Development And Application Of Turbine Engine Thermal Barrier Coatings

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Barrier Coatings Technology Background And Goals

The development of turbine engine thermal barrier coatings (TBCs) has been driven by the need for improved engine efficiency, durability, and performance. TBCs are ceramic coatings applied to the hot section components of turbine engines, providing thermal insulation and protection against high temperatures and corrosive environments.

The primary objective of this research is to explore the current state, challenges, and future directions in the development and application of TBCs for turbine engines. It aims to provide insights into the key technologies, materials, and processes involved, as well as the potential for innovation and advancements in this field.

The primary objective of this research is to explore the current state, challenges, and future directions in the development and application of TBCs for turbine engines. It aims to provide insights into the key technologies, materials, and processes involved, as well as the potential for innovation and advancements in this field.

Thermal Barrier Coatings Market Demand Analysis

- Market Size and Growth

The global thermal barrier coatings market is projected to experience significant growth, driven by the increasing demand for energy-efficient and high-performance turbine engines in the aerospace and industrial sectors. - Key Application Areas

Thermal barrier coatings find extensive applications in gas turbine engines for aircraft, power generation, and industrial processes, where they enhance engine efficiency, durability, and operational lifespan. - Regional Demand Dynamics

North America and Europe are currently the leading markets for thermal barrier coatings, driven by the presence of major aerospace and power generation industries. However, the Asia-Pacific region is expected to witness the highest growth rate due to the rapid industrialization and expansion of the aviation sector. - End-User Industries

The aerospace industry is the largest consumer of thermal barrier coatings, followed by the power generation and industrial sectors, including chemical processing, petrochemical, and manufacturing industries.

Thermal Barrier Coatings Technology Status And Challenges

- Coating Materials

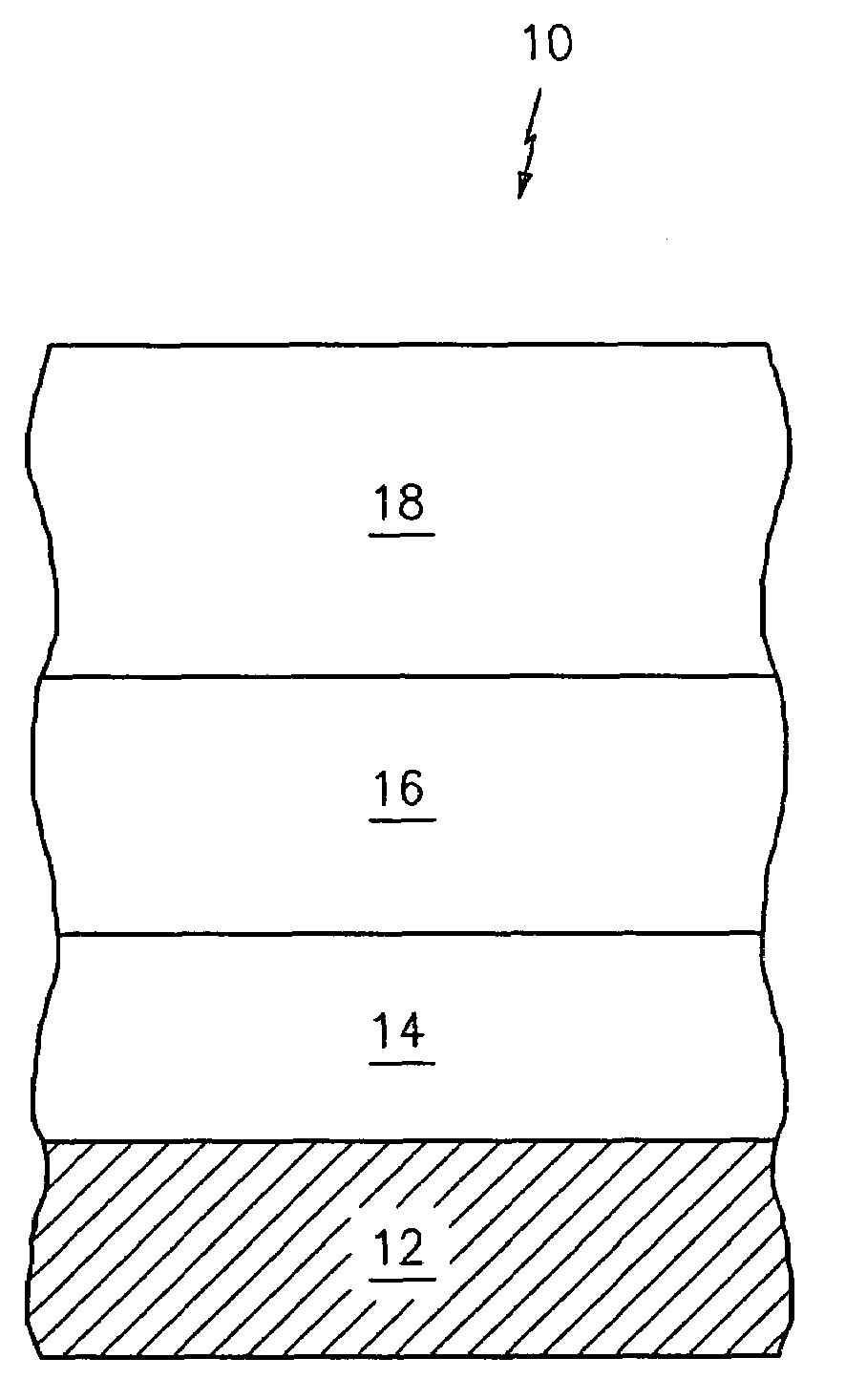

Thermal barrier coatings (TBCs) are typically composed of ceramic materials like yttria-stabilized zirconia (YSZ) or gadolinium zirconate. These materials have low thermal conductivity and high melting points. - Coating Structures

TBCs consist of a metallic bond coat and a ceramic top coat. The bond coat provides adhesion to the substrate, while the top coat provides thermal insulation. - Coating Deposition Methods

Common deposition techniques include air plasma spraying (APS), electron beam physical vapor deposition (EB-PVD), and suspension plasma spraying (SPS). - Coating Degradation Mechanisms

TBCs can degrade due to thermal cycling, oxidation, hot corrosion, erosion, and foreign object damage. Understanding these mechanisms is crucial for improving coating durability. - Coating Characterization

Various techniques, such as scanning electron microscopy (SEM), X-ray diffraction (XRD), and thermal conductivity measurements, are used to characterize the microstructure, phase composition, and thermal properties of TBCs.

Thermal Barrier Coatings Current Technical Solutions

01 Improved Thermal Insulation

Coatings designed to provide enhanced thermal insulation for turbine engine components, protecting them from high temperatures and prolonging service life. Typically consist of low thermal conductivity and high thermal stability ceramic materials like yttria-stabilized zirconia (YSZ) or advanced ceramics.- Improved Thermal Insulation: Coatings designed for enhanced thermal insulation of turbine engine components, protecting them from high temperatures and improving durability. Typically consist of low thermal conductivity and high thermal stability ceramic materials like yttria-stabilized zirconia (YSZ) or advanced ceramics.

- Multilayer Thermal Barrier Coatings: Coatings with multiple layers, each with different compositions and properties, to enhance thermal insulation performance. Layers may include a bond coat, a thermally grown oxide layer, and a ceramic top coat, contributing to improved thermal protection and durability.

- Improved Adhesion and Spallation Resistance: Coatings designed for better adhesion to the underlying substrate and improved resistance to spallation (flaking or chipping) under high temperatures and thermal cycling conditions. Achieved through optimized compositions, surface treatments, or graded/functionally graded coatings.

- Improved Thermal Shock Resistance: Coatings formulated to withstand rapid temperature changes and thermal cycling without cracking or delamination. Achieved through tailored coefficients of thermal expansion, porosity control, or incorporation of reinforcing phases or additives.

- Enhanced Erosion Resistance: Coatings designed to resist erosion caused by particulate matter or high-velocity gas streams, preventing degradation and maintaining effectiveness. Achieved through harder or more erosion-resistant materials, or by incorporating erosion-resistant layers or coatings.

02 Multilayer Thermal Barrier Coatings

Coatings with multiple layers, each with different compositions and properties, to enhance thermal insulation and durability. Layers may include a bond coat, a thermally grown oxide layer, and a ceramic top coat, contributing to improved thermal protection and adhesion.Expand Specific Solutions03 Improved Strain Tolerance

Coatings designed to withstand thermal stresses and strains experienced by turbine engine components during operation. May incorporate materials or structures that enhance strain tolerance, such as columnar microstructures or graded compositions, to prevent cracking and delamination.Expand Specific Solutions04 Improved Erosion Resistance

Coatings formulated to resist erosion caused by particulates or debris in the turbine engine environment. May incorporate harder materials like oxides or nitrides, or have a dense, erosion-resistant microstructure to improve durability and longevity.Expand Specific Solutions05 Improved Environmental Resistance

Coatings designed to withstand harsh environmental conditions like high temperatures, corrosive atmospheres, and thermal cycling encountered in turbine engines. May incorporate materials or structures that enhance oxidation resistance, hot corrosion resistance, or thermal shock resistance.Expand Specific Solutions

Thermal Barrier Coatings Key Players Analysis

The turbine engine thermal barrier coatings technology is a mature field with a large market size, driven by the continuous growth of the aviation and power generation industries.

United Technologies Corp.

Technical Solution: United Technologies (now part of Raytheon Technologies) has developed advanced TBC systems for turbine engines, incorporating ceramic topcoats and bond coat layers for high-temperature oxidation resistance and thermal insulation, improving engine efficiency, durability, and performance.

Strengths: Extensive aerospace and industrial expertise, advanced materials and coating technologies. Weaknesses: Proprietary technology, focus on aerospace and power generation markets.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced TBC systems for turbine engines, incorporating ceramic topcoats and bond coat layers for high-temperature oxidation resistance and thermal insulation, improving engine efficiency, durability, and performance.

Strengths: Extensive experience in aerospace and industrial technologies, advanced materials and coating processes. Weaknesses: Proprietary technology, competition from major players.

Thermal Barrier Coatings Core Technology Interpretation

Dual layer ceramic coating

PatentInactiveUS20080044663A1

Innovation

- The dual layer ceramic coating has a cracked structure in both the first and second ceramic layers, allowing the coating to expand and contract with thermal cycles, increasing strain tolerance and durability.

- The coating comprises a bond coat applied to the substrate, followed by a first ceramic layer with a cracked structure, and then a second ceramic layer with a cracked structure applied on top.

- The method for forming the coating involves sequentially applying the bond coat, first ceramic layer, and second ceramic layer to the substrate.

Thermal Barrier Coatings Environmental Impact Assessment

Thermal barrier coatings (TBCs) are advanced material systems designed to protect critical components in turbine engines from extreme temperatures and harsh environments. These coatings play a crucial role in enhancing engine efficiency, durability, and overall performance. However, their environmental impact is a significant consideration that must be carefully evaluated.

The production and application of TBCs involve various processes that can potentially contribute to environmental concerns. The raw materials used in the coatings, such as ceramics and metals, require mining and processing, which can lead to resource depletion and emissions. Additionally, the coating application techniques, including thermal spraying and vapor deposition, may generate particulate matter and gaseous byproducts that require proper management.

During the operational phase, TBCs can potentially release particles or compounds into the atmosphere through erosion or degradation mechanisms. These emissions may include ceramic particles, metallic elements, and other compounds, depending on the specific coating composition and operating conditions. Proper monitoring and control measures are essential to minimize the environmental impact of these emissions and ensure compliance with relevant regulations.

The production and application of TBCs involve various processes that can potentially contribute to environmental concerns. The raw materials used in the coatings, such as ceramics and metals, require mining and processing, which can lead to resource depletion and emissions. Additionally, the coating application techniques, including thermal spraying and vapor deposition, may generate particulate matter and gaseous byproducts that require proper management.

During the operational phase, TBCs can potentially release particles or compounds into the atmosphere through erosion or degradation mechanisms. These emissions may include ceramic particles, metallic elements, and other compounds, depending on the specific coating composition and operating conditions. Proper monitoring and control measures are essential to minimize the environmental impact of these emissions and ensure compliance with relevant regulations.

Thermal Barrier Coatings Regulatory And Standardization Landscape

Thermal barrier coatings (TBCs) are critical components in turbine engines, protecting metallic components from extreme temperatures and enabling higher operating temperatures for improved efficiency. The regulatory and standardization landscape surrounding TBCs is complex, involving various national and international organizations.

Major regulatory bodies, such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), have established stringent certification requirements for TBCs used in aircraft engines. These regulations cover material composition, manufacturing processes, and performance criteria to ensure safety and reliability. Additionally, organizations like the International Organization for Standardization (ISO) and ASTM International have developed standards for TBC testing, characterization, and quality control.

Beyond aviation, TBCs are also regulated in other industries, such as power generation and automotive. Regulatory agencies like the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) have implemented emissions standards that indirectly impact TBC development and application. As environmental concerns grow, the demand for more efficient and cleaner engines will likely drive further regulatory changes affecting TBC technology.

Major regulatory bodies, such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), have established stringent certification requirements for TBCs used in aircraft engines. These regulations cover material composition, manufacturing processes, and performance criteria to ensure safety and reliability. Additionally, organizations like the International Organization for Standardization (ISO) and ASTM International have developed standards for TBC testing, characterization, and quality control.

Beyond aviation, TBCs are also regulated in other industries, such as power generation and automotive. Regulatory agencies like the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) have implemented emissions standards that indirectly impact TBC development and application. As environmental concerns grow, the demand for more efficient and cleaner engines will likely drive further regulatory changes affecting TBC technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!