Self-Healing Materials For Turbine Engines

SEP 23, 20255 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Materials for Turbine Engines Background and Objectives

Self-healing materials for turbine engines have emerged as a promising solution to address the issue of material degradation caused by extreme operating conditions. The primary objective of this research is to explore innovative approaches that enable turbine engine components to autonomously repair damage, thereby enhancing their durability and extending their operational lifespan.

This technology aims to develop materials with intrinsic self-healing capabilities, which can autonomously detect and repair cracks, erosion, or other forms of damage without external intervention. By incorporating self-healing mechanisms into turbine engine components, the need for frequent maintenance and replacement can be reduced, leading to significant cost savings and improved operational efficiency.

This technology aims to develop materials with intrinsic self-healing capabilities, which can autonomously detect and repair cracks, erosion, or other forms of damage without external intervention. By incorporating self-healing mechanisms into turbine engine components, the need for frequent maintenance and replacement can be reduced, leading to significant cost savings and improved operational efficiency.

Self-Healing Materials for Turbine Engines Market Demand Analysis

- Market Size and Growth

The global market for self-healing materials in turbine engines is projected to experience significant growth, driven by the increasing demand for efficient and durable turbine components. The market size is expected to expand at a CAGR of around 7-9% during the forecast period. - Key Application Areas

Self-healing materials find applications in various turbine engine components, including turbine blades, combustion chambers, and thermal barrier coatings. These materials offer enhanced durability, reduced maintenance costs, and extended service life for turbine engines. - Industry Trends

The aviation industry's focus on reducing emissions and improving fuel efficiency is driving the demand for lightweight and durable turbine components. Additionally, the need for extended maintenance intervals and reduced downtime is fueling the adoption of self-healing materials. - Regional Demand

The demand for self-healing materials in turbine engines is particularly high in regions with significant aerospace and power generation industries, such as North America, Europe, and Asia-Pacific. These regions are investing heavily in advanced turbine technologies to meet stringent emission regulations and performance requirements.

Current Status and Challenges of Self-Healing Materials for Turbine Engines

- Current Challenges

Durability and reliability issues due to harsh operating conditions. Self-healing materials face challenges in maintaining their properties under high temperatures, pressures, and corrosive environments in turbine engines. - Healing Efficiency

Achieving efficient and rapid self-healing capabilities is a significant challenge. The healing process needs to be fast enough to prevent further damage propagation and maintain structural integrity. - Healing Mechanism Limitations

Existing self-healing mechanisms, such as capsule-based or vascular systems, have limitations in terms of healing capacity, healing cycle repetition, and compatibility with complex geometries. - Integration and Scalability

Integrating self-healing materials into turbine engine components while maintaining their mechanical properties and ensuring scalability for large-scale production is a significant challenge. - Monitoring and Damage Detection

Developing effective monitoring systems to detect and locate damage in real-time is crucial for triggering the self-healing process and ensuring timely repair.

Existing Solutions for Self-Healing Materials for Turbine Engines

01 Self-healing Coatings for Turbine Engine Components

Self-healing coatings can be applied to turbine engine components to protect them from damage and extend their service life. These coatings have the ability to repair cracks or defects by releasing healing agents that seal the damaged areas, preventing further degradation and improving the overall durability of the components.- Self-healing Coatings for Turbine Engine Components: Self-healing coatings can be applied to turbine engine components to provide protection against wear, erosion, and corrosion. These coatings have the ability to repair themselves when damaged, extending the lifespan of the components.

- Self-healing Thermal Barrier Coatings: Self-healing thermal barrier coatings (TBCs) can repair cracks and defects, improving their durability and extending the service life of turbine engine components. These coatings may incorporate self-healing agents or have intrinsic self-healing properties.

- Self-healing Coatings for Turbine Blades: Self-healing coatings can be applied to turbine blades to protect them from harsh environments, including high temperatures, erosion, and corrosion. These coatings can repair cracks, defects, and other damage, improving the durability and performance of the blades.

- Self-healing Coatings for Turbine Engine Combustors: Self-healing coatings can be applied to combustor components in turbine engines to protect them from high temperatures and corrosive environments. These coatings can repair cracks, defects, and other damage, extending the service life of the combustors.

- Self-healing Coatings for Turbine Engine Compressors: Self-healing coatings can be applied to compressor components in turbine engines to protect them from erosion, corrosion, and other forms of damage. These coatings can repair cracks, defects, and other damage, improving the efficiency and performance of the compressors.

02 Self-healing Thermal Barrier Coatings

Self-healing thermal barrier coatings (TBCs) incorporate materials or mechanisms that can repair cracks or defects in the coating, improving its insulating properties and extending the component's lifespan.Expand Specific Solutions03 Self-healing Ceramic Matrix Composites

Self-healing ceramic matrix composites (CMCs) contain additives or mechanisms that can repair cracks or damage, improving their mechanical properties and durability under high-temperature conditions.Expand Specific Solutions04 Self-healing Coatings for Turbine Blade Protection

Self-healing coatings can be applied to turbine blades to protect them from damage, such as oxidation, corrosion, and erosion. These coatings can repair defects or cracks, extending the lifespan of the blades.Expand Specific Solutions05 Self-healing Materials for Turbine Engine Components

Various self-healing materials, such as shape memory alloys, polymers, and composites, can be used in the construction of turbine engine components. These materials have the ability to repair damage or cracks through mechanisms like shape recovery, crack closure, or healing agent release, improving the durability and reliability of the components.Expand Specific Solutions

Key Players in Self-Healing Materials for Turbine Engines Industry

The research on self-healing materials for turbine engines is a rapidly evolving field driven by the need for enhanced durability and reduced maintenance costs in the aerospace industry. While the market size is still relatively small, the technology's potential for extending component lifespans and improving operational efficiency has attracted significant interest from major players like NASA, Toyota, United Technologies, and Rolls-Royce. However, the technology's maturity varies, with companies like The Regents of the University of California, Nanyang Technological University, and Fundación Tecnalia Research & Innovation leading the way in developing advanced self-healing material solutions, while others like Shenyang University of Chemical Technology and Nanjing University are still in the early research stages.

National Aeronautics & Space Administration

Technical Solution: NASA focuses on developing self-healing coatings and composites with self-healing agents for autonomous crack repair in turbine engines.

The Regents of the University of California

Technical Solution: The University of California explores shape memory alloys and polymer composites with shape memory components for self-healing turbine engine materials.

Core Patents and Literature on Self-Healing Materials for Turbine Engines

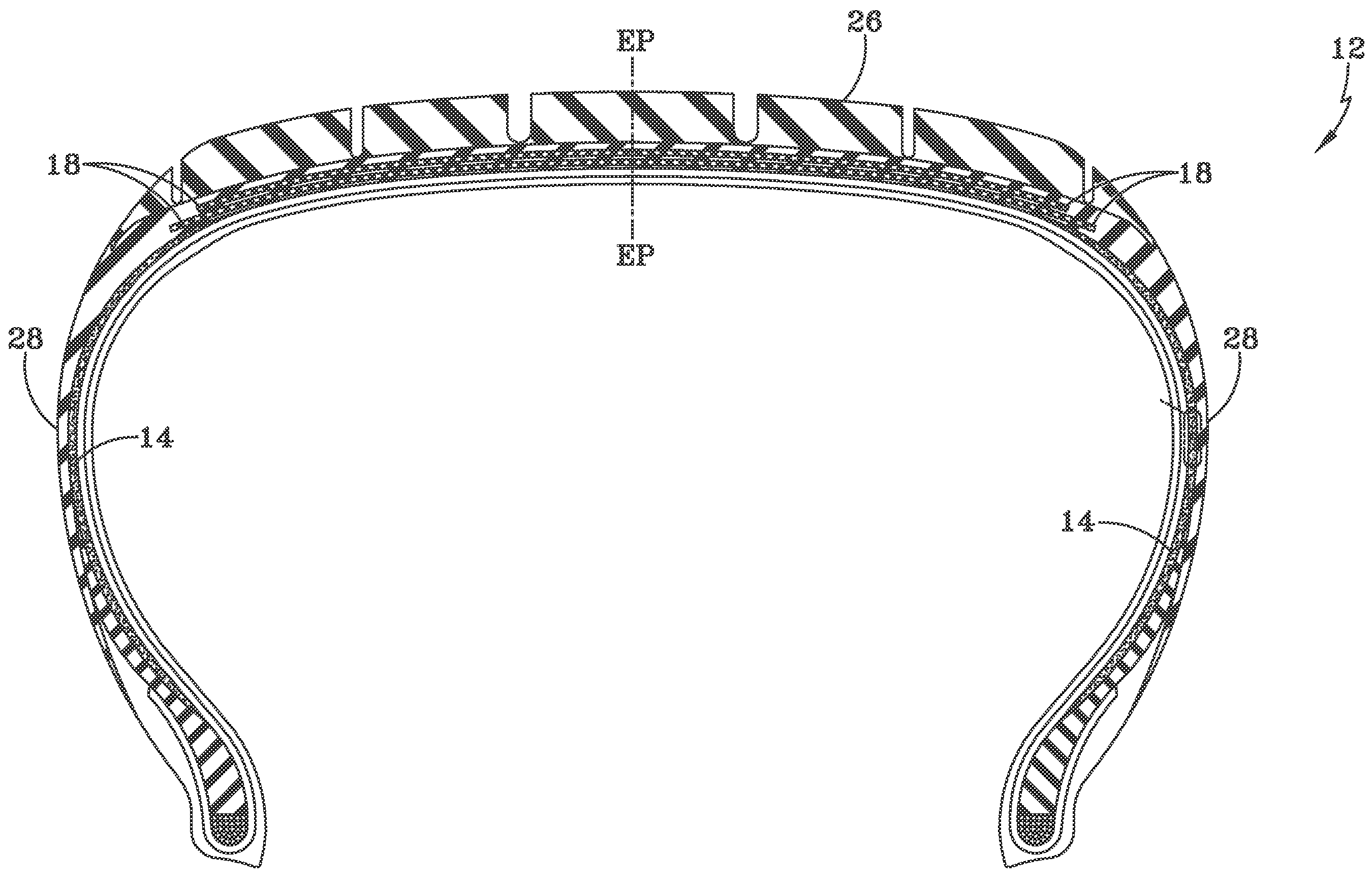

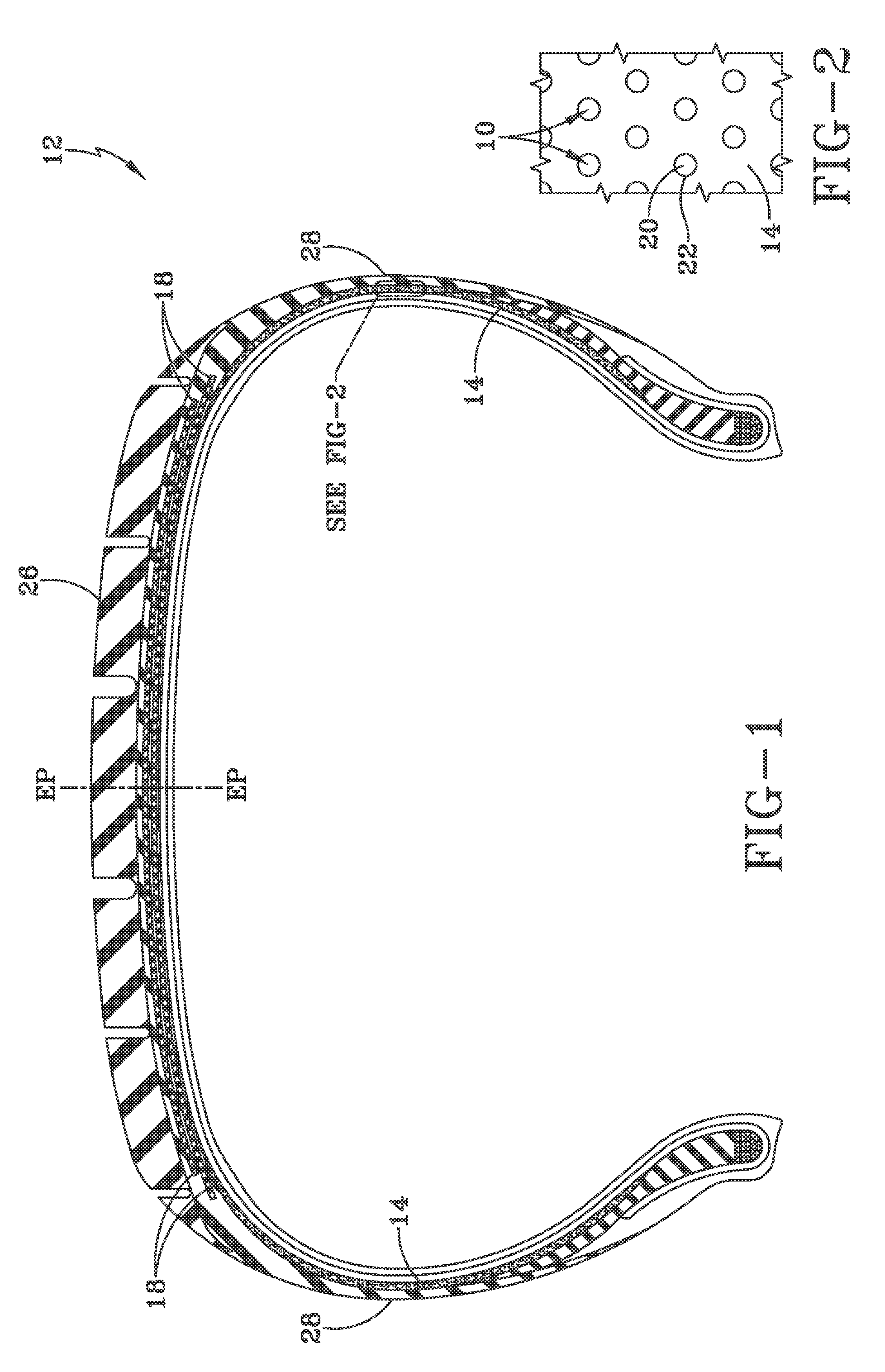

Self-healing materials and use thereof for extending the lifespan of a tire

PatentInactiveUS20080173382A1

Innovation

- 1. The self-healing material includes a rubber healing agent, e.g., sulfur, encapsulated by a coating material, e.g., polypropylene, defining a microcapsule.

- 2. The microcapsule coating material is selected to prevent release of the healing agent during the processing steps of the rubber compound and to release the healing agent at a desired temperature greater than a tire's running temperature.

- 3. The released healing agent can help repair damage to local polymeric structure, such as broken cross-links, by reacting with the surrounding rubber, thereby prolonging the life of the tire.

Environmental Impact of Self-Healing Materials for Turbine Engines

Environmental impacts of self-healing materials for turbine engines encompass various aspects throughout their lifecycle. During the production phase, the manufacturing processes and raw materials utilized may contribute to greenhouse gas emissions, energy consumption, and waste generation. However, the potential benefits of these materials lie in their ability to extend the operational lifespan of turbine engines, reducing the need for frequent replacements and minimizing the environmental footprint associated with manufacturing new components.

During the operational phase, self-healing materials can potentially improve fuel efficiency by maintaining optimal aerodynamic performance, thereby reducing emissions from turbine engines. Additionally, the reduced maintenance requirements and extended service life can lead to lower resource consumption and waste generation.

At the end-of-life stage, the recyclability and biodegradability of self-healing materials become crucial factors. Materials that can be easily recycled or biodegraded can minimize the environmental impact of disposal, while non-biodegradable materials may contribute to landfill waste or require specialized disposal methods. Overall, a comprehensive life cycle assessment is necessary to evaluate the net environmental impact of self-healing materials for turbine engines, considering factors such as energy consumption, emissions, waste generation, and resource depletion.

During the operational phase, self-healing materials can potentially improve fuel efficiency by maintaining optimal aerodynamic performance, thereby reducing emissions from turbine engines. Additionally, the reduced maintenance requirements and extended service life can lead to lower resource consumption and waste generation.

At the end-of-life stage, the recyclability and biodegradability of self-healing materials become crucial factors. Materials that can be easily recycled or biodegraded can minimize the environmental impact of disposal, while non-biodegradable materials may contribute to landfill waste or require specialized disposal methods. Overall, a comprehensive life cycle assessment is necessary to evaluate the net environmental impact of self-healing materials for turbine engines, considering factors such as energy consumption, emissions, waste generation, and resource depletion.

Regulatory Landscape for Self-Healing Materials in Turbine Engines

The regulatory landscape for self-healing materials in turbine engines is a complex and evolving area. Governments and industry bodies have established guidelines and standards to ensure the safety and reliability of these advanced materials. Key regulations cover material composition, performance testing, and certification processes for aerospace applications.

Strict requirements are in place for the use of self-healing materials in critical components, such as turbine blades and combustion chambers. These materials must undergo rigorous testing to demonstrate their ability to withstand extreme temperatures, pressures, and mechanical stresses encountered during engine operation. Regulatory bodies closely monitor the development and implementation of self-healing technologies to mitigate potential risks and ensure compliance with safety protocols.

Additionally, environmental regulations play a role in governing the use of self-healing materials. Authorities assess the potential impact of these materials on air quality, emissions, and waste management throughout their lifecycle. Compliance with environmental regulations is crucial for the widespread adoption of self-healing materials in turbine engines.

Strict requirements are in place for the use of self-healing materials in critical components, such as turbine blades and combustion chambers. These materials must undergo rigorous testing to demonstrate their ability to withstand extreme temperatures, pressures, and mechanical stresses encountered during engine operation. Regulatory bodies closely monitor the development and implementation of self-healing technologies to mitigate potential risks and ensure compliance with safety protocols.

Additionally, environmental regulations play a role in governing the use of self-healing materials. Authorities assess the potential impact of these materials on air quality, emissions, and waste management throughout their lifecycle. Compliance with environmental regulations is crucial for the widespread adoption of self-healing materials in turbine engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!