Role of PHEV in the circular economy model

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV Technology Evolution

The evolution of Plug-in Hybrid Electric Vehicle (PHEV) technology has been marked by significant advancements and innovations over the past two decades. Initially introduced as a bridge between conventional internal combustion engine vehicles and fully electric vehicles, PHEVs have undergone substantial improvements in battery technology, powertrain efficiency, and overall system integration.

In the early 2000s, PHEVs were primarily concept vehicles with limited electric-only range and high production costs. The first generation of commercially available PHEVs, such as the Chevrolet Volt and Toyota Prius Plug-in Hybrid, entered the market around 2010-2012. These vehicles offered electric ranges of 10-40 miles and utilized nickel-metal hydride or early lithium-ion battery technologies.

As battery technology progressed, the second generation of PHEVs emerged in the mid-2010s. These vehicles featured improved lithium-ion batteries with higher energy density, resulting in extended electric ranges of 30-50 miles. Additionally, advancements in power electronics and motor efficiency led to better overall vehicle performance and fuel economy.

The integration of PHEVs into the circular economy model began to take shape during this period. Manufacturers started implementing design strategies that considered the entire lifecycle of the vehicle, including the reuse and recycling of battery components. This shift towards a more sustainable approach aligned with the growing emphasis on environmental consciousness and resource conservation.

Recent years have seen the third generation of PHEVs, characterized by even more advanced battery chemistries, such as lithium-ion polymer and solid-state batteries. These innovations have pushed electric ranges beyond 50 miles, with some models achieving up to 100 miles of all-electric driving. Improved power management systems and regenerative braking technologies have further enhanced energy efficiency and overall vehicle performance.

The role of PHEVs in the circular economy has become more pronounced with the development of vehicle-to-grid (V2G) capabilities. This technology allows PHEVs to not only draw power from the grid but also feed excess energy back, contributing to grid stability and renewable energy integration. Furthermore, advancements in battery management systems have extended battery life and improved the potential for second-life applications, such as stationary energy storage.

Looking ahead, the evolution of PHEV technology is expected to continue with a focus on increasing electric range, reducing production costs, and enhancing overall sustainability. Emerging technologies like wireless charging and advanced materials for lightweight construction are likely to play significant roles in future PHEV developments. As the circular economy model gains traction, PHEVs are poised to become even more integral to sustainable transportation solutions, bridging the gap between conventional vehicles and fully electric alternatives while minimizing environmental impact throughout their lifecycle.

In the early 2000s, PHEVs were primarily concept vehicles with limited electric-only range and high production costs. The first generation of commercially available PHEVs, such as the Chevrolet Volt and Toyota Prius Plug-in Hybrid, entered the market around 2010-2012. These vehicles offered electric ranges of 10-40 miles and utilized nickel-metal hydride or early lithium-ion battery technologies.

As battery technology progressed, the second generation of PHEVs emerged in the mid-2010s. These vehicles featured improved lithium-ion batteries with higher energy density, resulting in extended electric ranges of 30-50 miles. Additionally, advancements in power electronics and motor efficiency led to better overall vehicle performance and fuel economy.

The integration of PHEVs into the circular economy model began to take shape during this period. Manufacturers started implementing design strategies that considered the entire lifecycle of the vehicle, including the reuse and recycling of battery components. This shift towards a more sustainable approach aligned with the growing emphasis on environmental consciousness and resource conservation.

Recent years have seen the third generation of PHEVs, characterized by even more advanced battery chemistries, such as lithium-ion polymer and solid-state batteries. These innovations have pushed electric ranges beyond 50 miles, with some models achieving up to 100 miles of all-electric driving. Improved power management systems and regenerative braking technologies have further enhanced energy efficiency and overall vehicle performance.

The role of PHEVs in the circular economy has become more pronounced with the development of vehicle-to-grid (V2G) capabilities. This technology allows PHEVs to not only draw power from the grid but also feed excess energy back, contributing to grid stability and renewable energy integration. Furthermore, advancements in battery management systems have extended battery life and improved the potential for second-life applications, such as stationary energy storage.

Looking ahead, the evolution of PHEV technology is expected to continue with a focus on increasing electric range, reducing production costs, and enhancing overall sustainability. Emerging technologies like wireless charging and advanced materials for lightweight construction are likely to play significant roles in future PHEV developments. As the circular economy model gains traction, PHEVs are poised to become even more integral to sustainable transportation solutions, bridging the gap between conventional vehicles and fully electric alternatives while minimizing environmental impact throughout their lifecycle.

Circular Economy Demand

The circular economy model has gained significant traction in recent years as a sustainable approach to resource management and waste reduction. Within this context, Plug-in Hybrid Electric Vehicles (PHEVs) play a crucial role in addressing the growing demand for environmentally friendly transportation solutions. The market for PHEVs has been expanding rapidly, driven by increasing consumer awareness of environmental issues and supportive government policies aimed at reducing carbon emissions.

The demand for PHEVs in the circular economy is primarily fueled by their ability to bridge the gap between conventional internal combustion engine vehicles and fully electric vehicles. This transitional technology allows for a gradual shift towards electrification while addressing concerns such as range anxiety and charging infrastructure limitations. As a result, PHEVs have become an attractive option for consumers looking to reduce their carbon footprint without compromising on convenience.

In the circular economy model, PHEVs contribute to resource efficiency and waste reduction through various mechanisms. The hybrid nature of these vehicles allows for optimal use of both electric and conventional fuel sources, potentially reducing overall energy consumption and emissions. Additionally, the battery systems in PHEVs can be repurposed for second-life applications, such as stationary energy storage, further extending their useful life and minimizing waste.

The market demand for PHEVs is also driven by their potential to integrate with smart grid systems and renewable energy sources. As part of a broader circular economy strategy, PHEVs can serve as mobile energy storage units, participating in vehicle-to-grid (V2G) systems that help balance electricity demand and supply. This capability aligns with the circular economy principle of maximizing resource utilization and creating closed-loop systems.

Furthermore, the circular economy model emphasizes the importance of product longevity and repairability. PHEVs, with their dual powertrain systems, offer opportunities for extended vehicle life through maintenance and upgrades of individual components. This approach supports the circular economy's goal of keeping products and materials in use for as long as possible, reducing the need for new resource extraction and manufacturing.

The demand for PHEVs in the circular economy is also influenced by evolving consumer preferences and regulatory frameworks. As sustainability becomes a key factor in purchasing decisions, consumers are increasingly seeking vehicles that align with circular economy principles. Simultaneously, governments worldwide are implementing stricter emissions standards and incentives for low-emission vehicles, further driving the adoption of PHEVs as a transitional technology in the move towards a more sustainable transportation sector.

The demand for PHEVs in the circular economy is primarily fueled by their ability to bridge the gap between conventional internal combustion engine vehicles and fully electric vehicles. This transitional technology allows for a gradual shift towards electrification while addressing concerns such as range anxiety and charging infrastructure limitations. As a result, PHEVs have become an attractive option for consumers looking to reduce their carbon footprint without compromising on convenience.

In the circular economy model, PHEVs contribute to resource efficiency and waste reduction through various mechanisms. The hybrid nature of these vehicles allows for optimal use of both electric and conventional fuel sources, potentially reducing overall energy consumption and emissions. Additionally, the battery systems in PHEVs can be repurposed for second-life applications, such as stationary energy storage, further extending their useful life and minimizing waste.

The market demand for PHEVs is also driven by their potential to integrate with smart grid systems and renewable energy sources. As part of a broader circular economy strategy, PHEVs can serve as mobile energy storage units, participating in vehicle-to-grid (V2G) systems that help balance electricity demand and supply. This capability aligns with the circular economy principle of maximizing resource utilization and creating closed-loop systems.

Furthermore, the circular economy model emphasizes the importance of product longevity and repairability. PHEVs, with their dual powertrain systems, offer opportunities for extended vehicle life through maintenance and upgrades of individual components. This approach supports the circular economy's goal of keeping products and materials in use for as long as possible, reducing the need for new resource extraction and manufacturing.

The demand for PHEVs in the circular economy is also influenced by evolving consumer preferences and regulatory frameworks. As sustainability becomes a key factor in purchasing decisions, consumers are increasingly seeking vehicles that align with circular economy principles. Simultaneously, governments worldwide are implementing stricter emissions standards and incentives for low-emission vehicles, further driving the adoption of PHEVs as a transitional technology in the move towards a more sustainable transportation sector.

PHEV Challenges

Plug-in Hybrid Electric Vehicles (PHEVs) face several challenges in their integration into the circular economy model. One of the primary obstacles is the complexity of their dual powertrain system, which combines both internal combustion engines and electric motors. This complexity makes it more difficult to design PHEVs for easy disassembly, repair, and recycling, key principles of the circular economy.

The battery technology used in PHEVs presents another significant challenge. While smaller than those in fully electric vehicles, PHEV batteries still contain valuable and potentially harmful materials. The recycling process for these batteries is complex and energy-intensive, often making it economically unfeasible. Additionally, the lifespan of these batteries is a concern, as their degradation over time can lead to decreased vehicle performance and increased waste.

Manufacturing PHEVs also poses challenges from a circular economy perspective. The production process requires a diverse range of materials, including rare earth elements for electric motors and sophisticated electronics. Sourcing these materials sustainably and ensuring their recoverability at the end of the vehicle's life is a complex task that requires significant innovation in supply chain management and material science.

The maintenance and repair of PHEVs present unique challenges due to their hybrid nature. Specialized knowledge and tools are required to service both the electric and combustion components, which can limit the ability for independent repair and potentially increase the overall environmental impact through reduced vehicle longevity.

From an energy perspective, PHEVs face the challenge of balancing their dual power sources in a way that maximizes efficiency and minimizes environmental impact. This includes optimizing the use of electric power versus fossil fuels, which can vary greatly depending on driving patterns and charging habits. The reliance on fossil fuels, even if reduced, still presents a barrier to full circularity.

Lastly, the end-of-life management of PHEVs is a significant challenge. The variety of materials and components used in these vehicles makes it difficult to achieve high rates of recycling and material recovery. Developing efficient processes for dismantling, sorting, and recycling the diverse components of PHEVs is crucial for their integration into a circular economy model, but remains a complex and evolving field.

The battery technology used in PHEVs presents another significant challenge. While smaller than those in fully electric vehicles, PHEV batteries still contain valuable and potentially harmful materials. The recycling process for these batteries is complex and energy-intensive, often making it economically unfeasible. Additionally, the lifespan of these batteries is a concern, as their degradation over time can lead to decreased vehicle performance and increased waste.

Manufacturing PHEVs also poses challenges from a circular economy perspective. The production process requires a diverse range of materials, including rare earth elements for electric motors and sophisticated electronics. Sourcing these materials sustainably and ensuring their recoverability at the end of the vehicle's life is a complex task that requires significant innovation in supply chain management and material science.

The maintenance and repair of PHEVs present unique challenges due to their hybrid nature. Specialized knowledge and tools are required to service both the electric and combustion components, which can limit the ability for independent repair and potentially increase the overall environmental impact through reduced vehicle longevity.

From an energy perspective, PHEVs face the challenge of balancing their dual power sources in a way that maximizes efficiency and minimizes environmental impact. This includes optimizing the use of electric power versus fossil fuels, which can vary greatly depending on driving patterns and charging habits. The reliance on fossil fuels, even if reduced, still presents a barrier to full circularity.

Lastly, the end-of-life management of PHEVs is a significant challenge. The variety of materials and components used in these vehicles makes it difficult to achieve high rates of recycling and material recovery. Developing efficient processes for dismantling, sorting, and recycling the diverse components of PHEVs is crucial for their integration into a circular economy model, but remains a complex and evolving field.

Current PHEV Solutions

01 Power management systems for PHEVs

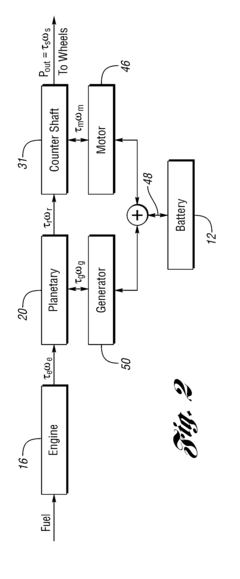

Advanced power management systems are crucial for optimizing the performance of plug-in hybrid electric vehicles. These systems control the distribution of power between the electric motor and internal combustion engine, manage battery charging, and improve overall energy efficiency. They often incorporate intelligent algorithms to adapt to driving conditions and user preferences, maximizing the use of electric power and reducing fuel consumption.- Power management systems for PHEVs: Advanced power management systems are crucial for optimizing the performance of plug-in hybrid electric vehicles. These systems control the distribution of power between the electric motor and internal combustion engine, manage battery charging, and improve overall energy efficiency. They also incorporate intelligent algorithms to adapt to driving conditions and user preferences, enhancing the vehicle's range and fuel economy.

- Charging infrastructure and systems for PHEVs: Developing efficient charging infrastructure is essential for the widespread adoption of plug-in hybrid electric vehicles. This includes the design of charging stations, integration with smart grids, and development of fast-charging technologies. Advanced charging systems may incorporate features such as wireless charging, vehicle-to-grid (V2G) capabilities, and smart scheduling to optimize charging times and reduce strain on the electrical grid.

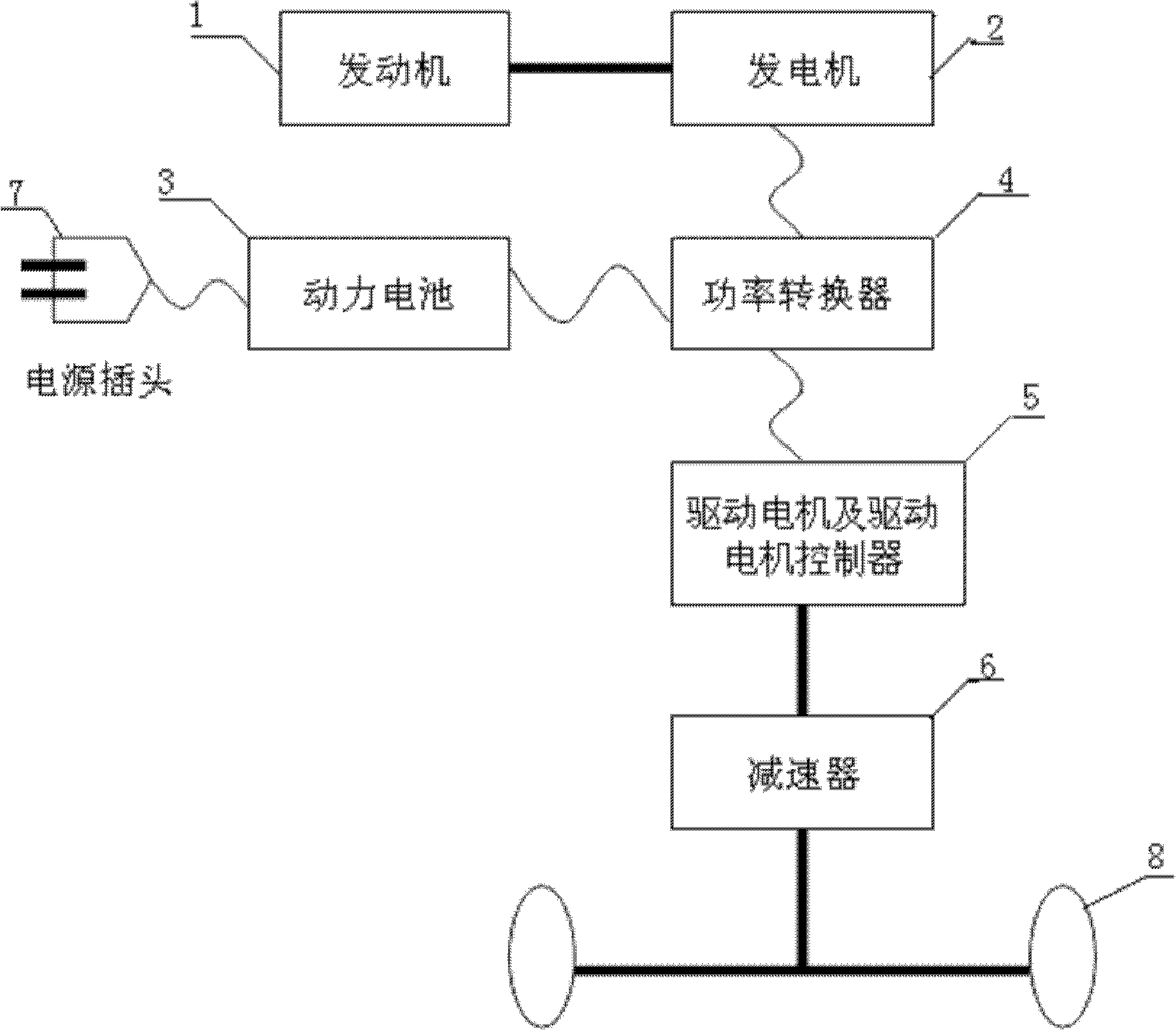

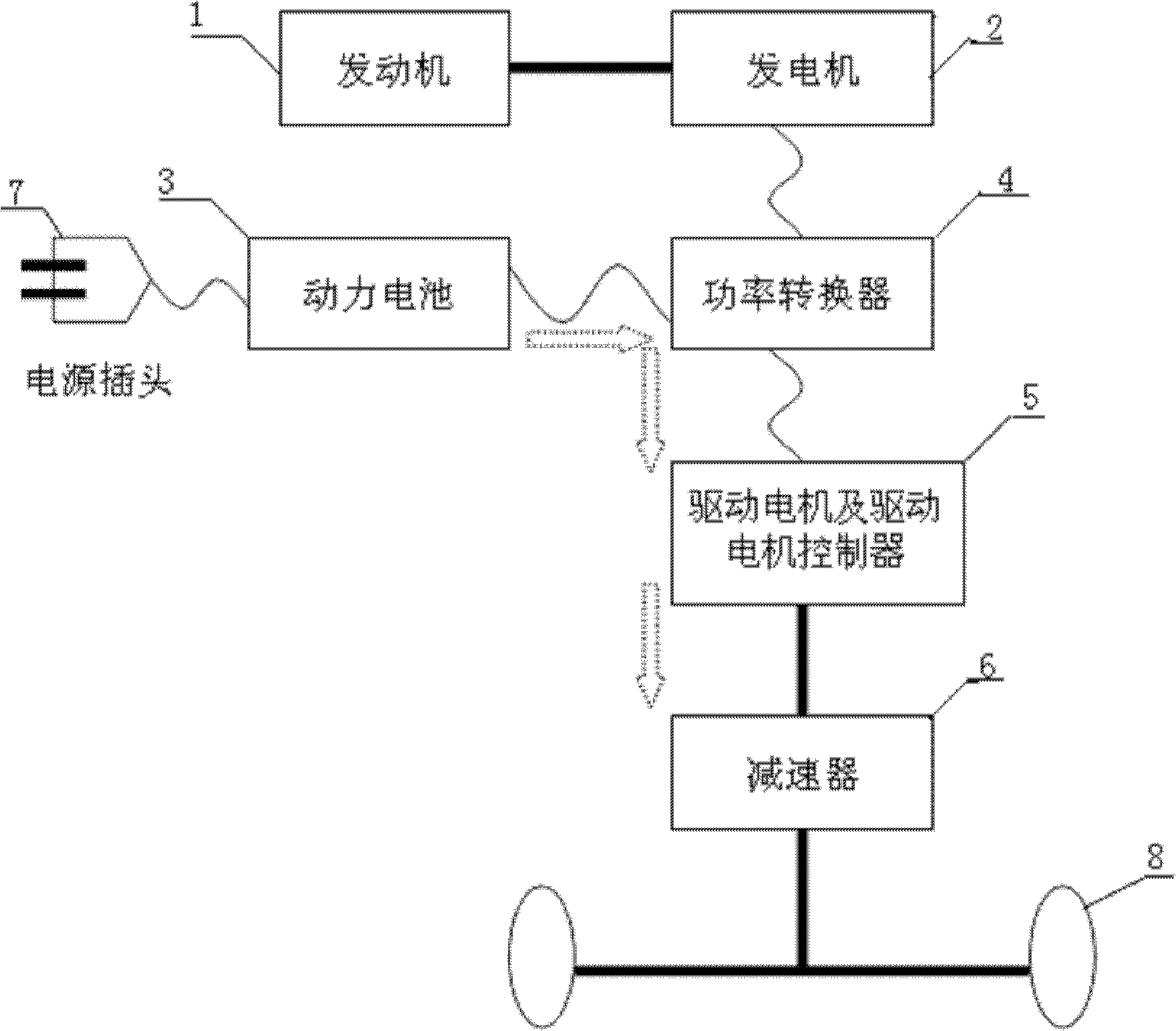

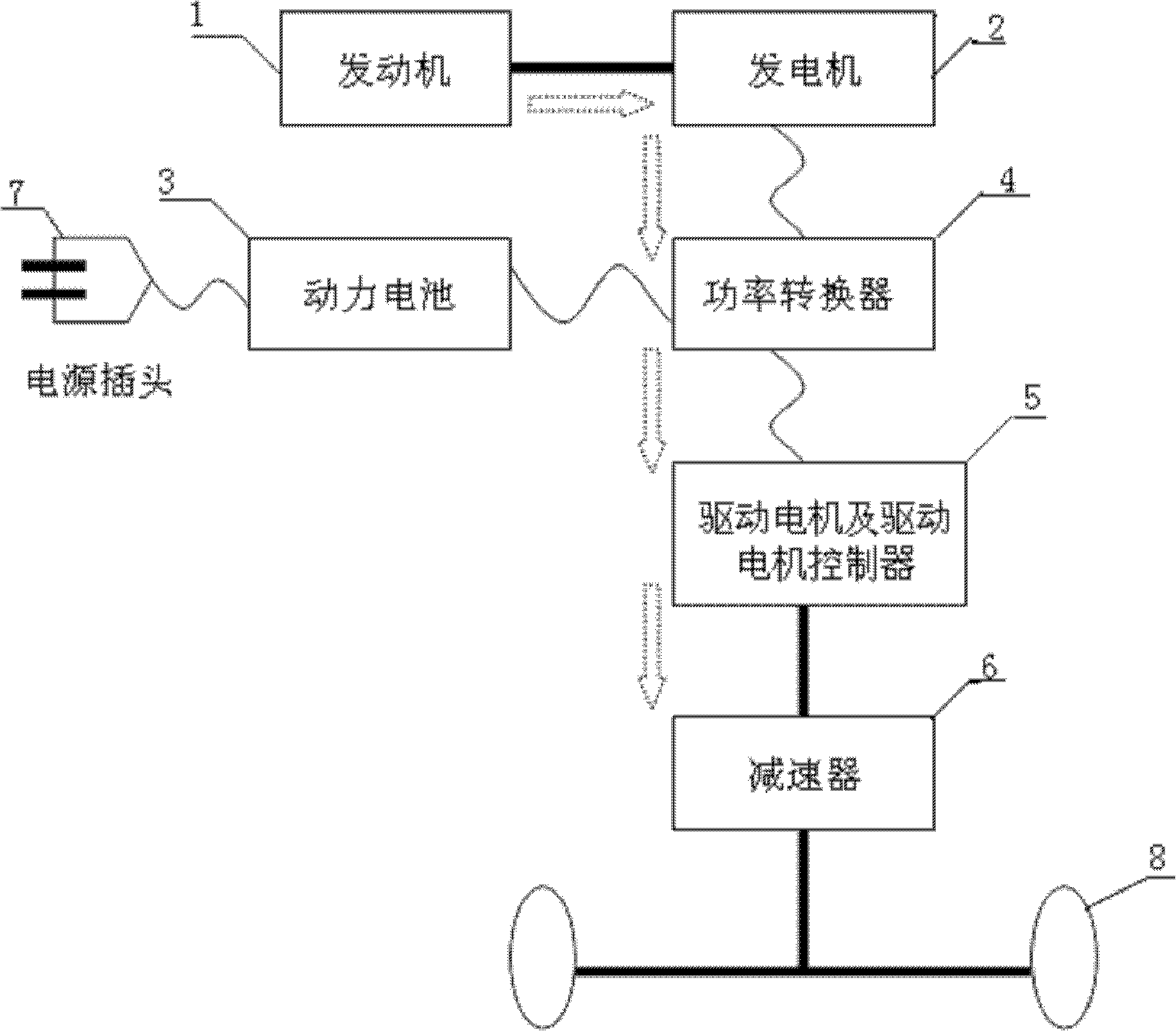

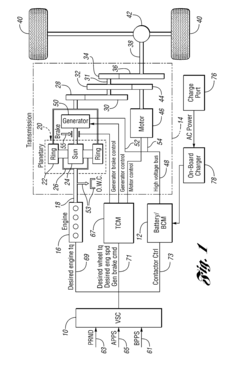

- Hybrid powertrain configurations for PHEVs: Various hybrid powertrain configurations are being developed to improve the performance and efficiency of plug-in hybrid electric vehicles. These include series, parallel, and power-split architectures, each with its own advantages. Innovations in this area focus on optimizing the integration of electric motors, internal combustion engines, and transmission systems to maximize power output, energy efficiency, and driving range.

- Battery technology advancements for PHEVs: Continuous improvements in battery technology are crucial for enhancing the performance of plug-in hybrid electric vehicles. This includes developing high-capacity, fast-charging batteries with improved energy density, longer lifespan, and enhanced safety features. Research is also focused on new battery chemistries, thermal management systems, and battery management systems to optimize performance and extend the electric-only driving range of PHEVs.

- Control strategies for PHEV operation modes: Sophisticated control strategies are being developed to manage the various operation modes of plug-in hybrid electric vehicles. These strategies optimize the use of electric and combustion power sources based on factors such as driving conditions, battery state of charge, and user preferences. Advanced control algorithms may incorporate machine learning and predictive techniques to further improve vehicle efficiency and performance across different driving scenarios.

02 Charging infrastructure and systems for PHEVs

Developing efficient charging infrastructure is essential for the widespread adoption of PHEVs. This includes the design of charging stations, integration with smart grids, and implementation of fast-charging technologies. Advanced charging systems may incorporate features such as wireless charging, vehicle-to-grid (V2G) capabilities, and smart scheduling to optimize charging times and reduce grid load.Expand Specific Solutions03 Drivetrain and transmission technologies for PHEVs

Innovative drivetrain and transmission designs are key to improving the performance and efficiency of PHEVs. These may include advanced electric motors, regenerative braking systems, and hybrid transmissions that seamlessly integrate electric and combustion power sources. Such technologies aim to reduce energy losses, improve power delivery, and enhance the overall driving experience of PHEVs.Expand Specific Solutions04 Battery technologies and management for PHEVs

Advancements in battery technology are crucial for extending the electric range and overall performance of PHEVs. This includes the development of high-capacity, fast-charging batteries, as well as sophisticated battery management systems. These systems monitor battery health, optimize charging and discharging cycles, and ensure safe operation under various conditions, ultimately improving the longevity and reliability of PHEV batteries.Expand Specific Solutions05 Control strategies and software for PHEVs

Sophisticated control strategies and software are essential for optimizing the performance of PHEVs. These include adaptive control algorithms that learn from driving patterns, predictive energy management based on route information, and integration with vehicle connectivity systems. Advanced software can also provide drivers with real-time information on energy consumption, charging status, and optimal driving modes to maximize efficiency.Expand Specific Solutions

Key PHEV Manufacturers

The role of Plug-in Hybrid Electric Vehicles (PHEVs) in the circular economy model is evolving within a competitive landscape characterized by rapid technological advancements and shifting market dynamics. The industry is in a transitional phase, with global PHEV market size projected to grow significantly in the coming years. Technological maturity varies among key players, with established automakers like Ford, BMW, and Volvo leading in PHEV development. Emerging companies such as Chery Automobile and innovative tech firms like Turntide Technologies are also making strides in this space. The integration of PHEVs into circular economy principles is gaining traction, with companies focusing on sustainable manufacturing, battery recycling, and end-of-life vehicle management to maximize resource efficiency and minimize environmental impact.

Ford Motor Co.

Technical Solution: Ford has developed a comprehensive PHEV strategy as part of its circular economy model. The company's approach includes designing PHEVs with easily recyclable materials, implementing battery second-life programs, and establishing closed-loop recycling processes for critical components. Ford's PHEVs feature modular designs that facilitate easy disassembly and refurbishment, extending vehicle lifespan. The company has also invested in advanced battery recycling technologies, recovering up to 95% of raw materials from end-of-life batteries[1]. Additionally, Ford has implemented a "Core Recovery Program" that collects and remanufactures used parts, reducing waste and energy consumption in the production process[2].

Strengths: Established infrastructure for recycling and remanufacturing, strong focus on battery second-life applications. Weaknesses: Dependency on consumer participation in recycling programs, potential challenges in scaling up circular processes globally.

International Business Machines Corp.

Technical Solution: IBM, while not a direct PHEV manufacturer, plays a crucial role in enabling circular economy models for PHEVs through its advanced technology solutions. IBM has developed a blockchain-based platform called "Responsible Sourcing Blockchain Network" (RSBN) that tracks and verifies the ethical sourcing of materials used in PHEV batteries, ensuring transparency and sustainability throughout the supply chain[9]. The company's AI and IoT solutions are being utilized by PHEV manufacturers to optimize vehicle performance, predict maintenance needs, and extend battery life. IBM's quantum computing research is also exploring new materials and chemical processes that could revolutionize PHEV battery recycling, potentially increasing material recovery rates to over 98%[10]. Additionally, IBM's cloud-based analytics platforms are helping PHEV manufacturers implement predictive maintenance strategies, reducing waste and extending vehicle lifespans.

Strengths: Cutting-edge technology solutions for supply chain transparency and battery optimization. Weaknesses: Indirect involvement in PHEV production, reliance on partnerships with automotive manufacturers for implementation.

PHEV Circular Innovations

Cost based method for optimizing external PHEV (Plug-in Hybrid Electric Vehicle) power assembly and application thereof

PatentInactiveCN102180169A

Innovation

- By establishing a cost-based optimization method, determine the variables to be optimized and construct a cost objective function equation, and use quadratic programming or matrix partitioning optimization algorithms to optimize the maximum output power of the engine, the maximum output power of the drive motor, the output power of the power battery and the capacity of the power battery pack. , to achieve the lowest cost powertrain design.

Method for increasing fuel economy of plug-in hybrid electric vehicles

PatentInactiveUS9580062B2

Innovation

- Implementing a control strategy that prioritizes electric energy use in the charge-depleting mode and operates the engine below peak efficiency to supply only the power difference when battery power is insufficient, switching to charge-sustaining mode to maximize fuel economy by depleting the battery to a minimum state of charge before engine use.

PHEV Lifecycle Analysis

The lifecycle analysis of Plug-in Hybrid Electric Vehicles (PHEVs) is crucial for understanding their role in the circular economy model. This analysis encompasses the entire lifespan of a PHEV, from raw material extraction to end-of-life disposal and recycling.

At the production stage, PHEVs require more energy-intensive processes compared to conventional vehicles due to the manufacturing of battery packs and electric powertrains. However, this initial environmental impact is often offset by the vehicle's reduced emissions during its operational phase.

During the use phase, PHEVs demonstrate significant advantages in terms of energy efficiency and emissions reduction. The ability to operate in all-electric mode for short trips and switch to hybrid mode for longer journeys allows for optimal fuel consumption and lower greenhouse gas emissions. This flexibility contributes to the overall reduction of the vehicle's carbon footprint throughout its operational life.

Maintenance and repair considerations for PHEVs differ from traditional vehicles. While the electric components may require specialized servicing, the reduced wear on the internal combustion engine can lead to extended service intervals for certain parts. This aspect of the lifecycle can contribute to resource conservation and waste reduction.

The end-of-life stage of PHEVs presents both challenges and opportunities within the circular economy framework. The complex nature of PHEV components, particularly the battery systems, necessitates advanced recycling and disposal processes. However, this complexity also drives innovation in recycling technologies, potentially creating new economic opportunities and reducing the demand for virgin materials.

Battery recycling is a critical aspect of PHEV lifecycle analysis. As battery technology evolves, so do the methods for recovering valuable materials such as lithium, cobalt, and nickel. The development of efficient recycling processes not only mitigates environmental impacts but also contributes to the circular economy by reducing reliance on primary resource extraction.

Furthermore, the potential for second-life applications of PHEV batteries in stationary energy storage systems extends their useful life beyond the automotive sector. This repurposing aligns with circular economy principles by maximizing resource utilization and creating additional value streams.

In conclusion, the lifecycle analysis of PHEVs reveals their potential to contribute positively to the circular economy model. While challenges exist, particularly in production and end-of-life stages, the overall benefits in terms of operational efficiency, emissions reduction, and material recovery present opportunities for sustainable transportation solutions.

At the production stage, PHEVs require more energy-intensive processes compared to conventional vehicles due to the manufacturing of battery packs and electric powertrains. However, this initial environmental impact is often offset by the vehicle's reduced emissions during its operational phase.

During the use phase, PHEVs demonstrate significant advantages in terms of energy efficiency and emissions reduction. The ability to operate in all-electric mode for short trips and switch to hybrid mode for longer journeys allows for optimal fuel consumption and lower greenhouse gas emissions. This flexibility contributes to the overall reduction of the vehicle's carbon footprint throughout its operational life.

Maintenance and repair considerations for PHEVs differ from traditional vehicles. While the electric components may require specialized servicing, the reduced wear on the internal combustion engine can lead to extended service intervals for certain parts. This aspect of the lifecycle can contribute to resource conservation and waste reduction.

The end-of-life stage of PHEVs presents both challenges and opportunities within the circular economy framework. The complex nature of PHEV components, particularly the battery systems, necessitates advanced recycling and disposal processes. However, this complexity also drives innovation in recycling technologies, potentially creating new economic opportunities and reducing the demand for virgin materials.

Battery recycling is a critical aspect of PHEV lifecycle analysis. As battery technology evolves, so do the methods for recovering valuable materials such as lithium, cobalt, and nickel. The development of efficient recycling processes not only mitigates environmental impacts but also contributes to the circular economy by reducing reliance on primary resource extraction.

Furthermore, the potential for second-life applications of PHEV batteries in stationary energy storage systems extends their useful life beyond the automotive sector. This repurposing aligns with circular economy principles by maximizing resource utilization and creating additional value streams.

In conclusion, the lifecycle analysis of PHEVs reveals their potential to contribute positively to the circular economy model. While challenges exist, particularly in production and end-of-life stages, the overall benefits in terms of operational efficiency, emissions reduction, and material recovery present opportunities for sustainable transportation solutions.

PHEV Policy Landscape

The PHEV policy landscape has evolved significantly over the past decade, reflecting the growing importance of plug-in hybrid electric vehicles in the transition towards sustainable transportation. Governments worldwide have implemented a range of policies to promote PHEV adoption and support their integration into the circular economy model.

At the national level, many countries have introduced financial incentives to encourage PHEV purchases. These include tax credits, rebates, and subsidies that reduce the upfront cost of PHEVs for consumers. For example, the United States offers federal tax credits of up to $7,500 for eligible PHEVs, while China provides subsidies based on the vehicle's electric range and energy efficiency.

In addition to financial incentives, governments have established regulatory frameworks to drive PHEV adoption. Fuel economy standards and emissions regulations have been tightened in many regions, pushing automakers to invest in PHEV technology. The European Union's CO2 emissions targets for new vehicles have been particularly influential, leading to a surge in PHEV offerings from European manufacturers.

Local and regional policies have also played a crucial role in shaping the PHEV landscape. Many cities have implemented low-emission zones, where PHEVs enjoy preferential access compared to conventional vehicles. Urban areas have also invested in charging infrastructure, with some offering free or discounted parking for PHEVs to encourage their use in city centers.

The circular economy aspect of PHEVs has gained increasing attention in recent policy developments. Several countries have introduced regulations aimed at promoting the reuse and recycling of PHEV components, particularly batteries. For instance, the European Union's proposed Battery Regulation sets targets for the recovery of materials from end-of-life batteries and mandates the use of recycled content in new batteries.

Looking ahead, policymakers are focusing on integrating PHEVs into broader sustainable mobility strategies. This includes policies to support vehicle-to-grid (V2G) technology, enabling PHEVs to contribute to grid stability and renewable energy integration. Some countries are also exploring policies to encourage the use of PHEVs in car-sharing and ride-hailing services, further enhancing their role in sustainable urban mobility.

However, the policy landscape for PHEVs is not without challenges. There is ongoing debate about the environmental benefits of PHEVs compared to fully electric vehicles, leading some policymakers to reconsider incentives for PHEVs in favor of battery electric vehicles. Additionally, concerns about the real-world emissions of PHEVs when not operated in electric mode have prompted discussions about potential policy adjustments to ensure their environmental benefits are realized.

At the national level, many countries have introduced financial incentives to encourage PHEV purchases. These include tax credits, rebates, and subsidies that reduce the upfront cost of PHEVs for consumers. For example, the United States offers federal tax credits of up to $7,500 for eligible PHEVs, while China provides subsidies based on the vehicle's electric range and energy efficiency.

In addition to financial incentives, governments have established regulatory frameworks to drive PHEV adoption. Fuel economy standards and emissions regulations have been tightened in many regions, pushing automakers to invest in PHEV technology. The European Union's CO2 emissions targets for new vehicles have been particularly influential, leading to a surge in PHEV offerings from European manufacturers.

Local and regional policies have also played a crucial role in shaping the PHEV landscape. Many cities have implemented low-emission zones, where PHEVs enjoy preferential access compared to conventional vehicles. Urban areas have also invested in charging infrastructure, with some offering free or discounted parking for PHEVs to encourage their use in city centers.

The circular economy aspect of PHEVs has gained increasing attention in recent policy developments. Several countries have introduced regulations aimed at promoting the reuse and recycling of PHEV components, particularly batteries. For instance, the European Union's proposed Battery Regulation sets targets for the recovery of materials from end-of-life batteries and mandates the use of recycled content in new batteries.

Looking ahead, policymakers are focusing on integrating PHEVs into broader sustainable mobility strategies. This includes policies to support vehicle-to-grid (V2G) technology, enabling PHEVs to contribute to grid stability and renewable energy integration. Some countries are also exploring policies to encourage the use of PHEVs in car-sharing and ride-hailing services, further enhancing their role in sustainable urban mobility.

However, the policy landscape for PHEVs is not without challenges. There is ongoing debate about the environmental benefits of PHEVs compared to fully electric vehicles, leading some policymakers to reconsider incentives for PHEVs in favor of battery electric vehicles. Additionally, concerns about the real-world emissions of PHEVs when not operated in electric mode have prompted discussions about potential policy adjustments to ensure their environmental benefits are realized.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!