Novel Piezoelectric Ceramics for Advanced Sensing

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Ceramics Background and Objectives

Piezoelectric ceramics have been at the forefront of sensing technology for decades, revolutionizing various industries with their unique ability to convert mechanical stress into electrical signals and vice versa. The journey of piezoelectric materials began with the discovery of the piezoelectric effect in quartz by Jacques and Pierre Curie in 1880. Since then, the field has witnessed remarkable advancements, particularly in the development of synthetic piezoelectric ceramics.

The evolution of piezoelectric ceramics has been driven by the increasing demand for more sensitive, reliable, and versatile sensing solutions across multiple sectors. From aerospace and automotive to medical diagnostics and consumer electronics, the applications of piezoelectric ceramics have expanded exponentially. This growth has been fueled by continuous improvements in material composition, manufacturing techniques, and device design.

In recent years, the focus has shifted towards developing novel piezoelectric ceramics that can overcome the limitations of traditional materials. These limitations include temperature sensitivity, brittleness, and restricted operational frequency ranges. The primary objective of current research is to create advanced piezoelectric ceramics that exhibit enhanced performance characteristics, such as higher sensitivity, broader frequency response, improved temperature stability, and greater durability.

One of the key trends in piezoelectric ceramics research is the exploration of lead-free alternatives. This shift is driven by environmental concerns and regulatory pressures to reduce the use of toxic materials. Researchers are investigating various compositions based on bismuth, potassium, and sodium to develop eco-friendly piezoelectric ceramics that can match or surpass the performance of lead-based materials.

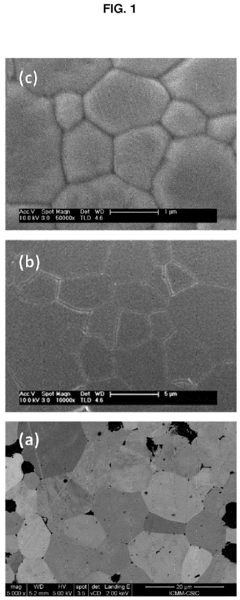

Another significant trend is the development of nanostructured piezoelectric ceramics. By manipulating the material at the nanoscale, scientists aim to enhance the piezoelectric properties and create materials with unprecedented sensitivity and efficiency. This approach opens up new possibilities for miniaturization and integration of sensors in compact devices.

The objectives of current research on novel piezoelectric ceramics for advanced sensing are multifaceted. They include improving the electromechanical coupling coefficient, increasing the Curie temperature for high-temperature applications, enhancing the mechanical strength and flexibility of the materials, and developing ceramics with tailored properties for specific sensing applications.

Furthermore, there is a growing interest in creating multifunctional piezoelectric ceramics that can simultaneously sense multiple parameters or combine sensing with energy harvesting capabilities. This direction of research aims to develop smart materials that can adapt to changing environmental conditions and provide more comprehensive data for advanced sensing systems.

The evolution of piezoelectric ceramics has been driven by the increasing demand for more sensitive, reliable, and versatile sensing solutions across multiple sectors. From aerospace and automotive to medical diagnostics and consumer electronics, the applications of piezoelectric ceramics have expanded exponentially. This growth has been fueled by continuous improvements in material composition, manufacturing techniques, and device design.

In recent years, the focus has shifted towards developing novel piezoelectric ceramics that can overcome the limitations of traditional materials. These limitations include temperature sensitivity, brittleness, and restricted operational frequency ranges. The primary objective of current research is to create advanced piezoelectric ceramics that exhibit enhanced performance characteristics, such as higher sensitivity, broader frequency response, improved temperature stability, and greater durability.

One of the key trends in piezoelectric ceramics research is the exploration of lead-free alternatives. This shift is driven by environmental concerns and regulatory pressures to reduce the use of toxic materials. Researchers are investigating various compositions based on bismuth, potassium, and sodium to develop eco-friendly piezoelectric ceramics that can match or surpass the performance of lead-based materials.

Another significant trend is the development of nanostructured piezoelectric ceramics. By manipulating the material at the nanoscale, scientists aim to enhance the piezoelectric properties and create materials with unprecedented sensitivity and efficiency. This approach opens up new possibilities for miniaturization and integration of sensors in compact devices.

The objectives of current research on novel piezoelectric ceramics for advanced sensing are multifaceted. They include improving the electromechanical coupling coefficient, increasing the Curie temperature for high-temperature applications, enhancing the mechanical strength and flexibility of the materials, and developing ceramics with tailored properties for specific sensing applications.

Furthermore, there is a growing interest in creating multifunctional piezoelectric ceramics that can simultaneously sense multiple parameters or combine sensing with energy harvesting capabilities. This direction of research aims to develop smart materials that can adapt to changing environmental conditions and provide more comprehensive data for advanced sensing systems.

Market Analysis for Advanced Sensing Applications

The market for advanced sensing applications utilizing novel piezoelectric ceramics is experiencing significant growth, driven by increasing demand across various industries. The global advanced sensor market is projected to reach $38.7 billion by 2025, with a compound annual growth rate (CAGR) of 9.2% from 2020 to 2025. This growth is primarily fueled by the rising adoption of Internet of Things (IoT) devices, smart manufacturing processes, and the need for enhanced safety and security systems.

In the automotive sector, piezoelectric sensors are gaining traction for applications such as tire pressure monitoring, engine knock detection, and advanced driver assistance systems (ADAS). The automotive sensor market alone is expected to grow at a CAGR of 6.8% from 2020 to 2025, reaching $37.6 billion. This growth is largely attributed to the increasing focus on vehicle electrification and autonomous driving technologies.

The healthcare industry is another key market for advanced sensing applications. Piezoelectric sensors are being utilized in medical imaging devices, surgical instruments, and wearable health monitoring devices. The global medical sensors market is anticipated to reach $15.2 billion by 2025, growing at a CAGR of 8.5% from 2020 to 2025. The demand for non-invasive diagnostic tools and personalized healthcare solutions is driving this growth.

In the industrial sector, novel piezoelectric ceramics are finding applications in structural health monitoring, vibration sensing, and process control. The industrial sensor market is expected to grow at a CAGR of 7.3% from 2020 to 2025, reaching $21.6 billion. This growth is driven by the increasing adoption of Industry 4.0 technologies and the need for predictive maintenance in manufacturing facilities.

The aerospace and defense sector is also a significant market for advanced sensing applications. Piezoelectric sensors are used in aircraft structural health monitoring, missile guidance systems, and underwater acoustic sensing. The aerospace and defense sensor market is projected to grow at a CAGR of 5.9% from 2020 to 2025, reaching $4.8 billion.

Geographically, North America and Europe are currently the largest markets for advanced sensing applications, owing to their well-established industrial and automotive sectors. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing automotive production, and government initiatives promoting smart manufacturing.

Key challenges in the market include the high cost of advanced piezoelectric materials and the complexity of integrating these sensors into existing systems. However, ongoing research and development efforts are focused on addressing these challenges, potentially opening up new opportunities for market growth and technological advancements in the field of novel piezoelectric ceramics for advanced sensing applications.

In the automotive sector, piezoelectric sensors are gaining traction for applications such as tire pressure monitoring, engine knock detection, and advanced driver assistance systems (ADAS). The automotive sensor market alone is expected to grow at a CAGR of 6.8% from 2020 to 2025, reaching $37.6 billion. This growth is largely attributed to the increasing focus on vehicle electrification and autonomous driving technologies.

The healthcare industry is another key market for advanced sensing applications. Piezoelectric sensors are being utilized in medical imaging devices, surgical instruments, and wearable health monitoring devices. The global medical sensors market is anticipated to reach $15.2 billion by 2025, growing at a CAGR of 8.5% from 2020 to 2025. The demand for non-invasive diagnostic tools and personalized healthcare solutions is driving this growth.

In the industrial sector, novel piezoelectric ceramics are finding applications in structural health monitoring, vibration sensing, and process control. The industrial sensor market is expected to grow at a CAGR of 7.3% from 2020 to 2025, reaching $21.6 billion. This growth is driven by the increasing adoption of Industry 4.0 technologies and the need for predictive maintenance in manufacturing facilities.

The aerospace and defense sector is also a significant market for advanced sensing applications. Piezoelectric sensors are used in aircraft structural health monitoring, missile guidance systems, and underwater acoustic sensing. The aerospace and defense sensor market is projected to grow at a CAGR of 5.9% from 2020 to 2025, reaching $4.8 billion.

Geographically, North America and Europe are currently the largest markets for advanced sensing applications, owing to their well-established industrial and automotive sectors. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing automotive production, and government initiatives promoting smart manufacturing.

Key challenges in the market include the high cost of advanced piezoelectric materials and the complexity of integrating these sensors into existing systems. However, ongoing research and development efforts are focused on addressing these challenges, potentially opening up new opportunities for market growth and technological advancements in the field of novel piezoelectric ceramics for advanced sensing applications.

Current Challenges in Piezoelectric Ceramic Technology

Despite significant advancements in piezoelectric ceramic technology, several challenges persist in the development of novel materials for advanced sensing applications. One of the primary obstacles is achieving a balance between high sensitivity and broad frequency range. Traditional piezoelectric ceramics often exhibit excellent performance in a narrow frequency band but struggle to maintain sensitivity across a wide spectrum, limiting their versatility in complex sensing environments.

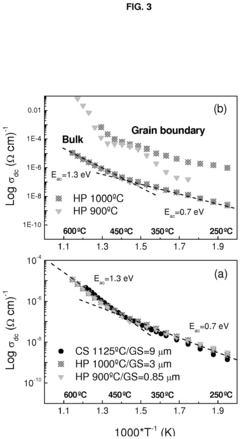

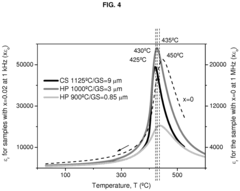

Another critical challenge lies in the enhancement of temperature stability. Many existing piezoelectric ceramics suffer from performance degradation at elevated temperatures, restricting their use in harsh environments such as automotive, aerospace, and industrial applications. Researchers are grappling with the task of developing materials that can maintain their piezoelectric properties over a broader temperature range without compromising other essential characteristics.

The miniaturization of piezoelectric sensors presents yet another hurdle. As devices become increasingly compact, there is a growing demand for piezoelectric ceramics that can deliver high performance in reduced dimensions. This challenge is particularly pronounced in the development of MEMS (Micro-Electro-Mechanical Systems) devices, where the integration of piezoelectric materials at the microscale introduces complexities in fabrication and reliability.

Durability and longevity of piezoelectric ceramics under continuous operation and in harsh conditions remain significant concerns. Fatigue, aging, and degradation of piezoelectric properties over time can lead to reduced sensor accuracy and reliability. Addressing these issues requires innovative approaches in material composition and structure to enhance the long-term stability of piezoelectric ceramics.

The environmental impact of piezoelectric materials is an emerging challenge that cannot be overlooked. Many high-performance piezoelectric ceramics contain lead, which poses environmental and health risks. The development of lead-free alternatives that can match or exceed the performance of lead-based materials is a critical area of research, driven by increasingly stringent environmental regulations worldwide.

Lastly, the scalability of production processes for novel piezoelectric ceramics presents a significant challenge. While promising materials may be developed in laboratory settings, transitioning these innovations to large-scale, cost-effective manufacturing processes remains a hurdle. This challenge encompasses aspects of material synthesis, quality control, and process optimization to ensure consistent properties across production batches.

Another critical challenge lies in the enhancement of temperature stability. Many existing piezoelectric ceramics suffer from performance degradation at elevated temperatures, restricting their use in harsh environments such as automotive, aerospace, and industrial applications. Researchers are grappling with the task of developing materials that can maintain their piezoelectric properties over a broader temperature range without compromising other essential characteristics.

The miniaturization of piezoelectric sensors presents yet another hurdle. As devices become increasingly compact, there is a growing demand for piezoelectric ceramics that can deliver high performance in reduced dimensions. This challenge is particularly pronounced in the development of MEMS (Micro-Electro-Mechanical Systems) devices, where the integration of piezoelectric materials at the microscale introduces complexities in fabrication and reliability.

Durability and longevity of piezoelectric ceramics under continuous operation and in harsh conditions remain significant concerns. Fatigue, aging, and degradation of piezoelectric properties over time can lead to reduced sensor accuracy and reliability. Addressing these issues requires innovative approaches in material composition and structure to enhance the long-term stability of piezoelectric ceramics.

The environmental impact of piezoelectric materials is an emerging challenge that cannot be overlooked. Many high-performance piezoelectric ceramics contain lead, which poses environmental and health risks. The development of lead-free alternatives that can match or exceed the performance of lead-based materials is a critical area of research, driven by increasingly stringent environmental regulations worldwide.

Lastly, the scalability of production processes for novel piezoelectric ceramics presents a significant challenge. While promising materials may be developed in laboratory settings, transitioning these innovations to large-scale, cost-effective manufacturing processes remains a hurdle. This challenge encompasses aspects of material synthesis, quality control, and process optimization to ensure consistent properties across production batches.

Existing Piezoelectric Ceramic Solutions

01 Novel piezoelectric ceramic compositions

Development of new piezoelectric ceramic materials with enhanced sensing capabilities. These compositions may include modified lead zirconate titanate (PZT) or lead-free alternatives, designed to improve sensitivity, temperature stability, and overall performance in sensing applications.- Novel piezoelectric ceramic compositions: Development of new piezoelectric ceramic materials with enhanced sensing properties. These compositions may include modified lead-free materials or doped ceramics to improve sensitivity, temperature stability, and overall performance for sensing applications.

- Piezoelectric ceramic sensor structures: Design of innovative sensor structures using piezoelectric ceramics. This includes multilayer configurations, thin films, and nanostructured materials to enhance sensitivity and broaden the range of detectable stimuli.

- Integration of piezoelectric ceramics in MEMS devices: Incorporation of piezoelectric ceramic materials into microelectromechanical systems (MEMS) for advanced sensing capabilities. This integration allows for miniaturization and improved performance in various sensing applications.

- Signal processing techniques for piezoelectric ceramic sensors: Development of advanced signal processing methods to enhance the sensitivity and accuracy of piezoelectric ceramic sensors. This includes noise reduction algorithms, data fusion techniques, and machine learning approaches for improved sensor performance.

- Applications of novel piezoelectric ceramic sensors: Exploration of new applications for piezoelectric ceramic sensors, including structural health monitoring, biomedical devices, environmental sensing, and energy harvesting. These applications leverage the unique properties of piezoelectric ceramics for improved sensing capabilities.

02 Fabrication techniques for piezoelectric ceramic sensors

Advanced manufacturing methods for producing piezoelectric ceramic sensors, including thin-film deposition, screen printing, and 3D printing technologies. These techniques aim to create more precise and efficient sensor structures with improved piezoelectric properties.Expand Specific Solutions03 Integration of piezoelectric ceramics in MEMS devices

Incorporation of piezoelectric ceramic materials into microelectromechanical systems (MEMS) for sensing applications. This integration enables the development of miniaturized, highly sensitive sensors for various fields such as automotive, aerospace, and consumer electronics.Expand Specific Solutions04 Signal processing and readout circuits for piezoelectric sensors

Development of advanced signal processing techniques and readout circuits specifically designed for piezoelectric ceramic sensors. These innovations aim to improve signal-to-noise ratio, reduce interference, and enhance the overall sensitivity and accuracy of the sensing system.Expand Specific Solutions05 Application-specific piezoelectric ceramic sensor designs

Customized piezoelectric ceramic sensor designs tailored for specific applications such as pressure sensing, acceleration measurement, and vibration detection. These designs optimize the sensor geometry, electrode configuration, and packaging to meet the unique requirements of each application.Expand Specific Solutions

Key Players in Piezoelectric Ceramic Industry

The research on novel piezoelectric ceramics for advanced sensing is in a mature development stage, with a significant global market estimated to reach $31.8 billion by 2028. The technology has evolved from basic materials to sophisticated sensing applications across various industries. Key players like TDK Corp., Kyocera Corp., and Murata Manufacturing Co. Ltd. have established strong positions through continuous innovation and product development. Universities such as Tianjin University and Xiamen University contribute to fundamental research, while companies like CeramTec GmbH and AAC Technologies focus on commercialization. The competitive landscape is characterized by a mix of large multinational corporations and specialized firms, with ongoing efforts to improve performance, miniaturization, and integration of piezoelectric sensors in emerging technologies.

TDK Corp.

Technical Solution: TDK has made significant advancements in piezoelectric ceramics for sensing applications. Their research focuses on developing high-performance lead-free piezoelectric materials, such as bismuth ferrite-based ceramics with enhanced piezoelectric properties[4]. TDK has also developed novel composite structures combining piezoelectric ceramics with polymers to create flexible sensors with improved sensitivity and durability[5]. Their innovative approach includes the use of nanostructured ceramics to enhance the piezoelectric response and energy harvesting capabilities. TDK has successfully applied these materials in various sensing devices, including pressure sensors, accelerometers, and ultrasonic transducers for medical imaging[6].

Strengths: Diverse product portfolio, strong market presence, advanced manufacturing capabilities. Weaknesses: Intense competition in the electronics industry, potential supply chain vulnerabilities.

Kyocera Corp.

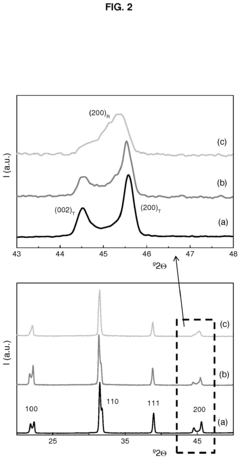

Technical Solution: Kyocera has made substantial progress in developing novel piezoelectric ceramics for advanced sensing applications. Their research focuses on creating lead-free piezoelectric materials with improved performance, such as potassium niobate-based ceramics with enhanced piezoelectric coefficients[7]. Kyocera has also developed innovative processing techniques, including spark plasma sintering, to produce dense and fine-grained piezoelectric ceramics with superior properties[8]. Their approach includes the development of textured ceramics to maximize the piezoelectric response in specific crystallographic directions. Kyocera has successfully applied these materials in various sensing devices, including high-frequency ultrasonic transducers and vibration sensors for structural health monitoring[9].

Strengths: Vertically integrated manufacturing, diverse technology portfolio, strong presence in multiple industries. Weaknesses: Reliance on traditional markets, potential challenges in adapting to rapidly changing technologies.

Innovative Piezoelectric Ceramic Compositions

A high temperature and power piezoelectric, bisco3-pbtio3 based ceramic material microstructurally engineered for enhanced mechanical performance, a procedure for obtaining said ceramic material and its use as part of an ultrasound generation device or ultrasonic actuation device

PatentInactiveEP3409651A1

Innovation

- A Bi0.36Pb0.64Sc0.36-xMn0.64O3 ceramic material with a tailored ultrafine grained microstructure and engineered point defects, achieved through hot pressing of nanocrystalline powders by mechanosynthesis, reduces dielectric and mechanical losses and enhances mechanical performance, maintaining high piezoelectric response.

Piezoelectric ceramic

PatentInactiveJP2020202338A

Innovation

- A piezoelectric ceramic with a perovskite crystal structure, composed of {(1-x)(1-y)BiFeO3-yLaFeO3}-xBaTiO3-zMnO2, where 0.1<x<0.3, 0<y≤0.1, 0<z≤0.01, optimized to enhance resistivity, densification, and piezoelectric characteristics by adding appropriate amounts of LaFeO3 and MnO2.

Environmental Impact of Piezoelectric Materials

The environmental impact of piezoelectric materials is a critical consideration in the development and application of novel piezoelectric ceramics for advanced sensing. These materials, while offering significant technological benefits, also pose potential environmental challenges throughout their lifecycle.

The production process of piezoelectric ceramics often involves the use of heavy metals and toxic elements, such as lead, which can have detrimental effects on ecosystems if not properly managed. Lead-based piezoelectric materials, like lead zirconate titanate (PZT), have been widely used due to their excellent piezoelectric properties. However, the toxicity of lead has raised concerns about environmental contamination and human health risks.

In response to these concerns, there has been a growing focus on developing lead-free piezoelectric materials. Alternatives such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT) are being explored as more environmentally friendly options. These materials aim to maintain high performance while reducing the ecological footprint associated with traditional lead-based piezoelectrics.

The disposal of piezoelectric devices at the end of their lifecycle presents another environmental challenge. Improper disposal can lead to the leaching of harmful substances into soil and water systems. To address this issue, researchers are investigating recycling methods for piezoelectric materials, aiming to recover valuable components and minimize waste.

Energy consumption during the manufacturing of piezoelectric ceramics is another environmental consideration. The high-temperature sintering processes required for ceramic production can be energy-intensive, contributing to carbon emissions. Efforts are being made to develop more energy-efficient production techniques, such as low-temperature sintering methods and microwave processing.

The use of piezoelectric materials in energy harvesting applications offers a positive environmental impact. These materials can convert mechanical energy from ambient vibrations into electrical energy, potentially reducing reliance on traditional power sources and lowering overall energy consumption in sensing systems.

As research on novel piezoelectric ceramics advances, there is an increasing emphasis on life cycle assessment (LCA) studies. These assessments evaluate the environmental impact of piezoelectric materials from raw material extraction to disposal, providing valuable insights for sustainable material design and production processes.

In conclusion, while piezoelectric ceramics offer significant technological advantages for advanced sensing, their environmental impact must be carefully considered. The development of eco-friendly alternatives, improved production processes, and effective recycling methods are crucial steps towards minimizing the ecological footprint of these materials while maintaining their performance benefits.

The production process of piezoelectric ceramics often involves the use of heavy metals and toxic elements, such as lead, which can have detrimental effects on ecosystems if not properly managed. Lead-based piezoelectric materials, like lead zirconate titanate (PZT), have been widely used due to their excellent piezoelectric properties. However, the toxicity of lead has raised concerns about environmental contamination and human health risks.

In response to these concerns, there has been a growing focus on developing lead-free piezoelectric materials. Alternatives such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT) are being explored as more environmentally friendly options. These materials aim to maintain high performance while reducing the ecological footprint associated with traditional lead-based piezoelectrics.

The disposal of piezoelectric devices at the end of their lifecycle presents another environmental challenge. Improper disposal can lead to the leaching of harmful substances into soil and water systems. To address this issue, researchers are investigating recycling methods for piezoelectric materials, aiming to recover valuable components and minimize waste.

Energy consumption during the manufacturing of piezoelectric ceramics is another environmental consideration. The high-temperature sintering processes required for ceramic production can be energy-intensive, contributing to carbon emissions. Efforts are being made to develop more energy-efficient production techniques, such as low-temperature sintering methods and microwave processing.

The use of piezoelectric materials in energy harvesting applications offers a positive environmental impact. These materials can convert mechanical energy from ambient vibrations into electrical energy, potentially reducing reliance on traditional power sources and lowering overall energy consumption in sensing systems.

As research on novel piezoelectric ceramics advances, there is an increasing emphasis on life cycle assessment (LCA) studies. These assessments evaluate the environmental impact of piezoelectric materials from raw material extraction to disposal, providing valuable insights for sustainable material design and production processes.

In conclusion, while piezoelectric ceramics offer significant technological advantages for advanced sensing, their environmental impact must be carefully considered. The development of eco-friendly alternatives, improved production processes, and effective recycling methods are crucial steps towards minimizing the ecological footprint of these materials while maintaining their performance benefits.

Standardization and Testing Protocols

Standardization and testing protocols play a crucial role in the development and implementation of novel piezoelectric ceramics for advanced sensing applications. These protocols ensure consistency, reliability, and comparability of results across different research groups and industrial settings. The establishment of standardized testing methods is essential for evaluating the performance, durability, and efficiency of new piezoelectric materials.

One of the primary aspects of standardization involves the preparation and characterization of piezoelectric ceramic samples. This includes defining specific dimensions, surface treatments, and electrode configurations to ensure uniformity in testing conditions. Standardized sample preparation techniques help minimize variations that could affect the accuracy of measurements and allow for more meaningful comparisons between different materials.

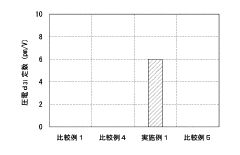

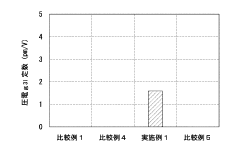

Electrical characterization protocols are fundamental in assessing the piezoelectric properties of novel ceramics. These typically include measurements of piezoelectric coefficients, electromechanical coupling factors, and dielectric constants. Standardized procedures for applying electric fields, measuring strain responses, and analyzing frequency-dependent behavior are essential for obtaining reliable and reproducible results. Additionally, protocols for measuring hysteresis loops and determining Curie temperatures are crucial for understanding the material's behavior under various operating conditions.

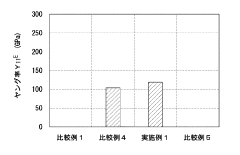

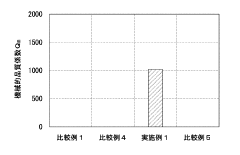

Mechanical testing protocols are equally important in evaluating the robustness and longevity of piezoelectric ceramics. These may include standardized methods for measuring elastic moduli, fracture toughness, and fatigue resistance. Cyclic loading tests and long-term stability assessments are particularly relevant for sensing applications, where the materials may be subjected to continuous or intermittent stress over extended periods.

Environmental testing protocols are critical for assessing the performance of piezoelectric ceramics under various operating conditions. This includes standardized procedures for evaluating temperature dependence, humidity resistance, and chemical stability. Accelerated aging tests and exposure to harsh environments help predict the long-term reliability of these materials in real-world sensing applications.

Sensitivity and resolution testing protocols are essential for determining the effectiveness of novel piezoelectric ceramics in sensing applications. These may include standardized methods for measuring minimum detectable signals, signal-to-noise ratios, and response times. Calibration procedures and reference standards are crucial for ensuring accurate and comparable measurements across different sensing systems.

The development of standardized testing protocols often involves collaboration between academic institutions, industry partners, and regulatory bodies. International organizations such as IEEE, ASTM, and IEC play a significant role in establishing and maintaining these standards. Regular review and updating of these protocols are necessary to keep pace with advancements in piezoelectric materials and sensing technologies.

One of the primary aspects of standardization involves the preparation and characterization of piezoelectric ceramic samples. This includes defining specific dimensions, surface treatments, and electrode configurations to ensure uniformity in testing conditions. Standardized sample preparation techniques help minimize variations that could affect the accuracy of measurements and allow for more meaningful comparisons between different materials.

Electrical characterization protocols are fundamental in assessing the piezoelectric properties of novel ceramics. These typically include measurements of piezoelectric coefficients, electromechanical coupling factors, and dielectric constants. Standardized procedures for applying electric fields, measuring strain responses, and analyzing frequency-dependent behavior are essential for obtaining reliable and reproducible results. Additionally, protocols for measuring hysteresis loops and determining Curie temperatures are crucial for understanding the material's behavior under various operating conditions.

Mechanical testing protocols are equally important in evaluating the robustness and longevity of piezoelectric ceramics. These may include standardized methods for measuring elastic moduli, fracture toughness, and fatigue resistance. Cyclic loading tests and long-term stability assessments are particularly relevant for sensing applications, where the materials may be subjected to continuous or intermittent stress over extended periods.

Environmental testing protocols are critical for assessing the performance of piezoelectric ceramics under various operating conditions. This includes standardized procedures for evaluating temperature dependence, humidity resistance, and chemical stability. Accelerated aging tests and exposure to harsh environments help predict the long-term reliability of these materials in real-world sensing applications.

Sensitivity and resolution testing protocols are essential for determining the effectiveness of novel piezoelectric ceramics in sensing applications. These may include standardized methods for measuring minimum detectable signals, signal-to-noise ratios, and response times. Calibration procedures and reference standards are crucial for ensuring accurate and comparable measurements across different sensing systems.

The development of standardized testing protocols often involves collaboration between academic institutions, industry partners, and regulatory bodies. International organizations such as IEEE, ASTM, and IEC play a significant role in establishing and maintaining these standards. Regular review and updating of these protocols are necessary to keep pace with advancements in piezoelectric materials and sensing technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!