Polyimide Nanocomposite Coatings: Properties And Applications

SEP 24, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polyimide Nanocomposite Coatings Technology Background and Goals

### 技术背景与目标

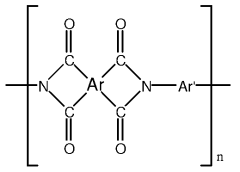

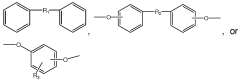

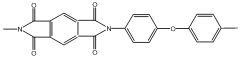

Polyimide nanocomposite coatings have garnered significant attention due to their exceptional thermal stability, mechanical strength, and chemical resistance. These coatings are widely used in aerospace, electronics, and automotive industries. The primary goal is to enhance the performance characteristics of polyimide coatings by incorporating nanomaterials, which can improve properties such as thermal conductivity, electrical insulation, and mechanical durability. The evolution of this technology has seen advancements from traditional polyimide coatings to the integration of various nanomaterials like carbon nanotubes, graphene, and metal oxides, aiming to achieve superior performance metrics. The focus is on understanding the synthesis methods, dispersion techniques, and the resultant properties of these nanocomposites to meet the stringent requirements of advanced industrial applications.

Polyimide Nanocomposite Coatings Market Demand Analysis

- Market Potential: Polyimide nanocomposite coatings have significant potential in various industries due to their excellent thermal stability, mechanical properties, and chemical resistance. These coatings are particularly valuable in electronics, aerospace, automotive, and energy sectors.

- Industry Trends: The demand for high-performance materials in advanced applications is driving the growth of polyimide nanocomposite coatings. The trend towards miniaturization in electronics and the need for lightweight, durable materials in aerospace and automotive industries are key factors.

- Market Size: The global market for polyimide nanocomposite coatings is expected to grow steadily, with increasing investments in research and development. The market size is projected to expand as more industries adopt these advanced materials for their superior properties.

- Competitive Landscape: Major players in the market include companies specializing in advanced materials and nanotechnology. These companies are investing in innovation and expanding their product portfolios to meet the growing demand.

- Geographical Distribution: The market is geographically diverse, with significant growth in regions such as North America, Europe, and Asia-Pacific. These regions have strong industrial bases and are investing heavily in advanced materials research.

- Challenges and Opportunities: While the market shows promise, challenges such as high production costs and technical complexities need to be addressed. However, advancements in nanotechnology and material science present opportunities for overcoming these challenges and driving market growth.

Polyimide Nanocomposite Coatings Technology Status and Challenges

### Polyimide Nanocomposite Coatings Technology Status and Challenges

**Current Development Status**:

- Polyimide nanocomposite coatings are advanced materials combining polyimide polymers with nanoparticles, offering enhanced thermal stability, mechanical strength, and chemical resistance.

- These coatings are widely researched for applications in electronics, aerospace, and automotive industries due to their superior properties.

**Key Challenges**:

- **Dispersion of Nanoparticles**: Achieving uniform dispersion of nanoparticles within the polyimide matrix remains a significant challenge, affecting the overall performance of the coatings.

- **Interfacial Compatibility**: Ensuring strong interfacial bonding between polyimide and nanoparticles is crucial for optimizing mechanical and thermal properties.

- **Scalability**: Developing cost-effective and scalable manufacturing processes for these nanocomposite coatings is essential for commercial viability.

- **Environmental and Health Concerns**: Addressing potential environmental and health risks associated with nanoparticle use and disposal is necessary for sustainable development.

**Geographical Distribution**:

- Research and development activities are predominantly concentrated in technologically advanced regions such as North America, Europe, and East Asia, with significant contributions from leading universities and research institutions.

Polyimide Nanocomposite Coatings Current Technical Solutions

01 Enhanced mechanical properties

Polyimide nanocomposite coatings enhance tensile strength, flexibility, and hardness. Nanoparticles like silica, carbon nanotubes, or clay improve mechanical performance.- Enhanced mechanical properties: Polyimide nanocomposite coatings enhance tensile strength, elasticity, and hardness. Nanoparticles like silica, carbon nanotubes, or clay improve durability and resistance to mechanical stress.

- Improved thermal stability: Nanoparticles in polyimide coatings enhance thermal stability, allowing them to withstand higher temperatures. Common nanoparticles include alumina and titanium dioxide.

- Enhanced barrier properties: Polyimide nanocomposite coatings provide superior barrier properties against gases and moisture. Nanoparticles like graphene or montmorillonite reduce permeability, ideal for protective applications.

- Improved electrical properties: Conductive nanoparticles like carbon nanotubes or graphene enhance electrical properties of polyimide coatings, increasing conductivity for electronic applications.

- Enhanced surface properties: Nanoparticles like silica or titanium dioxide improve surface properties such as hydrophobicity, scratch resistance, and adhesion, enhancing performance and longevity.

02 Improved thermal stability

Nanoparticles in polyimide coatings significantly improve thermal stability, allowing them to withstand higher temperatures without degradation.Expand Specific Solutions03 Enhanced electrical properties

Polyimide nanocomposite coatings exhibit enhanced electrical properties, such as increased dielectric constant and conductivity, by incorporating conductive nanoparticles like graphene or carbon nanotubes.Expand Specific Solutions04 Improved barrier properties

Nanoparticles in polyimide coatings improve barrier properties, making them more resistant to gas and moisture permeation, ideal for protective applications.Expand Specific Solutions05 Enhanced surface properties

Nanoparticles in polyimide coatings enhance surface properties like hydrophobicity, reduced friction, and improved wear resistance.Expand Specific Solutions

Polyimide Nanocomposite Coatings Main Player Analysis

The competitive landscape for polyimide nanocomposite coatings features diverse players from industry and academia, highlighting the technology's growth and market potential. Companies like DuPont de Nemours, Inc., and International Business Machines Corp. lead in industrial applications, leveraging extensive R&D. Academic institutions such as Donghua University and the University of Cincinnati advance fundamental research. Specialized entities like the Korea Research Institute of Chemical Technology and the Chinese Academy of Science Institute of Chemistry contribute to the technology's maturity. The market is expanding, driven by the coatings' superior thermal and mechanical properties, crucial for electronics, aerospace, and high-performance sectors.

DuPont de Nemours, Inc.

Technical Solution: DuPont's polyimide nanocomposite coatings offer enhanced thermal stability, mechanical strength, and chemical resistance for aerospace, electronics, and automotive industries.

Strengths: High thermal stability and mechanical strength. Weaknesses: High production costs.

International Business Machines Corp.

Technical Solution: IBM researches polyimide nanocomposite coatings for electronic applications, focusing on improving dielectric properties and thermal stability to enhance electronic devices.

Strengths: Advanced research capabilities in electronics. Weaknesses: Limited application outside electronics.

Polyimide Nanocomposite Coatings Key Technology Interpretation

Filtration method using polyimide nanoweb with amidized surface and apparatus therefor

PatentWO2012078627A2

Innovation

- The use of secondary amide functional groups on the surface of aromatic polyimide nanowebs to improve compatibility and surface properties.

- The process of chemically altering the surface of the nanoweb by contacting it with a primary amine to increase hydrophobicity and chemical reactivity.

- The application of polyimide nanowebs in filtration apparatus and electrochemical cells, leveraging their improved surface properties.

Polyimide Nanocomposite Coatings Environmental Impact Assessment

Polyimide nanocomposite coatings have significant environmental impacts due to their synthesis and application processes. The production involves the use of solvents and chemicals that can release volatile organic compounds (VOCs), contributing to air pollution. Additionally, the disposal of these coatings can lead to soil and water contamination if not managed properly. However, their durability and resistance to harsh environmental conditions can reduce the frequency of reapplications, potentially lowering the overall environmental footprint. Future research should focus on developing eco-friendly synthesis methods and improving the recyclability of these coatings to mitigate their environmental impact.

Polyimide Nanocomposite Coatings Regulatory and Compliance Analysis

Polyimide nanocomposite coatings are subject to various regulatory and compliance standards to ensure safety and performance. These coatings must adhere to environmental regulations, such as REACH and RoHS, which restrict hazardous substances. Additionally, compliance with industry-specific standards, like those from ASTM and ISO, is crucial for ensuring material quality and reliability. Manufacturers must also consider health and safety guidelines to protect workers during production and application. Understanding and navigating these regulatory frameworks is essential for successful market entry and sustained product development in the polyimide nanocomposite coatings sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!