Miniature Acoustic Sensors Powered by Piezoelectric Technology

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Acoustic Sensor Evolution and Objectives

Piezoelectric acoustic sensors have undergone significant evolution since their inception in the early 20th century. Initially developed as simple transducers, these sensors have transformed into sophisticated devices capable of detecting and measuring a wide range of acoustic phenomena. The journey began with the discovery of the piezoelectric effect by Jacques and Pierre Curie in 1880, which laid the foundation for the development of acoustic sensors.

In the 1950s and 1960s, piezoelectric materials such as quartz and barium titanate were widely used in acoustic sensors for sonar and underwater detection applications. The advent of synthetic piezoelectric materials like lead zirconate titanate (PZT) in the 1960s marked a significant milestone, offering improved sensitivity and broader frequency response.

The miniaturization trend in electronics during the 1970s and 1980s led to the development of smaller, more efficient piezoelectric acoustic sensors. This period saw the integration of these sensors into various consumer and industrial applications, including automotive systems, medical devices, and structural health monitoring.

The 1990s and early 2000s witnessed a surge in research focused on enhancing the performance of piezoelectric acoustic sensors. Advances in material science and fabrication techniques enabled the creation of sensors with higher sensitivity, broader bandwidth, and improved signal-to-noise ratios. The introduction of micro-electromechanical systems (MEMS) technology further revolutionized the field, allowing for the production of extremely small and highly sensitive acoustic sensors.

In recent years, the focus has shifted towards developing miniature acoustic sensors powered by piezoelectric technology. This trend is driven by the growing demand for compact, energy-efficient sensors in applications such as wearable devices, IoT systems, and smart infrastructure. The objectives of current research include further miniaturization, improved energy harvesting capabilities, and enhanced acoustic performance in challenging environments.

Looking ahead, the primary goals for piezoelectric acoustic sensor development include achieving ultra-low power consumption, expanding the detectable frequency range, and improving durability in harsh conditions. Researchers are also exploring novel materials and structures to enhance sensitivity and reduce manufacturing costs. The integration of artificial intelligence and machine learning algorithms with these sensors is expected to open up new possibilities for real-time acoustic analysis and intelligent decision-making in various applications.

In the 1950s and 1960s, piezoelectric materials such as quartz and barium titanate were widely used in acoustic sensors for sonar and underwater detection applications. The advent of synthetic piezoelectric materials like lead zirconate titanate (PZT) in the 1960s marked a significant milestone, offering improved sensitivity and broader frequency response.

The miniaturization trend in electronics during the 1970s and 1980s led to the development of smaller, more efficient piezoelectric acoustic sensors. This period saw the integration of these sensors into various consumer and industrial applications, including automotive systems, medical devices, and structural health monitoring.

The 1990s and early 2000s witnessed a surge in research focused on enhancing the performance of piezoelectric acoustic sensors. Advances in material science and fabrication techniques enabled the creation of sensors with higher sensitivity, broader bandwidth, and improved signal-to-noise ratios. The introduction of micro-electromechanical systems (MEMS) technology further revolutionized the field, allowing for the production of extremely small and highly sensitive acoustic sensors.

In recent years, the focus has shifted towards developing miniature acoustic sensors powered by piezoelectric technology. This trend is driven by the growing demand for compact, energy-efficient sensors in applications such as wearable devices, IoT systems, and smart infrastructure. The objectives of current research include further miniaturization, improved energy harvesting capabilities, and enhanced acoustic performance in challenging environments.

Looking ahead, the primary goals for piezoelectric acoustic sensor development include achieving ultra-low power consumption, expanding the detectable frequency range, and improving durability in harsh conditions. Researchers are also exploring novel materials and structures to enhance sensitivity and reduce manufacturing costs. The integration of artificial intelligence and machine learning algorithms with these sensors is expected to open up new possibilities for real-time acoustic analysis and intelligent decision-making in various applications.

Market Analysis for Miniature Acoustic Sensors

The market for miniature acoustic sensors powered by piezoelectric technology is experiencing significant growth, driven by the increasing demand for compact and efficient sensing solutions across various industries. These sensors, which convert acoustic energy into electrical signals using piezoelectric materials, are finding applications in consumer electronics, automotive, healthcare, and industrial sectors.

In the consumer electronics market, miniature acoustic sensors are being integrated into smartphones, wearables, and smart home devices. The trend towards smaller, more feature-rich devices is fueling the demand for these sensors, as they offer high sensitivity and low power consumption in a compact form factor. The smartphone market, in particular, is a major driver, with manufacturers constantly seeking ways to improve audio quality and introduce new features such as active noise cancellation and voice recognition.

The automotive industry is another key market for miniature acoustic sensors. These sensors are used in advanced driver assistance systems (ADAS), engine noise reduction, and in-car infotainment systems. As vehicles become more connected and autonomous, the demand for acoustic sensing technologies is expected to grow further. The sensors play a crucial role in enhancing safety features and improving the overall driving experience.

In the healthcare sector, miniature acoustic sensors are finding applications in medical devices such as hearing aids, patient monitoring systems, and diagnostic equipment. The aging population and the increasing prevalence of hearing disorders are driving the demand for more sophisticated and miniaturized hearing aid technologies. Additionally, these sensors are being used in wearable health monitoring devices, contributing to the growth of the digital health market.

The industrial sector is also adopting miniature acoustic sensors for various applications, including predictive maintenance, quality control, and environmental monitoring. These sensors are used to detect anomalies in machinery operation, measure sound levels in workplaces, and monitor industrial processes for improved efficiency and safety.

The market for miniature acoustic sensors is characterized by intense competition and rapid technological advancements. Key players in the market are focusing on research and development to improve sensor performance, reduce size, and enhance energy efficiency. The integration of artificial intelligence and machine learning algorithms with these sensors is opening up new possibilities for advanced signal processing and pattern recognition.

Geographically, North America and Asia-Pacific are the leading markets for miniature acoustic sensors, with Europe following closely. The Asia-Pacific region, in particular, is expected to witness the highest growth rate due to the presence of major consumer electronics manufacturers and the rapid adoption of IoT technologies in countries like China, Japan, and South Korea.

In the consumer electronics market, miniature acoustic sensors are being integrated into smartphones, wearables, and smart home devices. The trend towards smaller, more feature-rich devices is fueling the demand for these sensors, as they offer high sensitivity and low power consumption in a compact form factor. The smartphone market, in particular, is a major driver, with manufacturers constantly seeking ways to improve audio quality and introduce new features such as active noise cancellation and voice recognition.

The automotive industry is another key market for miniature acoustic sensors. These sensors are used in advanced driver assistance systems (ADAS), engine noise reduction, and in-car infotainment systems. As vehicles become more connected and autonomous, the demand for acoustic sensing technologies is expected to grow further. The sensors play a crucial role in enhancing safety features and improving the overall driving experience.

In the healthcare sector, miniature acoustic sensors are finding applications in medical devices such as hearing aids, patient monitoring systems, and diagnostic equipment. The aging population and the increasing prevalence of hearing disorders are driving the demand for more sophisticated and miniaturized hearing aid technologies. Additionally, these sensors are being used in wearable health monitoring devices, contributing to the growth of the digital health market.

The industrial sector is also adopting miniature acoustic sensors for various applications, including predictive maintenance, quality control, and environmental monitoring. These sensors are used to detect anomalies in machinery operation, measure sound levels in workplaces, and monitor industrial processes for improved efficiency and safety.

The market for miniature acoustic sensors is characterized by intense competition and rapid technological advancements. Key players in the market are focusing on research and development to improve sensor performance, reduce size, and enhance energy efficiency. The integration of artificial intelligence and machine learning algorithms with these sensors is opening up new possibilities for advanced signal processing and pattern recognition.

Geographically, North America and Asia-Pacific are the leading markets for miniature acoustic sensors, with Europe following closely. The Asia-Pacific region, in particular, is expected to witness the highest growth rate due to the presence of major consumer electronics manufacturers and the rapid adoption of IoT technologies in countries like China, Japan, and South Korea.

Current Challenges in Piezoelectric Sensor Miniaturization

The miniaturization of piezoelectric acoustic sensors presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is maintaining sensor sensitivity and performance as the device size decreases. Reducing the dimensions of piezoelectric materials often leads to a decrease in their piezoelectric coefficients, which directly impacts the sensor's ability to convert acoustic energy into electrical signals effectively.

Another critical challenge lies in the integration of miniaturized sensors with other electronic components. As sensors become smaller, the complexity of interconnections and packaging increases, requiring innovative solutions to ensure reliable electrical connections and protection from environmental factors. This integration challenge extends to power management systems, as miniature sensors often have limited energy harvesting capabilities and may require novel approaches to energy storage and consumption.

Material selection and fabrication techniques pose additional hurdles in the miniaturization process. Traditional piezoelectric materials may not exhibit the same properties at microscale or nanoscale dimensions, necessitating the exploration of new materials or composite structures. Advanced fabrication methods, such as micro-electromechanical systems (MEMS) technologies, are being employed to create miniature sensors, but these processes come with their own set of challenges related to precision, repeatability, and scalability.

The reduction in sensor size also impacts the acoustic performance, particularly in terms of frequency response and directivity. Smaller sensors may have difficulty capturing low-frequency sounds or achieving desired directional characteristics, which are crucial for many applications. Engineers must develop innovative designs and signal processing techniques to overcome these limitations and maintain broad-spectrum acoustic sensing capabilities.

Thermal management becomes increasingly critical as sensor dimensions shrink. The compact nature of miniaturized devices can lead to heat concentration, potentially affecting the piezoelectric properties and overall sensor performance. Developing effective heat dissipation mechanisms within the confined space of a miniature sensor is a significant engineering challenge.

Lastly, the cost-effectiveness of producing miniature piezoelectric acoustic sensors at scale remains a considerable hurdle. While miniaturization can lead to material savings, the complexity of fabrication and the need for specialized equipment often result in higher production costs. Striking a balance between miniaturization, performance, and economic viability is crucial for the widespread adoption of these sensors in various applications.

Another critical challenge lies in the integration of miniaturized sensors with other electronic components. As sensors become smaller, the complexity of interconnections and packaging increases, requiring innovative solutions to ensure reliable electrical connections and protection from environmental factors. This integration challenge extends to power management systems, as miniature sensors often have limited energy harvesting capabilities and may require novel approaches to energy storage and consumption.

Material selection and fabrication techniques pose additional hurdles in the miniaturization process. Traditional piezoelectric materials may not exhibit the same properties at microscale or nanoscale dimensions, necessitating the exploration of new materials or composite structures. Advanced fabrication methods, such as micro-electromechanical systems (MEMS) technologies, are being employed to create miniature sensors, but these processes come with their own set of challenges related to precision, repeatability, and scalability.

The reduction in sensor size also impacts the acoustic performance, particularly in terms of frequency response and directivity. Smaller sensors may have difficulty capturing low-frequency sounds or achieving desired directional characteristics, which are crucial for many applications. Engineers must develop innovative designs and signal processing techniques to overcome these limitations and maintain broad-spectrum acoustic sensing capabilities.

Thermal management becomes increasingly critical as sensor dimensions shrink. The compact nature of miniaturized devices can lead to heat concentration, potentially affecting the piezoelectric properties and overall sensor performance. Developing effective heat dissipation mechanisms within the confined space of a miniature sensor is a significant engineering challenge.

Lastly, the cost-effectiveness of producing miniature piezoelectric acoustic sensors at scale remains a considerable hurdle. While miniaturization can lead to material savings, the complexity of fabrication and the need for specialized equipment often result in higher production costs. Striking a balance between miniaturization, performance, and economic viability is crucial for the widespread adoption of these sensors in various applications.

State-of-the-Art Miniaturization Techniques

01 Miniaturization of acoustic sensors

Advancements in miniaturization techniques have led to the development of extremely small acoustic sensors. These miniature sensors can be integrated into various devices and systems, offering improved sensitivity and reduced power consumption while maintaining high performance in sound detection and analysis.- Miniaturization of acoustic sensors: Advancements in miniaturization techniques have led to the development of extremely small acoustic sensors. These miniature sensors can be integrated into various devices and systems, offering improved sensitivity and reduced power consumption while maintaining high performance in sound detection and analysis.

- MEMS-based acoustic sensors: Micro-Electro-Mechanical Systems (MEMS) technology is utilized to create miniature acoustic sensors. These MEMS-based sensors offer advantages such as small form factor, high sensitivity, and the ability to be mass-produced at low cost, making them suitable for a wide range of applications including consumer electronics and industrial monitoring.

- Integration of acoustic sensors in wearable devices: Miniature acoustic sensors are being incorporated into wearable devices such as hearing aids, smartwatches, and fitness trackers. These sensors enable various functionalities including voice recognition, environmental sound monitoring, and health-related acoustic measurements, all while maintaining a compact and user-friendly form factor.

- Acoustic sensor arrays for improved performance: Multiple miniature acoustic sensors are arranged in arrays to enhance performance in applications such as directional sound detection, noise cancellation, and acoustic imaging. These sensor arrays leverage the small size of individual sensors to create compact yet powerful acoustic sensing systems.

- Nanoscale acoustic sensors: Research is being conducted on nanoscale acoustic sensors that push the boundaries of miniaturization. These ultra-small sensors, often based on novel materials and fabrication techniques, offer unprecedented levels of sensitivity and the potential for integration into molecular-scale devices and systems.

02 MEMS-based acoustic sensors

Micro-Electro-Mechanical Systems (MEMS) technology is utilized to create ultra-small acoustic sensors. These MEMS-based sensors offer advantages such as reduced size, lower cost, and improved integration capabilities, making them suitable for applications in consumer electronics, automotive, and medical devices.Expand Specific Solutions03 Array configurations for miniature acoustic sensors

Multiple miniature acoustic sensors can be arranged in array configurations to enhance sound detection capabilities. These arrays allow for improved directionality, noise cancellation, and spatial audio processing, while maintaining a compact overall size suitable for various applications.Expand Specific Solutions04 Integration of miniature acoustic sensors in wearable devices

The small size of miniature acoustic sensors enables their integration into wearable devices such as hearing aids, smart earbuds, and health monitoring systems. This integration allows for continuous audio monitoring and analysis in a compact, user-friendly form factor.Expand Specific Solutions05 Nanoscale acoustic sensors

Research and development efforts are focused on creating nanoscale acoustic sensors, pushing the boundaries of miniaturization. These nanoscale sensors offer unprecedented levels of sensitivity and the potential for integration into molecular-level applications, opening up new possibilities in fields such as medical diagnostics and environmental monitoring.Expand Specific Solutions

Key Players in Piezoelectric Acoustic Sensor Industry

The research on miniature acoustic sensors powered by piezoelectric technology is in a growth phase, with increasing market potential and technological advancements. The global market for these sensors is expanding, driven by applications in consumer electronics, healthcare, and industrial sectors. While the technology is maturing, there's still room for innovation and improvement. Key players like Samsung Electronics, Murata Manufacturing, and STMicroelectronics are leading the field, leveraging their expertise in semiconductor and electronic component manufacturing. Universities such as the University of Freiburg and Xi'an Jiaotong University are contributing to fundamental research, potentially bridging the gap between academic discoveries and industrial applications. The involvement of diverse companies and institutions indicates a competitive and collaborative landscape, fostering further technological progress in this domain.

Stmicroelectronics Srl

Technical Solution: STMicroelectronics has focused on developing MEMS-based piezoelectric acoustic sensors with integrated signal processing capabilities. Their approach combines a piezoelectric sensing element with a low-noise amplifier and an analog-to-digital converter on a single chip. This integration allows for improved signal quality and reduced overall system size. ST's sensors feature a dynamic range of up to 130 dB and can operate in harsh environments with temperatures ranging from -40°C to +85°C[2]. The company has also implemented advanced packaging techniques, such as through-silicon vias (TSVs), to minimize parasitic capacitance and improve overall performance.

Strengths: High level of integration, wide dynamic range, and robust performance in harsh conditions. Weaknesses: Potentially higher cost compared to traditional electret microphones.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced piezoelectric MEMS (Micro-Electro-Mechanical Systems) technology for miniature acoustic sensors. Their approach involves using thin-film piezoelectric materials, such as aluminum nitride (AlN) or lead zirconate titanate (PZT), deposited on silicon wafers. This allows for the creation of highly sensitive and compact microphones with low power consumption. Murata's sensors can detect sound pressures as low as 20 dB SPL and operate in a frequency range of 20 Hz to 20 kHz[1][3]. The company has also implemented innovative packaging techniques to enhance the sensors' durability and reduce electromagnetic interference.

Strengths: High sensitivity, wide frequency response, and low power consumption. Weaknesses: Potential challenges in mass production and cost-effectiveness for consumer applications.

Breakthrough Patents in Piezoelectric Sensor Design

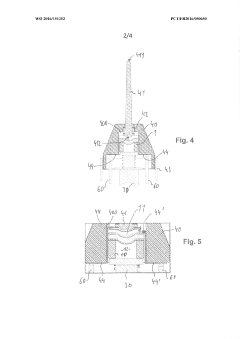

Piezoelectric sensor and instrument including such a sensor

PatentWO2016151252A1

Innovation

- A piezoelectric sensor with a membrane comprising a polymer support layer and a sensitive layer made of synthetic material charged with inorganic nanomaterials, eliminating the need for an interface and allowing adaptation of acoustic impedance, combined with a transmission rod for measuring low amplitude vibrations, particularly in the ear.

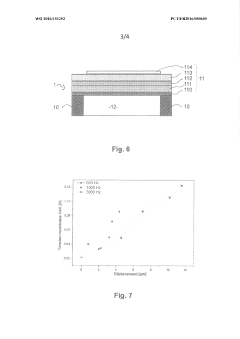

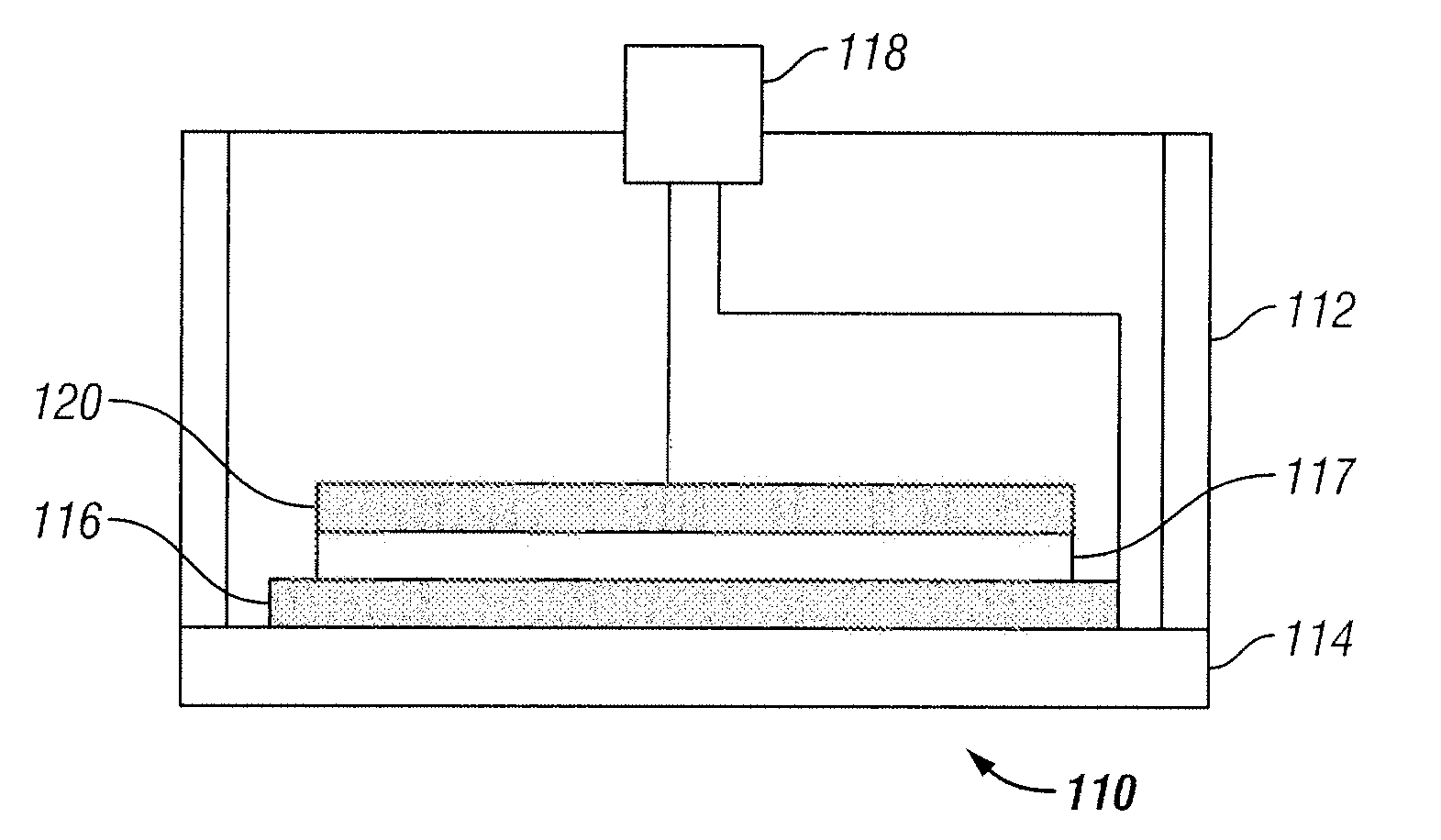

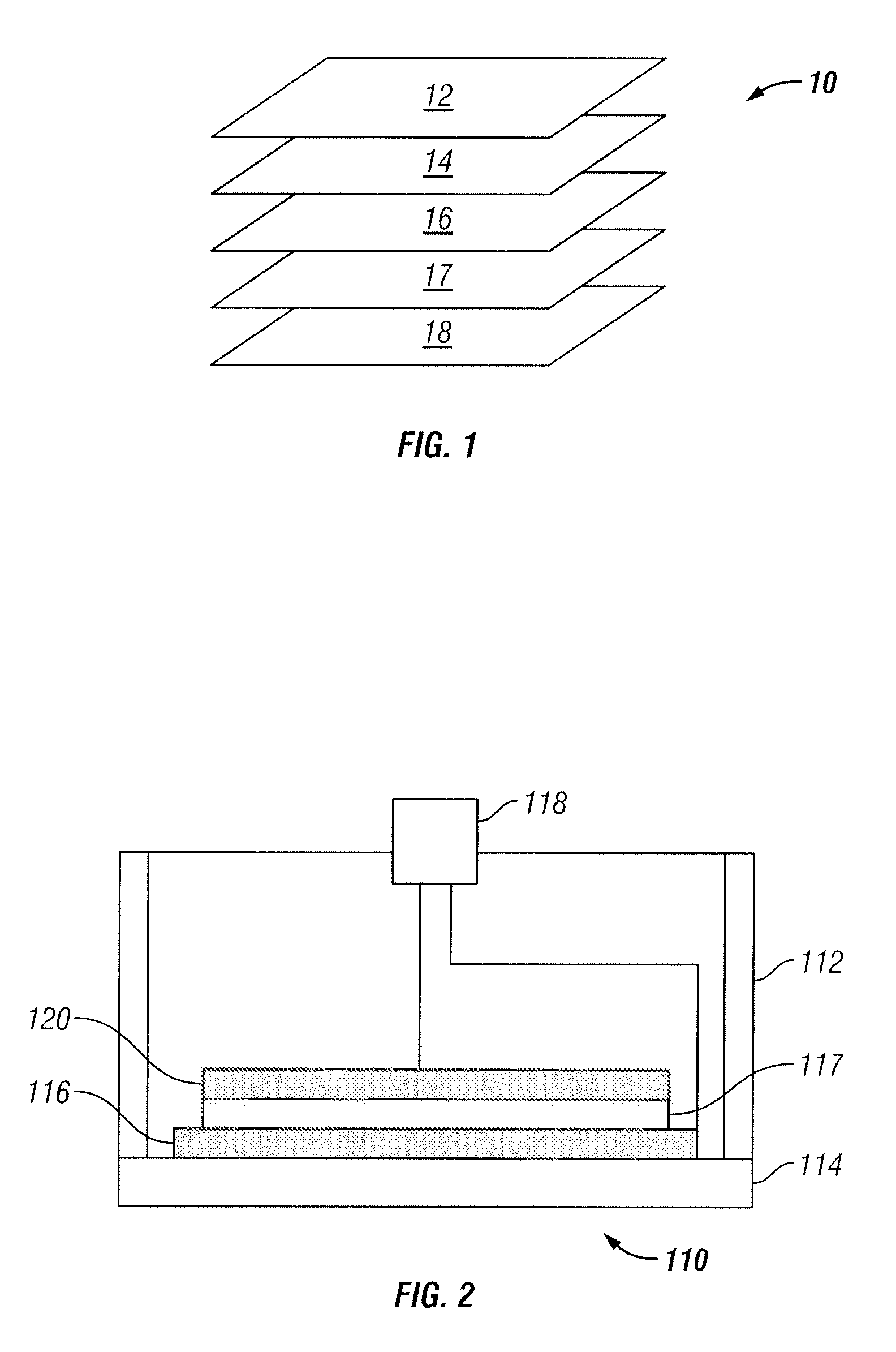

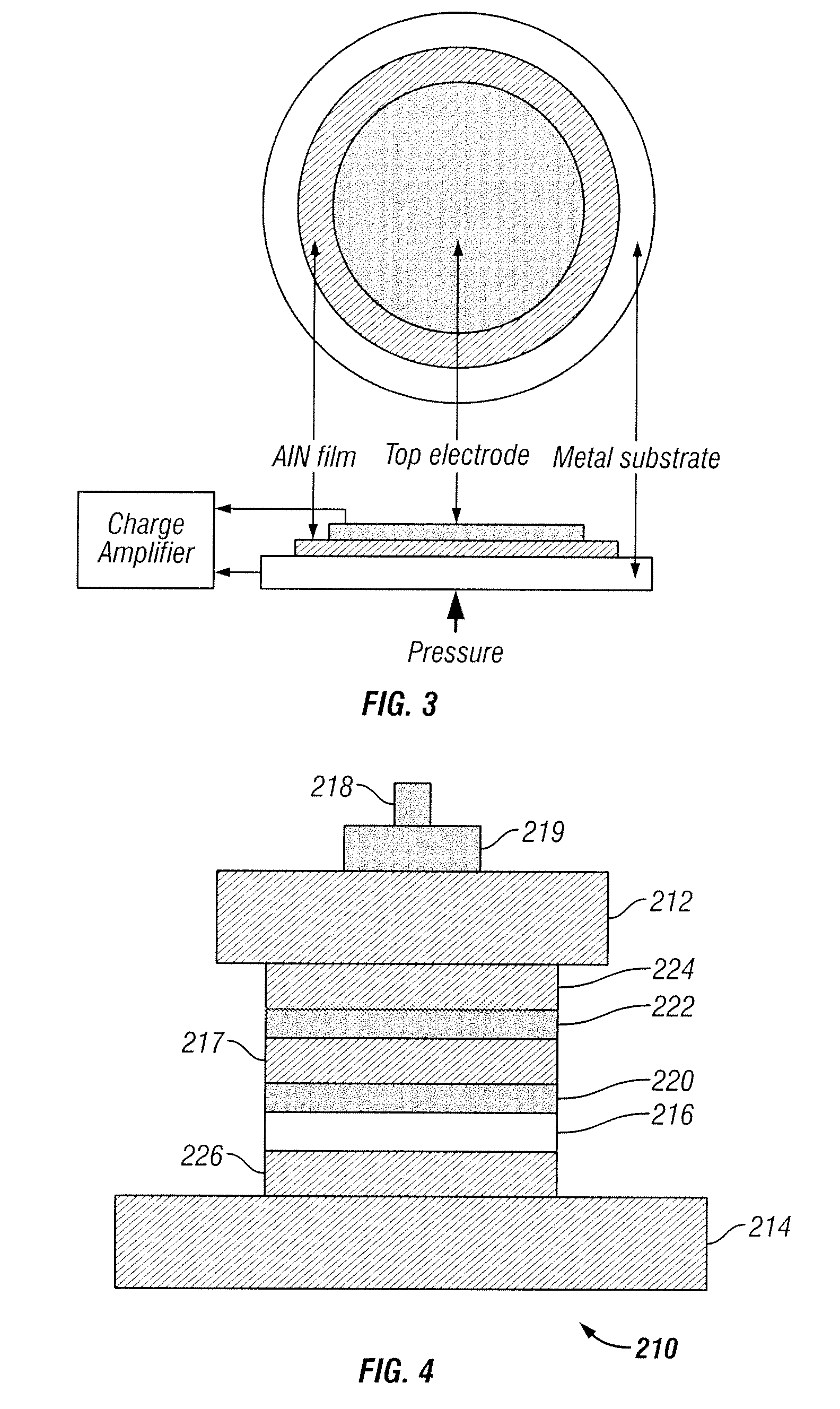

High temperature sustainable piezoelectric sensors using etched or micromachined piezoelectric films

PatentInactiveUS20080129150A1

Innovation

- Development of wide band-gap piezoelectric thin films like aluminum nitride, zinc oxide, and tantalum oxide, integrated into sensors using microfabrication techniques, enabling high-temperature operation up to 800-1000°C and miniaturization for enhanced performance.

Environmental Impact of Piezoelectric Materials

The environmental impact of piezoelectric materials used in miniature acoustic sensors is a critical consideration in the development and deployment of these technologies. Piezoelectric materials, while offering significant advantages in sensor design, also present potential environmental challenges throughout their lifecycle.

During the production phase, the manufacturing of piezoelectric materials often involves the use of lead-based compounds, particularly lead zirconate titanate (PZT). The extraction and processing of lead can result in environmental contamination, affecting soil, water, and air quality. Moreover, the energy-intensive production processes contribute to greenhouse gas emissions and resource depletion.

In the operational phase, piezoelectric sensors generally have a low environmental footprint due to their energy efficiency and long lifespan. These sensors can operate with minimal power requirements, often harvesting energy from ambient vibrations, which reduces the need for battery replacements and associated waste. However, the potential for lead leaching from PZT-based sensors in certain environmental conditions remains a concern, particularly in aquatic or high-humidity environments.

End-of-life disposal of piezoelectric sensors presents significant environmental challenges. The presence of lead and other heavy metals in these materials necessitates careful handling and specialized recycling processes to prevent environmental contamination. Improper disposal can lead to the release of toxic substances into ecosystems, posing risks to wildlife and human health.

To address these environmental concerns, research is increasingly focused on developing lead-free piezoelectric materials. Alternatives such as bismuth sodium titanate (BNT) and potassium sodium niobate (KNN) are being explored as more environmentally friendly options. These materials aim to maintain or improve upon the performance of traditional lead-based piezoelectrics while reducing environmental impact.

The miniaturization of acoustic sensors powered by piezoelectric technology also contributes to reducing material usage and waste. Smaller sensors require less raw material, potentially decreasing the overall environmental footprint of production. Additionally, the compact size of these sensors can lead to more efficient transportation and reduced packaging waste.

As environmental regulations become more stringent, particularly concerning the use of hazardous substances in electronic equipment, the piezoelectric sensor industry is adapting. This shift is driving innovation in material science and manufacturing processes, aiming to create more sustainable and eco-friendly sensor technologies. The development of green piezoelectric materials and improved recycling techniques are key areas of focus in mitigating the environmental impact of these essential components in modern acoustic sensing applications.

During the production phase, the manufacturing of piezoelectric materials often involves the use of lead-based compounds, particularly lead zirconate titanate (PZT). The extraction and processing of lead can result in environmental contamination, affecting soil, water, and air quality. Moreover, the energy-intensive production processes contribute to greenhouse gas emissions and resource depletion.

In the operational phase, piezoelectric sensors generally have a low environmental footprint due to their energy efficiency and long lifespan. These sensors can operate with minimal power requirements, often harvesting energy from ambient vibrations, which reduces the need for battery replacements and associated waste. However, the potential for lead leaching from PZT-based sensors in certain environmental conditions remains a concern, particularly in aquatic or high-humidity environments.

End-of-life disposal of piezoelectric sensors presents significant environmental challenges. The presence of lead and other heavy metals in these materials necessitates careful handling and specialized recycling processes to prevent environmental contamination. Improper disposal can lead to the release of toxic substances into ecosystems, posing risks to wildlife and human health.

To address these environmental concerns, research is increasingly focused on developing lead-free piezoelectric materials. Alternatives such as bismuth sodium titanate (BNT) and potassium sodium niobate (KNN) are being explored as more environmentally friendly options. These materials aim to maintain or improve upon the performance of traditional lead-based piezoelectrics while reducing environmental impact.

The miniaturization of acoustic sensors powered by piezoelectric technology also contributes to reducing material usage and waste. Smaller sensors require less raw material, potentially decreasing the overall environmental footprint of production. Additionally, the compact size of these sensors can lead to more efficient transportation and reduced packaging waste.

As environmental regulations become more stringent, particularly concerning the use of hazardous substances in electronic equipment, the piezoelectric sensor industry is adapting. This shift is driving innovation in material science and manufacturing processes, aiming to create more sustainable and eco-friendly sensor technologies. The development of green piezoelectric materials and improved recycling techniques are key areas of focus in mitigating the environmental impact of these essential components in modern acoustic sensing applications.

Standardization and Testing Protocols

Standardization and testing protocols play a crucial role in ensuring the reliability, consistency, and comparability of miniature acoustic sensors powered by piezoelectric technology. As this field continues to evolve rapidly, establishing comprehensive and universally accepted standards becomes increasingly important for both manufacturers and end-users.

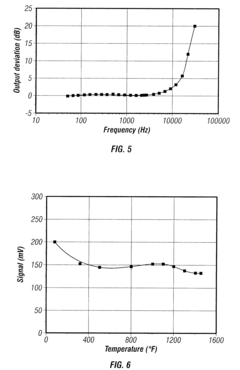

The development of standardization for these sensors typically involves collaboration between industry leaders, academic institutions, and regulatory bodies. Key areas of focus include sensor performance metrics, environmental testing conditions, and calibration procedures. Performance metrics often encompass sensitivity, frequency response, dynamic range, and signal-to-noise ratio. These parameters must be clearly defined and measured using consistent methodologies to enable meaningful comparisons between different sensor models and manufacturers.

Environmental testing protocols are essential for evaluating the robustness and reliability of miniature acoustic sensors in various operating conditions. These tests may include temperature cycling, humidity exposure, vibration resistance, and electromagnetic compatibility. Standardized procedures ensure that sensors can withstand the rigors of their intended applications, whether in consumer electronics, industrial settings, or specialized fields such as aerospace or medical devices.

Calibration procedures form another critical aspect of standardization. Accurate and repeatable calibration is vital for maintaining sensor performance over time and ensuring consistency across different production batches. Standardized calibration methods may involve the use of reference microphones, acoustic calibrators, or specialized equipment designed specifically for piezoelectric sensors.

Interoperability standards are becoming increasingly important as these sensors are integrated into complex systems and IoT devices. Protocols for data communication, power management, and signal processing must be standardized to facilitate seamless integration and interchangeability between different sensor models and manufacturers.

As the technology advances, standards must evolve to address emerging challenges and capabilities. For instance, the miniaturization of sensors may require new testing methodologies to accurately assess performance at increasingly small scales. Additionally, the integration of smart features and on-board processing capabilities in modern sensors necessitates the development of standards for firmware validation and software testing.

International organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) play a pivotal role in developing and maintaining global standards for acoustic sensors. These organizations work to harmonize national standards and ensure that testing protocols are universally applicable across different regions and industries.

The development of standardization for these sensors typically involves collaboration between industry leaders, academic institutions, and regulatory bodies. Key areas of focus include sensor performance metrics, environmental testing conditions, and calibration procedures. Performance metrics often encompass sensitivity, frequency response, dynamic range, and signal-to-noise ratio. These parameters must be clearly defined and measured using consistent methodologies to enable meaningful comparisons between different sensor models and manufacturers.

Environmental testing protocols are essential for evaluating the robustness and reliability of miniature acoustic sensors in various operating conditions. These tests may include temperature cycling, humidity exposure, vibration resistance, and electromagnetic compatibility. Standardized procedures ensure that sensors can withstand the rigors of their intended applications, whether in consumer electronics, industrial settings, or specialized fields such as aerospace or medical devices.

Calibration procedures form another critical aspect of standardization. Accurate and repeatable calibration is vital for maintaining sensor performance over time and ensuring consistency across different production batches. Standardized calibration methods may involve the use of reference microphones, acoustic calibrators, or specialized equipment designed specifically for piezoelectric sensors.

Interoperability standards are becoming increasingly important as these sensors are integrated into complex systems and IoT devices. Protocols for data communication, power management, and signal processing must be standardized to facilitate seamless integration and interchangeability between different sensor models and manufacturers.

As the technology advances, standards must evolve to address emerging challenges and capabilities. For instance, the miniaturization of sensors may require new testing methodologies to accurately assess performance at increasingly small scales. Additionally, the integration of smart features and on-board processing capabilities in modern sensors necessitates the development of standards for firmware validation and software testing.

International organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) play a pivotal role in developing and maintaining global standards for acoustic sensors. These organizations work to harmonize national standards and ensure that testing protocols are universally applicable across different regions and industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!