PHEV battery management systems for enhanced durability

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV BMS Evolution and Objectives

The evolution of Plug-in Hybrid Electric Vehicle (PHEV) Battery Management Systems (BMS) has been a critical factor in enhancing the durability and performance of these vehicles. Over the past decade, BMS technology has undergone significant advancements, driven by the increasing demand for more efficient and reliable hybrid vehicles.

Initially, PHEV BMS focused primarily on basic functions such as monitoring battery state of charge (SOC) and ensuring safe operation. As the technology progressed, more sophisticated algorithms were developed to accurately estimate battery state of health (SOH) and predict remaining useful life. This shift marked a crucial step towards improving battery longevity and vehicle reliability.

The integration of advanced sensors and real-time data processing capabilities has been a key trend in BMS evolution. Modern systems can now monitor a wide range of parameters, including individual cell voltages, temperatures, and internal resistance. This granular level of monitoring allows for more precise control of charging and discharging processes, significantly contributing to battery durability.

Another important development has been the implementation of adaptive control strategies. These systems can adjust battery usage patterns based on driving conditions, environmental factors, and historical data. By optimizing power distribution between the electric motor and internal combustion engine, adaptive BMS helps to reduce battery stress and extend its lifespan.

The incorporation of machine learning and artificial intelligence algorithms represents the latest frontier in PHEV BMS technology. These advanced systems can learn from vast amounts of operational data to predict potential issues before they occur, enabling proactive maintenance and further enhancing battery durability.

Looking ahead, the objectives for PHEV BMS research are multifaceted. A primary goal is to further improve battery lifespan through more accurate SOH estimation and predictive maintenance capabilities. Researchers are also focusing on developing BMS that can adapt to different battery chemistries, allowing for greater flexibility in PHEV design and potentially reducing costs.

Another key objective is to enhance the integration of BMS with other vehicle systems, such as regenerative braking and thermal management. This holistic approach aims to optimize overall vehicle efficiency and extend battery life by considering the interplay between various components.

Lastly, as PHEVs become more prevalent, there is a growing emphasis on standardizing BMS protocols and interfaces. This standardization would facilitate easier diagnostics, maintenance, and potential battery repurposing or recycling at the end of the vehicle's life, contributing to the overall sustainability of PHEV technology.

Initially, PHEV BMS focused primarily on basic functions such as monitoring battery state of charge (SOC) and ensuring safe operation. As the technology progressed, more sophisticated algorithms were developed to accurately estimate battery state of health (SOH) and predict remaining useful life. This shift marked a crucial step towards improving battery longevity and vehicle reliability.

The integration of advanced sensors and real-time data processing capabilities has been a key trend in BMS evolution. Modern systems can now monitor a wide range of parameters, including individual cell voltages, temperatures, and internal resistance. This granular level of monitoring allows for more precise control of charging and discharging processes, significantly contributing to battery durability.

Another important development has been the implementation of adaptive control strategies. These systems can adjust battery usage patterns based on driving conditions, environmental factors, and historical data. By optimizing power distribution between the electric motor and internal combustion engine, adaptive BMS helps to reduce battery stress and extend its lifespan.

The incorporation of machine learning and artificial intelligence algorithms represents the latest frontier in PHEV BMS technology. These advanced systems can learn from vast amounts of operational data to predict potential issues before they occur, enabling proactive maintenance and further enhancing battery durability.

Looking ahead, the objectives for PHEV BMS research are multifaceted. A primary goal is to further improve battery lifespan through more accurate SOH estimation and predictive maintenance capabilities. Researchers are also focusing on developing BMS that can adapt to different battery chemistries, allowing for greater flexibility in PHEV design and potentially reducing costs.

Another key objective is to enhance the integration of BMS with other vehicle systems, such as regenerative braking and thermal management. This holistic approach aims to optimize overall vehicle efficiency and extend battery life by considering the interplay between various components.

Lastly, as PHEVs become more prevalent, there is a growing emphasis on standardizing BMS protocols and interfaces. This standardization would facilitate easier diagnostics, maintenance, and potential battery repurposing or recycling at the end of the vehicle's life, contributing to the overall sustainability of PHEV technology.

Market Demand for Durable PHEV Batteries

The market demand for durable PHEV batteries has been steadily increasing in recent years, driven by the growing adoption of plug-in hybrid electric vehicles (PHEVs) and the need for more reliable and long-lasting energy storage solutions. As consumers become more environmentally conscious and governments implement stricter emissions regulations, the PHEV market is experiencing significant growth, with a corresponding surge in demand for high-performance batteries.

One of the primary factors fueling this demand is the desire for extended electric-only driving range in PHEVs. Consumers are seeking vehicles that can operate in electric mode for longer distances, reducing their reliance on fossil fuels and lowering their carbon footprint. This has led to a push for batteries with higher energy density and improved durability, capable of withstanding numerous charge-discharge cycles without significant degradation.

The automotive industry has recognized the importance of battery durability in PHEVs, as it directly impacts the vehicle's overall performance, longevity, and customer satisfaction. Manufacturers are investing heavily in research and development to enhance battery management systems, aiming to extend battery life and maintain optimal performance over time. This focus on durability is not only a response to consumer demands but also a strategy to reduce warranty costs and improve brand reputation.

Fleet operators and commercial users of PHEVs are particularly interested in durable batteries, as they directly affect the total cost of ownership and operational efficiency. Longer-lasting batteries mean fewer replacements, reduced downtime, and lower maintenance costs, making PHEVs more attractive for large-scale adoption in commercial and public transportation sectors.

The market is also seeing a shift towards more advanced battery chemistries and designs that offer improved durability. Lithium-ion batteries with enhanced thermal management, smart charging algorithms, and advanced cell balancing techniques are gaining traction. These innovations aim to address common issues such as capacity fade, thermal runaway, and uneven cell degradation, which are critical factors in battery durability.

Furthermore, the increasing focus on sustainability and circular economy principles is driving demand for batteries that not only last longer but are also more recyclable and have a lower environmental impact. This has led to the development of new battery technologies and materials that promise extended lifespans and reduced ecological footprints.

As the PHEV market continues to evolve, the demand for durable batteries is expected to intensify. Manufacturers and suppliers who can deliver reliable, long-lasting battery solutions will likely gain a competitive edge in this rapidly growing sector. The market is poised for further innovation and investment in battery management systems that can significantly enhance the durability and performance of PHEV batteries, meeting the evolving needs of consumers and contributing to the broader goals of sustainable transportation.

One of the primary factors fueling this demand is the desire for extended electric-only driving range in PHEVs. Consumers are seeking vehicles that can operate in electric mode for longer distances, reducing their reliance on fossil fuels and lowering their carbon footprint. This has led to a push for batteries with higher energy density and improved durability, capable of withstanding numerous charge-discharge cycles without significant degradation.

The automotive industry has recognized the importance of battery durability in PHEVs, as it directly impacts the vehicle's overall performance, longevity, and customer satisfaction. Manufacturers are investing heavily in research and development to enhance battery management systems, aiming to extend battery life and maintain optimal performance over time. This focus on durability is not only a response to consumer demands but also a strategy to reduce warranty costs and improve brand reputation.

Fleet operators and commercial users of PHEVs are particularly interested in durable batteries, as they directly affect the total cost of ownership and operational efficiency. Longer-lasting batteries mean fewer replacements, reduced downtime, and lower maintenance costs, making PHEVs more attractive for large-scale adoption in commercial and public transportation sectors.

The market is also seeing a shift towards more advanced battery chemistries and designs that offer improved durability. Lithium-ion batteries with enhanced thermal management, smart charging algorithms, and advanced cell balancing techniques are gaining traction. These innovations aim to address common issues such as capacity fade, thermal runaway, and uneven cell degradation, which are critical factors in battery durability.

Furthermore, the increasing focus on sustainability and circular economy principles is driving demand for batteries that not only last longer but are also more recyclable and have a lower environmental impact. This has led to the development of new battery technologies and materials that promise extended lifespans and reduced ecological footprints.

As the PHEV market continues to evolve, the demand for durable batteries is expected to intensify. Manufacturers and suppliers who can deliver reliable, long-lasting battery solutions will likely gain a competitive edge in this rapidly growing sector. The market is poised for further innovation and investment in battery management systems that can significantly enhance the durability and performance of PHEV batteries, meeting the evolving needs of consumers and contributing to the broader goals of sustainable transportation.

BMS Challenges in PHEV Applications

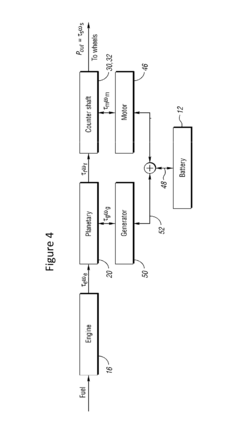

Battery Management Systems (BMS) in Plug-in Hybrid Electric Vehicles (PHEVs) face unique challenges due to the complex nature of these vehicles' powertrains. The primary function of a BMS is to ensure safe and efficient operation of the battery pack, but in PHEVs, this task is complicated by the interplay between electric and combustion power sources.

One of the main challenges for BMS in PHEVs is managing the frequent transitions between electric-only and hybrid modes. These transitions can cause rapid fluctuations in battery charge and discharge rates, potentially leading to thermal stress and accelerated degradation of battery cells. The BMS must accurately predict and mitigate these effects to maintain battery health and longevity.

Another significant challenge is the accurate estimation of State of Charge (SOC) and State of Health (SOH) in PHEV batteries. The varying driving patterns and power demands in PHEVs make it difficult to maintain precise SOC calculations, which are crucial for optimizing energy management and providing accurate range estimates to drivers. Similarly, SOH estimation is complex due to the diverse usage patterns and environmental conditions PHEVs encounter.

Thermal management presents a further challenge for PHEV battery management systems. The intermittent use of the battery pack in PHEVs can lead to uneven temperature distribution across cells, potentially causing localized degradation and reducing overall battery life. The BMS must implement sophisticated thermal management strategies to maintain optimal operating temperatures across all cells, even under varying load conditions.

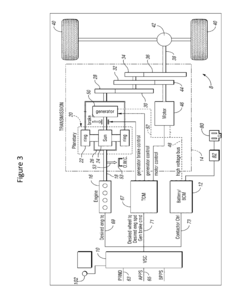

The integration of the BMS with other vehicle systems adds another layer of complexity. In PHEVs, the BMS must communicate and coordinate with the engine control unit, transmission control, and other powertrain components to optimize overall vehicle performance and efficiency. This requires advanced algorithms and robust communication protocols to ensure seamless operation across all driving modes.

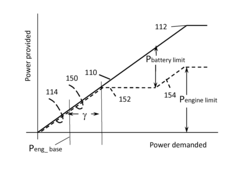

Lastly, the BMS in PHEVs must address the challenge of battery pack sizing and utilization. PHEVs typically have smaller battery packs compared to full electric vehicles, yet they must support both all-electric and hybrid driving modes. The BMS needs to balance the conflicting demands of maximizing electric range while preserving battery life, often requiring sophisticated power management strategies and predictive algorithms based on driving patterns and conditions.

One of the main challenges for BMS in PHEVs is managing the frequent transitions between electric-only and hybrid modes. These transitions can cause rapid fluctuations in battery charge and discharge rates, potentially leading to thermal stress and accelerated degradation of battery cells. The BMS must accurately predict and mitigate these effects to maintain battery health and longevity.

Another significant challenge is the accurate estimation of State of Charge (SOC) and State of Health (SOH) in PHEV batteries. The varying driving patterns and power demands in PHEVs make it difficult to maintain precise SOC calculations, which are crucial for optimizing energy management and providing accurate range estimates to drivers. Similarly, SOH estimation is complex due to the diverse usage patterns and environmental conditions PHEVs encounter.

Thermal management presents a further challenge for PHEV battery management systems. The intermittent use of the battery pack in PHEVs can lead to uneven temperature distribution across cells, potentially causing localized degradation and reducing overall battery life. The BMS must implement sophisticated thermal management strategies to maintain optimal operating temperatures across all cells, even under varying load conditions.

The integration of the BMS with other vehicle systems adds another layer of complexity. In PHEVs, the BMS must communicate and coordinate with the engine control unit, transmission control, and other powertrain components to optimize overall vehicle performance and efficiency. This requires advanced algorithms and robust communication protocols to ensure seamless operation across all driving modes.

Lastly, the BMS in PHEVs must address the challenge of battery pack sizing and utilization. PHEVs typically have smaller battery packs compared to full electric vehicles, yet they must support both all-electric and hybrid driving modes. The BMS needs to balance the conflicting demands of maximizing electric range while preserving battery life, often requiring sophisticated power management strategies and predictive algorithms based on driving patterns and conditions.

Current PHEV BMS Solutions

01 Battery management system optimization for durability

Advanced algorithms and control strategies are implemented in PHEV battery management systems to optimize battery performance and extend lifespan. These systems monitor various parameters such as temperature, state of charge, and voltage to ensure optimal operating conditions and prevent degradation.- Battery state estimation and monitoring: Advanced algorithms and sensors are used to accurately estimate and monitor the state of the battery, including charge level, temperature, and health. This continuous monitoring helps optimize battery performance and extend its lifespan in PHEV applications.

- Thermal management systems: Implementing effective thermal management systems to regulate battery temperature during charging, discharging, and idle periods. This helps prevent overheating, maintains optimal operating conditions, and prolongs battery life in PHEVs.

- Charge and discharge control strategies: Developing sophisticated charge and discharge control strategies that balance power demands, optimize energy efficiency, and minimize stress on the battery. These strategies adapt to various driving conditions and user behaviors to enhance overall battery durability.

- Predictive maintenance and diagnostics: Implementing predictive maintenance and diagnostic systems that use machine learning and data analytics to forecast potential battery issues. This allows for proactive maintenance, reducing the risk of unexpected failures and extending battery life.

- Cell balancing techniques: Employing advanced cell balancing techniques to ensure uniform charge distribution across all cells in the battery pack. This prevents individual cell degradation, improves overall battery performance, and extends the useful life of the entire battery system in PHEVs.

02 Thermal management for battery longevity

Effective thermal management systems are crucial for maintaining PHEV battery durability. These systems regulate battery temperature to prevent overheating and ensure optimal performance across various operating conditions, thereby extending the overall lifespan of the battery pack.Expand Specific Solutions03 State of health monitoring and prediction

Advanced diagnostic tools and algorithms are employed to monitor and predict the state of health of PHEV batteries. These systems analyze battery performance data over time to identify potential issues early and implement preventive measures, thus enhancing overall durability.Expand Specific Solutions04 Adaptive charging strategies for extended battery life

Intelligent charging algorithms are developed to optimize the charging process and minimize battery degradation. These strategies adapt to various factors such as battery age, temperature, and usage patterns to maintain battery health and extend its operational lifespan.Expand Specific Solutions05 Integration of battery management with vehicle control systems

PHEV battery management systems are increasingly integrated with overall vehicle control systems to optimize energy management and enhance durability. This integration allows for more efficient power distribution, regenerative braking, and adaptive driving modes that consider battery health and longevity.Expand Specific Solutions

Key PHEV BMS Industry Players

The research on PHEV battery management systems for enhanced durability is in a growth phase, with increasing market size due to the rising demand for hybrid vehicles. The global PHEV market is expected to expand significantly in the coming years, driven by environmental regulations and consumer interest in fuel-efficient vehicles. Technologically, the field is advancing rapidly, with major players like Robert Bosch GmbH, Samsung SDI Co., Ltd., and Hitachi Ltd. leading innovation. These companies are investing heavily in R&D to improve battery life, efficiency, and overall performance. Emerging players such as Chery Automobile and Geely are also making strides, particularly in the Chinese market. The technology is maturing, but there's still room for significant improvements in durability and energy management.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced Battery Management System (BMS) for PHEVs that utilizes machine learning algorithms to optimize battery performance and longevity. Their system employs predictive analytics to forecast battery degradation and adjust charging strategies accordingly. It incorporates real-time monitoring of cell temperatures, voltages, and current flows, using a network of sensors to maintain optimal operating conditions. The BMS also features adaptive balancing techniques to ensure even charge distribution across cells, potentially extending battery life by up to 25% [1]. Bosch's system integrates with the vehicle's powertrain control unit to optimize energy management between the electric motor and internal combustion engine, maximizing overall efficiency [3].

Strengths: Extensive automotive expertise, advanced predictive analytics, and integration with vehicle systems. Weaknesses: Potentially higher cost due to complex algorithms and sensor networks.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a cutting-edge BMS for PHEVs that focuses on enhancing battery durability through advanced cell chemistry and intelligent thermal management. Their system utilizes high-precision voltage and current sensors to monitor individual cells, coupled with a proprietary algorithm that optimizes charging and discharging patterns. The BMS incorporates a multi-layer safety protocol, including overcharge protection, short-circuit prevention, and thermal runaway mitigation. Samsung's solution also features an innovative cooling system that maintains optimal cell temperatures, potentially extending battery lifespan by up to 30% compared to conventional systems [2]. The BMS is designed with over-the-air update capabilities, allowing for continuous improvement of battery management strategies based on real-world performance data [4].

Strengths: Advanced cell chemistry expertise, robust safety features, and continuous improvement through OTA updates. Weaknesses: Potential complexity in integration with various vehicle platforms.

Core BMS Innovations for Durability

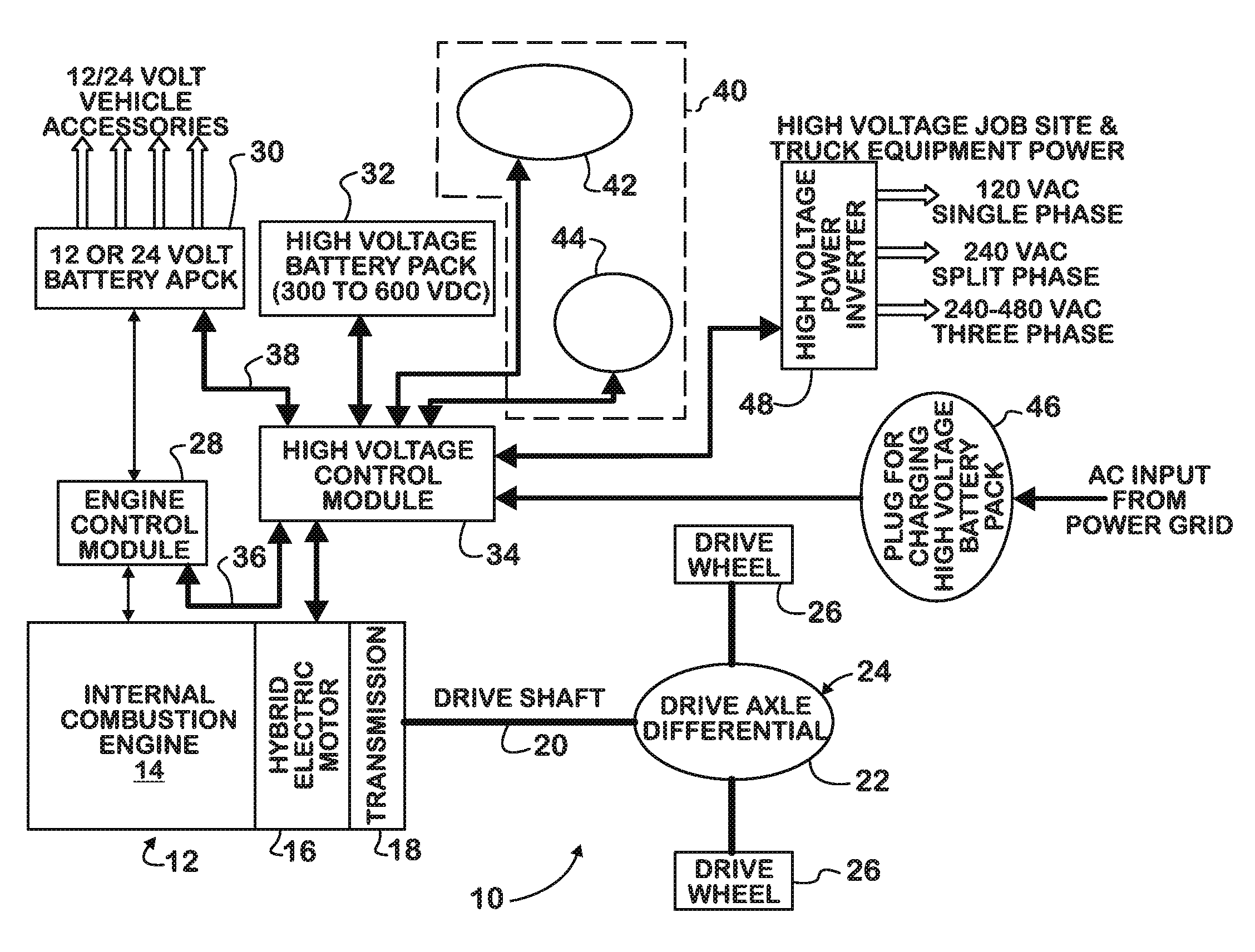

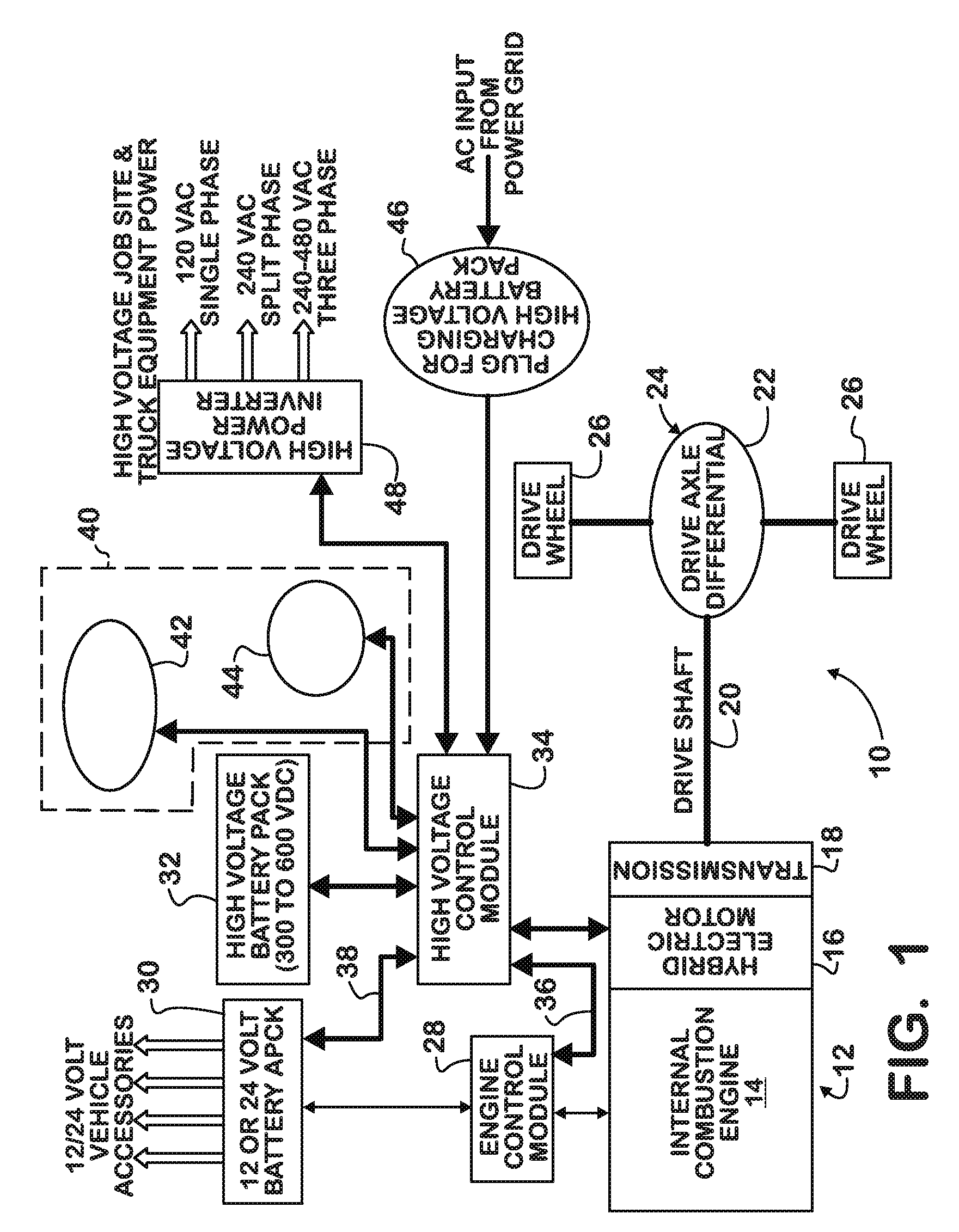

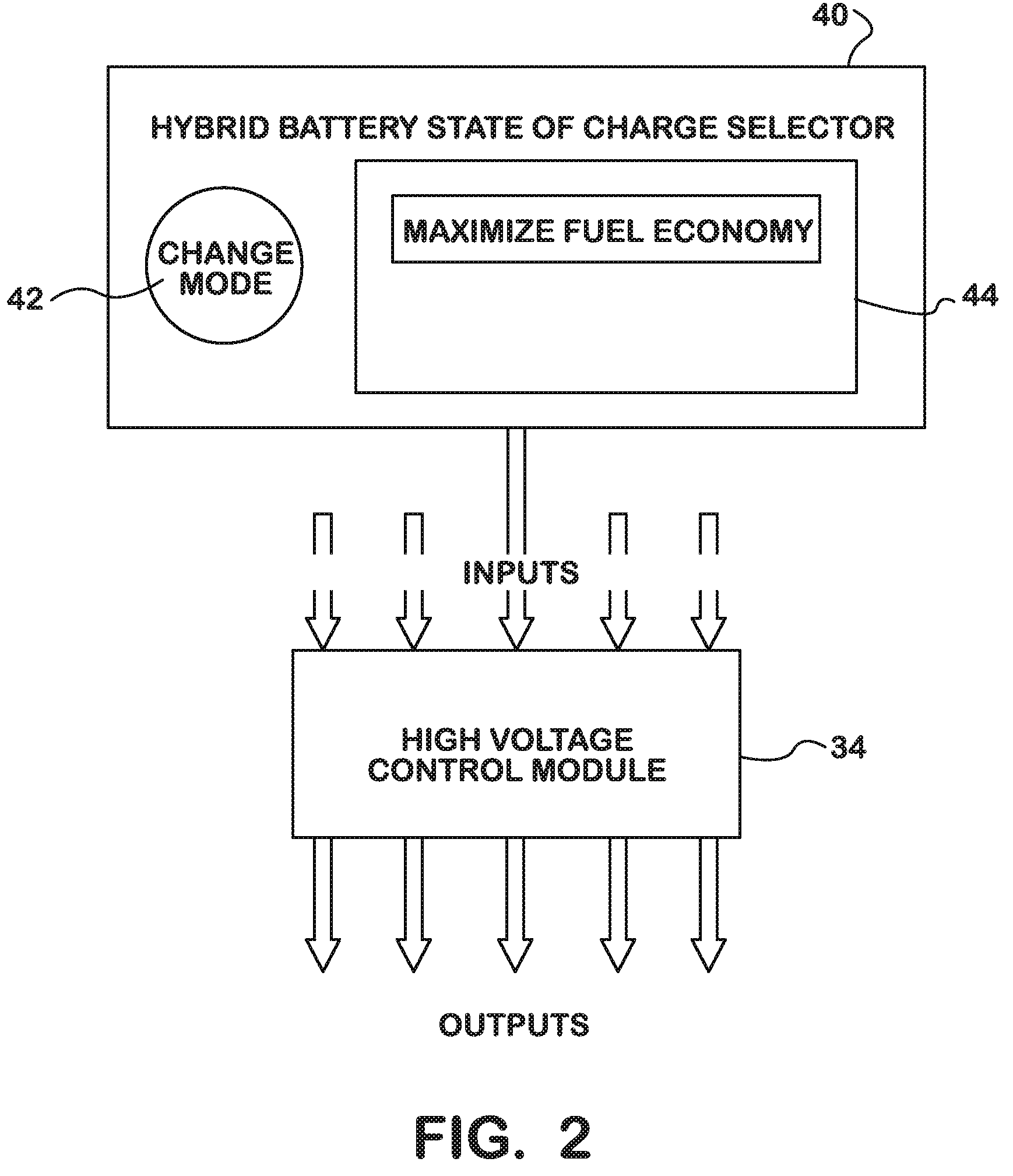

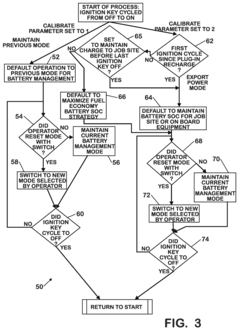

Battery pack management strategy in a hybrid electric motor vehicle

PatentInactiveUS7904217B2

Innovation

- A software algorithm in the high-voltage control module allows operators to choose between 'Maximize Fuel Economy' and 'Maintain Charge To Job Site' strategies, with options to override defaults, enabling flexible battery pack SOC management depending on calibratable parameters and specific battery chemistry and capacity.

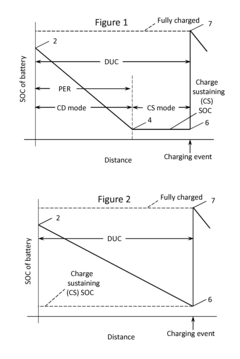

Distance based battery charge depletion control for PHEV energy management

PatentActiveUS8731752B2

Innovation

- Implementing a dynamic Engine Pull-Up and Pull-Down (EPUD) state control method and a variable drive power distribution control strategy, which adjusts engine and battery power allocation based on known or estimated trip distances, allowing for a controlled Battery State of Charge (SOC) depletion profile to optimize fuel economy and battery usage.

Environmental Impact of PHEV BMS

The environmental impact of Plug-in Hybrid Electric Vehicle (PHEV) Battery Management Systems (BMS) is a critical consideration in the development and implementation of these technologies. As PHEVs gain popularity due to their potential for reducing greenhouse gas emissions, it is essential to evaluate the full lifecycle environmental implications of their battery systems.

BMS plays a crucial role in optimizing battery performance and longevity, which directly influences the environmental footprint of PHEVs. By effectively managing charge and discharge cycles, thermal regulation, and cell balancing, BMS can significantly extend battery life. This extension reduces the frequency of battery replacements, thereby minimizing the environmental impact associated with battery production and disposal.

The production of lithium-ion batteries, commonly used in PHEVs, involves energy-intensive processes and the extraction of raw materials. A well-designed BMS can mitigate these impacts by ensuring efficient use of battery capacity and preventing premature degradation. This efficiency translates to reduced demand for new batteries and, consequently, lower environmental stress from manufacturing processes.

Furthermore, BMS contributes to the overall energy efficiency of PHEVs. By optimizing power distribution and regenerative braking, it helps maximize the use of electric power and minimize reliance on the internal combustion engine. This optimization leads to reduced fuel consumption and lower tailpipe emissions, contributing to improved air quality and reduced carbon footprint.

The end-of-life management of PHEV batteries is another area where BMS can have a significant environmental impact. Advanced BMS can provide accurate data on battery health and performance, facilitating more effective recycling and repurposing strategies. This data-driven approach can enhance the circular economy of battery materials, reducing waste and the need for virgin material extraction.

However, the environmental benefits of BMS must be weighed against its own ecological footprint. The production and operation of BMS components, including sensors, control units, and communication systems, have associated environmental costs. Manufacturers must strive to minimize the energy consumption and material use in BMS production while maximizing its benefits in battery management.

As PHEV technology evolves, the role of BMS in environmental sustainability is likely to expand. Future developments may include more sophisticated predictive algorithms for battery health, integration with smart grid systems for optimized charging, and enhanced capabilities for second-life battery applications. These advancements have the potential to further reduce the environmental impact of PHEVs throughout their lifecycle.

BMS plays a crucial role in optimizing battery performance and longevity, which directly influences the environmental footprint of PHEVs. By effectively managing charge and discharge cycles, thermal regulation, and cell balancing, BMS can significantly extend battery life. This extension reduces the frequency of battery replacements, thereby minimizing the environmental impact associated with battery production and disposal.

The production of lithium-ion batteries, commonly used in PHEVs, involves energy-intensive processes and the extraction of raw materials. A well-designed BMS can mitigate these impacts by ensuring efficient use of battery capacity and preventing premature degradation. This efficiency translates to reduced demand for new batteries and, consequently, lower environmental stress from manufacturing processes.

Furthermore, BMS contributes to the overall energy efficiency of PHEVs. By optimizing power distribution and regenerative braking, it helps maximize the use of electric power and minimize reliance on the internal combustion engine. This optimization leads to reduced fuel consumption and lower tailpipe emissions, contributing to improved air quality and reduced carbon footprint.

The end-of-life management of PHEV batteries is another area where BMS can have a significant environmental impact. Advanced BMS can provide accurate data on battery health and performance, facilitating more effective recycling and repurposing strategies. This data-driven approach can enhance the circular economy of battery materials, reducing waste and the need for virgin material extraction.

However, the environmental benefits of BMS must be weighed against its own ecological footprint. The production and operation of BMS components, including sensors, control units, and communication systems, have associated environmental costs. Manufacturers must strive to minimize the energy consumption and material use in BMS production while maximizing its benefits in battery management.

As PHEV technology evolves, the role of BMS in environmental sustainability is likely to expand. Future developments may include more sophisticated predictive algorithms for battery health, integration with smart grid systems for optimized charging, and enhanced capabilities for second-life battery applications. These advancements have the potential to further reduce the environmental impact of PHEVs throughout their lifecycle.

BMS Standards and Regulations

Battery Management System (BMS) standards and regulations play a crucial role in ensuring the safety, reliability, and performance of Plug-in Hybrid Electric Vehicle (PHEV) battery systems. These standards provide guidelines for manufacturers and developers to design, implement, and test BMS solutions that enhance battery durability and overall vehicle performance.

One of the key standards in this domain is ISO 26262, which focuses on functional safety for road vehicles. This standard outlines the requirements for BMS design, development, and validation processes to ensure the system's reliability and safety. It emphasizes the importance of risk assessment, fault tolerance, and systematic failure mitigation in BMS development.

The SAE J2464 standard specifically addresses electric and hybrid vehicle battery systems. It provides guidelines for design validation and verification of rechargeable energy storage systems, including BMS components. This standard helps ensure that BMS solutions meet the necessary performance and safety requirements for PHEV applications.

IEC 62660 is another important standard that focuses on secondary lithium-ion cells for electric vehicle propulsion. It outlines test procedures and performance requirements for lithium-ion cells used in PHEVs, including aspects related to BMS functionality and battery durability.

Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) have also established guidelines and regulations for electric and hybrid vehicle safety, including BMS-related requirements. These regulations often focus on thermal management, overcharge protection, and crash safety aspects of battery systems.

The United Nations Economic Commission for Europe (UNECE) Regulation No. 100 provides specific requirements for the construction and functional safety of electric power train vehicles. This regulation includes provisions for BMS design and implementation to ensure the safe operation of high-voltage battery systems in PHEVs.

As the PHEV market continues to grow, new standards and regulations are being developed to address emerging challenges in BMS design for enhanced durability. For instance, the development of fast-charging technologies has led to the creation of standards like IEC 61851, which defines requirements for electric vehicle conductive charging systems and their impact on BMS functionality.

Compliance with these standards and regulations is essential for PHEV manufacturers to ensure their vehicles meet safety and performance requirements across different markets. As BMS technology evolves, these standards are regularly updated to reflect advancements in battery chemistry, charging technologies, and vehicle electrification strategies.

One of the key standards in this domain is ISO 26262, which focuses on functional safety for road vehicles. This standard outlines the requirements for BMS design, development, and validation processes to ensure the system's reliability and safety. It emphasizes the importance of risk assessment, fault tolerance, and systematic failure mitigation in BMS development.

The SAE J2464 standard specifically addresses electric and hybrid vehicle battery systems. It provides guidelines for design validation and verification of rechargeable energy storage systems, including BMS components. This standard helps ensure that BMS solutions meet the necessary performance and safety requirements for PHEV applications.

IEC 62660 is another important standard that focuses on secondary lithium-ion cells for electric vehicle propulsion. It outlines test procedures and performance requirements for lithium-ion cells used in PHEVs, including aspects related to BMS functionality and battery durability.

Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) have also established guidelines and regulations for electric and hybrid vehicle safety, including BMS-related requirements. These regulations often focus on thermal management, overcharge protection, and crash safety aspects of battery systems.

The United Nations Economic Commission for Europe (UNECE) Regulation No. 100 provides specific requirements for the construction and functional safety of electric power train vehicles. This regulation includes provisions for BMS design and implementation to ensure the safe operation of high-voltage battery systems in PHEVs.

As the PHEV market continues to grow, new standards and regulations are being developed to address emerging challenges in BMS design for enhanced durability. For instance, the development of fast-charging technologies has led to the creation of standards like IEC 61851, which defines requirements for electric vehicle conductive charging systems and their impact on BMS functionality.

Compliance with these standards and regulations is essential for PHEV manufacturers to ensure their vehicles meet safety and performance requirements across different markets. As BMS technology evolves, these standards are regularly updated to reflect advancements in battery chemistry, charging technologies, and vehicle electrification strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!