PHEV integration with advanced manufacturing technologies

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV and AMT Background

Plug-in Hybrid Electric Vehicles (PHEVs) have emerged as a significant technological advancement in the automotive industry, bridging the gap between conventional internal combustion engine vehicles and fully electric vehicles. PHEVs combine the benefits of both technologies, offering improved fuel efficiency, reduced emissions, and extended driving range. The development of PHEVs has been driven by increasing environmental concerns, stricter emissions regulations, and the need for more sustainable transportation solutions.

Advanced Manufacturing Technologies (AMT) encompass a wide range of innovative processes and systems that enhance production efficiency, quality, and flexibility. These technologies include automation, robotics, artificial intelligence, Internet of Things (IoT), additive manufacturing, and advanced materials. AMT has revolutionized various industries, enabling faster production cycles, reduced costs, and improved product customization.

The integration of PHEVs with AMT represents a convergence of two transformative technological domains. This synergy aims to address the challenges associated with PHEV production, such as complex powertrain systems, battery manufacturing, and the need for precise assembly processes. By leveraging AMT, PHEV manufacturers can optimize production lines, enhance quality control, and reduce manufacturing costs.

The evolution of PHEV technology has been marked by continuous improvements in battery capacity, electric motor efficiency, and powertrain integration. Concurrently, AMT has progressed rapidly, with advancements in areas such as collaborative robotics, machine learning-driven quality control, and digital twin technology for virtual product development and testing.

The automotive industry has witnessed a significant shift towards electrification, with major manufacturers investing heavily in PHEV and electric vehicle (EV) technologies. This transition has necessitated the adoption of AMT to meet the unique manufacturing requirements of these vehicles. The integration of PHEVs with AMT is not only reshaping vehicle production but also influencing the entire automotive supply chain.

As the demand for PHEVs continues to grow, driven by consumer preferences and government incentives, the role of AMT in their production becomes increasingly critical. This integration is expected to lead to more efficient and cost-effective manufacturing processes, ultimately making PHEVs more accessible to a broader market. The ongoing research in this field aims to further optimize the synergy between PHEV technology and advanced manufacturing techniques, paving the way for the next generation of sustainable and technologically advanced vehicles.

Advanced Manufacturing Technologies (AMT) encompass a wide range of innovative processes and systems that enhance production efficiency, quality, and flexibility. These technologies include automation, robotics, artificial intelligence, Internet of Things (IoT), additive manufacturing, and advanced materials. AMT has revolutionized various industries, enabling faster production cycles, reduced costs, and improved product customization.

The integration of PHEVs with AMT represents a convergence of two transformative technological domains. This synergy aims to address the challenges associated with PHEV production, such as complex powertrain systems, battery manufacturing, and the need for precise assembly processes. By leveraging AMT, PHEV manufacturers can optimize production lines, enhance quality control, and reduce manufacturing costs.

The evolution of PHEV technology has been marked by continuous improvements in battery capacity, electric motor efficiency, and powertrain integration. Concurrently, AMT has progressed rapidly, with advancements in areas such as collaborative robotics, machine learning-driven quality control, and digital twin technology for virtual product development and testing.

The automotive industry has witnessed a significant shift towards electrification, with major manufacturers investing heavily in PHEV and electric vehicle (EV) technologies. This transition has necessitated the adoption of AMT to meet the unique manufacturing requirements of these vehicles. The integration of PHEVs with AMT is not only reshaping vehicle production but also influencing the entire automotive supply chain.

As the demand for PHEVs continues to grow, driven by consumer preferences and government incentives, the role of AMT in their production becomes increasingly critical. This integration is expected to lead to more efficient and cost-effective manufacturing processes, ultimately making PHEVs more accessible to a broader market. The ongoing research in this field aims to further optimize the synergy between PHEV technology and advanced manufacturing techniques, paving the way for the next generation of sustainable and technologically advanced vehicles.

PHEV Market Analysis

The PHEV (Plug-in Hybrid Electric Vehicle) market has experienced significant growth in recent years, driven by increasing environmental concerns, government incentives, and advancements in battery technology. As a bridge between conventional internal combustion engine vehicles and fully electric vehicles, PHEVs offer consumers the benefits of both technologies, making them an attractive option for those seeking improved fuel efficiency and reduced emissions without compromising on range.

Global PHEV sales have shown a steady upward trend, with major automotive markets such as China, Europe, and North America leading the adoption. In 2020, despite the overall automotive industry downturn due to the COVID-19 pandemic, PHEV sales demonstrated resilience and continued growth. This trend is expected to persist in the coming years as more automakers expand their PHEV offerings and consumers become increasingly aware of the benefits of electrified vehicles.

The market demand for PHEVs is influenced by several factors, including government policies, fuel prices, and consumer preferences. Many countries have implemented stringent emissions regulations and offer financial incentives for purchasing low-emission vehicles, which has significantly boosted PHEV adoption. Additionally, as battery costs continue to decrease and charging infrastructure expands, the total cost of ownership for PHEVs is becoming more competitive with conventional vehicles, further driving market growth.

In terms of market segmentation, PHEVs are available across various vehicle categories, including sedans, SUVs, and light commercial vehicles. The SUV segment, in particular, has seen strong demand for PHEV models, aligning with the global trend towards larger vehicles. This diversification of PHEV offerings has helped broaden the market appeal and cater to a wider range of consumer preferences.

Looking at industry trends, there is a growing focus on improving PHEV technology to enhance electric-only range, reduce charging times, and increase overall efficiency. Automakers are investing heavily in research and development to optimize the integration of electric powertrains with conventional engines, aiming to maximize the benefits of both technologies. This ongoing innovation is expected to further improve the performance and appeal of PHEVs in the coming years.

The PHEV market is also influenced by the broader shift towards sustainable transportation and the push for carbon neutrality. As governments worldwide set ambitious targets for reducing greenhouse gas emissions, PHEVs are seen as a crucial transitional technology in the journey towards full electrification of the automotive sector. This positioning has led to increased support for PHEV adoption through policy measures and infrastructure development.

Global PHEV sales have shown a steady upward trend, with major automotive markets such as China, Europe, and North America leading the adoption. In 2020, despite the overall automotive industry downturn due to the COVID-19 pandemic, PHEV sales demonstrated resilience and continued growth. This trend is expected to persist in the coming years as more automakers expand their PHEV offerings and consumers become increasingly aware of the benefits of electrified vehicles.

The market demand for PHEVs is influenced by several factors, including government policies, fuel prices, and consumer preferences. Many countries have implemented stringent emissions regulations and offer financial incentives for purchasing low-emission vehicles, which has significantly boosted PHEV adoption. Additionally, as battery costs continue to decrease and charging infrastructure expands, the total cost of ownership for PHEVs is becoming more competitive with conventional vehicles, further driving market growth.

In terms of market segmentation, PHEVs are available across various vehicle categories, including sedans, SUVs, and light commercial vehicles. The SUV segment, in particular, has seen strong demand for PHEV models, aligning with the global trend towards larger vehicles. This diversification of PHEV offerings has helped broaden the market appeal and cater to a wider range of consumer preferences.

Looking at industry trends, there is a growing focus on improving PHEV technology to enhance electric-only range, reduce charging times, and increase overall efficiency. Automakers are investing heavily in research and development to optimize the integration of electric powertrains with conventional engines, aiming to maximize the benefits of both technologies. This ongoing innovation is expected to further improve the performance and appeal of PHEVs in the coming years.

The PHEV market is also influenced by the broader shift towards sustainable transportation and the push for carbon neutrality. As governments worldwide set ambitious targets for reducing greenhouse gas emissions, PHEVs are seen as a crucial transitional technology in the journey towards full electrification of the automotive sector. This positioning has led to increased support for PHEV adoption through policy measures and infrastructure development.

AMT Challenges in PHEV

The integration of Plug-in Hybrid Electric Vehicles (PHEVs) with Advanced Manufacturing Technologies (AMT) presents several significant challenges. These obstacles stem from the complex nature of PHEV systems and the need for precise, efficient manufacturing processes to ensure their reliability and performance.

One of the primary challenges lies in the production of high-capacity, long-lasting batteries. AMT must adapt to handle the intricate assembly of battery packs, which require precise cell alignment, thermal management systems, and sophisticated battery management systems. The manufacturing process must ensure consistent quality and safety standards, as any defects in battery production can lead to severe performance issues or safety hazards.

Another critical challenge is the integration of electric powertrains with traditional internal combustion engines. This hybrid system requires advanced manufacturing techniques to seamlessly combine two distinct propulsion technologies. Precision in component manufacturing and assembly is crucial to ensure optimal performance and energy efficiency of the hybrid powertrain.

The production of lightweight materials for PHEV bodies and components presents another significant hurdle. Advanced manufacturing technologies must be developed to efficiently process and form materials such as carbon fiber composites, high-strength aluminum alloys, and advanced plastics. These materials are essential for reducing vehicle weight and improving energy efficiency but require specialized manufacturing processes and equipment.

Furthermore, the complexity of PHEV electrical systems demands highly sophisticated manufacturing and quality control processes. The integration of power electronics, control units, and various sensors requires advanced assembly techniques and rigorous testing procedures to ensure reliability and functionality under diverse operating conditions.

Achieving cost-effectiveness in PHEV manufacturing is another substantial challenge. While AMT can potentially reduce production costs through automation and improved efficiency, the initial investment in specialized equipment and processes can be significant. Balancing these costs with the need for high-quality, reliable production is a constant challenge for manufacturers.

Lastly, the rapid evolution of PHEV technologies necessitates flexible manufacturing systems that can quickly adapt to new designs and components. This adaptability is crucial for staying competitive in the fast-paced automotive industry but requires continuous investment in AMT research and development.

In conclusion, the integration of PHEVs with AMT faces multifaceted challenges, ranging from battery production and powertrain integration to material processing and system complexity. Overcoming these challenges requires ongoing innovation in manufacturing technologies and processes, as well as significant investment in research and development.

One of the primary challenges lies in the production of high-capacity, long-lasting batteries. AMT must adapt to handle the intricate assembly of battery packs, which require precise cell alignment, thermal management systems, and sophisticated battery management systems. The manufacturing process must ensure consistent quality and safety standards, as any defects in battery production can lead to severe performance issues or safety hazards.

Another critical challenge is the integration of electric powertrains with traditional internal combustion engines. This hybrid system requires advanced manufacturing techniques to seamlessly combine two distinct propulsion technologies. Precision in component manufacturing and assembly is crucial to ensure optimal performance and energy efficiency of the hybrid powertrain.

The production of lightweight materials for PHEV bodies and components presents another significant hurdle. Advanced manufacturing technologies must be developed to efficiently process and form materials such as carbon fiber composites, high-strength aluminum alloys, and advanced plastics. These materials are essential for reducing vehicle weight and improving energy efficiency but require specialized manufacturing processes and equipment.

Furthermore, the complexity of PHEV electrical systems demands highly sophisticated manufacturing and quality control processes. The integration of power electronics, control units, and various sensors requires advanced assembly techniques and rigorous testing procedures to ensure reliability and functionality under diverse operating conditions.

Achieving cost-effectiveness in PHEV manufacturing is another substantial challenge. While AMT can potentially reduce production costs through automation and improved efficiency, the initial investment in specialized equipment and processes can be significant. Balancing these costs with the need for high-quality, reliable production is a constant challenge for manufacturers.

Lastly, the rapid evolution of PHEV technologies necessitates flexible manufacturing systems that can quickly adapt to new designs and components. This adaptability is crucial for staying competitive in the fast-paced automotive industry but requires continuous investment in AMT research and development.

In conclusion, the integration of PHEVs with AMT faces multifaceted challenges, ranging from battery production and powertrain integration to material processing and system complexity. Overcoming these challenges requires ongoing innovation in manufacturing technologies and processes, as well as significant investment in research and development.

Current PHEV-AMT Solutions

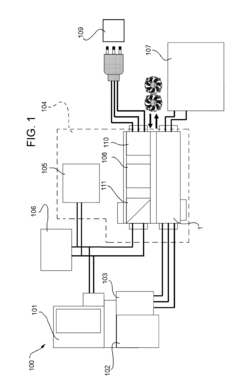

01 Power management systems for PHEVs

Advanced power management systems are crucial for optimizing the performance of plug-in hybrid electric vehicles. These systems control the distribution of power between the electric motor and internal combustion engine, manage battery charging, and improve overall energy efficiency. They often incorporate intelligent algorithms to predict driving conditions and adjust power output accordingly.- Power management systems for PHEVs: Advanced power management systems are crucial for optimizing the performance of plug-in hybrid electric vehicles. These systems control the distribution of power between the electric motor and internal combustion engine, manage battery charging, and improve overall energy efficiency. They often incorporate intelligent algorithms to predict and adapt to driving conditions, maximizing the use of electric power and reducing fuel consumption.

- Charging infrastructure and methods for PHEVs: Developing efficient charging infrastructure is essential for the widespread adoption of PHEVs. This includes the design of charging stations, integration with smart grids, and implementation of fast-charging technologies. Advanced charging methods, such as wireless charging and vehicle-to-grid systems, are being explored to enhance convenience and grid stability.

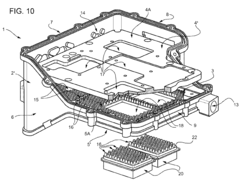

- Battery technology advancements for PHEVs: Improving battery technology is a key focus in PHEV development. This includes increasing energy density, extending battery life, enhancing thermal management, and reducing costs. Research is ongoing in areas such as solid-state batteries, advanced lithium-ion chemistries, and battery management systems to improve the electric range and overall performance of PHEVs.

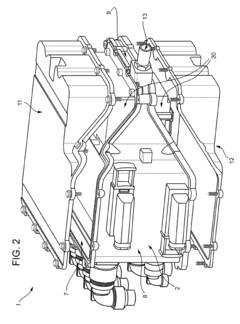

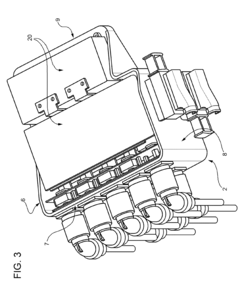

- Drivetrain and transmission systems for PHEVs: Innovative drivetrain and transmission designs are being developed to optimize the integration of electric motors with internal combustion engines. These systems aim to improve power delivery, reduce energy losses, and enhance overall vehicle efficiency. Advanced control strategies and mechanical designs are employed to seamlessly switch between electric and hybrid modes.

- Regenerative braking and energy recovery in PHEVs: Regenerative braking systems are crucial for recovering and storing energy in PHEVs. These systems convert kinetic energy during deceleration into electrical energy, which is then stored in the battery. Advanced regenerative braking technologies aim to maximize energy recovery while maintaining smooth braking performance and driver comfort.

02 Charging infrastructure and methods for PHEVs

Developing efficient charging infrastructure is essential for the widespread adoption of PHEVs. This includes the design of charging stations, integration with smart grids, and implementation of fast-charging technologies. Advanced charging methods, such as wireless charging and vehicle-to-grid systems, are also being explored to enhance convenience and grid stability.Expand Specific Solutions03 Drivetrain and transmission systems for PHEVs

Innovative drivetrain and transmission systems are being developed to improve the performance and efficiency of PHEVs. These include advanced hybrid transmissions, dual-clutch systems, and continuously variable transmissions (CVTs) specifically designed for hybrid powertrains. The goal is to seamlessly integrate the electric motor and internal combustion engine for optimal power delivery and fuel economy.Expand Specific Solutions04 Battery technology and management for PHEVs

Advancements in battery technology are crucial for improving the electric range and overall performance of PHEVs. This includes the development of high-capacity lithium-ion batteries, thermal management systems, and battery monitoring technologies. Research is also focused on extending battery life, improving charging speeds, and reducing costs to make PHEVs more competitive in the automotive market.Expand Specific Solutions05 Control strategies and software for PHEVs

Sophisticated control strategies and software are being developed to optimize the operation of PHEVs. These include adaptive control algorithms, predictive energy management systems, and integration with vehicle connectivity and autonomous driving technologies. The aim is to enhance fuel efficiency, reduce emissions, and improve the overall driving experience of PHEVs.Expand Specific Solutions

Key PHEV-AMT Players

The integration of PHEVs with advanced manufacturing technologies is in a transitional phase, with the market showing significant growth potential. The global PHEV market is expanding rapidly, driven by increasing environmental concerns and government incentives. However, the technology is still evolving, with varying levels of maturity across different manufacturers. Companies like Ford Global Technologies LLC, Volvo Lastvagnar AB, and Mercedes-Benz Group AG are at the forefront of PHEV development, leveraging their extensive automotive expertise. Chinese manufacturers such as Guangzhou Automobile Group and Chery Automobile Co., Ltd. are also making significant strides in this field. Academic institutions like Tsinghua University and South China University of Technology are contributing to research and innovation in PHEV integration, further accelerating technological advancements in this sector.

Ford Global Technologies LLC

Technical Solution: Ford's approach to integrating PHEVs with advanced manufacturing technologies focuses on modular production systems and flexible assembly lines. They have developed a scalable C2 platform that can accommodate multiple powertrain options, including PHEVs[1]. This platform utilizes advanced robotics and AI-driven quality control systems to ensure precise assembly of complex hybrid powertrains. Ford has also implemented digital twin technology to optimize production processes, reducing time-to-market for new PHEV models by up to 20%[2]. Their manufacturing strategy includes the use of additive manufacturing for rapid prototyping and production of complex PHEV components, such as battery cooling systems and power electronics housings[3].

Strengths: Highly flexible production systems, reduced time-to-market, and improved quality control. Weaknesses: High initial investment costs and potential challenges in workforce reskilling.

Guangzhou Automobile Group Co., Ltd.

Technical Solution: Guangzhou Automobile Group (GAC) has developed a comprehensive approach to integrating PHEVs with advanced manufacturing technologies, focusing on smart factory implementation and modular production systems. Their "GAC Intelligent Manufacturing 4.0" initiative incorporates AI-driven quality inspection systems, which have improved defect detection rates in PHEV production by up to 35%[8]. GAC has also implemented a flexible assembly line concept that can switch between different PHEV models with minimal downtime, utilizing advanced robotics and automated guided vehicles (AGVs) for material handling. Their manufacturing strategy includes the use of big data analytics to optimize production scheduling and energy management, resulting in a 15% reduction in overall energy consumption for PHEV manufacturing[9]. GAC has also invested in advanced battery assembly technologies, including automated cell stacking and laser welding systems, to enhance the efficiency and quality of PHEV battery pack production.

Strengths: Advanced quality control systems, flexible production capabilities, and improved energy efficiency. Weaknesses: Potential challenges in scaling up advanced technologies across all production facilities and ensuring consistent implementation.

PHEV-AMT Core Innovations

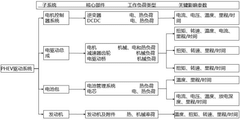

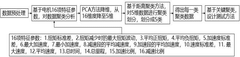

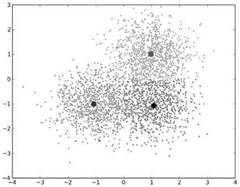

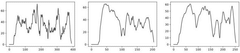

Method for testing and detecting reliability of whole plug-in hybrid electric automobile

PatentPendingCN119915526A

Innovation

- A special vehicle reliability test and detection method is designed, including vehicle structure test and detection, power and transmission test and environmental test test parts. Through market user surveys and real user load spectrum data analysis, the reliability target of PHEV cars is determined, and K-mean clustering analysis technology is used to construct typical test conditions to ensure that the test method is equivalent to user requirements.

Automotive inverter assembly

PatentInactiveEP2203039A2

Innovation

- The proposed automotive inverter assembly incorporates a supporting body with parallel walls and fins to enhance heat exchange efficiency, using a cooling fluid that flows through a thermally coupled volume, with deflectors and fins to promote turbulent flow and increase the heat exchange surface, while allowing for easier assembly and reduced energy losses.

Supply Chain Implications

The integration of Plug-in Hybrid Electric Vehicles (PHEVs) with advanced manufacturing technologies has significant implications for the automotive supply chain. This convergence necessitates a fundamental restructuring of existing supply networks to accommodate the unique components and production processes associated with PHEVs.

Suppliers are required to develop new capabilities in electric powertrain technologies, including battery systems, electric motors, and power electronics. This shift demands substantial investments in research and development, as well as retooling of production facilities. Consequently, traditional automotive suppliers may face challenges in adapting to these new requirements, potentially leading to a reshaping of the supplier landscape.

The introduction of PHEVs also impacts raw material sourcing strategies. The increased demand for battery materials such as lithium, cobalt, and nickel has led to concerns about supply chain resilience and geopolitical risks associated with these critical resources. Manufacturers must develop robust supply chain risk management strategies to ensure a stable supply of these materials.

Advanced manufacturing technologies, such as additive manufacturing and Industry 4.0 concepts, are being increasingly adopted in PHEV production. These technologies enable greater flexibility in production processes, allowing for more efficient customization and rapid prototyping. This shift towards digital manufacturing requires suppliers to invest in new technologies and develop digital competencies to remain competitive.

The complexity of PHEV systems necessitates closer collaboration between OEMs and suppliers. Integrated design and development processes are becoming more prevalent, with suppliers taking on greater responsibility for innovation and system integration. This trend is driving the emergence of new partnership models and strategic alliances within the automotive industry.

Logistics and distribution networks are also evolving to support PHEV production and sales. The need for specialized handling and transportation of high-voltage batteries, as well as the establishment of charging infrastructure, presents new challenges and opportunities for logistics providers. This evolution is driving the development of new service offerings and expertise in the automotive logistics sector.

As PHEVs gain market share, the aftermarket and service sectors are adapting to new maintenance requirements. This shift creates opportunities for new entrants specializing in electric vehicle components and services, while traditional service providers must invest in training and equipment to support these advanced vehicles.

Suppliers are required to develop new capabilities in electric powertrain technologies, including battery systems, electric motors, and power electronics. This shift demands substantial investments in research and development, as well as retooling of production facilities. Consequently, traditional automotive suppliers may face challenges in adapting to these new requirements, potentially leading to a reshaping of the supplier landscape.

The introduction of PHEVs also impacts raw material sourcing strategies. The increased demand for battery materials such as lithium, cobalt, and nickel has led to concerns about supply chain resilience and geopolitical risks associated with these critical resources. Manufacturers must develop robust supply chain risk management strategies to ensure a stable supply of these materials.

Advanced manufacturing technologies, such as additive manufacturing and Industry 4.0 concepts, are being increasingly adopted in PHEV production. These technologies enable greater flexibility in production processes, allowing for more efficient customization and rapid prototyping. This shift towards digital manufacturing requires suppliers to invest in new technologies and develop digital competencies to remain competitive.

The complexity of PHEV systems necessitates closer collaboration between OEMs and suppliers. Integrated design and development processes are becoming more prevalent, with suppliers taking on greater responsibility for innovation and system integration. This trend is driving the emergence of new partnership models and strategic alliances within the automotive industry.

Logistics and distribution networks are also evolving to support PHEV production and sales. The need for specialized handling and transportation of high-voltage batteries, as well as the establishment of charging infrastructure, presents new challenges and opportunities for logistics providers. This evolution is driving the development of new service offerings and expertise in the automotive logistics sector.

As PHEVs gain market share, the aftermarket and service sectors are adapting to new maintenance requirements. This shift creates opportunities for new entrants specializing in electric vehicle components and services, while traditional service providers must invest in training and equipment to support these advanced vehicles.

Sustainability Aspects

The integration of Plug-in Hybrid Electric Vehicles (PHEVs) with advanced manufacturing technologies presents significant opportunities for enhancing sustainability in the automotive industry. This synergy addresses environmental concerns while promoting economic viability and social responsibility.

From an environmental perspective, the combination of PHEVs and advanced manufacturing processes contributes to reduced carbon emissions and improved energy efficiency. Advanced manufacturing techniques, such as additive manufacturing and precision robotics, enable the production of lighter and more aerodynamic vehicle components. These innovations directly translate to increased fuel efficiency and extended electric-only driving ranges for PHEVs, further reducing their environmental impact.

The economic sustainability of PHEV production is bolstered by the implementation of smart manufacturing systems. Industry 4.0 technologies, including Internet of Things (IoT) sensors and artificial intelligence-driven predictive maintenance, optimize production processes and minimize waste. This results in lower manufacturing costs, improved product quality, and increased overall efficiency, making PHEVs more accessible to a broader consumer base.

Advanced manufacturing technologies also contribute to the circular economy model in PHEV production. Techniques such as 3D printing facilitate the creation of complex, multi-material components that are easier to disassemble and recycle at the end of the vehicle's life cycle. This approach not only reduces waste but also promotes the reuse and recycling of valuable materials, aligning with sustainability goals.

The social dimension of sustainability is addressed through the creation of high-skilled jobs in both PHEV development and advanced manufacturing sectors. As these industries grow, they foster innovation ecosystems that drive technological advancements and economic growth. Additionally, the improved air quality resulting from increased PHEV adoption positively impacts public health, particularly in urban areas.

The integration of PHEVs with advanced manufacturing also supports grid stability and renewable energy integration. Smart charging systems, enabled by advanced manufacturing and IoT technologies, allow PHEVs to serve as distributed energy storage units. This capability helps balance electricity demand and supply, facilitating the integration of intermittent renewable energy sources into the power grid.

In conclusion, the convergence of PHEV technology and advanced manufacturing processes creates a powerful synergy that addresses multiple facets of sustainability. By reducing environmental impact, enhancing economic viability, and promoting social benefits, this integration paves the way for a more sustainable automotive industry and transportation sector.

From an environmental perspective, the combination of PHEVs and advanced manufacturing processes contributes to reduced carbon emissions and improved energy efficiency. Advanced manufacturing techniques, such as additive manufacturing and precision robotics, enable the production of lighter and more aerodynamic vehicle components. These innovations directly translate to increased fuel efficiency and extended electric-only driving ranges for PHEVs, further reducing their environmental impact.

The economic sustainability of PHEV production is bolstered by the implementation of smart manufacturing systems. Industry 4.0 technologies, including Internet of Things (IoT) sensors and artificial intelligence-driven predictive maintenance, optimize production processes and minimize waste. This results in lower manufacturing costs, improved product quality, and increased overall efficiency, making PHEVs more accessible to a broader consumer base.

Advanced manufacturing technologies also contribute to the circular economy model in PHEV production. Techniques such as 3D printing facilitate the creation of complex, multi-material components that are easier to disassemble and recycle at the end of the vehicle's life cycle. This approach not only reduces waste but also promotes the reuse and recycling of valuable materials, aligning with sustainability goals.

The social dimension of sustainability is addressed through the creation of high-skilled jobs in both PHEV development and advanced manufacturing sectors. As these industries grow, they foster innovation ecosystems that drive technological advancements and economic growth. Additionally, the improved air quality resulting from increased PHEV adoption positively impacts public health, particularly in urban areas.

The integration of PHEVs with advanced manufacturing also supports grid stability and renewable energy integration. Smart charging systems, enabled by advanced manufacturing and IoT technologies, allow PHEVs to serve as distributed energy storage units. This capability helps balance electricity demand and supply, facilitating the integration of intermittent renewable energy sources into the power grid.

In conclusion, the convergence of PHEV technology and advanced manufacturing processes creates a powerful synergy that addresses multiple facets of sustainability. By reducing environmental impact, enhancing economic viability, and promoting social benefits, this integration paves the way for a more sustainable automotive industry and transportation sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!