Nichrome in High-Temperature Lab Equipment

JUL 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Evolution and Research Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone material in high-temperature laboratory equipment for over a century. Its evolution and research objectives have been driven by the increasing demands for materials capable of withstanding extreme temperatures and corrosive environments in scientific and industrial applications.

The development of nichrome can be traced back to the early 20th century when Albert Marsh patented the first nichrome alloy in 1906. This breakthrough marked the beginning of a new era in electrical heating elements and high-temperature applications. The initial composition, consisting of approximately 80% nickel and 20% chromium, demonstrated remarkable resistance to oxidation and excellent electrical properties at elevated temperatures.

As the field of materials science progressed, researchers began to explore variations in the nichrome composition to enhance its performance characteristics. The addition of small amounts of other elements, such as silicon, manganese, and iron, led to the creation of different grades of nichrome with tailored properties for specific applications. These advancements expanded the use of nichrome in laboratory equipment, including furnaces, heating mantles, and hot plates.

The primary research objectives in nichrome development have focused on improving its thermal stability, oxidation resistance, and mechanical properties at high temperatures. Scientists have been working to extend the operational temperature range of nichrome-based equipment, with the goal of pushing beyond the current limits of around 1200°C for sustained use. This pursuit has led to investigations into the microstructure of nichrome and its behavior under various thermal and mechanical stresses.

Another significant area of research has been the optimization of nichrome's electrical properties. As laboratory equipment becomes more sophisticated, there is a growing need for precise temperature control and uniform heating. Researchers have been exploring ways to fine-tune the electrical resistivity of nichrome alloys to achieve better performance in heating applications, including faster response times and more accurate temperature regulation.

The environmental impact and sustainability of nichrome production and use have also become important research objectives in recent years. Scientists are investigating methods to reduce the energy consumption in nichrome manufacturing processes and exploring recycling techniques to minimize waste. Additionally, there is ongoing research into potential substitutes or complementary materials that could offer similar performance with reduced environmental footprint.

As we look to the future, the research objectives for nichrome in high-temperature lab equipment continue to evolve. There is a growing interest in developing smart nichrome-based materials that can self-monitor their condition and performance, potentially leading to more efficient and safer laboratory equipment. Furthermore, the integration of nichrome with advanced ceramics and other high-performance materials is being explored to create hybrid systems capable of withstanding even more extreme conditions.

The development of nichrome can be traced back to the early 20th century when Albert Marsh patented the first nichrome alloy in 1906. This breakthrough marked the beginning of a new era in electrical heating elements and high-temperature applications. The initial composition, consisting of approximately 80% nickel and 20% chromium, demonstrated remarkable resistance to oxidation and excellent electrical properties at elevated temperatures.

As the field of materials science progressed, researchers began to explore variations in the nichrome composition to enhance its performance characteristics. The addition of small amounts of other elements, such as silicon, manganese, and iron, led to the creation of different grades of nichrome with tailored properties for specific applications. These advancements expanded the use of nichrome in laboratory equipment, including furnaces, heating mantles, and hot plates.

The primary research objectives in nichrome development have focused on improving its thermal stability, oxidation resistance, and mechanical properties at high temperatures. Scientists have been working to extend the operational temperature range of nichrome-based equipment, with the goal of pushing beyond the current limits of around 1200°C for sustained use. This pursuit has led to investigations into the microstructure of nichrome and its behavior under various thermal and mechanical stresses.

Another significant area of research has been the optimization of nichrome's electrical properties. As laboratory equipment becomes more sophisticated, there is a growing need for precise temperature control and uniform heating. Researchers have been exploring ways to fine-tune the electrical resistivity of nichrome alloys to achieve better performance in heating applications, including faster response times and more accurate temperature regulation.

The environmental impact and sustainability of nichrome production and use have also become important research objectives in recent years. Scientists are investigating methods to reduce the energy consumption in nichrome manufacturing processes and exploring recycling techniques to minimize waste. Additionally, there is ongoing research into potential substitutes or complementary materials that could offer similar performance with reduced environmental footprint.

As we look to the future, the research objectives for nichrome in high-temperature lab equipment continue to evolve. There is a growing interest in developing smart nichrome-based materials that can self-monitor their condition and performance, potentially leading to more efficient and safer laboratory equipment. Furthermore, the integration of nichrome with advanced ceramics and other high-performance materials is being explored to create hybrid systems capable of withstanding even more extreme conditions.

Market Analysis for High-Temp Lab Equipment

The market for high-temperature laboratory equipment, particularly those utilizing nichrome components, has shown significant growth in recent years. This expansion is driven by increasing demand across various industries, including materials science, metallurgy, ceramics, and advanced manufacturing. The global market for high-temperature lab equipment is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to exceed 5% over the next five years.

Key factors contributing to this market growth include the rising focus on research and development activities in both academic and industrial sectors, the need for advanced materials testing in emerging technologies, and the continuous evolution of manufacturing processes requiring precise high-temperature control. Additionally, the increasing adoption of automation and digitalization in laboratory settings has further boosted the demand for sophisticated high-temperature equipment.

The nichrome-based high-temperature lab equipment segment holds a substantial market share due to its excellent heat resistance, durability, and cost-effectiveness. Nichrome's unique properties make it an ideal material for heating elements, thermocouples, and other components used in furnaces, ovens, and thermal analysis instruments.

Geographically, North America and Europe dominate the market, accounting for a significant portion of the global revenue. This is attributed to the presence of well-established research institutions, robust industrial sectors, and high investment in R&D activities. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, government initiatives to promote scientific research, and the expansion of manufacturing capabilities in countries like China, Japan, and South Korea.

The competitive landscape of the high-temperature lab equipment market is characterized by a mix of large multinational corporations and specialized niche players. Leading companies are focusing on product innovation, incorporating advanced materials and technologies to enhance the performance and efficiency of their equipment. There is also a growing trend towards the development of modular and customizable solutions to meet specific research and industrial requirements.

Customer preferences in this market are shifting towards equipment that offers higher precision, improved energy efficiency, and enhanced safety features. There is also an increasing demand for integrated systems that can provide comprehensive data analysis and remote monitoring capabilities, aligning with the broader trend of laboratory digitalization.

In terms of challenges, the market faces issues related to the high initial cost of advanced high-temperature equipment, which can be a barrier for smaller research institutions and companies. Additionally, stringent regulatory requirements for safety and emissions in certain regions pose compliance challenges for manufacturers.

Looking ahead, the market for high-temperature lab equipment, particularly those incorporating nichrome components, is poised for continued growth. Emerging applications in fields such as nanotechnology, advanced composites, and renewable energy research are expected to create new opportunities for market expansion and technological innovation in the coming years.

Key factors contributing to this market growth include the rising focus on research and development activities in both academic and industrial sectors, the need for advanced materials testing in emerging technologies, and the continuous evolution of manufacturing processes requiring precise high-temperature control. Additionally, the increasing adoption of automation and digitalization in laboratory settings has further boosted the demand for sophisticated high-temperature equipment.

The nichrome-based high-temperature lab equipment segment holds a substantial market share due to its excellent heat resistance, durability, and cost-effectiveness. Nichrome's unique properties make it an ideal material for heating elements, thermocouples, and other components used in furnaces, ovens, and thermal analysis instruments.

Geographically, North America and Europe dominate the market, accounting for a significant portion of the global revenue. This is attributed to the presence of well-established research institutions, robust industrial sectors, and high investment in R&D activities. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, government initiatives to promote scientific research, and the expansion of manufacturing capabilities in countries like China, Japan, and South Korea.

The competitive landscape of the high-temperature lab equipment market is characterized by a mix of large multinational corporations and specialized niche players. Leading companies are focusing on product innovation, incorporating advanced materials and technologies to enhance the performance and efficiency of their equipment. There is also a growing trend towards the development of modular and customizable solutions to meet specific research and industrial requirements.

Customer preferences in this market are shifting towards equipment that offers higher precision, improved energy efficiency, and enhanced safety features. There is also an increasing demand for integrated systems that can provide comprehensive data analysis and remote monitoring capabilities, aligning with the broader trend of laboratory digitalization.

In terms of challenges, the market faces issues related to the high initial cost of advanced high-temperature equipment, which can be a barrier for smaller research institutions and companies. Additionally, stringent regulatory requirements for safety and emissions in certain regions pose compliance challenges for manufacturers.

Looking ahead, the market for high-temperature lab equipment, particularly those incorporating nichrome components, is poised for continued growth. Emerging applications in fields such as nanotechnology, advanced composites, and renewable energy research are expected to create new opportunities for market expansion and technological innovation in the coming years.

Nichrome Properties and Current Limitations

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone material in high-temperature laboratory equipment due to its exceptional properties. This alloy typically contains 80% nickel and 20% chromium, though variations exist to optimize specific characteristics. Nichrome's most notable property is its high resistance to oxidation at elevated temperatures, making it ideal for applications in furnaces, heating elements, and other high-temperature environments.

The material exhibits excellent electrical resistivity, which remains relatively stable across a wide temperature range. This property, combined with its high melting point of approximately 1400°C, allows nichrome to function effectively in heating elements that require consistent performance under extreme conditions. Additionally, nichrome possesses good mechanical strength and ductility, enabling it to withstand thermal cycling and mechanical stresses common in laboratory settings.

Despite its numerous advantages, nichrome does face certain limitations that restrict its use in some high-temperature applications. One significant constraint is its maximum operating temperature, which is typically around 1200°C for continuous use. Beyond this temperature, the material's oxidation resistance begins to degrade, leading to potential failure of the equipment. This limitation becomes particularly relevant in ultra-high temperature research or industrial processes that demand even higher operating temperatures.

Another limitation of nichrome is its susceptibility to sulfur attack at high temperatures. In environments containing sulfur-bearing gases, nichrome can experience accelerated corrosion, leading to premature failure of the equipment. This vulnerability necessitates careful consideration of the operating environment and may require alternative materials in sulfur-rich atmospheres.

Nichrome also faces challenges in terms of its thermal expansion characteristics. While its coefficient of thermal expansion is relatively low compared to many metals, it can still cause issues in applications requiring precise dimensional stability across wide temperature ranges. This property can lead to warping or distortion in certain laboratory equipment designs, potentially affecting experimental accuracy or equipment longevity.

Furthermore, while nichrome's electrical resistivity is advantageous for heating elements, it can be a limitation in applications requiring high electrical conductivity. This characteristic restricts its use in certain types of electrical contacts or conductive components within high-temperature laboratory equipment.

In conclusion, while nichrome remains a crucial material in high-temperature laboratory equipment, its current limitations in maximum operating temperature, sulfur resistance, thermal expansion, and electrical conductivity present ongoing challenges for researchers and equipment designers. Addressing these limitations through material modifications or alternative alloy development continues to be an active area of research in the field of high-temperature materials science.

The material exhibits excellent electrical resistivity, which remains relatively stable across a wide temperature range. This property, combined with its high melting point of approximately 1400°C, allows nichrome to function effectively in heating elements that require consistent performance under extreme conditions. Additionally, nichrome possesses good mechanical strength and ductility, enabling it to withstand thermal cycling and mechanical stresses common in laboratory settings.

Despite its numerous advantages, nichrome does face certain limitations that restrict its use in some high-temperature applications. One significant constraint is its maximum operating temperature, which is typically around 1200°C for continuous use. Beyond this temperature, the material's oxidation resistance begins to degrade, leading to potential failure of the equipment. This limitation becomes particularly relevant in ultra-high temperature research or industrial processes that demand even higher operating temperatures.

Another limitation of nichrome is its susceptibility to sulfur attack at high temperatures. In environments containing sulfur-bearing gases, nichrome can experience accelerated corrosion, leading to premature failure of the equipment. This vulnerability necessitates careful consideration of the operating environment and may require alternative materials in sulfur-rich atmospheres.

Nichrome also faces challenges in terms of its thermal expansion characteristics. While its coefficient of thermal expansion is relatively low compared to many metals, it can still cause issues in applications requiring precise dimensional stability across wide temperature ranges. This property can lead to warping or distortion in certain laboratory equipment designs, potentially affecting experimental accuracy or equipment longevity.

Furthermore, while nichrome's electrical resistivity is advantageous for heating elements, it can be a limitation in applications requiring high electrical conductivity. This characteristic restricts its use in certain types of electrical contacts or conductive components within high-temperature laboratory equipment.

In conclusion, while nichrome remains a crucial material in high-temperature laboratory equipment, its current limitations in maximum operating temperature, sulfur resistance, thermal expansion, and electrical conductivity present ongoing challenges for researchers and equipment designers. Addressing these limitations through material modifications or alternative alloy development continues to be an active area of research in the field of high-temperature materials science.

Current Nichrome Applications in Lab Equipment

01 Composition and properties of nichrome alloys

Nichrome is an alloy primarily composed of nickel and chromium, with varying compositions for different applications. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.- Composition and properties of Nichrome alloys: Nichrome is an alloy primarily composed of nickel and chromium, with varying compositions for different applications. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.

- Manufacturing processes for Nichrome components: Various manufacturing processes are employed to produce Nichrome components, including wire drawing, thin film deposition, and powder metallurgy techniques. These processes aim to achieve specific dimensions, properties, and performance characteristics for different applications.

- Applications in heating elements and sensors: Nichrome is widely used in heating elements for appliances, industrial equipment, and scientific instruments due to its high resistance and stability at elevated temperatures. It is also utilized in temperature sensors and thermocouples for accurate temperature measurement and control.

- Nichrome in electronic and electrical components: Nichrome finds applications in various electronic and electrical components, including resistors, potentiometers, and circuit elements. Its stable electrical properties and resistance to oxidation make it suitable for use in precision instruments and control systems.

- Surface treatments and coatings for Nichrome: Various surface treatments and coatings are applied to Nichrome components to enhance their performance, durability, and specific properties. These treatments may include oxidation resistance coatings, insulation layers, or protective films to improve the longevity and functionality of Nichrome-based products.

02 Manufacturing processes for nichrome components

Various manufacturing processes are employed to produce nichrome components, including wire drawing, thin film deposition, and powder metallurgy. These processes allow for the creation of nichrome wires, films, and other forms used in different applications. Specific techniques may be used to control the microstructure and properties of the final product.Expand Specific Solutions03 Applications in heating elements and sensors

Nichrome is widely used in heating elements for appliances, industrial equipment, and scientific instruments due to its high resistance and stability at elevated temperatures. It is also employed in temperature sensors and thermocouples, taking advantage of its thermoelectric properties and resistance to oxidation.Expand Specific Solutions04 Use in electronic and electrical components

Nichrome finds applications in various electronic and electrical components, including resistors, potentiometers, and circuit elements. Its stable electrical properties and ability to withstand high temperatures make it suitable for use in precision instruments and high-reliability electronics.Expand Specific Solutions05 Surface treatment and coating techniques

Various surface treatment and coating techniques are applied to nichrome components to enhance their properties or protect them from environmental factors. These may include oxidation treatments, protective coatings, or surface modifications to improve adhesion, wear resistance, or other specific characteristics.Expand Specific Solutions

Key Manufacturers in Lab Equipment Industry

The research on Nichrome in high-temperature lab equipment is in a mature stage, with a well-established market and diverse applications. The competitive landscape is characterized by a mix of academic institutions, specialized manufacturers, and large multinational corporations. Companies like JEOL Ltd., Samsung Electro-Mechanics, and General Electric are leveraging their extensive R&D capabilities to develop advanced Nichrome-based solutions. Smaller firms such as SLT-Technologies and Gaona Aero Material are focusing on niche applications, while research institutions like Kyoto University and CNRS are driving fundamental advancements. The market is expected to grow steadily due to increasing demand in sectors such as aerospace, electronics, and materials science.

SLT-Technologies GmbH & Co. KG

Technical Solution: SLT-Technologies has focused on developing precision nichrome wire and foil products for high-temperature lab equipment. Their research emphasizes the production of ultra-thin nichrome elements with tight tolerances and consistent properties. SLT's manufacturing process includes multiple drawing and annealing steps to achieve wire diameters as small as 10 micrometers while maintaining uniform composition[7]. They have also developed proprietary surface treatments to enhance the oxidation resistance and electrical stability of their nichrome products at high temperatures. SLT's nichrome wires and foils are widely used in miniaturized heating elements, sensors, and specialized lab equipment requiring rapid thermal response and precise temperature control[8].

Strengths: Ultra-thin wire and foil products, excellent dimensional consistency, rapid thermal response. Weaknesses: Limited to wire and foil forms, potentially more susceptible to mechanical damage due to small dimensions.

Gaona Aero Material Co., Ltd.

Technical Solution: Gaona Aero Material Co., Ltd. has conducted research on high-performance nichrome alloys for aerospace and laboratory applications. Their focus is on developing nichrome variants with improved high-temperature strength and oxidation resistance. Gaona's nichrome alloys incorporate small amounts of rare earth elements and refractory metals to enhance grain boundary strength and oxide scale adhesion[9]. They have implemented a sophisticated vacuum induction melting and electroslag remelting process to ensure high purity and consistent microstructure. Gaona's nichrome products demonstrate exceptional creep resistance at temperatures up to 1300°C, making them suitable for long-term use in high-temperature lab furnaces and thermal processing equipment[10].

Strengths: Exceptional high-temperature strength and creep resistance, improved long-term stability in oxidizing environments. Weaknesses: Higher cost due to rare earth additions and specialized processing, limited availability in certain product forms.

Innovations in Nichrome Composition and Structure

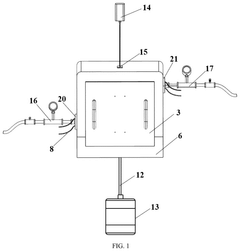

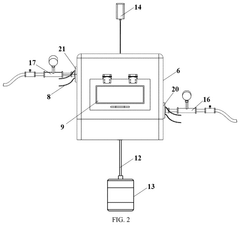

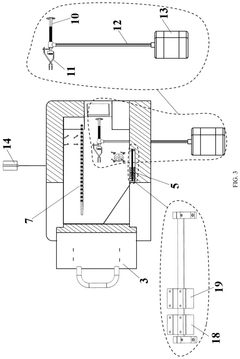

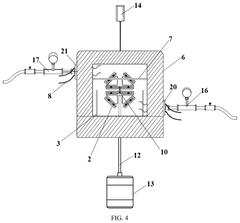

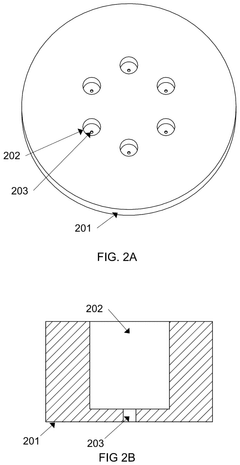

High-temperature vibration modal testing device for variable cross-section carbon fiber resin-based composites

PatentActiveUS12241867B1

Innovation

- A high-temperature vibration modal testing device is designed to create a thermal vibration environment above 1000°C for variable cross-section carbon fiber resin-based composites, using an infrared radiation heating array and a ceramic force transmission rod to apply random vibration, while a laser vibration measurer and protective gas environment ensure safe and accurate testing.

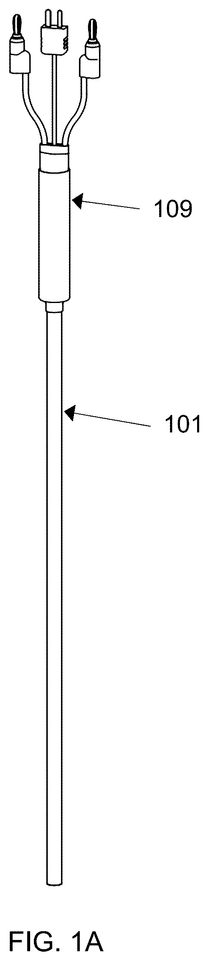

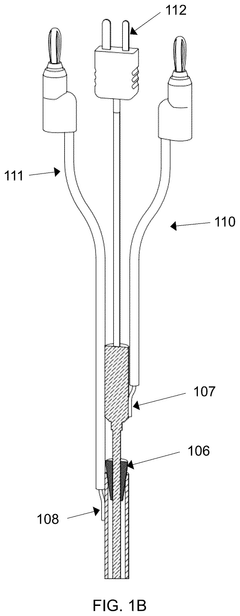

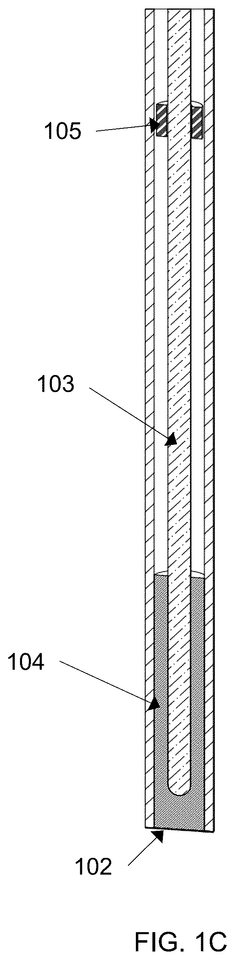

High-temperature reference electrode, venturi flow tip for a high-temperature reference electrode, and engineered salt bridge for a high-temperature reference electrode

PatentPendingUS20250216357A1

Innovation

- Development of a high-temperature reference electrode with a venturi flow tip and engineered salt bridge, allowing the use of commercial off-the-shelf electrodes in high-temperature environments, and incorporating features like a porous membrane, thermocouple reference wire, and insulating coatings to withstand extreme temperatures and prevent corrosion.

Safety Standards for High-Temp Lab Equipment

Safety standards for high-temperature laboratory equipment are crucial for ensuring the well-being of researchers and the integrity of experiments. These standards encompass a wide range of considerations, from material selection to operational procedures. In the context of nichrome usage in high-temperature lab equipment, safety standards are particularly stringent due to the extreme conditions involved.

One of the primary safety concerns is the prevention of electrical hazards. Nichrome, being an electrical resistance alloy, requires proper insulation and grounding to prevent electric shock. Safety standards mandate the use of high-quality insulation materials that can withstand the high temperatures generated by nichrome heating elements. Regular inspections and maintenance of electrical connections are also required to prevent short circuits or arcing.

Thermal management is another critical aspect of safety standards. High-temperature equipment must be designed with adequate heat dissipation mechanisms to prevent overheating and potential fire hazards. This includes the use of heat-resistant materials for equipment housing and the implementation of temperature control systems with fail-safe mechanisms. Safety standards often specify maximum operating temperatures and require the installation of thermal cutoff devices to automatically shut down equipment if temperature limits are exceeded.

Ventilation and fume control are essential components of safety standards for high-temperature lab equipment. When nichrome is heated to extreme temperatures, it may release potentially harmful fumes or particulates. Safety guidelines mandate the use of proper ventilation systems, including fume hoods and exhaust systems, to remove any hazardous emissions from the laboratory environment. Regular air quality monitoring may also be required to ensure compliance with occupational health and safety regulations.

Personal protective equipment (PPE) requirements are clearly outlined in safety standards for high-temperature lab work. This typically includes heat-resistant gloves, face shields, and protective clothing made from flame-retardant materials. Training in the proper use of PPE and emergency procedures is mandatory for all personnel working with high-temperature equipment.

Emergency response protocols form a critical part of safety standards. These include the installation of easily accessible emergency shut-off switches, fire suppression systems, and clearly marked evacuation routes. Regular safety drills and training sessions are required to ensure that all laboratory personnel are familiar with emergency procedures and can respond effectively in case of accidents or equipment malfunctions.

Material compatibility is another important consideration in safety standards. Nichrome and other materials used in high-temperature equipment must be carefully selected to avoid unwanted chemical reactions or degradation at elevated temperatures. Standards may specify approved materials lists and require documentation of material properties and compatibility testing.

Lastly, safety standards for high-temperature lab equipment emphasize the importance of proper documentation and record-keeping. This includes maintaining detailed logs of equipment usage, maintenance schedules, and any incidents or near-misses. Regular safety audits and compliance checks are typically mandated to ensure ongoing adherence to established safety protocols and to identify areas for improvement in equipment design and operational procedures.

One of the primary safety concerns is the prevention of electrical hazards. Nichrome, being an electrical resistance alloy, requires proper insulation and grounding to prevent electric shock. Safety standards mandate the use of high-quality insulation materials that can withstand the high temperatures generated by nichrome heating elements. Regular inspections and maintenance of electrical connections are also required to prevent short circuits or arcing.

Thermal management is another critical aspect of safety standards. High-temperature equipment must be designed with adequate heat dissipation mechanisms to prevent overheating and potential fire hazards. This includes the use of heat-resistant materials for equipment housing and the implementation of temperature control systems with fail-safe mechanisms. Safety standards often specify maximum operating temperatures and require the installation of thermal cutoff devices to automatically shut down equipment if temperature limits are exceeded.

Ventilation and fume control are essential components of safety standards for high-temperature lab equipment. When nichrome is heated to extreme temperatures, it may release potentially harmful fumes or particulates. Safety guidelines mandate the use of proper ventilation systems, including fume hoods and exhaust systems, to remove any hazardous emissions from the laboratory environment. Regular air quality monitoring may also be required to ensure compliance with occupational health and safety regulations.

Personal protective equipment (PPE) requirements are clearly outlined in safety standards for high-temperature lab work. This typically includes heat-resistant gloves, face shields, and protective clothing made from flame-retardant materials. Training in the proper use of PPE and emergency procedures is mandatory for all personnel working with high-temperature equipment.

Emergency response protocols form a critical part of safety standards. These include the installation of easily accessible emergency shut-off switches, fire suppression systems, and clearly marked evacuation routes. Regular safety drills and training sessions are required to ensure that all laboratory personnel are familiar with emergency procedures and can respond effectively in case of accidents or equipment malfunctions.

Material compatibility is another important consideration in safety standards. Nichrome and other materials used in high-temperature equipment must be carefully selected to avoid unwanted chemical reactions or degradation at elevated temperatures. Standards may specify approved materials lists and require documentation of material properties and compatibility testing.

Lastly, safety standards for high-temperature lab equipment emphasize the importance of proper documentation and record-keeping. This includes maintaining detailed logs of equipment usage, maintenance schedules, and any incidents or near-misses. Regular safety audits and compliance checks are typically mandated to ensure ongoing adherence to established safety protocols and to identify areas for improvement in equipment design and operational procedures.

Environmental Impact of Nichrome Production

The production of nichrome, a widely used alloy in high-temperature laboratory equipment, has significant environmental implications that warrant careful consideration. The manufacturing process involves the extraction and processing of nickel and chromium, two metals with substantial environmental footprints.

Mining operations for nickel and chromium contribute to land degradation, habitat destruction, and potential water pollution. Open-pit mining, commonly used for these metals, leads to large-scale landscape alterations and can disrupt local ecosystems. The extraction process often requires the removal of substantial amounts of overburden, resulting in increased erosion and sedimentation in nearby water bodies.

The refining of nickel and chromium is energy-intensive, contributing to greenhouse gas emissions and air pollution. Smelting operations release sulfur dioxide, particulate matter, and heavy metals into the atmosphere, potentially impacting air quality in surrounding areas. Additionally, the high energy demand of these processes often relies on fossil fuel consumption, further exacerbating carbon emissions.

Water usage and contamination are critical concerns in nichrome production. Both nickel and chromium processing require significant volumes of water for cooling, cleaning, and chemical processes. This can strain local water resources, particularly in water-scarce regions. Moreover, wastewater from these operations may contain toxic compounds and heavy metals, posing risks to aquatic ecosystems if not properly treated.

The disposal of waste products from nichrome manufacturing presents another environmental challenge. Slag, tailings, and other byproducts can contain hazardous materials that require careful management to prevent soil and groundwater contamination. Improper disposal practices can lead to long-term environmental degradation and potential health risks for nearby communities.

Recycling and resource recovery efforts in the nichrome industry can help mitigate some of these environmental impacts. Reclaiming nichrome from discarded laboratory equipment and industrial scrap can reduce the demand for primary metal extraction. However, the recycling process itself requires energy and may generate its own set of environmental concerns, albeit typically less severe than primary production.

As environmental regulations become more stringent, nichrome manufacturers are increasingly adopting cleaner production technologies and waste management practices. These include improved filtration systems for air emissions, closed-loop water recycling systems, and more efficient energy utilization. Such advancements aim to reduce the overall environmental footprint of nichrome production, though challenges remain in balancing economic viability with environmental stewardship.

Mining operations for nickel and chromium contribute to land degradation, habitat destruction, and potential water pollution. Open-pit mining, commonly used for these metals, leads to large-scale landscape alterations and can disrupt local ecosystems. The extraction process often requires the removal of substantial amounts of overburden, resulting in increased erosion and sedimentation in nearby water bodies.

The refining of nickel and chromium is energy-intensive, contributing to greenhouse gas emissions and air pollution. Smelting operations release sulfur dioxide, particulate matter, and heavy metals into the atmosphere, potentially impacting air quality in surrounding areas. Additionally, the high energy demand of these processes often relies on fossil fuel consumption, further exacerbating carbon emissions.

Water usage and contamination are critical concerns in nichrome production. Both nickel and chromium processing require significant volumes of water for cooling, cleaning, and chemical processes. This can strain local water resources, particularly in water-scarce regions. Moreover, wastewater from these operations may contain toxic compounds and heavy metals, posing risks to aquatic ecosystems if not properly treated.

The disposal of waste products from nichrome manufacturing presents another environmental challenge. Slag, tailings, and other byproducts can contain hazardous materials that require careful management to prevent soil and groundwater contamination. Improper disposal practices can lead to long-term environmental degradation and potential health risks for nearby communities.

Recycling and resource recovery efforts in the nichrome industry can help mitigate some of these environmental impacts. Reclaiming nichrome from discarded laboratory equipment and industrial scrap can reduce the demand for primary metal extraction. However, the recycling process itself requires energy and may generate its own set of environmental concerns, albeit typically less severe than primary production.

As environmental regulations become more stringent, nichrome manufacturers are increasingly adopting cleaner production technologies and waste management practices. These include improved filtration systems for air emissions, closed-loop water recycling systems, and more efficient energy utilization. Such advancements aim to reduce the overall environmental footprint of nichrome production, though challenges remain in balancing economic viability with environmental stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!