operating conditions.

- The wear-resistant coating is applied to seal plates in gas turbine engines, which are particularly susceptible to wear and deterioration due to high friction and temperature, leading to failure of the seal mechanism and detrimental engine operation.

- The coating helps to extend the life of critical components like seal plates, mitigating the need for frequent replacements and reducing maintenance costs and downtime for gas turbine engines.

Turbine Engine Wear Resistance Material Analysis

Turbine engines are subjected to extreme operating conditions, including high temperatures, pressures, and corrosive environments, which can lead to accelerated wear and degradation of critical components. Improving the wear resistance of turbine engines is crucial for enhancing their durability, reliability, and operational lifespan.

Advanced materials and coatings play a pivotal role in mitigating wear and erosion in turbine engines. Ceramic matrix composites (CMCs), intermetallic compounds, and thermal barrier coatings (TBCs) are among the promising solutions being explored. These materials exhibit superior high-temperature strength, oxidation resistance, and thermal insulation properties, enabling them to withstand the harsh conditions encountered in turbine engines.

Additionally, surface engineering techniques, such as shot peening, nitriding, and laser cladding, can enhance the surface properties of turbine components, improving their resistance to wear, erosion, and fatigue. These techniques modify the surface microstructure and introduce compressive residual stresses, thereby increasing the material's hardness and resistance to crack initiation and propagation.

Advanced materials and coatings play a pivotal role in mitigating wear and erosion in turbine engines. Ceramic matrix composites (CMCs), intermetallic compounds, and thermal barrier coatings (TBCs) are among the promising solutions being explored. These materials exhibit superior high-temperature strength, oxidation resistance, and thermal insulation properties, enabling them to withstand the harsh conditions encountered in turbine engines.

Additionally, surface engineering techniques, such as shot peening, nitriding, and laser cladding, can enhance the surface properties of turbine components, improving their resistance to wear, erosion, and fatigue. These techniques modify the surface microstructure and introduce compressive residual stresses, thereby increasing the material's hardness and resistance to crack initiation and propagation.

Environmental Impact of Turbine Engine Wear Resistance

Environmental impact is a crucial consideration when evaluating the wear resistance of turbine engines. Increased wear leads to more frequent replacement of components, resulting in higher material consumption and waste generation. This not only incurs economic costs but also contributes to environmental pollution during the manufacturing and disposal processes.

Moreover, wear debris from turbine engines can be released into the atmosphere, potentially causing air pollution and posing risks to human health and ecosystems. Particulate matter and heavy metals from wear particles may contribute to respiratory issues and environmental contamination. Improving wear resistance can mitigate these negative impacts by extending component lifetimes and reducing the frequency of replacements.

Additionally, enhanced wear resistance can improve fuel efficiency by maintaining optimal aerodynamic profiles and minimizing performance degradation over time. This translates into reduced greenhouse gas emissions and a lower carbon footprint for turbine engine operations. Consequently, addressing wear resistance not only enhances operational reliability and cost-effectiveness but also aligns with sustainability goals and environmental stewardship.

Moreover, wear debris from turbine engines can be released into the atmosphere, potentially causing air pollution and posing risks to human health and ecosystems. Particulate matter and heavy metals from wear particles may contribute to respiratory issues and environmental contamination. Improving wear resistance can mitigate these negative impacts by extending component lifetimes and reducing the frequency of replacements.

Additionally, enhanced wear resistance can improve fuel efficiency by maintaining optimal aerodynamic profiles and minimizing performance degradation over time. This translates into reduced greenhouse gas emissions and a lower carbon footprint for turbine engine operations. Consequently, addressing wear resistance not only enhances operational reliability and cost-effectiveness but also aligns with sustainability goals and environmental stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!