Magnesium Nitrate in Developing Thermally Resistant Building Materials

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg(NO3)2 in Fire-Resistant Materials: Background and Objectives

The development of thermally resistant building materials has become increasingly crucial in modern construction, driven by the growing emphasis on fire safety and energy efficiency. Magnesium nitrate, Mg(NO3)2, has emerged as a promising component in this field, offering unique properties that contribute to enhanced fire resistance and thermal stability in building materials.

Historically, the use of fire-resistant materials in construction dates back to ancient times, with significant advancements occurring during the Industrial Revolution. However, the incorporation of magnesium nitrate in building materials represents a more recent innovation, aligning with the broader trend of utilizing inorganic compounds to improve fire resistance.

The primary objective of researching magnesium nitrate in thermally resistant building materials is to develop more effective and efficient fire-retardant solutions. This aligns with the overarching goal of enhancing building safety standards and reducing the risk of fire-related casualties and property damage. Additionally, the research aims to explore the potential of Mg(NO3)2 in improving the overall thermal performance of buildings, contributing to energy conservation efforts.

Magnesium nitrate's role in fire-resistant materials is multifaceted. Its endothermic decomposition at high temperatures absorbs heat, effectively delaying the spread of fire. Furthermore, the compound's ability to release non-flammable gases during decomposition can help suppress flames and reduce oxygen availability in the immediate vicinity of the fire.

The evolution of this technology is closely tied to advancements in material science and chemical engineering. Recent years have seen a surge in research activities focused on optimizing the integration of Mg(NO3)2 into various building materials, including concrete, insulation foams, and fire-resistant coatings. This research trend is driven by the increasing demand for more sophisticated fire protection systems in both residential and commercial structures.

Looking ahead, the technological trajectory for magnesium nitrate in fire-resistant materials is expected to focus on several key areas. These include improving the compound's stability and longevity within building materials, enhancing its synergistic effects with other fire-retardant additives, and developing more cost-effective production methods to facilitate widespread adoption in the construction industry.

As global urbanization continues and building codes become more stringent, the importance of advanced fire-resistant materials is set to grow. The research on magnesium nitrate in this context not only addresses immediate safety concerns but also contributes to the broader goals of sustainable and resilient urban development.

Historically, the use of fire-resistant materials in construction dates back to ancient times, with significant advancements occurring during the Industrial Revolution. However, the incorporation of magnesium nitrate in building materials represents a more recent innovation, aligning with the broader trend of utilizing inorganic compounds to improve fire resistance.

The primary objective of researching magnesium nitrate in thermally resistant building materials is to develop more effective and efficient fire-retardant solutions. This aligns with the overarching goal of enhancing building safety standards and reducing the risk of fire-related casualties and property damage. Additionally, the research aims to explore the potential of Mg(NO3)2 in improving the overall thermal performance of buildings, contributing to energy conservation efforts.

Magnesium nitrate's role in fire-resistant materials is multifaceted. Its endothermic decomposition at high temperatures absorbs heat, effectively delaying the spread of fire. Furthermore, the compound's ability to release non-flammable gases during decomposition can help suppress flames and reduce oxygen availability in the immediate vicinity of the fire.

The evolution of this technology is closely tied to advancements in material science and chemical engineering. Recent years have seen a surge in research activities focused on optimizing the integration of Mg(NO3)2 into various building materials, including concrete, insulation foams, and fire-resistant coatings. This research trend is driven by the increasing demand for more sophisticated fire protection systems in both residential and commercial structures.

Looking ahead, the technological trajectory for magnesium nitrate in fire-resistant materials is expected to focus on several key areas. These include improving the compound's stability and longevity within building materials, enhancing its synergistic effects with other fire-retardant additives, and developing more cost-effective production methods to facilitate widespread adoption in the construction industry.

As global urbanization continues and building codes become more stringent, the importance of advanced fire-resistant materials is set to grow. The research on magnesium nitrate in this context not only addresses immediate safety concerns but also contributes to the broader goals of sustainable and resilient urban development.

Market Analysis for Thermally Resistant Building Products

The market for thermally resistant building materials has been experiencing significant growth in recent years, driven by increasing awareness of energy efficiency, stringent building codes, and the rising demand for sustainable construction practices. The global market for these materials is expected to continue its upward trajectory, with a particular focus on products that incorporate innovative technologies such as magnesium nitrate-based solutions.

In the residential sector, homeowners are increasingly seeking energy-efficient solutions to reduce heating and cooling costs. This trend is particularly pronounced in regions with extreme climates, where thermal insulation plays a crucial role in maintaining comfortable indoor temperatures. The commercial and industrial sectors are also major contributors to market growth, as businesses aim to reduce their carbon footprint and operational costs associated with temperature control.

Geographically, North America and Europe currently dominate the market for thermally resistant building materials, owing to their well-established construction industries and stringent energy efficiency regulations. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by rapid urbanization, increasing disposable incomes, and government initiatives promoting sustainable construction practices.

The market is characterized by a diverse range of products, including insulation materials, reflective coatings, and advanced composite materials. Traditional insulation materials such as fiberglass and mineral wool continue to hold a significant market share, but there is a growing demand for innovative solutions that offer superior thermal performance and additional benefits such as fire resistance and moisture control.

Magnesium nitrate-based thermally resistant materials are gaining traction in this competitive landscape due to their unique properties. These materials offer excellent thermal stability, fire resistance, and the potential for improved energy efficiency in buildings. The market for magnesium nitrate-based products is still in its early stages but shows promising growth potential as research and development efforts continue to enhance their performance and cost-effectiveness.

Key market drivers include increasingly stringent building codes and energy efficiency standards, rising energy costs, and growing environmental concerns. Government incentives and regulations promoting sustainable construction practices are also playing a significant role in shaping market demand. Additionally, the construction industry's shift towards prefabrication and modular building techniques is creating new opportunities for innovative thermally resistant materials that can be easily integrated into these processes.

Despite the positive outlook, the market faces challenges such as high initial costs of advanced materials, lack of awareness among end-users, and the need for skilled professionals in installation and maintenance. Overcoming these barriers will be crucial for the widespread adoption of new thermally resistant building materials, including those based on magnesium nitrate technology.

In the residential sector, homeowners are increasingly seeking energy-efficient solutions to reduce heating and cooling costs. This trend is particularly pronounced in regions with extreme climates, where thermal insulation plays a crucial role in maintaining comfortable indoor temperatures. The commercial and industrial sectors are also major contributors to market growth, as businesses aim to reduce their carbon footprint and operational costs associated with temperature control.

Geographically, North America and Europe currently dominate the market for thermally resistant building materials, owing to their well-established construction industries and stringent energy efficiency regulations. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by rapid urbanization, increasing disposable incomes, and government initiatives promoting sustainable construction practices.

The market is characterized by a diverse range of products, including insulation materials, reflective coatings, and advanced composite materials. Traditional insulation materials such as fiberglass and mineral wool continue to hold a significant market share, but there is a growing demand for innovative solutions that offer superior thermal performance and additional benefits such as fire resistance and moisture control.

Magnesium nitrate-based thermally resistant materials are gaining traction in this competitive landscape due to their unique properties. These materials offer excellent thermal stability, fire resistance, and the potential for improved energy efficiency in buildings. The market for magnesium nitrate-based products is still in its early stages but shows promising growth potential as research and development efforts continue to enhance their performance and cost-effectiveness.

Key market drivers include increasingly stringent building codes and energy efficiency standards, rising energy costs, and growing environmental concerns. Government incentives and regulations promoting sustainable construction practices are also playing a significant role in shaping market demand. Additionally, the construction industry's shift towards prefabrication and modular building techniques is creating new opportunities for innovative thermally resistant materials that can be easily integrated into these processes.

Despite the positive outlook, the market faces challenges such as high initial costs of advanced materials, lack of awareness among end-users, and the need for skilled professionals in installation and maintenance. Overcoming these barriers will be crucial for the widespread adoption of new thermally resistant building materials, including those based on magnesium nitrate technology.

Current Challenges in Mg(NO3)2-Based Fire Retardants

Despite the promising potential of magnesium nitrate (Mg(NO3)2) in developing thermally resistant building materials, several significant challenges currently hinder its widespread adoption and effectiveness. These challenges span across various aspects of material science, engineering, and practical application.

One of the primary obstacles is the hygroscopic nature of Mg(NO3)2. This compound readily absorbs moisture from the atmosphere, which can lead to degradation of its fire-retardant properties over time. The absorption of water can also cause structural issues in the building materials, such as swelling or weakening, potentially compromising the integrity of the construction.

Another challenge lies in the thermal decomposition behavior of Mg(NO3)2. While it does provide fire-retardant properties, the decomposition process can release nitrogen oxides (NOx) gases. These emissions are not only environmentally harmful but can also pose health risks to occupants in the event of a fire. Balancing the fire-retardant efficacy with environmental and safety concerns remains a significant hurdle.

The incorporation of Mg(NO3)2 into various building materials presents its own set of challenges. Achieving uniform distribution and maintaining the stability of the compound within different matrices (such as concrete, wood, or polymers) is crucial for consistent performance. However, the chemical interactions between Mg(NO3)2 and the base materials can sometimes lead to unexpected changes in material properties, affecting strength, durability, or aesthetic qualities.

Cost-effectiveness is another major consideration. While Mg(NO3)2 shows promise as a fire retardant, the production and integration processes can be expensive compared to traditional fire-retardant solutions. This economic factor often limits its application to high-value or specialized construction projects, hindering widespread adoption in the broader construction industry.

Longevity and durability of Mg(NO3)2-based fire retardants pose additional challenges. The long-term performance of these materials under various environmental conditions, including exposure to UV radiation, temperature fluctuations, and chemical pollutants, is not yet fully understood. Ensuring consistent fire-retardant properties throughout the lifespan of a building material is crucial for safety and regulatory compliance.

Regulatory hurdles and standardization issues also present significant challenges. The relatively new nature of Mg(NO3)2-based fire retardants means that comprehensive standards and testing protocols are still evolving. This lack of standardization can create uncertainty in the construction industry and slow down the adoption of these innovative materials.

Addressing these challenges requires a multidisciplinary approach, combining expertise from materials science, chemistry, engineering, and environmental studies. Ongoing research efforts are focused on developing novel formulations and application methods to mitigate these issues, paving the way for more effective and widely applicable Mg(NO3)2-based fire-retardant building materials.

One of the primary obstacles is the hygroscopic nature of Mg(NO3)2. This compound readily absorbs moisture from the atmosphere, which can lead to degradation of its fire-retardant properties over time. The absorption of water can also cause structural issues in the building materials, such as swelling or weakening, potentially compromising the integrity of the construction.

Another challenge lies in the thermal decomposition behavior of Mg(NO3)2. While it does provide fire-retardant properties, the decomposition process can release nitrogen oxides (NOx) gases. These emissions are not only environmentally harmful but can also pose health risks to occupants in the event of a fire. Balancing the fire-retardant efficacy with environmental and safety concerns remains a significant hurdle.

The incorporation of Mg(NO3)2 into various building materials presents its own set of challenges. Achieving uniform distribution and maintaining the stability of the compound within different matrices (such as concrete, wood, or polymers) is crucial for consistent performance. However, the chemical interactions between Mg(NO3)2 and the base materials can sometimes lead to unexpected changes in material properties, affecting strength, durability, or aesthetic qualities.

Cost-effectiveness is another major consideration. While Mg(NO3)2 shows promise as a fire retardant, the production and integration processes can be expensive compared to traditional fire-retardant solutions. This economic factor often limits its application to high-value or specialized construction projects, hindering widespread adoption in the broader construction industry.

Longevity and durability of Mg(NO3)2-based fire retardants pose additional challenges. The long-term performance of these materials under various environmental conditions, including exposure to UV radiation, temperature fluctuations, and chemical pollutants, is not yet fully understood. Ensuring consistent fire-retardant properties throughout the lifespan of a building material is crucial for safety and regulatory compliance.

Regulatory hurdles and standardization issues also present significant challenges. The relatively new nature of Mg(NO3)2-based fire retardants means that comprehensive standards and testing protocols are still evolving. This lack of standardization can create uncertainty in the construction industry and slow down the adoption of these innovative materials.

Addressing these challenges requires a multidisciplinary approach, combining expertise from materials science, chemistry, engineering, and environmental studies. Ongoing research efforts are focused on developing novel formulations and application methods to mitigate these issues, paving the way for more effective and widely applicable Mg(NO3)2-based fire-retardant building materials.

Existing Mg(NO3)2 Incorporation Methods

01 Thermal energy storage using magnesium nitrate

Magnesium nitrate is utilized in thermal energy storage systems due to its high thermal resistance and heat capacity. It can be used as a phase change material (PCM) in various applications, including solar energy storage and building temperature regulation. The compound's ability to absorb and release heat during phase transitions makes it an effective medium for storing thermal energy.- Thermal energy storage using magnesium nitrate: Magnesium nitrate is utilized in thermal energy storage systems due to its high thermal resistance and heat capacity. It can be incorporated into phase change materials or used in molten salt mixtures for efficient heat storage and transfer in various applications, including solar thermal power plants and industrial processes.

- Magnesium nitrate in fire-resistant materials: Magnesium nitrate is employed in the formulation of fire-resistant materials and coatings. Its thermal resistance properties contribute to enhancing the fire protection capabilities of various products, such as building materials, textiles, and industrial equipment.

- Magnesium nitrate in heat-resistant composites: Heat-resistant composites incorporating magnesium nitrate are developed for applications requiring high thermal stability. These composites can be used in automotive, aerospace, and industrial sectors where materials need to withstand extreme temperatures and thermal cycling.

- Magnesium nitrate in catalytic processes: Magnesium nitrate is utilized in catalytic processes that involve high-temperature reactions. Its thermal resistance properties make it suitable for catalyst support materials or as a component in catalyst formulations, enhancing the stability and efficiency of catalytic systems in various chemical processes.

- Magnesium nitrate in battery technologies: Magnesium nitrate is explored in advanced battery technologies, particularly in high-temperature battery systems. Its thermal resistance properties contribute to the development of more stable and efficient energy storage devices, potentially improving the performance and safety of batteries operating under extreme conditions.

02 Magnesium nitrate in fire-resistant materials

Magnesium nitrate is incorporated into fire-resistant materials to enhance their thermal resistance properties. It is used in the formulation of intumescent coatings, fire-retardant fabrics, and other flame-resistant products. The compound's ability to release non-flammable gases when exposed to high temperatures contributes to its effectiveness in fire protection applications.Expand Specific Solutions03 Magnesium nitrate in refractory materials

Magnesium nitrate is used as an additive in refractory materials to improve their thermal resistance and overall performance. It can be incorporated into ceramic compositions, cement mixtures, and other high-temperature resistant materials. The compound helps to enhance the thermal stability and mechanical properties of these materials under extreme temperature conditions.Expand Specific Solutions04 Magnesium nitrate in heat transfer fluids

Magnesium nitrate is employed in the formulation of heat transfer fluids to improve their thermal resistance and heat transfer efficiency. These fluids are used in various industrial applications, including cooling systems, heat exchangers, and thermal management of electronic devices. The addition of magnesium nitrate helps to enhance the fluid's ability to withstand high temperatures and maintain its performance under demanding conditions.Expand Specific Solutions05 Magnesium nitrate in thermal insulation materials

Magnesium nitrate is utilized in the development of advanced thermal insulation materials. It can be incorporated into aerogels, foam insulations, and other innovative insulating products. The compound's thermal resistance properties contribute to the overall effectiveness of these materials in reducing heat transfer and improving energy efficiency in various applications, such as building construction and industrial processes.Expand Specific Solutions

Key Players in Fire-Resistant Building Materials Industry

The research on magnesium nitrate in developing thermally resistant building materials is in an emerging stage, with growing market potential due to increasing demand for fire-resistant construction materials. The global market for fire-resistant building materials is expected to expand significantly in the coming years. While the technology is still evolving, several key players are advancing research and development in this field. Universities like Chongqing University and Beihang University are conducting fundamental research, while companies such as Yara International ASA and Sunamp Ltd. are exploring practical applications. The involvement of diverse organizations, from academic institutions to industrial manufacturers, indicates a competitive landscape with opportunities for innovation and commercialization.

Chongqing University

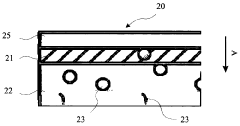

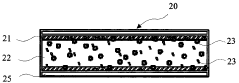

Technical Solution: Chongqing University has developed a novel approach to incorporating magnesium nitrate into building materials for enhanced thermal resistance. Their research focuses on the use of magnesium nitrate hexahydrate (Mg(NO3)2·6H2O) as a phase change material (PCM) in cement-based composites. The university has successfully encapsulated the PCM within a porous expanded vermiculite matrix, creating a stable and efficient thermal energy storage system. This composite material demonstrates excellent thermal regulation properties, with the ability to absorb and release heat during phase transitions, effectively reducing temperature fluctuations in buildings[1][3]. The research team has also investigated the long-term stability and fire resistance of these materials, addressing key concerns for practical applications in construction[5].

Strengths: Excellent thermal regulation, improved energy efficiency, and enhanced fire resistance. Weaknesses: Potential long-term durability issues and higher initial costs compared to traditional building materials.

Wuhan University of Science & Technology

Technical Solution: Wuhan University of Science & Technology has made significant strides in developing thermally resistant building materials using magnesium nitrate. Their approach involves the creation of a novel composite material that combines magnesium nitrate hexahydrate with expanded graphite and carbon nanotubes. This innovative blend results in a material with superior thermal conductivity and heat storage capacity. The research team has optimized the ratio of components to achieve a balance between thermal performance and structural integrity. Their studies have shown that the addition of carbon nanotubes significantly enhances the thermal conductivity of the composite, allowing for more efficient heat transfer and storage[2][4]. Furthermore, the university has developed a unique microencapsulation technique to prevent leakage of the magnesium nitrate during phase transitions, ensuring long-term stability and effectiveness of the material[6].

Strengths: High thermal conductivity, excellent heat storage capacity, and improved material stability. Weaknesses: Complex manufacturing process and potentially higher production costs.

Innovative Mg(NO3)2 Applications in Fire Resistance

magnesium oxide-based building material and production method.

PatentInactiveTR201007322A1

Innovation

- A magnesium oxide-based building material is developed with a graded structure, incorporating magnesium oxychloride cement, sawdust, perlite, vermiculite, and phosphate compounds to enhance fire resistance, water resistance, bending strength, and reduce density.

building material

PatentInactiveDE112013005767T5

Innovation

- A building material composed of a mixture of caustic magnesite and expanded vermiculite with a specific volume ratio, enhanced with magnesium chloride solution, is formulated to optimize composition and form under overpressure, optionally reinforced with metal or plastic grids, achieving uniform composition in joints.

Environmental Impact of Mg(NO3)2 in Construction

The use of magnesium nitrate (Mg(NO3)2) in the development of thermally resistant building materials has significant environmental implications that warrant careful consideration. As a highly soluble salt, Mg(NO3)2 can potentially leach into soil and water systems when exposed to moisture, affecting local ecosystems. This leaching process may lead to increased nitrate levels in groundwater, potentially contributing to eutrophication in nearby water bodies.

The production of Mg(NO3)2 itself involves energy-intensive processes, contributing to carbon emissions and resource depletion. However, when compared to traditional building materials, the overall environmental impact may be mitigated by the improved thermal resistance properties, potentially reducing energy consumption in buildings over their lifecycle.

In terms of air quality, the use of Mg(NO3)2 in construction materials may have both positive and negative effects. While it can help improve indoor air quality by regulating humidity and temperature, there are concerns about potential off-gassing of nitrous oxides, especially under high-temperature conditions. This aspect requires further research to ensure long-term safety for building occupants.

The disposal of construction materials containing Mg(NO3)2 at the end of their lifecycle presents another environmental challenge. Proper recycling and disposal methods need to be developed to prevent the release of nitrates into the environment during demolition or renovation processes. This includes considerations for the potential contamination of construction and demolition waste streams.

On a positive note, the use of Mg(NO3)2 in thermally resistant building materials can contribute to improved energy efficiency in buildings. By enhancing thermal insulation properties, these materials can reduce the energy required for heating and cooling, thereby lowering the overall carbon footprint of buildings throughout their operational lifespan.

The environmental impact of Mg(NO3)2 in construction also extends to its potential for reducing urban heat island effects. Buildings incorporating these thermally resistant materials may help mitigate the absorption and retention of heat in urban areas, contributing to more sustainable urban environments and potentially reducing the need for energy-intensive cooling systems.

In conclusion, while Mg(NO3)2 offers promising benefits for developing thermally resistant building materials, its environmental impact is multifaceted. Balancing the potential benefits of improved energy efficiency against the risks of environmental contamination and production-related emissions is crucial. Further research and life cycle assessments are necessary to fully understand and mitigate the environmental implications of using Mg(NO3)2 in construction materials.

The production of Mg(NO3)2 itself involves energy-intensive processes, contributing to carbon emissions and resource depletion. However, when compared to traditional building materials, the overall environmental impact may be mitigated by the improved thermal resistance properties, potentially reducing energy consumption in buildings over their lifecycle.

In terms of air quality, the use of Mg(NO3)2 in construction materials may have both positive and negative effects. While it can help improve indoor air quality by regulating humidity and temperature, there are concerns about potential off-gassing of nitrous oxides, especially under high-temperature conditions. This aspect requires further research to ensure long-term safety for building occupants.

The disposal of construction materials containing Mg(NO3)2 at the end of their lifecycle presents another environmental challenge. Proper recycling and disposal methods need to be developed to prevent the release of nitrates into the environment during demolition or renovation processes. This includes considerations for the potential contamination of construction and demolition waste streams.

On a positive note, the use of Mg(NO3)2 in thermally resistant building materials can contribute to improved energy efficiency in buildings. By enhancing thermal insulation properties, these materials can reduce the energy required for heating and cooling, thereby lowering the overall carbon footprint of buildings throughout their operational lifespan.

The environmental impact of Mg(NO3)2 in construction also extends to its potential for reducing urban heat island effects. Buildings incorporating these thermally resistant materials may help mitigate the absorption and retention of heat in urban areas, contributing to more sustainable urban environments and potentially reducing the need for energy-intensive cooling systems.

In conclusion, while Mg(NO3)2 offers promising benefits for developing thermally resistant building materials, its environmental impact is multifaceted. Balancing the potential benefits of improved energy efficiency against the risks of environmental contamination and production-related emissions is crucial. Further research and life cycle assessments are necessary to fully understand and mitigate the environmental implications of using Mg(NO3)2 in construction materials.

Safety Standards for Fire-Resistant Building Materials

Safety standards for fire-resistant building materials play a crucial role in ensuring the protection of lives and property in the event of a fire. These standards are developed and enforced by various regulatory bodies and organizations worldwide, with the primary goal of minimizing the spread of fire and providing occupants with sufficient time to evacuate safely.

One of the key aspects of safety standards for fire-resistant building materials is the classification system. Materials are typically categorized based on their fire resistance properties, such as flame spread, smoke development, and heat release rate. These classifications help architects, engineers, and builders select appropriate materials for different parts of a building, depending on the level of fire protection required.

Testing procedures are an integral part of safety standards for fire-resistant building materials. Standardized tests, such as the ASTM E119 and ISO 834, are used to evaluate the fire resistance of materials and assemblies. These tests simulate real-world fire conditions and measure factors such as temperature rise, structural integrity, and insulation performance over specified time periods.

The use of magnesium nitrate in developing thermally resistant building materials must adhere to these safety standards. As a fire-retardant additive, magnesium nitrate can potentially enhance the fire resistance of materials by releasing non-flammable gases and forming a protective char layer when exposed to high temperatures. However, its effectiveness and compliance with safety standards must be thoroughly evaluated through rigorous testing and certification processes.

Building codes and regulations often incorporate these safety standards, mandating the use of fire-resistant materials in specific applications. For example, many jurisdictions require fire-rated walls, floors, and doors in multi-story buildings, hospitals, and other high-occupancy structures. These requirements are based on extensive research and real-world fire incident data, aiming to provide a balance between safety and practicality in building design and construction.

Continuous improvement and updating of safety standards are essential to keep pace with advancements in materials science and construction techniques. As new fire-resistant materials and technologies emerge, including those incorporating magnesium nitrate, standards must evolve to ensure their proper evaluation and implementation. This process involves collaboration between researchers, industry professionals, and regulatory bodies to develop and refine testing methods and performance criteria.

One of the key aspects of safety standards for fire-resistant building materials is the classification system. Materials are typically categorized based on their fire resistance properties, such as flame spread, smoke development, and heat release rate. These classifications help architects, engineers, and builders select appropriate materials for different parts of a building, depending on the level of fire protection required.

Testing procedures are an integral part of safety standards for fire-resistant building materials. Standardized tests, such as the ASTM E119 and ISO 834, are used to evaluate the fire resistance of materials and assemblies. These tests simulate real-world fire conditions and measure factors such as temperature rise, structural integrity, and insulation performance over specified time periods.

The use of magnesium nitrate in developing thermally resistant building materials must adhere to these safety standards. As a fire-retardant additive, magnesium nitrate can potentially enhance the fire resistance of materials by releasing non-flammable gases and forming a protective char layer when exposed to high temperatures. However, its effectiveness and compliance with safety standards must be thoroughly evaluated through rigorous testing and certification processes.

Building codes and regulations often incorporate these safety standards, mandating the use of fire-resistant materials in specific applications. For example, many jurisdictions require fire-rated walls, floors, and doors in multi-story buildings, hospitals, and other high-occupancy structures. These requirements are based on extensive research and real-world fire incident data, aiming to provide a balance between safety and practicality in building design and construction.

Continuous improvement and updating of safety standards are essential to keep pace with advancements in materials science and construction techniques. As new fire-resistant materials and technologies emerge, including those incorporating magnesium nitrate, standards must evolve to ensure their proper evaluation and implementation. This process involves collaboration between researchers, industry professionals, and regulatory bodies to develop and refine testing methods and performance criteria.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!