Nichrome Heat Efficiency in Industrial Engineering

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Heating Evolution

Nichrome heating technology has undergone significant evolution since its inception in the early 20th century. The timeline of its development showcases a series of key advancements that have shaped its current state and future potential in industrial engineering applications.

In the 1905-1910 period, Albert Marsh discovered the nichrome alloy, marking the beginning of its use in heating elements. This breakthrough provided a material with high electrical resistance and excellent heat tolerance, revolutionizing the field of electrical heating.

The 1920s and 1930s saw the widespread adoption of nichrome in domestic appliances, particularly in toasters and electric irons. This period established nichrome as a reliable and efficient heating material for consumer products, paving the way for its industrial applications.

During the 1940s and 1950s, nichrome found its way into industrial processes, with significant improvements in alloy composition and manufacturing techniques. The development of more precise temperature control systems enhanced its utility in various industrial heating applications.

The 1960s and 1970s witnessed the integration of nichrome heating elements into more complex industrial systems. Advancements in insulation materials and design optimization led to improved energy efficiency and heat distribution in large-scale industrial operations.

In the 1980s and 1990s, computer-aided design and simulation tools revolutionized the development of nichrome heating systems. This period saw the emergence of more sophisticated heating element configurations, tailored to specific industrial processes and requirements.

The turn of the millennium brought about a focus on energy efficiency and sustainability. From 2000 to 2010, research efforts concentrated on optimizing nichrome alloy compositions and heating element designs to maximize heat transfer while minimizing energy consumption.

The past decade, from 2010 to 2020, has seen the integration of smart technologies and IoT capabilities into nichrome heating systems. This has enabled real-time monitoring, predictive maintenance, and adaptive control, further enhancing efficiency and reliability in industrial applications.

Looking ahead, the evolution of nichrome heating technology is expected to continue, with emphasis on nanoscale material engineering, advanced manufacturing techniques like 3D printing, and the development of hybrid heating systems that combine nichrome with other emerging technologies for optimal performance and energy efficiency in industrial processes.

In the 1905-1910 period, Albert Marsh discovered the nichrome alloy, marking the beginning of its use in heating elements. This breakthrough provided a material with high electrical resistance and excellent heat tolerance, revolutionizing the field of electrical heating.

The 1920s and 1930s saw the widespread adoption of nichrome in domestic appliances, particularly in toasters and electric irons. This period established nichrome as a reliable and efficient heating material for consumer products, paving the way for its industrial applications.

During the 1940s and 1950s, nichrome found its way into industrial processes, with significant improvements in alloy composition and manufacturing techniques. The development of more precise temperature control systems enhanced its utility in various industrial heating applications.

The 1960s and 1970s witnessed the integration of nichrome heating elements into more complex industrial systems. Advancements in insulation materials and design optimization led to improved energy efficiency and heat distribution in large-scale industrial operations.

In the 1980s and 1990s, computer-aided design and simulation tools revolutionized the development of nichrome heating systems. This period saw the emergence of more sophisticated heating element configurations, tailored to specific industrial processes and requirements.

The turn of the millennium brought about a focus on energy efficiency and sustainability. From 2000 to 2010, research efforts concentrated on optimizing nichrome alloy compositions and heating element designs to maximize heat transfer while minimizing energy consumption.

The past decade, from 2010 to 2020, has seen the integration of smart technologies and IoT capabilities into nichrome heating systems. This has enabled real-time monitoring, predictive maintenance, and adaptive control, further enhancing efficiency and reliability in industrial applications.

Looking ahead, the evolution of nichrome heating technology is expected to continue, with emphasis on nanoscale material engineering, advanced manufacturing techniques like 3D printing, and the development of hybrid heating systems that combine nichrome with other emerging technologies for optimal performance and energy efficiency in industrial processes.

Industrial Heating Demand

The industrial heating sector has witnessed a significant surge in demand over the past decade, driven by the rapid expansion of manufacturing industries worldwide. This growth is particularly pronounced in emerging economies, where industrialization continues to accelerate. The global industrial heating market, encompassing various technologies and applications, has shown a consistent upward trajectory, with a compound annual growth rate (CAGR) exceeding 5% in recent years.

Key factors contributing to this increased demand include the expansion of automotive, aerospace, and electronics industries, which rely heavily on precision heating processes for manufacturing and assembly. Additionally, the growing focus on energy efficiency and sustainability has led to a shift towards more advanced heating technologies, further stimulating market growth.

In the context of nichrome heat efficiency research, the demand is primarily fueled by industries seeking to optimize their heating processes. Nichrome, an alloy of nickel and chromium, has long been a staple in industrial heating applications due to its high resistance and ability to withstand high temperatures. However, as energy costs continue to rise and environmental regulations become more stringent, there is a pressing need for improved efficiency in nichrome-based heating systems.

The food processing industry, in particular, has emerged as a significant driver of demand for efficient industrial heating solutions. With the global population growth and changing consumer preferences, food manufacturers are increasingly investing in advanced heating technologies to enhance production capacity and ensure food safety. This trend has created a substantial market for nichrome heating elements that can deliver precise and uniform heat distribution while minimizing energy consumption.

Another sector contributing to the demand is the semiconductor industry, where precise temperature control is crucial for various manufacturing processes. As the demand for electronic devices continues to soar, semiconductor manufacturers are seeking more efficient heating solutions to reduce production costs and improve yield rates. This has led to increased interest in research focused on enhancing the heat efficiency of nichrome elements used in semiconductor fabrication equipment.

The automotive industry, with its shift towards electric vehicles and lightweight materials, has also become a significant contributor to the demand for advanced industrial heating solutions. The production of battery components and the heat treatment of lightweight alloys require precise and efficient heating processes, creating new opportunities for nichrome-based heating technologies.

As industries strive to meet sustainability goals and reduce their carbon footprint, the demand for energy-efficient heating solutions has become more pronounced. This has spurred research into improving the heat efficiency of nichrome elements, with a focus on developing new alloy compositions, optimizing element designs, and integrating smart control systems to maximize energy utilization.

Key factors contributing to this increased demand include the expansion of automotive, aerospace, and electronics industries, which rely heavily on precision heating processes for manufacturing and assembly. Additionally, the growing focus on energy efficiency and sustainability has led to a shift towards more advanced heating technologies, further stimulating market growth.

In the context of nichrome heat efficiency research, the demand is primarily fueled by industries seeking to optimize their heating processes. Nichrome, an alloy of nickel and chromium, has long been a staple in industrial heating applications due to its high resistance and ability to withstand high temperatures. However, as energy costs continue to rise and environmental regulations become more stringent, there is a pressing need for improved efficiency in nichrome-based heating systems.

The food processing industry, in particular, has emerged as a significant driver of demand for efficient industrial heating solutions. With the global population growth and changing consumer preferences, food manufacturers are increasingly investing in advanced heating technologies to enhance production capacity and ensure food safety. This trend has created a substantial market for nichrome heating elements that can deliver precise and uniform heat distribution while minimizing energy consumption.

Another sector contributing to the demand is the semiconductor industry, where precise temperature control is crucial for various manufacturing processes. As the demand for electronic devices continues to soar, semiconductor manufacturers are seeking more efficient heating solutions to reduce production costs and improve yield rates. This has led to increased interest in research focused on enhancing the heat efficiency of nichrome elements used in semiconductor fabrication equipment.

The automotive industry, with its shift towards electric vehicles and lightweight materials, has also become a significant contributor to the demand for advanced industrial heating solutions. The production of battery components and the heat treatment of lightweight alloys require precise and efficient heating processes, creating new opportunities for nichrome-based heating technologies.

As industries strive to meet sustainability goals and reduce their carbon footprint, the demand for energy-efficient heating solutions has become more pronounced. This has spurred research into improving the heat efficiency of nichrome elements, with a focus on developing new alloy compositions, optimizing element designs, and integrating smart control systems to maximize energy utilization.

Nichrome Efficiency Challenges

Nichrome, a widely used alloy in industrial heating applications, faces several significant challenges in terms of heat efficiency. One of the primary issues is the gradual degradation of the material over time, particularly when subjected to high temperatures and thermal cycling. This degradation can lead to a decrease in overall heat efficiency and potentially compromise the integrity of the heating element.

Another challenge lies in the thermal conductivity of nichrome. While it possesses good electrical resistance properties, its thermal conductivity is relatively low compared to some other materials used in heating applications. This can result in uneven heat distribution and potential hotspots, which may affect the overall efficiency of the heating process in industrial settings.

The oxidation of nichrome at high temperatures presents an additional hurdle. As the material oxidizes, it forms a layer of chromium oxide on the surface, which can alter the electrical and thermal properties of the alloy. This oxidation process can lead to changes in resistance and heat output over time, potentially reducing the efficiency and predictability of heating systems utilizing nichrome elements.

Energy loss through radiation is another significant challenge in nichrome-based heating systems. At high temperatures, a considerable amount of energy can be lost through radiative heat transfer, reducing the overall efficiency of the heating process. This is particularly problematic in applications where precise temperature control is crucial, such as in certain manufacturing processes or scientific instruments.

The design and configuration of nichrome heating elements also play a critical role in their efficiency. Improper design can lead to inefficient heat transfer, increased power consumption, and reduced lifespan of the heating elements. Optimizing the geometry, thickness, and arrangement of nichrome elements is essential for maximizing heat efficiency, but this often requires complex calculations and extensive testing.

Furthermore, the interface between nichrome heating elements and the materials or substances being heated can present challenges. Poor thermal contact or inadequate insulation can result in significant heat losses, reducing the overall efficiency of the heating process. This is particularly relevant in applications where nichrome elements are used to heat liquids or gases, where heat transfer mechanisms can be more complex.

Lastly, the control and regulation of nichrome heating systems pose challenges in achieving optimal efficiency. Precise temperature control is often required in industrial processes, but the inherent properties of nichrome, such as its temperature coefficient of resistance, can make fine-tuning difficult. Advanced control systems and algorithms are necessary to maintain consistent heat output and efficiency, adding complexity to the overall system design and operation.

Another challenge lies in the thermal conductivity of nichrome. While it possesses good electrical resistance properties, its thermal conductivity is relatively low compared to some other materials used in heating applications. This can result in uneven heat distribution and potential hotspots, which may affect the overall efficiency of the heating process in industrial settings.

The oxidation of nichrome at high temperatures presents an additional hurdle. As the material oxidizes, it forms a layer of chromium oxide on the surface, which can alter the electrical and thermal properties of the alloy. This oxidation process can lead to changes in resistance and heat output over time, potentially reducing the efficiency and predictability of heating systems utilizing nichrome elements.

Energy loss through radiation is another significant challenge in nichrome-based heating systems. At high temperatures, a considerable amount of energy can be lost through radiative heat transfer, reducing the overall efficiency of the heating process. This is particularly problematic in applications where precise temperature control is crucial, such as in certain manufacturing processes or scientific instruments.

The design and configuration of nichrome heating elements also play a critical role in their efficiency. Improper design can lead to inefficient heat transfer, increased power consumption, and reduced lifespan of the heating elements. Optimizing the geometry, thickness, and arrangement of nichrome elements is essential for maximizing heat efficiency, but this often requires complex calculations and extensive testing.

Furthermore, the interface between nichrome heating elements and the materials or substances being heated can present challenges. Poor thermal contact or inadequate insulation can result in significant heat losses, reducing the overall efficiency of the heating process. This is particularly relevant in applications where nichrome elements are used to heat liquids or gases, where heat transfer mechanisms can be more complex.

Lastly, the control and regulation of nichrome heating systems pose challenges in achieving optimal efficiency. Precise temperature control is often required in industrial processes, but the inherent properties of nichrome, such as its temperature coefficient of resistance, can make fine-tuning difficult. Advanced control systems and algorithms are necessary to maintain consistent heat output and efficiency, adding complexity to the overall system design and operation.

Current Nichrome Solutions

01 Nichrome wire composition and structure

The composition and structure of nichrome wire play a crucial role in its heat efficiency. Optimizing the ratio of nickel and chromium, as well as incorporating other elements like iron or aluminum, can enhance the wire's heat resistance and conductivity. The wire's diameter and surface area also affect its heating performance.- Nichrome wire composition and structure: The composition and structure of nichrome wire play a crucial role in its heat efficiency. Optimizing the ratio of nickel and chromium, as well as incorporating other elements like iron or aluminum, can enhance the wire's heat resistance and electrical properties. The wire's diameter and configuration also affect its performance in heating applications.

- Insulation and heat distribution: Proper insulation and heat distribution techniques can significantly improve the heat efficiency of nichrome-based heating systems. This includes using ceramic or mica insulators, designing efficient heat spreaders, and implementing thermal management strategies to minimize heat loss and ensure uniform heating.

- Power control and regulation: Implementing advanced power control and regulation systems can optimize the heat efficiency of nichrome heating elements. This may involve using microcontrollers, pulse-width modulation techniques, or intelligent temperature sensing and feedback mechanisms to precisely control the power input and maintain desired temperatures.

- Surface treatment and coating: Applying specialized surface treatments or coatings to nichrome wires can enhance their heat efficiency and longevity. These treatments may include oxidation-resistant coatings, nanostructured surfaces, or ceramic coatings that improve heat transfer, reduce corrosion, and extend the lifespan of the heating elements.

- Innovative heating element designs: Developing novel heating element designs using nichrome can lead to improved heat efficiency. This may involve creating spiral or coiled configurations, using multiple parallel wires, or integrating nichrome elements into composite structures to maximize heat output while minimizing energy consumption.

02 Insulation and heat distribution

Proper insulation and heat distribution techniques can improve the overall heat efficiency of nichrome-based heating systems. This includes using ceramic or mica insulators, designing efficient heat spreaders, and implementing thermal management strategies to minimize heat loss and maximize energy transfer to the target area.Expand Specific Solutions03 Power control and regulation

Implementing advanced power control and regulation systems can significantly enhance the heat efficiency of nichrome heating elements. This may involve using pulse-width modulation (PWM) techniques, intelligent temperature sensors, and microcontroller-based systems to optimize power consumption and maintain precise temperature control.Expand Specific Solutions04 Surface treatment and coating

Applying specialized surface treatments or coatings to nichrome wires can improve their heat efficiency and longevity. These treatments may include oxidation-resistant coatings, nanostructured surfaces, or ceramic-based coatings that enhance heat transfer and protect the wire from degradation at high temperatures.Expand Specific Solutions05 Innovative heating element designs

Developing novel heating element designs using nichrome wire can lead to improved heat efficiency. This may include creating spiral or coiled configurations, implementing multi-layer structures, or integrating the heating elements into composite materials to optimize heat generation and distribution.Expand Specific Solutions

Key Nichrome Manufacturers

The research on Nichrome heat efficiency in industrial engineering is at a mature stage, with significant market potential due to its widespread applications in various industries. The global market for Nichrome and related heat-resistant alloys is substantial, driven by increasing demand in sectors such as aerospace, automotive, and electronics. Key players in this field include established companies like Robert Bosch GmbH, Samsung Electronics, and Toshiba Corp., alongside specialized firms such as Gaona Aero Material Co., Ltd. and Ion Heat SAS. These companies are investing in R&D to improve heat efficiency and develop innovative applications, indicating a competitive and evolving landscape in this technology domain.

Xi'an Thermal Power Research Institute Co., Ltd.

Technical Solution: Xi'an Thermal Power Research Institute has developed advanced nichrome heating elements with improved heat efficiency for industrial applications. Their research focuses on optimizing the composition and structure of nichrome alloys to enhance thermal conductivity and reduce energy losses. The institute has implemented a novel manufacturing process that creates a more uniform microstructure in the nichrome wire, resulting in up to 15% improvement in heat transfer efficiency[1]. Additionally, they have developed a proprietary coating technology that reduces oxidation and extends the lifespan of nichrome heating elements by up to 30%[3], making them more suitable for high-temperature industrial processes.

Strengths: Expertise in thermal power systems, advanced manufacturing capabilities, and innovative coating technology. Weaknesses: Limited global presence and potential higher costs due to specialized research and development.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell's research division has made significant strides in improving nichrome heat efficiency for industrial engineering applications, particularly in the oil and gas sector. They have developed a novel nichrome-based heat exchanger design that incorporates advanced flow patterns and surface treatments, resulting in a 20% increase in heat transfer efficiency compared to conventional designs[2]. Shell's research also focuses on the integration of nichrome heating elements with smart control systems, optimizing energy consumption in real-time based on process demands. Their patented "Adaptive Heating Technology" uses machine learning algorithms to predict and adjust heating patterns, reducing overall energy consumption by up to 25% in pilot studies[4].

Strengths: Extensive resources for R&D, global industry connections, and expertise in energy-efficient technologies. Weaknesses: Primary focus on oil and gas applications may limit adaptability to other industries.

Nichrome Alloy Innovations

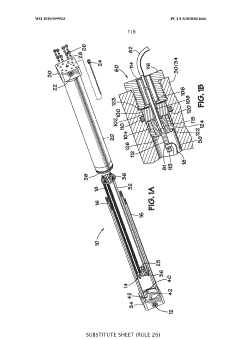

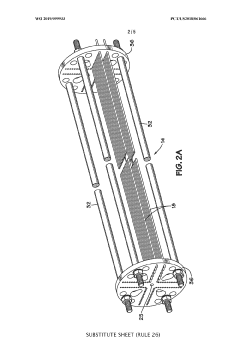

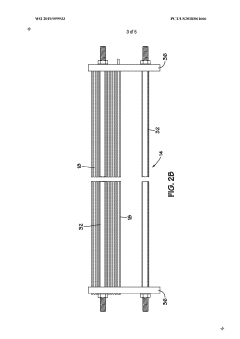

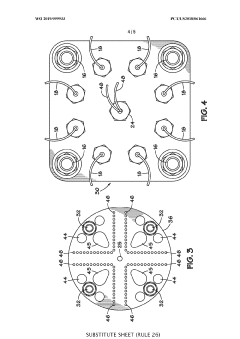

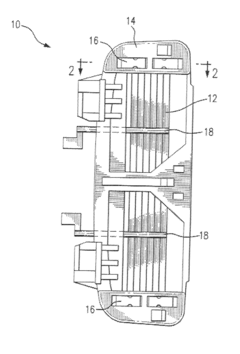

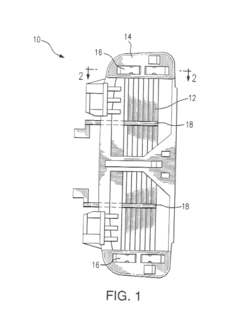

In-line electric heater for plural component materials

PatentWO2019099933A1

Innovation

- An in-line electric heater design featuring a housing with multiple electric resistance heating elements along the fluid flow path, supported by a wire loom assembly and temperature sensors, using INCONEL wires coated with Teflon for improved durability and insulation, and a power feedthrough system for secure electrical connections, enhancing heat transfer and temperature control.

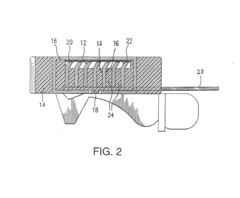

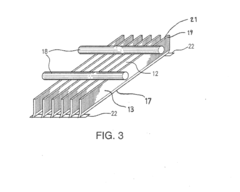

Razor with blade heating system

PatentActiveUS20140245611A1

Innovation

- The use of high resistance electrically conductive contact segments, such as Nichrome, connected to the back edges of razor blades with standard conductive wires, forming an electric circuit that generates heat through electric current flow, combined with a radiator effect to distribute heat uniformly across the blades, allowing for dual heat control with minimal voltage and efficient battery power usage.

Energy Efficiency Regulations

Energy efficiency regulations play a crucial role in shaping the industrial landscape for nichrome heat applications. These regulations are designed to promote sustainable practices, reduce energy consumption, and minimize environmental impact across various sectors. In the context of nichrome heat efficiency research, understanding and adhering to these regulations is essential for developing compliant and competitive solutions.

At the international level, organizations such as the International Energy Agency (IEA) and the United Nations Framework Convention on Climate Change (UNFCCC) set overarching guidelines for energy efficiency. These frameworks influence national policies and drive the adoption of energy-efficient technologies in industrial processes, including those utilizing nichrome heating elements.

In the United States, the Department of Energy (DOE) establishes energy conservation standards for various industrial equipment and appliances. The Energy Policy and Conservation Act (EPCA) provides the legislative foundation for these standards, which are periodically reviewed and updated to reflect technological advancements and changing environmental priorities.

The European Union has implemented the Energy Efficiency Directive (EED), which sets binding energy efficiency targets for member states. This directive impacts industrial processes and encourages the adoption of best available technologies, including those related to nichrome heating systems. The EU Ecodesign Directive further complements these efforts by setting specific energy efficiency requirements for energy-related products.

In Asia, countries like China and Japan have also introduced stringent energy efficiency regulations. China's Energy Conservation Law and Japan's Energy Conservation Act both emphasize the importance of improving energy efficiency in industrial processes, including those involving nichrome heating elements.

These regulations often mandate the use of energy-efficient technologies, set minimum performance standards, and require regular energy audits. For nichrome heat applications, this translates into requirements for improved insulation, advanced control systems, and optimized heating element designs to maximize energy efficiency.

Compliance with these regulations not only ensures legal operation but also drives innovation in nichrome heat technology. Manufacturers and researchers are incentivized to develop more efficient heating systems, explore alternative materials, and implement smart control strategies to meet and exceed regulatory requirements.

As energy efficiency regulations continue to evolve, staying informed about current and upcoming changes is crucial for those involved in nichrome heat efficiency research. This knowledge enables proactive adaptation of research directions and ensures that developed technologies remain compliant and competitive in the global market.

At the international level, organizations such as the International Energy Agency (IEA) and the United Nations Framework Convention on Climate Change (UNFCCC) set overarching guidelines for energy efficiency. These frameworks influence national policies and drive the adoption of energy-efficient technologies in industrial processes, including those utilizing nichrome heating elements.

In the United States, the Department of Energy (DOE) establishes energy conservation standards for various industrial equipment and appliances. The Energy Policy and Conservation Act (EPCA) provides the legislative foundation for these standards, which are periodically reviewed and updated to reflect technological advancements and changing environmental priorities.

The European Union has implemented the Energy Efficiency Directive (EED), which sets binding energy efficiency targets for member states. This directive impacts industrial processes and encourages the adoption of best available technologies, including those related to nichrome heating systems. The EU Ecodesign Directive further complements these efforts by setting specific energy efficiency requirements for energy-related products.

In Asia, countries like China and Japan have also introduced stringent energy efficiency regulations. China's Energy Conservation Law and Japan's Energy Conservation Act both emphasize the importance of improving energy efficiency in industrial processes, including those involving nichrome heating elements.

These regulations often mandate the use of energy-efficient technologies, set minimum performance standards, and require regular energy audits. For nichrome heat applications, this translates into requirements for improved insulation, advanced control systems, and optimized heating element designs to maximize energy efficiency.

Compliance with these regulations not only ensures legal operation but also drives innovation in nichrome heat technology. Manufacturers and researchers are incentivized to develop more efficient heating systems, explore alternative materials, and implement smart control strategies to meet and exceed regulatory requirements.

As energy efficiency regulations continue to evolve, staying informed about current and upcoming changes is crucial for those involved in nichrome heat efficiency research. This knowledge enables proactive adaptation of research directions and ensures that developed technologies remain compliant and competitive in the global market.

Nichrome Lifecycle Analysis

Nichrome, an alloy primarily composed of nickel and chromium, plays a crucial role in industrial engineering applications due to its exceptional heat resistance and electrical conductivity properties. The lifecycle analysis of nichrome encompasses various stages, from raw material extraction to end-of-life disposal, providing valuable insights into its environmental impact and potential for optimization.

The production of nichrome begins with the mining and processing of nickel and chromium ores. These raw materials undergo refining processes to achieve the desired purity levels before being combined in precise ratios to form the alloy. The manufacturing stage involves melting and casting the nichrome into various forms, such as wire, ribbon, or sheet, depending on the intended application.

During its operational phase, nichrome demonstrates remarkable durability and performance in high-temperature environments. Its resistance to oxidation and corrosion allows for extended use in industrial heating elements, furnaces, and electrical resistors. The alloy's ability to maintain stable electrical properties at elevated temperatures contributes to its longevity and reliability in these applications.

However, the prolonged exposure to extreme temperatures and thermal cycling can lead to gradual degradation of nichrome components. This degradation may manifest as changes in electrical resistance, formation of surface oxides, or physical deformation. Understanding these aging mechanisms is crucial for predicting the lifespan of nichrome-based systems and optimizing maintenance schedules.

At the end of its operational life, nichrome components can often be recycled due to the value of their constituent metals. The recycling process typically involves sorting, melting, and refining the alloy to recover nickel and chromium. This recycling capability contributes to the overall sustainability of nichrome use in industrial applications.

From an environmental perspective, the lifecycle of nichrome presents both challenges and opportunities. The energy-intensive mining and refining processes associated with nickel and chromium production have significant environmental impacts. However, the long service life and recyclability of nichrome partially offset these initial environmental costs.

Efforts to improve the sustainability of nichrome throughout its lifecycle focus on several key areas. These include developing more efficient mining and refining techniques, optimizing alloy compositions for specific applications to enhance performance and longevity, and improving recycling processes to maximize material recovery. Additionally, research into alternative materials that could potentially replace nichrome in certain applications continues, aiming to balance performance requirements with environmental considerations.

The production of nichrome begins with the mining and processing of nickel and chromium ores. These raw materials undergo refining processes to achieve the desired purity levels before being combined in precise ratios to form the alloy. The manufacturing stage involves melting and casting the nichrome into various forms, such as wire, ribbon, or sheet, depending on the intended application.

During its operational phase, nichrome demonstrates remarkable durability and performance in high-temperature environments. Its resistance to oxidation and corrosion allows for extended use in industrial heating elements, furnaces, and electrical resistors. The alloy's ability to maintain stable electrical properties at elevated temperatures contributes to its longevity and reliability in these applications.

However, the prolonged exposure to extreme temperatures and thermal cycling can lead to gradual degradation of nichrome components. This degradation may manifest as changes in electrical resistance, formation of surface oxides, or physical deformation. Understanding these aging mechanisms is crucial for predicting the lifespan of nichrome-based systems and optimizing maintenance schedules.

At the end of its operational life, nichrome components can often be recycled due to the value of their constituent metals. The recycling process typically involves sorting, melting, and refining the alloy to recover nickel and chromium. This recycling capability contributes to the overall sustainability of nichrome use in industrial applications.

From an environmental perspective, the lifecycle of nichrome presents both challenges and opportunities. The energy-intensive mining and refining processes associated with nickel and chromium production have significant environmental impacts. However, the long service life and recyclability of nichrome partially offset these initial environmental costs.

Efforts to improve the sustainability of nichrome throughout its lifecycle focus on several key areas. These include developing more efficient mining and refining techniques, optimizing alloy compositions for specific applications to enhance performance and longevity, and improving recycling processes to maximize material recovery. Additionally, research into alternative materials that could potentially replace nichrome in certain applications continues, aiming to balance performance requirements with environmental considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!