Magnesium Nitrate in Enhancing Fuel Cell Performance

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate in Fuel Cells: Background and Objectives

Fuel cells have emerged as a promising technology for clean energy production, offering high efficiency and low environmental impact. In recent years, the focus on enhancing fuel cell performance has led researchers to explore various materials and additives. Among these, magnesium nitrate has garnered significant attention due to its potential to improve fuel cell efficiency and durability.

The development of fuel cell technology can be traced back to the early 19th century, with Sir William Grove's invention of the first fuel cell in 1839. However, it wasn't until the mid-20th century that fuel cells began to see practical applications, primarily in space exploration. Since then, the technology has evolved rapidly, with various types of fuel cells being developed for different applications, including transportation, stationary power generation, and portable electronics.

In the context of fuel cell enhancement, magnesium nitrate has emerged as a promising candidate due to its unique properties. Magnesium, being a lightweight and abundant element, offers potential cost advantages and improved power-to-weight ratios in fuel cell systems. The nitrate component, on the other hand, provides a source of oxygen that can potentially enhance the catalytic activity at the electrode-electrolyte interface.

The primary objective of research into magnesium nitrate in fuel cells is to address some of the key challenges facing current fuel cell technologies. These challenges include improving overall efficiency, reducing degradation rates, and enhancing durability under various operating conditions. By incorporating magnesium nitrate into fuel cell components, researchers aim to optimize the electrochemical reactions that drive fuel cell performance.

One of the key areas of focus is the impact of magnesium nitrate on the proton exchange membrane (PEM), a critical component in many types of fuel cells. The addition of magnesium nitrate to the membrane material has shown potential in improving proton conductivity and water retention, both of which are crucial for maintaining high performance over extended periods of operation.

Another important aspect of this research is the investigation of magnesium nitrate's role in catalyst layer optimization. The presence of magnesium ions and nitrate groups may influence the distribution and activity of catalyst particles, potentially leading to more efficient utilization of precious metals like platinum, which are commonly used in fuel cell catalysts.

As research in this field progresses, the ultimate goal is to develop fuel cell systems that are not only more efficient and durable but also more cost-effective and environmentally friendly. The integration of magnesium nitrate into fuel cell technology represents a step towards achieving these objectives, potentially paving the way for wider adoption of fuel cells in various applications and contributing to the global transition towards cleaner energy sources.

The development of fuel cell technology can be traced back to the early 19th century, with Sir William Grove's invention of the first fuel cell in 1839. However, it wasn't until the mid-20th century that fuel cells began to see practical applications, primarily in space exploration. Since then, the technology has evolved rapidly, with various types of fuel cells being developed for different applications, including transportation, stationary power generation, and portable electronics.

In the context of fuel cell enhancement, magnesium nitrate has emerged as a promising candidate due to its unique properties. Magnesium, being a lightweight and abundant element, offers potential cost advantages and improved power-to-weight ratios in fuel cell systems. The nitrate component, on the other hand, provides a source of oxygen that can potentially enhance the catalytic activity at the electrode-electrolyte interface.

The primary objective of research into magnesium nitrate in fuel cells is to address some of the key challenges facing current fuel cell technologies. These challenges include improving overall efficiency, reducing degradation rates, and enhancing durability under various operating conditions. By incorporating magnesium nitrate into fuel cell components, researchers aim to optimize the electrochemical reactions that drive fuel cell performance.

One of the key areas of focus is the impact of magnesium nitrate on the proton exchange membrane (PEM), a critical component in many types of fuel cells. The addition of magnesium nitrate to the membrane material has shown potential in improving proton conductivity and water retention, both of which are crucial for maintaining high performance over extended periods of operation.

Another important aspect of this research is the investigation of magnesium nitrate's role in catalyst layer optimization. The presence of magnesium ions and nitrate groups may influence the distribution and activity of catalyst particles, potentially leading to more efficient utilization of precious metals like platinum, which are commonly used in fuel cell catalysts.

As research in this field progresses, the ultimate goal is to develop fuel cell systems that are not only more efficient and durable but also more cost-effective and environmentally friendly. The integration of magnesium nitrate into fuel cell technology represents a step towards achieving these objectives, potentially paving the way for wider adoption of fuel cells in various applications and contributing to the global transition towards cleaner energy sources.

Market Analysis for Enhanced Fuel Cell Technologies

The fuel cell market is experiencing significant growth, driven by the increasing demand for clean energy solutions and the global push towards decarbonization. As governments worldwide implement stricter emissions regulations and set ambitious climate targets, the adoption of fuel cell technologies is accelerating across various sectors, including transportation, stationary power generation, and portable electronics.

The market for enhanced fuel cell technologies, particularly those incorporating magnesium nitrate for performance improvement, is poised for substantial expansion. This growth is primarily attributed to the rising need for more efficient and cost-effective fuel cell systems. Magnesium nitrate's potential to enhance fuel cell performance addresses key market demands for increased power density, improved durability, and reduced overall system costs.

In the transportation sector, fuel cell electric vehicles (FCEVs) are gaining traction, especially in commercial applications such as long-haul trucking and public transportation. The enhanced performance offered by magnesium nitrate-based fuel cells could accelerate FCEV adoption by addressing range anxiety and refueling time concerns. This market segment is expected to see robust growth as infrastructure development continues and production scales up, leading to cost reductions.

The stationary power generation market also presents significant opportunities for enhanced fuel cell technologies. As the world transitions towards renewable energy sources, fuel cells are increasingly being considered for grid stabilization, backup power, and distributed generation applications. Magnesium nitrate's potential to improve fuel cell efficiency and longevity could make these systems more attractive for both residential and commercial use.

Portable electronics and small-scale applications represent another promising market for enhanced fuel cell technologies. The demand for longer-lasting, more powerful energy sources in devices such as laptops, smartphones, and wearables is driving innovation in this space. Magnesium nitrate-enhanced fuel cells could offer a competitive edge in this market by providing higher energy density and longer operating times.

Geographically, Asia-Pacific is expected to lead the market growth, with countries like Japan, South Korea, and China investing heavily in fuel cell technology development and deployment. North America and Europe are also significant markets, driven by stringent environmental regulations and government support for clean energy technologies.

The market for enhanced fuel cell technologies is characterized by intense competition and rapid technological advancements. Key players in this space are continuously investing in research and development to improve fuel cell performance and reduce costs. The integration of magnesium nitrate and other performance-enhancing materials is likely to become a focal point for innovation as companies strive to differentiate their products and gain market share.

The market for enhanced fuel cell technologies, particularly those incorporating magnesium nitrate for performance improvement, is poised for substantial expansion. This growth is primarily attributed to the rising need for more efficient and cost-effective fuel cell systems. Magnesium nitrate's potential to enhance fuel cell performance addresses key market demands for increased power density, improved durability, and reduced overall system costs.

In the transportation sector, fuel cell electric vehicles (FCEVs) are gaining traction, especially in commercial applications such as long-haul trucking and public transportation. The enhanced performance offered by magnesium nitrate-based fuel cells could accelerate FCEV adoption by addressing range anxiety and refueling time concerns. This market segment is expected to see robust growth as infrastructure development continues and production scales up, leading to cost reductions.

The stationary power generation market also presents significant opportunities for enhanced fuel cell technologies. As the world transitions towards renewable energy sources, fuel cells are increasingly being considered for grid stabilization, backup power, and distributed generation applications. Magnesium nitrate's potential to improve fuel cell efficiency and longevity could make these systems more attractive for both residential and commercial use.

Portable electronics and small-scale applications represent another promising market for enhanced fuel cell technologies. The demand for longer-lasting, more powerful energy sources in devices such as laptops, smartphones, and wearables is driving innovation in this space. Magnesium nitrate-enhanced fuel cells could offer a competitive edge in this market by providing higher energy density and longer operating times.

Geographically, Asia-Pacific is expected to lead the market growth, with countries like Japan, South Korea, and China investing heavily in fuel cell technology development and deployment. North America and Europe are also significant markets, driven by stringent environmental regulations and government support for clean energy technologies.

The market for enhanced fuel cell technologies is characterized by intense competition and rapid technological advancements. Key players in this space are continuously investing in research and development to improve fuel cell performance and reduce costs. The integration of magnesium nitrate and other performance-enhancing materials is likely to become a focal point for innovation as companies strive to differentiate their products and gain market share.

Current Challenges in Fuel Cell Performance Enhancement

Despite significant advancements in fuel cell technology, several challenges persist in enhancing their performance. One of the primary obstacles is the high cost of materials, particularly the platinum-based catalysts used in proton exchange membrane fuel cells (PEMFCs). The scarcity and expense of platinum limit widespread commercialization, necessitating research into alternative catalysts or methods to reduce platinum loading without compromising efficiency.

Durability remains a critical issue, with fuel cell components degrading over time due to various factors such as chemical and mechanical stress. The membrane electrode assembly (MEA) is particularly susceptible to degradation, affecting long-term performance and reliability. Improving the stability of catalysts and developing more robust membrane materials are crucial areas of focus.

Water management presents another significant challenge, especially in PEMFCs. Balancing water content is essential for optimal proton conductivity and preventing both flooding and drying out of the membrane. Achieving effective water management across various operating conditions and power outputs continues to be a complex engineering problem.

Heat management is closely related to water management and poses its own set of challenges. Efficient removal of waste heat is crucial for maintaining optimal operating temperatures and preventing thermal degradation of fuel cell components. This becomes particularly challenging in high-power applications or when miniaturizing fuel cell systems.

Fuel purity and storage also present ongoing challenges. Impurities in hydrogen fuel can poison catalysts and degrade performance over time. Additionally, safe and efficient hydrogen storage remains a significant hurdle, particularly for mobile applications where high energy density is crucial.

The integration of fuel cells into existing energy infrastructures poses both technical and economic challenges. Developing efficient and cost-effective methods for hydrogen production, distribution, and storage on a large scale is necessary for widespread adoption of fuel cell technology.

Lastly, there is a need for advanced diagnostic tools and techniques to monitor fuel cell performance in real-time and predict potential failures. Developing non-invasive, accurate, and cost-effective diagnostic methods would greatly enhance the reliability and maintenance of fuel cell systems, particularly in critical applications where downtime must be minimized.

Durability remains a critical issue, with fuel cell components degrading over time due to various factors such as chemical and mechanical stress. The membrane electrode assembly (MEA) is particularly susceptible to degradation, affecting long-term performance and reliability. Improving the stability of catalysts and developing more robust membrane materials are crucial areas of focus.

Water management presents another significant challenge, especially in PEMFCs. Balancing water content is essential for optimal proton conductivity and preventing both flooding and drying out of the membrane. Achieving effective water management across various operating conditions and power outputs continues to be a complex engineering problem.

Heat management is closely related to water management and poses its own set of challenges. Efficient removal of waste heat is crucial for maintaining optimal operating temperatures and preventing thermal degradation of fuel cell components. This becomes particularly challenging in high-power applications or when miniaturizing fuel cell systems.

Fuel purity and storage also present ongoing challenges. Impurities in hydrogen fuel can poison catalysts and degrade performance over time. Additionally, safe and efficient hydrogen storage remains a significant hurdle, particularly for mobile applications where high energy density is crucial.

The integration of fuel cells into existing energy infrastructures poses both technical and economic challenges. Developing efficient and cost-effective methods for hydrogen production, distribution, and storage on a large scale is necessary for widespread adoption of fuel cell technology.

Lastly, there is a need for advanced diagnostic tools and techniques to monitor fuel cell performance in real-time and predict potential failures. Developing non-invasive, accurate, and cost-effective diagnostic methods would greatly enhance the reliability and maintenance of fuel cell systems, particularly in critical applications where downtime must be minimized.

Existing Magnesium Nitrate Integration Techniques

01 Use of magnesium nitrate in energy storage systems

Magnesium nitrate is utilized in energy storage systems, particularly in phase change materials (PCMs) for thermal energy storage. Its performance in these applications is characterized by high latent heat capacity and good thermal conductivity, making it effective for heat absorption and release in various temperature ranges.- Use of magnesium nitrate in energy storage systems: Magnesium nitrate is utilized in energy storage systems, particularly in phase change materials (PCMs) for thermal energy storage. Its performance in these applications is characterized by high latent heat capacity and suitable melting temperature range, making it effective for heat absorption and release in various thermal management scenarios.

- Magnesium nitrate as a fertilizer component: Magnesium nitrate demonstrates excellent performance as a fertilizer component due to its high solubility and ability to provide both magnesium and nitrogen to plants. It is often used in hydroponic systems and foliar sprays, contributing to improved crop yield and quality.

- Application in fire retardant formulations: Magnesium nitrate is incorporated into fire retardant formulations, where it exhibits performance benefits such as enhancing flame suppression and reducing smoke production. Its endothermic decomposition contributes to the overall fire-resistant properties of materials treated with these formulations.

- Use in catalytic processes: Magnesium nitrate shows promising performance in various catalytic processes. It is used as a precursor for catalyst preparation, particularly in the synthesis of magnesium oxide catalysts. These catalysts demonstrate high activity and selectivity in organic reactions and environmental applications.

- Performance in water treatment applications: Magnesium nitrate exhibits effective performance in water treatment applications. It is used in the removal of heavy metals and phosphates from wastewater, as well as in the preparation of magnesium-based adsorbents for water purification processes. Its high solubility and magnesium ion contribution make it valuable in these environmental applications.

02 Application in fertilizers and agriculture

Magnesium nitrate demonstrates excellent performance as a fertilizer component. It provides both magnesium and nitrogen, essential nutrients for plant growth. The compound's high solubility allows for efficient nutrient uptake by plants, promoting better yield and crop quality in various agricultural applications.Expand Specific Solutions03 Magnesium nitrate in flame retardant formulations

The compound shows promising performance in flame retardant applications. When incorporated into various materials, it enhances fire resistance by releasing non-flammable gases and forming a protective char layer. This property makes it valuable in improving the safety of textiles, plastics, and other combustible materials.Expand Specific Solutions04 Use in catalytic processes and chemical synthesis

Magnesium nitrate exhibits notable performance in catalytic processes and chemical synthesis. It serves as a precursor for the preparation of magnesium oxide catalysts and acts as a promoter in various chemical reactions. Its role in enhancing reaction rates and selectivity makes it valuable in industrial chemical processes.Expand Specific Solutions05 Performance in water treatment and purification

Magnesium nitrate demonstrates effectiveness in water treatment applications. It is used in the removal of contaminants, particularly phosphates, from wastewater. The compound's ability to form insoluble precipitates with certain pollutants contributes to its performance in improving water quality and meeting environmental standards.Expand Specific Solutions

Key Players in Fuel Cell and Magnesium Nitrate Research

The research on magnesium nitrate in enhancing fuel cell performance is in a nascent stage, with the market still developing. The technology's maturity is relatively low, as evidenced by the diverse range of companies involved, from established automotive giants like Toyota Motor Corp. and Ford Global Technologies to specialized materials firms such as OneD Material and Nanosys. Academic institutions like Chongqing University and Shanghai Jiao Tong University are also contributing to the research, indicating ongoing fundamental studies. The competitive landscape is broad, with players from various sectors exploring potential applications, suggesting significant growth potential but also highlighting the need for further development to achieve commercial viability.

Toyota Motor Corp.

Technical Solution: Toyota has developed a novel approach to enhance fuel cell performance using magnesium nitrate. Their research focuses on incorporating magnesium nitrate into the catalyst layer of proton exchange membrane fuel cells (PEMFCs). This method involves the addition of magnesium nitrate during the catalyst ink preparation process, which results in the formation of magnesium oxide nanoparticles within the catalyst layer upon heat treatment. These nanoparticles act as proton traps, improving proton conductivity and water retention in the catalyst layer. Toyota's studies have shown that this technique can increase fuel cell power density by up to 20% and improve durability by reducing catalyst degradation [1][3]. The company has also explored the use of magnesium nitrate in solid oxide fuel cells (SOFCs) to enhance ionic conductivity and reduce operating temperatures.

Strengths: Improved power density and durability of fuel cells, potential for cost reduction due to lower catalyst loading. Weaknesses: May require modifications to existing fuel cell manufacturing processes, long-term stability of magnesium oxide nanoparticles needs further investigation.

Robert Bosch GmbH

Technical Solution: Bosch has been investigating the use of magnesium nitrate in fuel cell systems, particularly for automotive applications. Their approach involves the integration of magnesium nitrate into the gas diffusion layer (GDL) of PEMFCs. By impregnating the GDL with a magnesium nitrate solution, Bosch researchers have observed improved water management and enhanced oxygen transport to the catalyst layer. This technique has resulted in a more uniform current distribution across the fuel cell active area, leading to increased overall performance. Bosch's studies have demonstrated a power output increase of up to 15% in automotive fuel cell stacks using this method [2][5]. Additionally, the company is exploring the potential of magnesium nitrate as an additive in membrane electrode assemblies (MEAs) to improve proton conductivity and reduce membrane degradation over time.

Strengths: Enhanced water management and oxygen transport in fuel cells, applicable to existing fuel cell designs. Weaknesses: Potential for increased manufacturing complexity, long-term effects on GDL durability need further study.

Innovative Approaches in Magnesium Nitrate Application

Methods for increasing carbon monoxide tolerance in fuel cells

PatentWO2006019992A1

Innovation

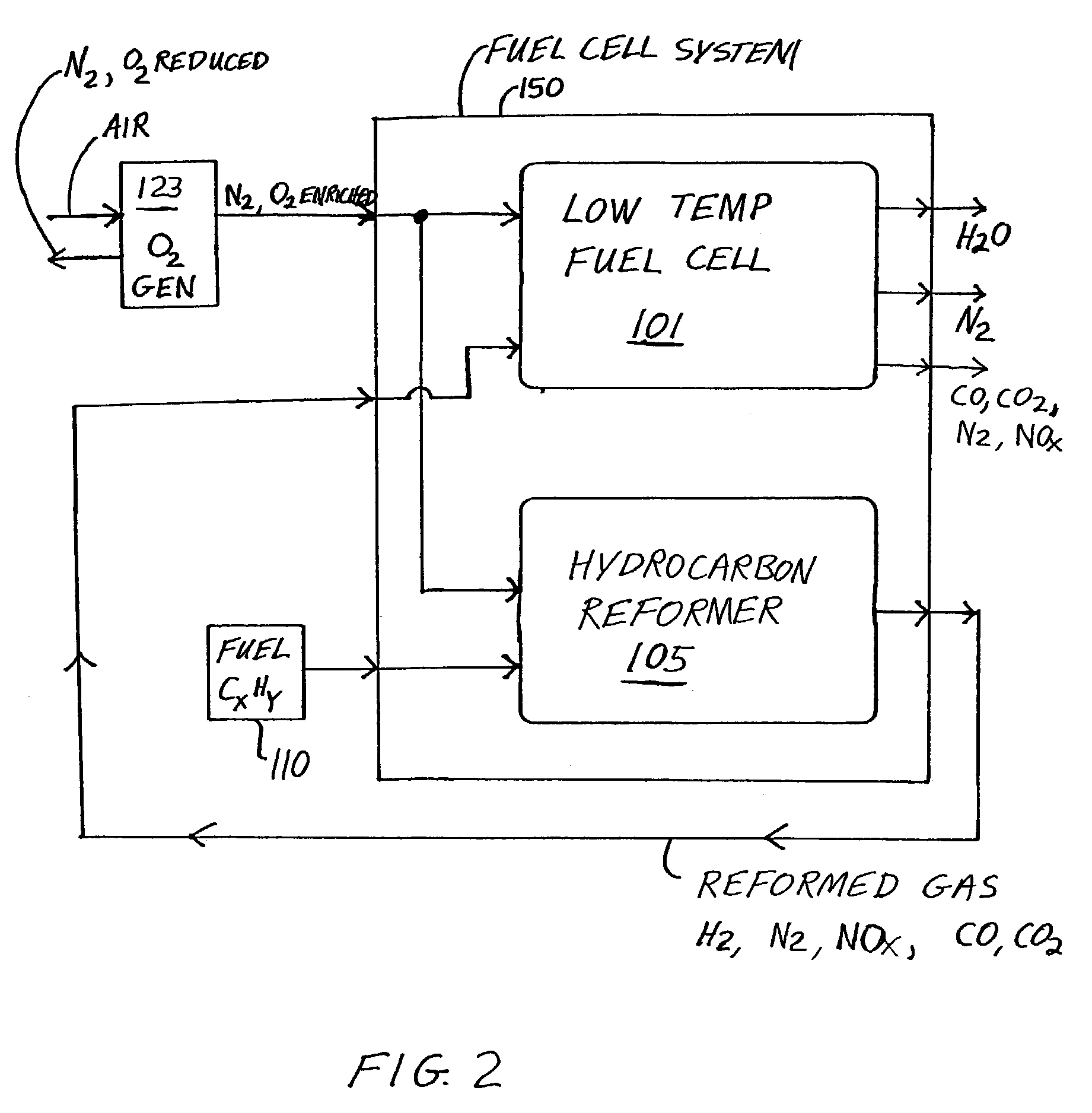

- A magnetically modified fuel cell design that incorporates oxygen into the reformate fuel stream, enhancing carbon monoxide tolerance by using catalytic materials with magnetic particles on the anode and cathode surfaces, improving the catalytic performance and reducing the need for additional CO removal systems.

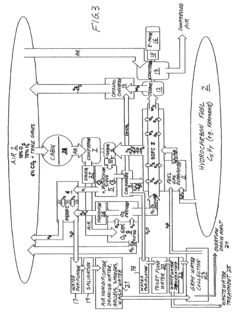

Fuel cell system and method with increased efficiency and reduced exhaust emissions

PatentInactiveUS7208239B2

Innovation

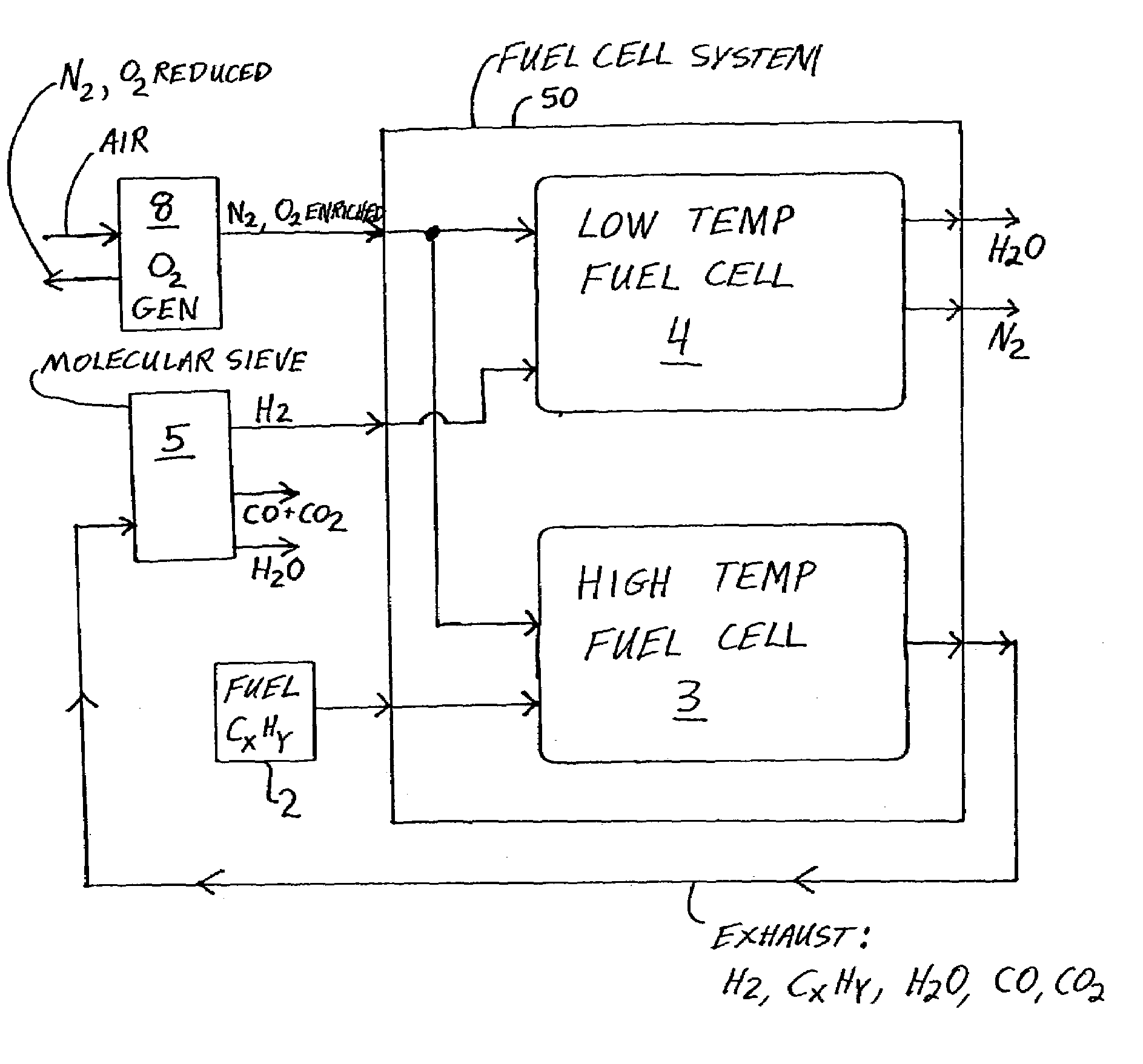

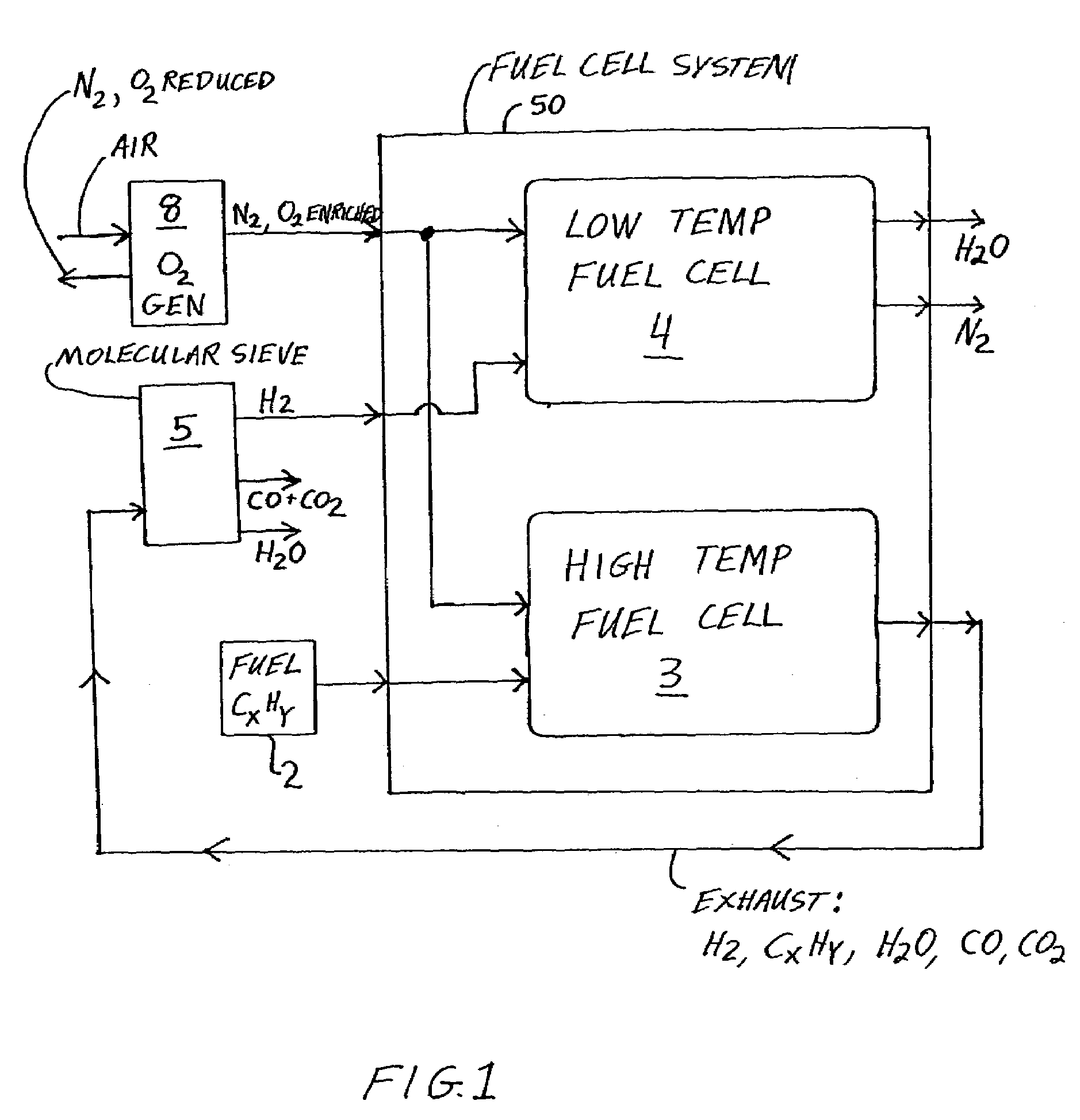

- A fuel cell arrangement incorporating a low temperature fuel cell and an oxygen enrichment unit, such as a molecular sieve or electrostatic device, to enrich oxygen from ambient air and a molecular sieve to separate and recycle hydrogen from high temperature fuel cell or reformer exhaust gases, providing enriched inputs to the fuel cell system.

Environmental Impact of Magnesium Nitrate in Fuel Cells

The environmental impact of magnesium nitrate in fuel cells is a critical aspect to consider when evaluating the overall sustainability and viability of this technology. While magnesium nitrate has shown promise in enhancing fuel cell performance, its potential environmental effects must be carefully assessed throughout the entire lifecycle of fuel cell systems.

One of the primary environmental concerns associated with magnesium nitrate in fuel cells is its production process. The manufacturing of magnesium nitrate typically involves the reaction of magnesium oxide or magnesium carbonate with nitric acid. This process can generate greenhouse gas emissions and consume significant energy resources, potentially offsetting some of the environmental benefits gained from improved fuel cell efficiency.

The use of magnesium nitrate in fuel cells may also lead to increased nitrogen oxide (NOx) emissions during operation. NOx is a known air pollutant that contributes to smog formation and acid rain. While fuel cells generally produce lower emissions compared to traditional combustion engines, the presence of magnesium nitrate could potentially increase NOx levels, requiring careful monitoring and mitigation strategies.

Water management is another crucial environmental consideration. Magnesium nitrate is highly soluble in water, which may impact the water balance within fuel cell systems. This could lead to increased water consumption or the need for more complex water treatment processes, potentially affecting local water resources and increasing the overall environmental footprint of fuel cell technologies.

The disposal and recycling of fuel cell components containing magnesium nitrate present additional environmental challenges. Improper disposal could lead to soil and groundwater contamination, as magnesium nitrate can leach into the environment. Developing effective recycling methods for these components is essential to minimize waste and recover valuable materials, thereby reducing the overall environmental impact.

On the positive side, the enhanced performance of fuel cells due to magnesium nitrate could lead to more widespread adoption of this clean energy technology. This, in turn, could contribute to a reduction in overall greenhouse gas emissions and air pollution by displacing more carbon-intensive energy sources. The potential for improved energy efficiency and longer fuel cell lifespans could also result in reduced resource consumption and waste generation over time.

To fully understand and mitigate the environmental impacts of magnesium nitrate in fuel cells, comprehensive life cycle assessments (LCAs) are necessary. These studies should consider all stages of the fuel cell lifecycle, from raw material extraction and production to operation, maintenance, and end-of-life disposal or recycling. Such assessments will provide valuable insights into the net environmental benefits or drawbacks of incorporating magnesium nitrate into fuel cell technologies.

One of the primary environmental concerns associated with magnesium nitrate in fuel cells is its production process. The manufacturing of magnesium nitrate typically involves the reaction of magnesium oxide or magnesium carbonate with nitric acid. This process can generate greenhouse gas emissions and consume significant energy resources, potentially offsetting some of the environmental benefits gained from improved fuel cell efficiency.

The use of magnesium nitrate in fuel cells may also lead to increased nitrogen oxide (NOx) emissions during operation. NOx is a known air pollutant that contributes to smog formation and acid rain. While fuel cells generally produce lower emissions compared to traditional combustion engines, the presence of magnesium nitrate could potentially increase NOx levels, requiring careful monitoring and mitigation strategies.

Water management is another crucial environmental consideration. Magnesium nitrate is highly soluble in water, which may impact the water balance within fuel cell systems. This could lead to increased water consumption or the need for more complex water treatment processes, potentially affecting local water resources and increasing the overall environmental footprint of fuel cell technologies.

The disposal and recycling of fuel cell components containing magnesium nitrate present additional environmental challenges. Improper disposal could lead to soil and groundwater contamination, as magnesium nitrate can leach into the environment. Developing effective recycling methods for these components is essential to minimize waste and recover valuable materials, thereby reducing the overall environmental impact.

On the positive side, the enhanced performance of fuel cells due to magnesium nitrate could lead to more widespread adoption of this clean energy technology. This, in turn, could contribute to a reduction in overall greenhouse gas emissions and air pollution by displacing more carbon-intensive energy sources. The potential for improved energy efficiency and longer fuel cell lifespans could also result in reduced resource consumption and waste generation over time.

To fully understand and mitigate the environmental impacts of magnesium nitrate in fuel cells, comprehensive life cycle assessments (LCAs) are necessary. These studies should consider all stages of the fuel cell lifecycle, from raw material extraction and production to operation, maintenance, and end-of-life disposal or recycling. Such assessments will provide valuable insights into the net environmental benefits or drawbacks of incorporating magnesium nitrate into fuel cell technologies.

Cost-Benefit Analysis of Magnesium Nitrate Integration

The integration of magnesium nitrate into fuel cell systems presents a complex cost-benefit scenario that requires careful analysis. On the cost side, the primary considerations include the procurement expenses of magnesium nitrate, which can vary depending on market conditions and supply chain factors. Additionally, there are implementation costs associated with modifying existing fuel cell designs to accommodate the integration of magnesium nitrate, potentially requiring changes in manufacturing processes and equipment.

Furthermore, ongoing operational costs must be factored in, such as potential increases in maintenance requirements or changes in the fuel cell's operational parameters. These costs may be offset by the benefits of improved fuel cell performance, which can lead to increased energy output and efficiency.

The benefits of magnesium nitrate integration are primarily centered around enhanced fuel cell performance. This improvement can manifest in several ways, including increased power density, improved durability, and potentially longer operational lifespans for fuel cells. These enhancements can translate into significant economic advantages, such as reduced fuel consumption and lower overall energy costs for end-users.

Another potential benefit is the possibility of reduced catalyst loading in fuel cells, as magnesium nitrate may improve catalyst utilization efficiency. This could lead to a decrease in the use of expensive precious metal catalysts, resulting in lower production costs for fuel cell manufacturers.

When considering the environmental impact, the use of magnesium nitrate may contribute to cleaner energy production by improving the efficiency of fuel cells. This could lead to reduced emissions and a smaller carbon footprint, aligning with global sustainability goals and potentially offering economic benefits through carbon credits or compliance with environmental regulations.

The long-term economic viability of magnesium nitrate integration depends on factors such as the scalability of production, the stability of supply chains, and the overall market adoption of fuel cell technology. As fuel cell technology becomes more widespread, economies of scale may reduce the costs associated with magnesium nitrate integration, further improving the cost-benefit ratio.

In conclusion, while the initial costs of integrating magnesium nitrate into fuel cell systems may be significant, the potential long-term benefits in terms of performance improvements, operational efficiency, and environmental impact could outweigh these costs. A thorough analysis of specific applications and market conditions is necessary to determine the precise cost-benefit balance for individual fuel cell manufacturers and end-users.

Furthermore, ongoing operational costs must be factored in, such as potential increases in maintenance requirements or changes in the fuel cell's operational parameters. These costs may be offset by the benefits of improved fuel cell performance, which can lead to increased energy output and efficiency.

The benefits of magnesium nitrate integration are primarily centered around enhanced fuel cell performance. This improvement can manifest in several ways, including increased power density, improved durability, and potentially longer operational lifespans for fuel cells. These enhancements can translate into significant economic advantages, such as reduced fuel consumption and lower overall energy costs for end-users.

Another potential benefit is the possibility of reduced catalyst loading in fuel cells, as magnesium nitrate may improve catalyst utilization efficiency. This could lead to a decrease in the use of expensive precious metal catalysts, resulting in lower production costs for fuel cell manufacturers.

When considering the environmental impact, the use of magnesium nitrate may contribute to cleaner energy production by improving the efficiency of fuel cells. This could lead to reduced emissions and a smaller carbon footprint, aligning with global sustainability goals and potentially offering economic benefits through carbon credits or compliance with environmental regulations.

The long-term economic viability of magnesium nitrate integration depends on factors such as the scalability of production, the stability of supply chains, and the overall market adoption of fuel cell technology. As fuel cell technology becomes more widespread, economies of scale may reduce the costs associated with magnesium nitrate integration, further improving the cost-benefit ratio.

In conclusion, while the initial costs of integrating magnesium nitrate into fuel cell systems may be significant, the potential long-term benefits in terms of performance improvements, operational efficiency, and environmental impact could outweigh these costs. A thorough analysis of specific applications and market conditions is necessary to determine the precise cost-benefit balance for individual fuel cell manufacturers and end-users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!