Development Of Turbine Engine Superalloys

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superalloys Technology Background and Goals

The development of turbine engine superalloys has been driven by the ever-increasing demand for higher operating temperatures and improved efficiency in gas turbine engines. These advanced materials possess exceptional high-temperature strength, oxidation resistance, and creep resistance, enabling them to withstand the extreme conditions encountered in modern turbine engines.

The primary objective of this research is to explore the cutting-edge advancements in turbine engine superalloy development, encompassing composition optimization, processing techniques, and microstructural engineering. By understanding the current state of the art and identifying potential avenues for innovation, this study aims to pave the way for the next generation of high-performance superalloys that can push the boundaries of turbine engine capabilities.

The primary objective of this research is to explore the cutting-edge advancements in turbine engine superalloy development, encompassing composition optimization, processing techniques, and microstructural engineering. By understanding the current state of the art and identifying potential avenues for innovation, this study aims to pave the way for the next generation of high-performance superalloys that can push the boundaries of turbine engine capabilities.

Superalloys Market Demand Analysis

- Surging Demand

The demand for superalloys in turbine engines is witnessing a surge, driven by the growing aviation industry and the need for more efficient and durable engines. The global market for superalloys is projected to expand at a significant rate, fueled by increasing aircraft production and the replacement of aging fleets. - Aerospace Dominance

The aerospace sector remains the primary consumer of superalloys, accounting for a substantial share of the market. Superalloys' exceptional high-temperature strength, corrosion resistance, and creep properties make them indispensable for critical components in jet engines, turbine blades, and other hot-section parts. - Power Generation Opportunities

The power generation industry, particularly gas turbines for electricity production, presents a promising market for superalloys. As the demand for efficient and environmentally-friendly power generation solutions grows, superalloys' ability to withstand extreme temperatures and pressures becomes increasingly valuable. - Emerging Applications

While aerospace and power generation dominate the superalloys market, emerging applications in industries such as chemical processing, oil and gas, and automotive are expected to contribute to market growth. The unique properties of superalloys make them suitable for components operating under harsh conditions. - Regional Dynamics

The Asia-Pacific region, led by countries like China and India, is anticipated to witness significant growth in the superalloys market. This is driven by the region's expanding aviation and power generation sectors, as well as increasing investments in infrastructure and manufacturing capabilities.

Superalloys Technology Status and Challenges

- Alloy Development History

Superalloys have evolved through several generations, driven by the need for higher temperature capabilities and improved performance. - Current Challenges

Key challenges include enhancing high-temperature strength, oxidation resistance, and thermal fatigue life while maintaining manufacturability. - Geographical Distribution

Major superalloy research and production centers are located in the United States, Europe, and emerging regions like China and India.

Current Superalloys Technical Solutions

01 Nickel-based Superalloys for Turbine Components

Nickel-based superalloys containing elements like chromium, cobalt, aluminum, and refractory metals are widely used for manufacturing turbine components due to their excellent high-temperature strength, oxidation resistance, and creep resistance.- Nickel-based Superalloys for Turbine Engines: Nickel-based superalloys are widely used for turbine engine components due to their exceptional high-temperature strength, oxidation resistance, and creep resistance, designed to withstand extreme operating conditions.

- Cobalt-based Superalloys for High-Temperature Applications: Cobalt-based superalloys exhibit excellent high-temperature strength, corrosion resistance, and thermal stability, making them suitable for turbine blades, vanes, and other critical components.

- Superalloy Coatings for Enhanced Performance: Superalloy coatings are applied to turbine engine components to provide additional protection against oxidation, hot corrosion, erosion, and improve thermal barrier properties, using techniques like thermal spraying and vapor deposition.

- Superalloy Processing and Manufacturing Techniques: Precise control of processing and manufacturing techniques, such as casting, forging, heat treatment, and forming processes, is crucial for achieving desired microstructure, mechanical properties, and dimensional accuracy in turbine engine components.

- Composition and Microstructure Optimization: Superalloy composition and microstructure are carefully engineered through alloying elements and controlled heat treatments to enhance specific properties like oxidation resistance, strength, and creep resistance for turbine engine applications.

02 Superalloy Compositions and Processing Methods

Various superalloy compositions and processing methods, including adjusting alloying elements, heat treatment processes, and manufacturing techniques like casting, forging, or powder metallurgy, are disclosed to improve the properties of turbine components.Expand Specific Solutions03 Coatings and Surface Treatments for Superalloys

Coatings and surface treatments, such as thermal barrier coatings, aluminide coatings, shot peening, and grit blasting, are applied to superalloys to enhance their performance in turbine engines by improving properties like oxidation resistance and fatigue life.Expand Specific Solutions04 Single-crystal and Directionally Solidified Superalloys

Single-crystal and directionally solidified superalloys with specific grain structure and orientation are used for turbine blades and vanes to improve their high-temperature creep and fatigue properties.Expand Specific Solutions05 Repair and Refurbishment of Superalloy Components

Various techniques, including welding, brazing, and thermal spraying, are employed for repairing and refurbishing superalloy components used in turbine engines, aiming to extend their service life and reduce maintenance costs.Expand Specific Solutions

Key Superalloys Players Analysis

The turbine engine superalloys market is mature, driven by aerospace and power generation industries. Key players like Honeywell, United Technologies, General Electric, Rolls-Royce, Siemens, and Mitsubishi Hitachi lead the way. However, research by universities and specialized companies continues to drive innovation.

Gaona Aero Material Co., Ltd.

Technical Solution: Gaona is a leading Chinese superalloy manufacturer for turbine engines. They have developed nickel-based alloys like GH4169 and GH4738 with high-temperature strength, creep resistance, and oxidation resistance. Gaona employs advanced casting, forging, and heat treatment techniques.

Strengths: Strong manufacturing capabilities, high-performance alloys, cost-effective solutions. Weaknesses: Limited research capabilities compared to larger corporations.

General Electric Company

Technical Solution: GE has developed advanced superalloys like René N6 and TMS-238 with superior high-temperature strength, oxidation resistance, and creep resistance for turbine components. GE's vacuum investment casting and directional solidification enable complex single-crystal turbine components.

Strengths: Extensive superalloy development experience, advanced manufacturing capabilities, broad product portfolio. Weaknesses: Reliance on proprietary technologies may limit collaboration.

Core Superalloys Patents and Literature Review

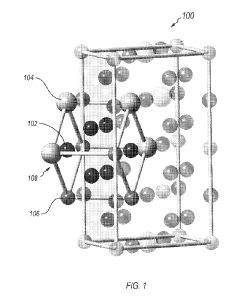

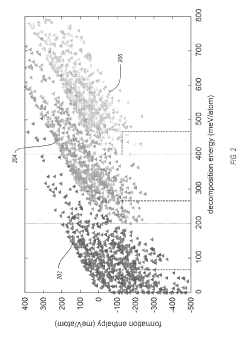

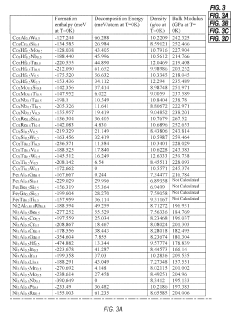

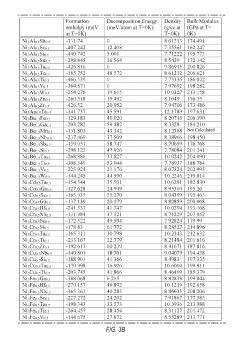

Superalloys compositions including at least one ternary intermetallic compound and applications thereof

PatentActiveUS20190112690A1

Innovation

- The discovery of new ternary intermetallic compounds with specific chemical compositions, which can potentially provide new properties and applications. by understanding the stability and mechanical properties of these compounds, researchers can explore a wide range of applications in aerospace and power industries.

Superalloys Environmental Impact Assessment

Superalloys are advanced metallic materials designed to withstand extreme temperatures and harsh environments encountered in turbine engines and other high-performance applications. Their environmental impact is a crucial consideration throughout their lifecycle, from production to disposal.

During the manufacturing process, the extraction and processing of raw materials, such as nickel, cobalt, and chromium, can have significant environmental consequences. These activities can lead to air and water pollution, energy consumption, and greenhouse gas emissions. Efforts to minimize these impacts through sustainable mining practices, efficient processing techniques, and the use of renewable energy sources are essential.

The operational phase of superalloys in turbine engines also poses environmental challenges. The combustion of fossil fuels in these engines contributes to air pollution, including the emission of nitrogen oxides, sulfur oxides, and particulate matter. Ongoing research focuses on improving fuel efficiency and developing alternative fuel sources to reduce these emissions. Additionally, the noise pollution associated with turbine engines remains a concern, particularly in densely populated areas.

During the manufacturing process, the extraction and processing of raw materials, such as nickel, cobalt, and chromium, can have significant environmental consequences. These activities can lead to air and water pollution, energy consumption, and greenhouse gas emissions. Efforts to minimize these impacts through sustainable mining practices, efficient processing techniques, and the use of renewable energy sources are essential.

The operational phase of superalloys in turbine engines also poses environmental challenges. The combustion of fossil fuels in these engines contributes to air pollution, including the emission of nitrogen oxides, sulfur oxides, and particulate matter. Ongoing research focuses on improving fuel efficiency and developing alternative fuel sources to reduce these emissions. Additionally, the noise pollution associated with turbine engines remains a concern, particularly in densely populated areas.

Superalloys Regulatory and Policy Landscape

The regulatory and policy landscape surrounding superalloys is a complex and ever-evolving domain. Governments and industry bodies have implemented stringent guidelines to ensure the safe and responsible development and application of these advanced materials. Environmental regulations play a pivotal role, as superalloys often involve hazardous elements and energy-intensive production processes.

Strict emission controls and waste management protocols are in place to mitigate the environmental impact. Additionally, intellectual property rights and technology transfer policies significantly influence the competitive dynamics within the superalloy industry. Comprehensive frameworks govern the sharing and dissemination of proprietary technologies, fostering innovation while protecting the interests of key players.

Furthermore, international trade agreements and export control regulations shape the global supply chain and market access for superalloy products. These policies aim to strike a balance between facilitating global collaboration and safeguarding national security interests. Navigating this intricate web of regulations and policies is crucial for stakeholders in the superalloy ecosystem to ensure compliance, maintain competitiveness, and drive sustainable growth.

Strict emission controls and waste management protocols are in place to mitigate the environmental impact. Additionally, intellectual property rights and technology transfer policies significantly influence the competitive dynamics within the superalloy industry. Comprehensive frameworks govern the sharing and dissemination of proprietary technologies, fostering innovation while protecting the interests of key players.

Furthermore, international trade agreements and export control regulations shape the global supply chain and market access for superalloy products. These policies aim to strike a balance between facilitating global collaboration and safeguarding national security interests. Navigating this intricate web of regulations and policies is crucial for stakeholders in the superalloy ecosystem to ensure compliance, maintain competitiveness, and drive sustainable growth.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!