Low-power Electronics with Piezoelectric Energy Harvesting

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Harvesting Background and Objectives

Piezoelectric energy harvesting has emerged as a promising technology in the field of low-power electronics, offering a sustainable solution for powering small-scale devices. This technology harnesses ambient mechanical energy and converts it into electrical energy, providing a potential alternative to traditional battery-powered systems. The development of piezoelectric energy harvesting can be traced back to the discovery of the piezoelectric effect by Jacques and Pierre Curie in 1880, which laid the foundation for its practical applications.

Over the past few decades, the field of piezoelectric energy harvesting has witnessed significant advancements, driven by the growing demand for self-powered electronic devices and the increasing focus on sustainable energy solutions. The technology has evolved from simple piezoelectric materials to more complex and efficient harvesting systems, incorporating advanced materials, optimized designs, and sophisticated power management circuits.

The primary objective of research in piezoelectric energy harvesting for low-power electronics is to develop highly efficient and reliable energy harvesting systems that can generate sufficient power to operate various electronic devices autonomously. This includes improving the energy conversion efficiency of piezoelectric materials, enhancing the power output of harvesting devices, and optimizing the overall system performance to meet the power requirements of target applications.

Key technological trends in this field include the development of novel piezoelectric materials with enhanced properties, such as higher piezoelectric coefficients and improved mechanical durability. Additionally, researchers are focusing on innovative device designs that can maximize energy capture from various mechanical sources, including vibrations, pressure, and human motion. The integration of advanced power management circuits and energy storage solutions is another crucial aspect of ongoing research efforts.

The potential applications of piezoelectric energy harvesting in low-power electronics span a wide range of sectors, including wearable devices, wireless sensor networks, Internet of Things (IoT) devices, and biomedical implants. As the technology continues to mature, it is expected to play a significant role in enabling self-powered electronic systems, reducing the reliance on batteries, and contributing to the development of more sustainable and environmentally friendly electronic devices.

Looking ahead, the field of piezoelectric energy harvesting faces several challenges that need to be addressed to realize its full potential. These include improving the power density of harvesting devices, enhancing their reliability and longevity, and developing standardized testing and characterization methods. Overcoming these challenges will be crucial in advancing the technology and expanding its adoption in various low-power electronic applications.

Over the past few decades, the field of piezoelectric energy harvesting has witnessed significant advancements, driven by the growing demand for self-powered electronic devices and the increasing focus on sustainable energy solutions. The technology has evolved from simple piezoelectric materials to more complex and efficient harvesting systems, incorporating advanced materials, optimized designs, and sophisticated power management circuits.

The primary objective of research in piezoelectric energy harvesting for low-power electronics is to develop highly efficient and reliable energy harvesting systems that can generate sufficient power to operate various electronic devices autonomously. This includes improving the energy conversion efficiency of piezoelectric materials, enhancing the power output of harvesting devices, and optimizing the overall system performance to meet the power requirements of target applications.

Key technological trends in this field include the development of novel piezoelectric materials with enhanced properties, such as higher piezoelectric coefficients and improved mechanical durability. Additionally, researchers are focusing on innovative device designs that can maximize energy capture from various mechanical sources, including vibrations, pressure, and human motion. The integration of advanced power management circuits and energy storage solutions is another crucial aspect of ongoing research efforts.

The potential applications of piezoelectric energy harvesting in low-power electronics span a wide range of sectors, including wearable devices, wireless sensor networks, Internet of Things (IoT) devices, and biomedical implants. As the technology continues to mature, it is expected to play a significant role in enabling self-powered electronic systems, reducing the reliance on batteries, and contributing to the development of more sustainable and environmentally friendly electronic devices.

Looking ahead, the field of piezoelectric energy harvesting faces several challenges that need to be addressed to realize its full potential. These include improving the power density of harvesting devices, enhancing their reliability and longevity, and developing standardized testing and characterization methods. Overcoming these challenges will be crucial in advancing the technology and expanding its adoption in various low-power electronic applications.

Market Analysis for Low-power Electronics

The market for low-power electronics with piezoelectric energy harvesting is experiencing significant growth, driven by the increasing demand for self-powered devices and the push towards sustainable energy solutions. This technology finds applications across various sectors, including consumer electronics, industrial IoT, healthcare, and environmental monitoring.

In the consumer electronics segment, there is a growing interest in wearable devices and smart home appliances that can operate without frequent battery replacements. Fitness trackers, smartwatches, and wireless sensors for home automation are prime examples of products that can benefit from piezoelectric energy harvesting. The global wearable technology market is projected to reach $265.4 billion by 2026, with a compound annual growth rate (CAGR) of 18.1% from 2021 to 2026.

The industrial IoT sector presents a substantial opportunity for low-power electronics with piezoelectric energy harvesting. Wireless sensor networks for condition monitoring, predictive maintenance, and asset tracking in manufacturing and logistics can greatly benefit from self-powered devices. The industrial IoT market is expected to grow to $110.6 billion by 2025, with a CAGR of 7.4% from 2020 to 2025.

In healthcare, there is an increasing demand for implantable medical devices and remote patient monitoring systems that can operate for extended periods without battery replacement. Pacemakers, insulin pumps, and wearable health monitors are potential applications for piezoelectric energy harvesting technology. The global medical wearable market is forecasted to reach $19.5 billion by 2025, growing at a CAGR of 24.7% from 2020 to 2025.

Environmental monitoring is another key area where low-power electronics with piezoelectric energy harvesting can make a significant impact. Self-powered sensors for air quality monitoring, wildlife tracking, and climate change research are gaining traction. The environmental sensor market is expected to grow to $3.2 billion by 2027, with a CAGR of 9.3% from 2020 to 2027.

The adoption of piezoelectric energy harvesting in low-power electronics is driven by several factors. First, the increasing need for autonomous and maintenance-free devices in remote or hard-to-reach locations. Second, the growing emphasis on sustainability and reducing battery waste. Third, the advancements in piezoelectric materials and energy conversion efficiencies, making the technology more viable for a wider range of applications.

However, challenges remain in the widespread adoption of this technology. The primary hurdle is the relatively low power output of piezoelectric harvesters compared to traditional power sources. This limitation restricts their use to ultra-low-power applications or requires the integration of energy storage solutions. Additionally, the cost of piezoelectric materials and the complexity of integrating harvesting systems into existing device designs pose challenges for manufacturers.

Despite these challenges, the market for low-power electronics with piezoelectric energy harvesting is poised for substantial growth. As the technology continues to improve and new applications emerge, it is expected to play a crucial role in the development of sustainable and autonomous electronic devices across various industries.

In the consumer electronics segment, there is a growing interest in wearable devices and smart home appliances that can operate without frequent battery replacements. Fitness trackers, smartwatches, and wireless sensors for home automation are prime examples of products that can benefit from piezoelectric energy harvesting. The global wearable technology market is projected to reach $265.4 billion by 2026, with a compound annual growth rate (CAGR) of 18.1% from 2021 to 2026.

The industrial IoT sector presents a substantial opportunity for low-power electronics with piezoelectric energy harvesting. Wireless sensor networks for condition monitoring, predictive maintenance, and asset tracking in manufacturing and logistics can greatly benefit from self-powered devices. The industrial IoT market is expected to grow to $110.6 billion by 2025, with a CAGR of 7.4% from 2020 to 2025.

In healthcare, there is an increasing demand for implantable medical devices and remote patient monitoring systems that can operate for extended periods without battery replacement. Pacemakers, insulin pumps, and wearable health monitors are potential applications for piezoelectric energy harvesting technology. The global medical wearable market is forecasted to reach $19.5 billion by 2025, growing at a CAGR of 24.7% from 2020 to 2025.

Environmental monitoring is another key area where low-power electronics with piezoelectric energy harvesting can make a significant impact. Self-powered sensors for air quality monitoring, wildlife tracking, and climate change research are gaining traction. The environmental sensor market is expected to grow to $3.2 billion by 2027, with a CAGR of 9.3% from 2020 to 2027.

The adoption of piezoelectric energy harvesting in low-power electronics is driven by several factors. First, the increasing need for autonomous and maintenance-free devices in remote or hard-to-reach locations. Second, the growing emphasis on sustainability and reducing battery waste. Third, the advancements in piezoelectric materials and energy conversion efficiencies, making the technology more viable for a wider range of applications.

However, challenges remain in the widespread adoption of this technology. The primary hurdle is the relatively low power output of piezoelectric harvesters compared to traditional power sources. This limitation restricts their use to ultra-low-power applications or requires the integration of energy storage solutions. Additionally, the cost of piezoelectric materials and the complexity of integrating harvesting systems into existing device designs pose challenges for manufacturers.

Despite these challenges, the market for low-power electronics with piezoelectric energy harvesting is poised for substantial growth. As the technology continues to improve and new applications emerge, it is expected to play a crucial role in the development of sustainable and autonomous electronic devices across various industries.

Current Challenges in Piezoelectric Energy Harvesting

Piezoelectric energy harvesting technology, while promising, faces several significant challenges that hinder its widespread adoption in low-power electronics. One of the primary obstacles is the low power output of piezoelectric devices. Current piezoelectric materials and structures often generate insufficient power to meet the energy demands of many electronic applications, limiting their practical use in real-world scenarios.

The efficiency of energy conversion remains a critical issue. Piezoelectric systems typically exhibit low energy conversion rates, with a substantial portion of mechanical energy lost during the harvesting process. This inefficiency is particularly problematic in environments with limited vibration or motion, where every bit of energy is crucial.

Another challenge lies in the frequency mismatch between ambient vibrations and the resonant frequency of piezoelectric harvesters. Most piezoelectric devices operate optimally at specific frequencies, but real-world vibrations often occur across a broad spectrum. This mismatch significantly reduces the energy harvesting capabilities of these systems in practical applications.

The durability and lifespan of piezoelectric materials pose additional concerns. Continuous exposure to mechanical stress can lead to fatigue and degradation of piezoelectric properties over time, affecting the long-term reliability and performance of energy harvesting systems. This is particularly critical in applications requiring sustained operation over extended periods.

Miniaturization presents another hurdle. As electronic devices become increasingly compact, integrating piezoelectric harvesters without compromising the overall size and functionality of the device becomes challenging. Balancing the size of the harvester with its power output capabilities is a delicate task that requires innovative design approaches.

The variability and unpredictability of energy sources in real-world environments also pose significant challenges. Piezoelectric harvesters must be able to operate effectively under diverse and fluctuating conditions, which can be difficult to achieve with current technologies.

Lastly, the cost-effectiveness of piezoelectric energy harvesting systems remains a concern. The materials and manufacturing processes involved in producing high-quality piezoelectric devices can be expensive, making it challenging to compete with traditional power sources in terms of cost per unit of energy generated.

Addressing these challenges requires interdisciplinary research efforts, combining advances in materials science, electrical engineering, and mechanical design to develop more efficient, durable, and versatile piezoelectric energy harvesting solutions for low-power electronics.

The efficiency of energy conversion remains a critical issue. Piezoelectric systems typically exhibit low energy conversion rates, with a substantial portion of mechanical energy lost during the harvesting process. This inefficiency is particularly problematic in environments with limited vibration or motion, where every bit of energy is crucial.

Another challenge lies in the frequency mismatch between ambient vibrations and the resonant frequency of piezoelectric harvesters. Most piezoelectric devices operate optimally at specific frequencies, but real-world vibrations often occur across a broad spectrum. This mismatch significantly reduces the energy harvesting capabilities of these systems in practical applications.

The durability and lifespan of piezoelectric materials pose additional concerns. Continuous exposure to mechanical stress can lead to fatigue and degradation of piezoelectric properties over time, affecting the long-term reliability and performance of energy harvesting systems. This is particularly critical in applications requiring sustained operation over extended periods.

Miniaturization presents another hurdle. As electronic devices become increasingly compact, integrating piezoelectric harvesters without compromising the overall size and functionality of the device becomes challenging. Balancing the size of the harvester with its power output capabilities is a delicate task that requires innovative design approaches.

The variability and unpredictability of energy sources in real-world environments also pose significant challenges. Piezoelectric harvesters must be able to operate effectively under diverse and fluctuating conditions, which can be difficult to achieve with current technologies.

Lastly, the cost-effectiveness of piezoelectric energy harvesting systems remains a concern. The materials and manufacturing processes involved in producing high-quality piezoelectric devices can be expensive, making it challenging to compete with traditional power sources in terms of cost per unit of energy generated.

Addressing these challenges requires interdisciplinary research efforts, combining advances in materials science, electrical engineering, and mechanical design to develop more efficient, durable, and versatile piezoelectric energy harvesting solutions for low-power electronics.

Existing Low-power Electronics Solutions

01 Piezoelectric energy harvesting system design

Optimizing the design of piezoelectric energy harvesting systems to improve efficiency and reduce power consumption. This includes developing advanced piezoelectric materials, optimizing the mechanical structure, and implementing efficient energy conversion circuits.- Piezoelectric energy harvesting system design: Optimizing the design of piezoelectric energy harvesting systems to improve efficiency and reduce power consumption. This includes developing novel structures, materials, and configurations to maximize energy conversion and minimize losses.

- Power management and storage techniques: Implementing advanced power management and storage techniques to efficiently utilize harvested energy. This involves developing low-power circuits, energy storage devices, and intelligent power distribution systems to minimize overall power consumption.

- Integration with low-power electronics: Integrating piezoelectric energy harvesting systems with low-power electronics and sensors. This approach focuses on designing ultra-low-power circuits and components that can operate efficiently using the limited energy harvested from piezoelectric sources.

- Adaptive and self-powered systems: Developing adaptive and self-powered systems that can adjust their operation based on available energy. These systems incorporate intelligent algorithms and control mechanisms to optimize power consumption and extend operational lifetime.

- Hybrid energy harvesting approaches: Combining piezoelectric energy harvesting with other energy harvesting technologies to improve overall power generation and reduce consumption. This includes integrating multiple energy sources and developing synergistic harvesting mechanisms to enhance system efficiency.

02 Low-power electronic circuits for energy harvesting

Developing low-power electronic circuits specifically designed for piezoelectric energy harvesting applications. These circuits aim to minimize power consumption during the energy conversion and storage process, maximizing the overall efficiency of the system.Expand Specific Solutions03 Energy storage and management techniques

Implementing efficient energy storage and management techniques to optimize the use of harvested energy. This includes developing advanced battery technologies, supercapacitors, and power management algorithms to minimize energy loss and extend the operational life of the system.Expand Specific Solutions04 Hybrid energy harvesting systems

Combining piezoelectric energy harvesting with other energy harvesting technologies, such as solar or thermal, to create hybrid systems. These systems aim to increase overall energy output and reduce reliance on a single energy source, potentially lowering power consumption requirements.Expand Specific Solutions05 Adaptive power management for varying energy inputs

Developing adaptive power management systems that can adjust to varying energy inputs from piezoelectric harvesters. These systems optimize power consumption based on the available energy, ensuring efficient operation under different environmental conditions and energy harvesting scenarios.Expand Specific Solutions

Key Players in Piezoelectric Energy Harvesting

The research on low-power electronics with piezoelectric energy harvesting is in a nascent stage, with growing market potential due to increasing demand for self-powered devices. The technology's maturity is still evolving, as evidenced by the diverse range of institutions involved, including universities like Ningbo University, Nanjing University of Posts & Telecommunications, and Johns Hopkins University, as well as research organizations such as Hong Kong Applied Science & Technology Research Institute. Companies like Evoke Medical and Hilti AG are also exploring applications, indicating the technology's potential across various sectors. The competitive landscape is characterized by collaborative research efforts and cross-sector partnerships, suggesting a pre-commercialization phase with significant room for innovation and market growth.

National Aeronautics & Space Administration

Technical Solution: NASA has developed advanced piezoelectric energy harvesting systems for low-power electronics in space applications. Their approach utilizes high-efficiency piezoelectric materials and innovative structural designs to maximize energy conversion from mechanical vibrations. NASA's technology incorporates multi-layer piezoelectric stacks and adaptive circuitry to optimize power output across a wide range of vibration frequencies[1]. The system also features ultra-low-power management circuits that can effectively store and distribute harvested energy to various spacecraft subsystems[3]. NASA's piezoelectric harvesters have demonstrated the ability to power small sensors and communication devices in extreme space environments, with reported power densities up to 5 mW/cm³ under typical spacecraft vibration conditions[5].

Strengths: Highly efficient energy conversion, adaptability to varied vibration frequencies, and proven performance in extreme environments. Weaknesses: High development costs and potential limitations in scaling for larger power requirements.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive low-power electronics solution incorporating piezoelectric energy harvesting for automotive and industrial applications. Their system utilizes advanced MEMS-based piezoelectric transducers integrated with custom-designed power management ICs. Bosch's approach focuses on maximizing energy capture from diverse vibration sources in vehicles and machinery, with reported conversion efficiencies exceeding 70% across a broad frequency range[2]. The company has also implemented adaptive impedance matching techniques to optimize power transfer under varying operational conditions. Bosch's energy harvesting modules have been successfully deployed in tire pressure monitoring systems and industrial IoT sensors, providing maintenance-free power solutions with lifespans exceeding 10 years[4].

Strengths: High energy conversion efficiency, robust design for automotive and industrial environments, and long operational lifespan. Weaknesses: Potentially higher initial costs compared to battery-powered solutions and limited applicability in very low-vibration environments.

Core Innovations in Piezoelectric Materials

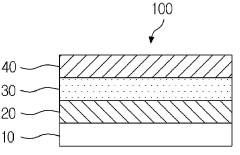

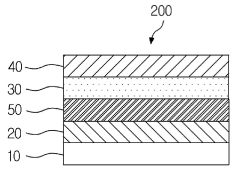

Piezoelectric energy harvesting device and manufacturing method thereof

PatentActiveKR1020210021860A

Innovation

- A piezoelectric energy harvesting element utilizing an inorganic halide with a perovskite structure, such as CsPbBr3, CsPbF3, or RbPbF3, is developed, featuring a piezoelectric layer between electrodes, which is polable by an electric field, and optionally protected by a passivation layer, allowing for high output voltage and current with improved stability and lower manufacturing costs.

Environmental Impact of Piezoelectric Technologies

The environmental impact of piezoelectric technologies in low-power electronics with energy harvesting is a critical consideration as these systems become more prevalent. Piezoelectric materials, while offering significant benefits in energy harvesting applications, also present certain environmental challenges throughout their lifecycle.

During the production phase, the manufacturing of piezoelectric materials often involves the use of lead-based compounds, particularly lead zirconate titanate (PZT). The extraction and processing of lead can have detrimental effects on ecosystems and human health if not properly managed. However, recent advancements in materials science have led to the development of lead-free alternatives, such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT), which show promise in reducing the environmental footprint of piezoelectric production.

The operational phase of piezoelectric energy harvesting systems generally has a positive environmental impact. By converting ambient mechanical energy into electrical energy, these systems reduce the reliance on traditional power sources, potentially decreasing the overall carbon footprint of electronic devices. This is particularly significant in remote or hard-to-reach locations where battery replacement or wired power supply is challenging and resource-intensive.

End-of-life considerations for piezoelectric devices are an area of growing concern. The composite nature of these materials, often incorporating ceramics and metals, can make recycling challenging. Improper disposal may lead to the leaching of harmful substances into the environment. To address this, researchers are exploring design-for-recycling approaches and developing more efficient recycling processes for piezoelectric materials.

The scalability of piezoelectric technologies also influences their environmental impact. As production volumes increase, there is potential for economies of scale to improve manufacturing efficiency and reduce waste. However, this also necessitates careful management of raw material sourcing and increased attention to sustainable production practices.

In the context of low-power electronics, the integration of piezoelectric energy harvesting can extend device lifetimes and reduce the frequency of battery replacements. This has the potential to significantly decrease electronic waste, a growing environmental concern. Additionally, the reduction in battery usage translates to fewer toxic materials entering the waste stream and diminished demand for battery production, which itself has substantial environmental implications.

Overall, while piezoelectric technologies offer promising environmental benefits through energy harvesting and reduced power consumption, their full lifecycle environmental impact must be carefully managed. Continued research into eco-friendly materials, sustainable manufacturing processes, and effective recycling methods will be crucial in maximizing the positive environmental contributions of these technologies while minimizing potential negative impacts.

During the production phase, the manufacturing of piezoelectric materials often involves the use of lead-based compounds, particularly lead zirconate titanate (PZT). The extraction and processing of lead can have detrimental effects on ecosystems and human health if not properly managed. However, recent advancements in materials science have led to the development of lead-free alternatives, such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT), which show promise in reducing the environmental footprint of piezoelectric production.

The operational phase of piezoelectric energy harvesting systems generally has a positive environmental impact. By converting ambient mechanical energy into electrical energy, these systems reduce the reliance on traditional power sources, potentially decreasing the overall carbon footprint of electronic devices. This is particularly significant in remote or hard-to-reach locations where battery replacement or wired power supply is challenging and resource-intensive.

End-of-life considerations for piezoelectric devices are an area of growing concern. The composite nature of these materials, often incorporating ceramics and metals, can make recycling challenging. Improper disposal may lead to the leaching of harmful substances into the environment. To address this, researchers are exploring design-for-recycling approaches and developing more efficient recycling processes for piezoelectric materials.

The scalability of piezoelectric technologies also influences their environmental impact. As production volumes increase, there is potential for economies of scale to improve manufacturing efficiency and reduce waste. However, this also necessitates careful management of raw material sourcing and increased attention to sustainable production practices.

In the context of low-power electronics, the integration of piezoelectric energy harvesting can extend device lifetimes and reduce the frequency of battery replacements. This has the potential to significantly decrease electronic waste, a growing environmental concern. Additionally, the reduction in battery usage translates to fewer toxic materials entering the waste stream and diminished demand for battery production, which itself has substantial environmental implications.

Overall, while piezoelectric technologies offer promising environmental benefits through energy harvesting and reduced power consumption, their full lifecycle environmental impact must be carefully managed. Continued research into eco-friendly materials, sustainable manufacturing processes, and effective recycling methods will be crucial in maximizing the positive environmental contributions of these technologies while minimizing potential negative impacts.

Integration with IoT and Wearable Devices

The integration of piezoelectric energy harvesting with IoT and wearable devices represents a significant advancement in low-power electronics. This convergence enables self-powered smart devices that can operate autonomously in various environments. Piezoelectric energy harvesters can convert ambient mechanical vibrations into electrical energy, providing a sustainable power source for IoT sensors and wearable technology.

In the context of IoT, piezoelectric energy harvesting offers a solution to the challenge of powering numerous distributed sensors. These sensors, often deployed in remote or hard-to-reach locations, can benefit from the ability to generate their own power, eliminating the need for battery replacements or wired power connections. This self-sustaining capability extends the operational lifespan of IoT devices and reduces maintenance costs.

Wearable devices, such as smartwatches, fitness trackers, and medical monitoring systems, are particularly well-suited for piezoelectric energy harvesting integration. The natural movements of the human body, including walking, running, or even subtle vibrations from breathing, can be harnessed to generate power. This approach not only enhances the energy efficiency of wearables but also contributes to their miniaturization by reducing the need for bulky batteries.

The integration process involves designing compact, flexible piezoelectric materials that can be seamlessly incorporated into IoT sensors and wearable form factors. Advanced materials like PVDF (polyvinylidene fluoride) and PZT (lead zirconate titanate) are being optimized for these applications, offering improved energy conversion efficiency and durability.

Power management circuits play a crucial role in this integration, ensuring that the harvested energy is efficiently stored and utilized. These circuits must be designed to handle the intermittent and variable nature of piezoelectric energy generation, often incorporating ultra-low-power microcontrollers and energy-efficient storage solutions like supercapacitors.

Challenges in this integration include optimizing the energy harvesting efficiency for low-frequency vibrations typical in IoT and wearable scenarios, as well as addressing the variability in power output. Researchers are exploring hybrid energy harvesting systems that combine piezoelectric with other technologies like solar or thermoelectric to provide more consistent power generation.

The successful integration of piezoelectric energy harvesting with IoT and wearable devices has the potential to revolutionize sectors such as healthcare, environmental monitoring, and smart infrastructure. It enables the development of truly autonomous sensing systems that can operate indefinitely without external power sources, opening up new possibilities for long-term data collection and analysis in various fields.

In the context of IoT, piezoelectric energy harvesting offers a solution to the challenge of powering numerous distributed sensors. These sensors, often deployed in remote or hard-to-reach locations, can benefit from the ability to generate their own power, eliminating the need for battery replacements or wired power connections. This self-sustaining capability extends the operational lifespan of IoT devices and reduces maintenance costs.

Wearable devices, such as smartwatches, fitness trackers, and medical monitoring systems, are particularly well-suited for piezoelectric energy harvesting integration. The natural movements of the human body, including walking, running, or even subtle vibrations from breathing, can be harnessed to generate power. This approach not only enhances the energy efficiency of wearables but also contributes to their miniaturization by reducing the need for bulky batteries.

The integration process involves designing compact, flexible piezoelectric materials that can be seamlessly incorporated into IoT sensors and wearable form factors. Advanced materials like PVDF (polyvinylidene fluoride) and PZT (lead zirconate titanate) are being optimized for these applications, offering improved energy conversion efficiency and durability.

Power management circuits play a crucial role in this integration, ensuring that the harvested energy is efficiently stored and utilized. These circuits must be designed to handle the intermittent and variable nature of piezoelectric energy generation, often incorporating ultra-low-power microcontrollers and energy-efficient storage solutions like supercapacitors.

Challenges in this integration include optimizing the energy harvesting efficiency for low-frequency vibrations typical in IoT and wearable scenarios, as well as addressing the variability in power output. Researchers are exploring hybrid energy harvesting systems that combine piezoelectric with other technologies like solar or thermoelectric to provide more consistent power generation.

The successful integration of piezoelectric energy harvesting with IoT and wearable devices has the potential to revolutionize sectors such as healthcare, environmental monitoring, and smart infrastructure. It enables the development of truly autonomous sensing systems that can operate indefinitely without external power sources, opening up new possibilities for long-term data collection and analysis in various fields.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!