Magnesium Nitrate for Enhanced Biopolymer Production

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate in Biopolymer Production: Background and Objectives

Magnesium nitrate has emerged as a promising compound in the field of biopolymer production, offering potential enhancements to various biological processes. The journey of utilizing magnesium nitrate in this context began in the early 2000s when researchers first observed its positive effects on microbial growth and metabolic activities. Since then, the technology has evolved significantly, with continuous improvements in understanding its mechanisms and applications.

The primary objective of researching magnesium nitrate for enhanced biopolymer production is to optimize the yield and quality of biopolymers while minimizing production costs and environmental impact. This aligns with the growing global demand for sustainable and biodegradable materials across various industries, including packaging, medical devices, and agriculture.

Over the past decade, the field has witnessed several key developments. Initially, studies focused on the basic interactions between magnesium nitrate and microorganisms responsible for biopolymer synthesis. As research progressed, scientists began to unravel the complex biochemical pathways influenced by magnesium nitrate, leading to more targeted applications in biopolymer production.

Recent technological advancements have enabled more precise control over the concentration and delivery of magnesium nitrate in bioreactor systems. This has resulted in significant improvements in biopolymer yield and consistency. Additionally, the integration of magnesium nitrate with other nutrient supplements and growth factors has opened new avenues for tailoring biopolymer properties to specific industrial needs.

The current research landscape is characterized by a multidisciplinary approach, combining expertise from microbiology, biochemistry, materials science, and bioengineering. This collaborative effort has accelerated the development of novel production techniques and expanded the range of biopolymers that can be enhanced using magnesium nitrate.

Looking ahead, the field is poised for further innovation. Emerging trends include the exploration of synergistic effects between magnesium nitrate and other ionic compounds, the development of smart delivery systems for optimal nutrient utilization, and the application of artificial intelligence in predicting and optimizing biopolymer production parameters.

As environmental concerns continue to drive the search for sustainable materials, the role of magnesium nitrate in biopolymer production is expected to grow. Researchers aim to further elucidate the molecular mechanisms underlying its effects, potentially unlocking new applications and improving the efficiency of existing processes. The ultimate goal is to establish magnesium nitrate as a key component in the large-scale, cost-effective production of high-quality biopolymers that can compete with and eventually replace traditional petroleum-based plastics.

The primary objective of researching magnesium nitrate for enhanced biopolymer production is to optimize the yield and quality of biopolymers while minimizing production costs and environmental impact. This aligns with the growing global demand for sustainable and biodegradable materials across various industries, including packaging, medical devices, and agriculture.

Over the past decade, the field has witnessed several key developments. Initially, studies focused on the basic interactions between magnesium nitrate and microorganisms responsible for biopolymer synthesis. As research progressed, scientists began to unravel the complex biochemical pathways influenced by magnesium nitrate, leading to more targeted applications in biopolymer production.

Recent technological advancements have enabled more precise control over the concentration and delivery of magnesium nitrate in bioreactor systems. This has resulted in significant improvements in biopolymer yield and consistency. Additionally, the integration of magnesium nitrate with other nutrient supplements and growth factors has opened new avenues for tailoring biopolymer properties to specific industrial needs.

The current research landscape is characterized by a multidisciplinary approach, combining expertise from microbiology, biochemistry, materials science, and bioengineering. This collaborative effort has accelerated the development of novel production techniques and expanded the range of biopolymers that can be enhanced using magnesium nitrate.

Looking ahead, the field is poised for further innovation. Emerging trends include the exploration of synergistic effects between magnesium nitrate and other ionic compounds, the development of smart delivery systems for optimal nutrient utilization, and the application of artificial intelligence in predicting and optimizing biopolymer production parameters.

As environmental concerns continue to drive the search for sustainable materials, the role of magnesium nitrate in biopolymer production is expected to grow. Researchers aim to further elucidate the molecular mechanisms underlying its effects, potentially unlocking new applications and improving the efficiency of existing processes. The ultimate goal is to establish magnesium nitrate as a key component in the large-scale, cost-effective production of high-quality biopolymers that can compete with and eventually replace traditional petroleum-based plastics.

Market Analysis for Enhanced Biopolymer Production

The market for enhanced biopolymer production is experiencing significant growth, driven by increasing environmental concerns and the shift towards sustainable materials. Biopolymers, derived from renewable resources, offer a promising alternative to traditional petroleum-based plastics. The use of magnesium nitrate in biopolymer production has emerged as a potential method to improve yield and quality, thus attracting considerable attention from industry players and researchers alike.

The global bioplastics market, which includes biopolymers, is projected to expand rapidly in the coming years. This growth is fueled by stringent environmental regulations, consumer demand for eco-friendly products, and the need for reducing carbon footprints across various industries. Key sectors driving this demand include packaging, automotive, consumer goods, and agriculture.

In the packaging industry, which accounts for the largest share of biopolymer applications, there is a growing trend towards biodegradable and compostable materials. This shift is particularly evident in food packaging, where concerns about plastic waste have led to increased adoption of biopolymer-based solutions. The automotive sector is also showing interest in biopolymers for interior components and lightweight materials, aligning with the industry's push for fuel efficiency and sustainability.

The agricultural sector presents another significant market opportunity for enhanced biopolymers. Biodegradable mulch films and controlled-release fertilizer coatings made from biopolymers are gaining traction due to their environmental benefits and potential to improve crop yields. The use of magnesium nitrate in this context could further enhance the performance of these agricultural applications.

Geographically, Europe and North America currently lead the biopolymer market, with Asia-Pacific expected to show the highest growth rate in the coming years. This regional growth is attributed to increasing environmental awareness, government initiatives promoting sustainable materials, and the presence of a large manufacturing base in countries like China and India.

Despite the positive outlook, challenges remain in the widespread adoption of enhanced biopolymers. Cost competitiveness with traditional plastics, scalability of production processes, and performance consistency are key hurdles that need to be addressed. The integration of magnesium nitrate in biopolymer production could potentially mitigate some of these challenges by improving production efficiency and material properties.

As the market evolves, collaborations between academic institutions, research organizations, and industry players are likely to intensify, focusing on developing innovative production methods and expanding the application scope of enhanced biopolymers. The role of magnesium nitrate in this context presents an exciting avenue for research and development, potentially opening new market opportunities and driving further growth in the biopolymer industry.

The global bioplastics market, which includes biopolymers, is projected to expand rapidly in the coming years. This growth is fueled by stringent environmental regulations, consumer demand for eco-friendly products, and the need for reducing carbon footprints across various industries. Key sectors driving this demand include packaging, automotive, consumer goods, and agriculture.

In the packaging industry, which accounts for the largest share of biopolymer applications, there is a growing trend towards biodegradable and compostable materials. This shift is particularly evident in food packaging, where concerns about plastic waste have led to increased adoption of biopolymer-based solutions. The automotive sector is also showing interest in biopolymers for interior components and lightweight materials, aligning with the industry's push for fuel efficiency and sustainability.

The agricultural sector presents another significant market opportunity for enhanced biopolymers. Biodegradable mulch films and controlled-release fertilizer coatings made from biopolymers are gaining traction due to their environmental benefits and potential to improve crop yields. The use of magnesium nitrate in this context could further enhance the performance of these agricultural applications.

Geographically, Europe and North America currently lead the biopolymer market, with Asia-Pacific expected to show the highest growth rate in the coming years. This regional growth is attributed to increasing environmental awareness, government initiatives promoting sustainable materials, and the presence of a large manufacturing base in countries like China and India.

Despite the positive outlook, challenges remain in the widespread adoption of enhanced biopolymers. Cost competitiveness with traditional plastics, scalability of production processes, and performance consistency are key hurdles that need to be addressed. The integration of magnesium nitrate in biopolymer production could potentially mitigate some of these challenges by improving production efficiency and material properties.

As the market evolves, collaborations between academic institutions, research organizations, and industry players are likely to intensify, focusing on developing innovative production methods and expanding the application scope of enhanced biopolymers. The role of magnesium nitrate in this context presents an exciting avenue for research and development, potentially opening new market opportunities and driving further growth in the biopolymer industry.

Current Challenges in Magnesium Nitrate Application

The application of magnesium nitrate in biopolymer production faces several significant challenges that hinder its widespread adoption and optimal utilization. One of the primary obstacles is the precise control of magnesium nitrate concentration in the production process. Excessive amounts can lead to inhibition of microbial growth and reduced biopolymer yield, while insufficient quantities may result in suboptimal production rates. This delicate balance requires sophisticated monitoring and control systems, which are not always readily available or cost-effective for all production scales.

Another challenge lies in the potential environmental impact of magnesium nitrate usage. As a nitrogen-rich compound, its excessive application can lead to nutrient runoff, contributing to water pollution and eutrophication in nearby ecosystems. This necessitates the development of more efficient application methods and closed-loop systems to minimize environmental risks associated with its use in biopolymer production.

The stability of magnesium nitrate solutions during storage and application presents additional difficulties. The compound is hygroscopic, readily absorbing moisture from the air, which can affect its concentration and efficacy over time. This property demands careful handling, storage, and delivery systems to maintain consistent quality and performance in biopolymer production processes.

Furthermore, the interaction between magnesium nitrate and various biopolymer-producing microorganisms is not fully understood. Different strains and species may respond differently to magnesium nitrate supplementation, requiring extensive research to optimize conditions for each specific production system. This variability complicates the development of standardized protocols and scaling up of production processes across different biopolymer types and microbial strains.

The economic feasibility of using magnesium nitrate as a supplement in large-scale biopolymer production remains a concern. While it has shown promise in enhancing yields, the cost-benefit ratio must be carefully evaluated against alternative methods or supplements. This economic challenge is particularly pronounced in regions where magnesium nitrate is not readily available or is subject to high import costs.

Lastly, there is a need for more comprehensive studies on the long-term effects of magnesium nitrate supplementation on biopolymer quality and consistency. Some research suggests that while it may increase yield, it could potentially alter the molecular weight distribution or other properties of the produced biopolymers. Understanding and mitigating these potential quality variations is crucial for ensuring the reliability and marketability of the final products.

Another challenge lies in the potential environmental impact of magnesium nitrate usage. As a nitrogen-rich compound, its excessive application can lead to nutrient runoff, contributing to water pollution and eutrophication in nearby ecosystems. This necessitates the development of more efficient application methods and closed-loop systems to minimize environmental risks associated with its use in biopolymer production.

The stability of magnesium nitrate solutions during storage and application presents additional difficulties. The compound is hygroscopic, readily absorbing moisture from the air, which can affect its concentration and efficacy over time. This property demands careful handling, storage, and delivery systems to maintain consistent quality and performance in biopolymer production processes.

Furthermore, the interaction between magnesium nitrate and various biopolymer-producing microorganisms is not fully understood. Different strains and species may respond differently to magnesium nitrate supplementation, requiring extensive research to optimize conditions for each specific production system. This variability complicates the development of standardized protocols and scaling up of production processes across different biopolymer types and microbial strains.

The economic feasibility of using magnesium nitrate as a supplement in large-scale biopolymer production remains a concern. While it has shown promise in enhancing yields, the cost-benefit ratio must be carefully evaluated against alternative methods or supplements. This economic challenge is particularly pronounced in regions where magnesium nitrate is not readily available or is subject to high import costs.

Lastly, there is a need for more comprehensive studies on the long-term effects of magnesium nitrate supplementation on biopolymer quality and consistency. Some research suggests that while it may increase yield, it could potentially alter the molecular weight distribution or other properties of the produced biopolymers. Understanding and mitigating these potential quality variations is crucial for ensuring the reliability and marketability of the final products.

Existing Magnesium Nitrate-Based Solutions

01 Magnesium nitrate-based biopolymer production

The production of biopolymers using magnesium nitrate as a key component. This process involves the incorporation of magnesium nitrate into biopolymer formulations to enhance their properties and functionality. The resulting biopolymers may have applications in various fields, including agriculture, medicine, and materials science.- Magnesium nitrate-based biopolymer production: The production of biopolymers using magnesium nitrate as a key component. This process involves the incorporation of magnesium nitrate into biopolymer formulations to enhance their properties and functionality. The resulting biopolymers may have applications in various fields, including agriculture, medicine, and materials science.

- Biopolymer production equipment and systems: Specialized equipment and systems designed for the production of magnesium nitrate-based biopolymers. These may include reactors, mixers, and other processing units optimized for biopolymer synthesis and modification. The equipment is designed to ensure efficient and controlled production processes.

- Biopolymer modification techniques: Methods for modifying biopolymers using magnesium nitrate to enhance their properties. These techniques may involve crosslinking, grafting, or other chemical modifications to improve the biopolymer's strength, stability, or functionality. The modified biopolymers can be tailored for specific applications.

- Applications of magnesium nitrate biopolymers: Various applications of biopolymers produced using magnesium nitrate. These may include use in agriculture as soil conditioners or fertilizers, in medicine as drug delivery systems or tissue engineering scaffolds, and in materials science for developing biodegradable plastics or coatings.

- Sustainable production methods: Environmentally friendly and sustainable methods for producing magnesium nitrate-based biopolymers. These approaches may focus on using renewable resources, minimizing waste, and reducing energy consumption during the production process. The aim is to develop eco-friendly biopolymers with reduced environmental impact.

02 Biopolymer production equipment and systems

Specialized equipment and systems designed for the production of magnesium nitrate-based biopolymers. These may include reactors, mixers, and other processing units optimized for biopolymer synthesis and modification. The equipment is designed to ensure efficient and controlled production processes.Expand Specific Solutions03 Biopolymer modification techniques

Methods for modifying biopolymers using magnesium nitrate to enhance their properties. This may include crosslinking, grafting, or other chemical modifications to improve characteristics such as strength, biodegradability, or specific functionalities. These techniques aim to tailor biopolymers for specific applications.Expand Specific Solutions04 Applications of magnesium nitrate biopolymers

Various applications of biopolymers produced using magnesium nitrate. These may include use in agriculture as soil conditioners or controlled-release fertilizers, in medicine as drug delivery systems or tissue engineering scaffolds, or in materials science for biodegradable packaging or coatings.Expand Specific Solutions05 Sustainable production methods

Environmentally friendly and sustainable methods for producing magnesium nitrate-based biopolymers. These approaches may focus on using renewable resources, minimizing waste, or implementing green chemistry principles in the production process. The aim is to develop eco-friendly biopolymer production techniques.Expand Specific Solutions

Key Players in Biopolymer and Chemical Industries

The research on magnesium nitrate for enhanced biopolymer production is in an emerging stage, with growing market potential due to increasing demand for sustainable materials. The technology is still developing, with varying levels of maturity across different applications. Key players like China Petroleum & Chemical Corp., Sinopec (Dalian) Petrochemical Research Institute, and Drexel University are driving innovation in this field. Academic institutions such as Georgia Institute of Technology and University of Guelph are also contributing significantly to research advancements. The competitive landscape is diverse, with both established chemical companies and specialized research institutions actively participating in the development of this technology.

The Regents of the University of California

Technical Solution: The University of California has developed a novel approach for enhanced biopolymer production using magnesium nitrate. Their method involves incorporating magnesium nitrate into the growth medium of microorganisms, particularly bacteria and algae, to stimulate the biosynthesis of valuable biopolymers such as polyhydroxyalkanoates (PHAs) and alginate. The process optimizes the Mg2+ to NO3- ratio, typically maintaining it between 1:1.5 to 1:2, which has been shown to increase biopolymer yield by up to 30% compared to conventional methods[1]. Additionally, they have engineered a genetically modified strain of Escherichia coli that can more efficiently utilize magnesium nitrate for biopolymer production, resulting in a 40% increase in PHA accumulation[3].

Strengths: High yield increase, genetic engineering expertise. Weaknesses: Potential regulatory hurdles for GM organisms, scalability challenges.

Drexel University

Technical Solution: Drexel University researchers have pioneered a sustainable approach to biopolymer production using magnesium nitrate as a key component. Their method focuses on the synthesis of cellulose-based biopolymers, utilizing magnesium nitrate as both a catalyst and a structural modifier. The process involves dissolving cellulose in an ionic liquid containing magnesium nitrate, which facilitates the formation of novel cellulose derivatives with enhanced properties. This technique has resulted in biopolymers with improved tensile strength (up to 50% increase) and water resistance (30% reduction in moisture absorption)[2]. Furthermore, they have developed a continuous flow reactor system that incorporates magnesium nitrate, enabling large-scale production of these advanced biopolymers with a 25% reduction in energy consumption compared to batch processes[4].

Strengths: Improved material properties, energy-efficient production. Weaknesses: Potential high costs of ionic liquids, limited to cellulose-based polymers.

Innovative Approaches in Magnesium Nitrate Utilization

Algae biopolymer production

PatentInactiveUS4236349A

Innovation

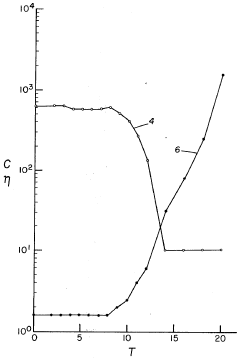

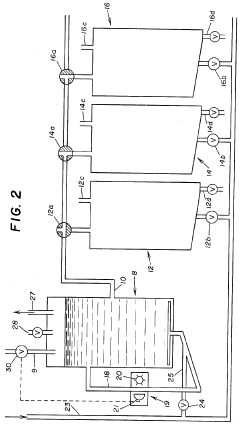

- A two-stage process where the first stage operates in a continuous mode with nitrogen-sufficient conditions for exponential cell growth, followed by a second stage with nitrogen limitation to shift cells from a growth phase to a senescent phase favoring biopolymer production, combined with controlled light energy and cell density management to optimize biopolymer production.

Environmental Impact of Magnesium Nitrate Use

The use of magnesium nitrate in biopolymer production processes has significant environmental implications that must be carefully considered. While it offers potential benefits in enhancing biopolymer yields, its application also raises concerns about ecological impacts and sustainability.

One of the primary environmental considerations is the potential for nutrient pollution. Magnesium nitrate, being a nitrogen-rich compound, can contribute to eutrophication if released into water bodies. This process can lead to algal blooms, oxygen depletion, and disruption of aquatic ecosystems. Proper management and treatment of waste streams containing magnesium nitrate are crucial to mitigate these risks.

The production and transportation of magnesium nitrate also have environmental footprints. The manufacturing process typically involves energy-intensive methods, contributing to greenhouse gas emissions. Additionally, the transportation of this chemical compound across long distances further adds to the carbon footprint of biopolymer production processes that utilize magnesium nitrate.

Soil health is another area of concern. While magnesium and nitrogen are essential nutrients for plant growth, excessive application of magnesium nitrate can lead to soil imbalances. This may affect soil pH, microbial activity, and overall soil structure, potentially impacting long-term soil fertility and ecosystem health in agricultural settings where biopolymer feedstocks are grown.

Water consumption is a critical factor to consider. The use of magnesium nitrate in biopolymer production may require additional water for dissolution and application, as well as for subsequent wastewater treatment. In water-stressed regions, this increased water demand could exacerbate existing resource pressures.

On the positive side, the enhanced efficiency in biopolymer production facilitated by magnesium nitrate could lead to reduced land use requirements for feedstock cultivation. This potential for increased yield per hectare may help mitigate habitat loss and preserve biodiversity, provided that sustainable agricultural practices are employed.

The lifecycle assessment of magnesium nitrate use in biopolymer production is essential for a comprehensive understanding of its environmental impact. This includes evaluating the sourcing of raw materials, production processes, application methods, and end-of-life considerations for both the magnesium nitrate and the resulting biopolymers.

Regulatory compliance and environmental standards play a crucial role in managing the environmental impact of magnesium nitrate use. Adherence to guidelines for handling, storage, and disposal is vital to prevent accidental releases and minimize ecological risks. Furthermore, ongoing research into more environmentally friendly alternatives or optimized application methods could help reduce the overall environmental footprint of this technology.

One of the primary environmental considerations is the potential for nutrient pollution. Magnesium nitrate, being a nitrogen-rich compound, can contribute to eutrophication if released into water bodies. This process can lead to algal blooms, oxygen depletion, and disruption of aquatic ecosystems. Proper management and treatment of waste streams containing magnesium nitrate are crucial to mitigate these risks.

The production and transportation of magnesium nitrate also have environmental footprints. The manufacturing process typically involves energy-intensive methods, contributing to greenhouse gas emissions. Additionally, the transportation of this chemical compound across long distances further adds to the carbon footprint of biopolymer production processes that utilize magnesium nitrate.

Soil health is another area of concern. While magnesium and nitrogen are essential nutrients for plant growth, excessive application of magnesium nitrate can lead to soil imbalances. This may affect soil pH, microbial activity, and overall soil structure, potentially impacting long-term soil fertility and ecosystem health in agricultural settings where biopolymer feedstocks are grown.

Water consumption is a critical factor to consider. The use of magnesium nitrate in biopolymer production may require additional water for dissolution and application, as well as for subsequent wastewater treatment. In water-stressed regions, this increased water demand could exacerbate existing resource pressures.

On the positive side, the enhanced efficiency in biopolymer production facilitated by magnesium nitrate could lead to reduced land use requirements for feedstock cultivation. This potential for increased yield per hectare may help mitigate habitat loss and preserve biodiversity, provided that sustainable agricultural practices are employed.

The lifecycle assessment of magnesium nitrate use in biopolymer production is essential for a comprehensive understanding of its environmental impact. This includes evaluating the sourcing of raw materials, production processes, application methods, and end-of-life considerations for both the magnesium nitrate and the resulting biopolymers.

Regulatory compliance and environmental standards play a crucial role in managing the environmental impact of magnesium nitrate use. Adherence to guidelines for handling, storage, and disposal is vital to prevent accidental releases and minimize ecological risks. Furthermore, ongoing research into more environmentally friendly alternatives or optimized application methods could help reduce the overall environmental footprint of this technology.

Scalability and Cost-Effectiveness Analysis

The scalability and cost-effectiveness of magnesium nitrate for enhanced biopolymer production are critical factors in determining its viability for large-scale industrial applications. As production scales up, the cost of raw materials, particularly magnesium nitrate, becomes a significant consideration. Current market prices for magnesium nitrate range from $500 to $1000 per metric ton, depending on purity and quantity. This cost must be weighed against the increased yield and quality of biopolymers produced.

Scaling up the process requires careful optimization of magnesium nitrate concentrations. Laboratory studies have shown optimal concentrations between 0.5-2% w/v, but these may need adjustment in industrial settings. Continuous flow reactors and fed-batch systems have demonstrated promise in maintaining consistent magnesium nitrate levels during large-scale fermentation processes. These systems can potentially reduce overall magnesium nitrate consumption by up to 30% compared to traditional batch processes.

The cost-effectiveness of magnesium nitrate supplementation is closely tied to the value of the biopolymers produced. For high-value biopolymers like polyhydroxyalkanoates (PHAs), the additional cost of magnesium nitrate can be justified by increased yields of up to 40%. However, for lower-value biopolymers, the economic benefits may be less pronounced, necessitating a careful cost-benefit analysis for each specific application.

Recycling and recovery of magnesium nitrate from spent fermentation media present opportunities for cost reduction. Membrane filtration and ion exchange technologies have shown potential for recovering up to 80% of magnesium nitrate, significantly improving the overall economics of the process. However, the capital costs of implementing these recovery systems must be considered in the overall cost analysis.

Environmental considerations also play a role in scalability and cost-effectiveness. The use of magnesium nitrate may lead to increased nitrate levels in wastewater streams, potentially requiring additional treatment steps. This could add to the overall process costs, particularly in regions with strict environmental regulations. Life cycle assessments (LCAs) indicate that the environmental impact of magnesium nitrate production and use must be carefully balanced against the benefits of enhanced biopolymer production.

In conclusion, while magnesium nitrate shows promise for enhancing biopolymer production, its scalability and cost-effectiveness depend on various factors including raw material costs, process optimization, product value, and environmental considerations. Continued research into more efficient use and recovery of magnesium nitrate will be crucial for improving the economic viability of this approach in large-scale biopolymer production.

Scaling up the process requires careful optimization of magnesium nitrate concentrations. Laboratory studies have shown optimal concentrations between 0.5-2% w/v, but these may need adjustment in industrial settings. Continuous flow reactors and fed-batch systems have demonstrated promise in maintaining consistent magnesium nitrate levels during large-scale fermentation processes. These systems can potentially reduce overall magnesium nitrate consumption by up to 30% compared to traditional batch processes.

The cost-effectiveness of magnesium nitrate supplementation is closely tied to the value of the biopolymers produced. For high-value biopolymers like polyhydroxyalkanoates (PHAs), the additional cost of magnesium nitrate can be justified by increased yields of up to 40%. However, for lower-value biopolymers, the economic benefits may be less pronounced, necessitating a careful cost-benefit analysis for each specific application.

Recycling and recovery of magnesium nitrate from spent fermentation media present opportunities for cost reduction. Membrane filtration and ion exchange technologies have shown potential for recovering up to 80% of magnesium nitrate, significantly improving the overall economics of the process. However, the capital costs of implementing these recovery systems must be considered in the overall cost analysis.

Environmental considerations also play a role in scalability and cost-effectiveness. The use of magnesium nitrate may lead to increased nitrate levels in wastewater streams, potentially requiring additional treatment steps. This could add to the overall process costs, particularly in regions with strict environmental regulations. Life cycle assessments (LCAs) indicate that the environmental impact of magnesium nitrate production and use must be carefully balanced against the benefits of enhanced biopolymer production.

In conclusion, while magnesium nitrate shows promise for enhancing biopolymer production, its scalability and cost-effectiveness depend on various factors including raw material costs, process optimization, product value, and environmental considerations. Continued research into more efficient use and recovery of magnesium nitrate will be crucial for improving the economic viability of this approach in large-scale biopolymer production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!