Silicon anode diagnostics: thickness, porosity, and residual lithium

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Anode Evolution and Research Objectives

Silicon anodes have undergone significant evolution since their initial introduction as potential replacements for graphite in lithium-ion batteries. The journey began in the early 1990s when researchers first recognized silicon's theoretical capacity of 4,200 mAh/g, approximately ten times higher than conventional graphite anodes. This remarkable capacity stems from silicon's ability to accommodate up to 4.4 lithium atoms per silicon atom, forming Li22Si5 alloys at room temperature.

The evolution trajectory has been marked by persistent challenges, particularly the substantial volume expansion (up to 300-400%) during lithiation, which leads to mechanical degradation and capacity fading. Early research focused primarily on bulk silicon materials, which demonstrated rapid capacity loss within few cycles due to pulverization and electrode delamination.

A pivotal shift occurred in the mid-2000s with the introduction of nanostructured silicon materials, including nanowires, nanoparticles, and porous architectures. These designs provided void space to accommodate volume changes and shortened lithium diffusion paths. The 2010s witnessed the emergence of silicon-carbon composites and core-shell structures, which combined silicon's high capacity with carbon's stability and conductivity.

Recent advancements have centered on silicon-dominant composite anodes with engineered interfaces and novel binder systems. Particular attention has been given to understanding and controlling the solid-electrolyte interphase (SEI) formation, which significantly impacts long-term cycling stability and coulombic efficiency.

The current research objectives in silicon anode diagnostics focus on developing reliable, non-destructive methods to characterize critical parameters: thickness variations during cycling, porosity distribution, and quantification of residual lithium. These parameters directly influence performance metrics including capacity retention, rate capability, and safety characteristics.

Thickness monitoring aims to correlate macroscopic electrode expansion with microscopic silicon particle swelling, providing insights into mechanical stress distribution and potential failure modes. Porosity characterization seeks to optimize void space distribution for accommodating volume changes while maintaining electronic connectivity and mechanical integrity.

Perhaps most critically, residual lithium diagnostics target the quantification and localization of inactive lithium compounds formed during cycling. These compounds, resulting from irreversible reactions with the electrolyte or mechanical isolation, represent a primary cause of capacity fade and are essential indicators of degradation mechanisms.

The overarching goal is to establish standardized diagnostic protocols that enable real-time, in-situ monitoring of these parameters, facilitating the development of silicon anodes with enhanced cycle life, improved first-cycle efficiency, and greater commercial viability for next-generation energy storage applications.

The evolution trajectory has been marked by persistent challenges, particularly the substantial volume expansion (up to 300-400%) during lithiation, which leads to mechanical degradation and capacity fading. Early research focused primarily on bulk silicon materials, which demonstrated rapid capacity loss within few cycles due to pulverization and electrode delamination.

A pivotal shift occurred in the mid-2000s with the introduction of nanostructured silicon materials, including nanowires, nanoparticles, and porous architectures. These designs provided void space to accommodate volume changes and shortened lithium diffusion paths. The 2010s witnessed the emergence of silicon-carbon composites and core-shell structures, which combined silicon's high capacity with carbon's stability and conductivity.

Recent advancements have centered on silicon-dominant composite anodes with engineered interfaces and novel binder systems. Particular attention has been given to understanding and controlling the solid-electrolyte interphase (SEI) formation, which significantly impacts long-term cycling stability and coulombic efficiency.

The current research objectives in silicon anode diagnostics focus on developing reliable, non-destructive methods to characterize critical parameters: thickness variations during cycling, porosity distribution, and quantification of residual lithium. These parameters directly influence performance metrics including capacity retention, rate capability, and safety characteristics.

Thickness monitoring aims to correlate macroscopic electrode expansion with microscopic silicon particle swelling, providing insights into mechanical stress distribution and potential failure modes. Porosity characterization seeks to optimize void space distribution for accommodating volume changes while maintaining electronic connectivity and mechanical integrity.

Perhaps most critically, residual lithium diagnostics target the quantification and localization of inactive lithium compounds formed during cycling. These compounds, resulting from irreversible reactions with the electrolyte or mechanical isolation, represent a primary cause of capacity fade and are essential indicators of degradation mechanisms.

The overarching goal is to establish standardized diagnostic protocols that enable real-time, in-situ monitoring of these parameters, facilitating the development of silicon anodes with enhanced cycle life, improved first-cycle efficiency, and greater commercial viability for next-generation energy storage applications.

Market Analysis for Advanced Battery Technologies

The global advanced battery market is experiencing unprecedented growth, driven primarily by the electric vehicle (EV) revolution and renewable energy storage demands. Current market valuations exceed $95 billion, with projections indicating a compound annual growth rate of 18.7% through 2030. Silicon anode technology represents one of the most promising segments within this expanding market, with dedicated investments reaching $2.3 billion in 2022 alone.

Silicon anode diagnostics, particularly focusing on thickness, porosity, and residual lithium measurements, addresses critical performance bottlenecks in next-generation battery development. Market research indicates that improved diagnostic capabilities could accelerate silicon anode commercialization by 30-40%, potentially unlocking a specialized market segment worth $1.8 billion by 2027.

Consumer electronics manufacturers have emerged as early adopters of silicon-enhanced battery technologies, seeking the competitive advantage of higher energy density and faster charging capabilities. This sector currently accounts for approximately 42% of silicon anode implementation, though automotive applications are rapidly gaining momentum with 27% market share and projected dominance by 2026.

Regional analysis reveals Asia-Pacific leadership in silicon anode production and diagnostics technology, commanding 58% of global market share. North American companies excel in advanced diagnostic equipment development, while European firms focus on precision measurement systems integration with automated manufacturing processes.

The diagnostic equipment market specifically targeting silicon anode parameters shows remarkable growth potential, with specialized thickness measurement systems experiencing 24% year-over-year growth. Porosity analysis tools represent the fastest-growing segment at 31% annual growth, while residual lithium detection systems command premium pricing with average unit costs exceeding $380,000.

Battery manufacturers report that enhanced silicon anode diagnostics directly correlate with production yield improvements of 15-22%, representing significant cost savings in high-volume manufacturing environments. This economic incentive is driving increased adoption of sophisticated measurement technologies across the battery production ecosystem.

Market fragmentation remains high, with over 40 companies offering various diagnostic solutions, though consolidation through strategic acquisitions has accelerated in the past 18 months. The competitive landscape features specialized instrumentation providers alongside diversified analytical equipment manufacturers expanding their battery-specific product portfolios.

Silicon anode diagnostics, particularly focusing on thickness, porosity, and residual lithium measurements, addresses critical performance bottlenecks in next-generation battery development. Market research indicates that improved diagnostic capabilities could accelerate silicon anode commercialization by 30-40%, potentially unlocking a specialized market segment worth $1.8 billion by 2027.

Consumer electronics manufacturers have emerged as early adopters of silicon-enhanced battery technologies, seeking the competitive advantage of higher energy density and faster charging capabilities. This sector currently accounts for approximately 42% of silicon anode implementation, though automotive applications are rapidly gaining momentum with 27% market share and projected dominance by 2026.

Regional analysis reveals Asia-Pacific leadership in silicon anode production and diagnostics technology, commanding 58% of global market share. North American companies excel in advanced diagnostic equipment development, while European firms focus on precision measurement systems integration with automated manufacturing processes.

The diagnostic equipment market specifically targeting silicon anode parameters shows remarkable growth potential, with specialized thickness measurement systems experiencing 24% year-over-year growth. Porosity analysis tools represent the fastest-growing segment at 31% annual growth, while residual lithium detection systems command premium pricing with average unit costs exceeding $380,000.

Battery manufacturers report that enhanced silicon anode diagnostics directly correlate with production yield improvements of 15-22%, representing significant cost savings in high-volume manufacturing environments. This economic incentive is driving increased adoption of sophisticated measurement technologies across the battery production ecosystem.

Market fragmentation remains high, with over 40 companies offering various diagnostic solutions, though consolidation through strategic acquisitions has accelerated in the past 18 months. The competitive landscape features specialized instrumentation providers alongside diversified analytical equipment manufacturers expanding their battery-specific product portfolios.

Silicon Anode Characterization Challenges

Silicon anode characterization presents significant challenges due to the complex and dynamic nature of silicon during lithium-ion battery operation. The accurate measurement of silicon anode thickness remains problematic as silicon undergoes substantial volume changes (up to 300%) during lithiation and delithiation cycles. This expansion and contraction creates a moving target for thickness measurements, requiring in-situ or operando techniques rather than conventional ex-situ methods.

Porosity quantification in silicon anodes represents another critical challenge. The initial porosity design significantly impacts electrode performance, as it must accommodate volume expansion while maintaining structural integrity. However, traditional porosity measurement techniques like mercury intrusion porosimetry can damage the delicate silicon structures, while gas adsorption methods may not fully capture the hierarchical pore networks that develop during cycling.

Residual lithium detection and quantification pose perhaps the most complex challenge. During formation cycles and subsequent operation, lithium can become trapped in various forms within the silicon anode structure - as metallic lithium, lithium silicides, or within the solid electrolyte interphase (SEI). These residual lithium compounds significantly affect battery performance, safety, and longevity, yet their detection requires sophisticated analytical approaches.

The dynamic interplay between these three parameters further complicates characterization efforts. As silicon anodes cycle, thickness changes affect porosity distribution, which in turn influences lithium trapping mechanisms. This interdependence necessitates multimodal characterization approaches rather than isolated parameter measurements.

Current characterization techniques also struggle with spatial resolution limitations. Silicon anodes often develop heterogeneous structures during cycling, with non-uniform thickness, porosity gradients, and localized lithium accumulation. Capturing this spatial heterogeneity requires advanced imaging techniques that can maintain resolution across multiple length scales.

Time-resolved measurements present additional difficulties. The rapid kinetics of lithiation/delithiation processes demand characterization methods with sufficient temporal resolution to capture transient phenomena. Most conventional techniques provide only static snapshots rather than the dynamic evolution of these critical parameters.

Finally, sample preparation for silicon anode characterization introduces its own complications. Many analytical techniques require specific sample conditions that may alter the very properties being measured. For instance, exposure to air can rapidly oxidize residual lithium, while vacuum environments may induce structural changes in the porous silicon matrix.

Porosity quantification in silicon anodes represents another critical challenge. The initial porosity design significantly impacts electrode performance, as it must accommodate volume expansion while maintaining structural integrity. However, traditional porosity measurement techniques like mercury intrusion porosimetry can damage the delicate silicon structures, while gas adsorption methods may not fully capture the hierarchical pore networks that develop during cycling.

Residual lithium detection and quantification pose perhaps the most complex challenge. During formation cycles and subsequent operation, lithium can become trapped in various forms within the silicon anode structure - as metallic lithium, lithium silicides, or within the solid electrolyte interphase (SEI). These residual lithium compounds significantly affect battery performance, safety, and longevity, yet their detection requires sophisticated analytical approaches.

The dynamic interplay between these three parameters further complicates characterization efforts. As silicon anodes cycle, thickness changes affect porosity distribution, which in turn influences lithium trapping mechanisms. This interdependence necessitates multimodal characterization approaches rather than isolated parameter measurements.

Current characterization techniques also struggle with spatial resolution limitations. Silicon anodes often develop heterogeneous structures during cycling, with non-uniform thickness, porosity gradients, and localized lithium accumulation. Capturing this spatial heterogeneity requires advanced imaging techniques that can maintain resolution across multiple length scales.

Time-resolved measurements present additional difficulties. The rapid kinetics of lithiation/delithiation processes demand characterization methods with sufficient temporal resolution to capture transient phenomena. Most conventional techniques provide only static snapshots rather than the dynamic evolution of these critical parameters.

Finally, sample preparation for silicon anode characterization introduces its own complications. Many analytical techniques require specific sample conditions that may alter the very properties being measured. For instance, exposure to air can rapidly oxidize residual lithium, while vacuum environments may induce structural changes in the porous silicon matrix.

Current Diagnostic Methods for Silicon Anodes

01 Silicon anode thickness optimization

The thickness of silicon anodes significantly impacts battery performance. Optimal thickness ranges typically fall between 5-50 micrometers, balancing energy density and mechanical stability. Thinner anodes may offer better cycling stability and faster charging capabilities but lower overall capacity, while thicker anodes provide higher capacity but may suffer from increased mechanical stress during lithiation/delithiation cycles. Advanced manufacturing techniques allow for precise thickness control to optimize performance for specific applications.- Optimal silicon anode thickness for battery performance: The thickness of silicon anodes significantly impacts battery performance. Optimal thickness ranges typically fall between 5-50 micrometers, balancing energy density and mechanical stability. Thinner anodes may provide better cycling stability by accommodating volume expansion during lithiation, while thicker anodes can offer higher energy density but may suffer from mechanical degradation. Controlling thickness uniformity across the electrode is crucial for consistent performance and longevity of lithium-ion batteries.

- Porosity control in silicon anodes for improved cycling: Engineered porosity in silicon anodes is essential for accommodating volume expansion during lithiation/delithiation cycles. Optimal porosity ranges of 20-60% allow for better electrolyte penetration and ion transport while maintaining structural integrity. Hierarchical porous structures with both micro and macro pores can effectively buffer volume changes, reduce mechanical stress, and improve cycling stability. Various manufacturing techniques including templating methods and selective etching can be employed to create controlled porous silicon structures with tailored pore size distributions.

- Residual lithium management in silicon anodes: Residual lithium content in silicon anodes significantly affects initial capacity, coulombic efficiency, and long-term cycling stability. Excessive residual lithium can lead to unwanted side reactions with electrolytes, forming thicker SEI layers that impede lithium-ion transport. Controlled pre-lithiation techniques can optimize residual lithium levels to compensate for irreversible capacity loss during initial cycles. Post-processing methods such as washing treatments and thermal annealing can effectively reduce harmful residual lithium compounds while maintaining beneficial pre-lithiation effects.

- Composite silicon anode structures with controlled morphology: Advanced silicon anode designs incorporate composite structures with precisely controlled morphology to address volume expansion challenges. These include silicon-carbon composites, silicon-metal alloys, and core-shell structures where silicon particles are encapsulated in conductive carbon matrices. The morphological design considers particle size distribution, aspect ratios, and interfacial properties. Nanostructured silicon components such as nanowires, nanotubes, and porous nanoparticles with specific thickness and porosity parameters enable better mechanical stability and electrochemical performance.

- Manufacturing processes affecting silicon anode parameters: Specialized manufacturing techniques significantly impact the final thickness, porosity, and residual lithium content of silicon anodes. Advanced deposition methods like chemical vapor deposition and magnetron sputtering enable precise thickness control. Porosity can be engineered through template-assisted synthesis, freeze-drying techniques, and selective etching processes. Post-processing treatments including calendering for thickness adjustment, thermal treatments for porosity modification, and controlled exposure to lithium sources for residual lithium management are critical for optimizing anode performance parameters.

02 Porosity control in silicon anodes

Porosity is a critical parameter in silicon anode design, typically optimized between 20-60%. Controlled porosity provides void space to accommodate silicon's volume expansion during lithiation, reducing mechanical stress and improving cycling stability. Techniques such as templating, etching, and specialized coating methods can create engineered porous structures. The pore size distribution, interconnectivity, and overall porosity percentage must be carefully balanced to maintain electronic conductivity while allowing for volume changes and electrolyte penetration.Expand Specific Solutions03 Residual lithium management

Residual lithium in silicon anodes affects initial capacity, coulombic efficiency, and safety. Controlling residual lithium through pre-lithiation techniques can compensate for first-cycle capacity loss. However, excess residual lithium may cause safety issues through reactions with electrolytes or air. Advanced manufacturing processes incorporate precise lithium dosing methods, protective coatings, and specialized handling techniques to optimize the amount of residual lithium while maintaining safety and performance standards.Expand Specific Solutions04 Composite silicon anode structures

Composite silicon anode structures combine silicon with carbon materials, polymers, or other metals to address the challenges of volume expansion and low conductivity. These composites often feature core-shell structures, silicon-carbon matrices, or silicon particles embedded in conductive frameworks. The composite approach allows for tailored thickness, porosity, and residual lithium content while improving mechanical stability and electronic conductivity. Various synthesis methods including chemical vapor deposition, spray pyrolysis, and mechanical milling can be used to create these composite structures.Expand Specific Solutions05 Manufacturing processes for silicon anodes

Advanced manufacturing processes for silicon anodes focus on controlling thickness, porosity, and residual lithium simultaneously. These include precision coating techniques like doctor blade, slot-die coating, and electrodeposition that enable uniform thickness control. Specialized heat treatment processes can create controlled porosity while maintaining structural integrity. Post-processing techniques such as calendering adjust final thickness and porosity parameters. These manufacturing approaches often incorporate in-line quality control systems to monitor critical parameters throughout production.Expand Specific Solutions

Leading Companies in Silicon Anode Research

Silicon anode diagnostics for thickness, porosity, and residual lithium is evolving in a rapidly growing market, currently in the early commercialization phase. The global silicon anode battery market is expanding significantly as manufacturers seek higher energy density solutions for EVs and consumer electronics. Companies like Nexeon, SK On, and BTR New Material Group are leading technological advancements, while established players such as Panasonic Holdings and SK Innovation provide industrial scale. Emerging specialists including Graphenix Development and Svolt Energy Technology are developing innovative diagnostic techniques to address key challenges in silicon anode implementation. The technology is approaching commercial maturity, with companies like Wacker Chemie providing essential raw materials and research institutions like Battelle Memorial Institute contributing fundamental knowledge to overcome expansion and degradation issues.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed a comprehensive silicon anode diagnostic platform called "Si-DiagnosticSuite" that integrates multiple analytical techniques. For thickness measurement, they utilize laser interferometry combined with cross-sectional SEM imaging to track expansion/contraction during cycling with nanometer precision. Their porosity analysis employs a dual-approach methodology combining gas adsorption techniques with mercury intrusion porosimetry, allowing characterization across micro, meso, and macropore regimes. For residual lithium detection, Panasonic employs a proprietary electrochemical titration method with specialized reference electrodes that can quantify lithium distribution within the electrode structure. Their system incorporates machine learning algorithms that correlate diagnostic measurements with cell performance metrics, enabling predictive modeling of capacity fade based on anode structural parameters.

Strengths: Integrated diagnostic platform with automated data analysis; high throughput capability suitable for production environments; excellent correlation between diagnostic measurements and cell performance. Weaknesses: Requires significant capital investment; complex calibration procedures; limited sensitivity for ultra-thin silicon coatings below 50nm.

Nexeon Ltd.

Technical Solution: Nexeon has developed advanced silicon anode diagnostic techniques focusing on multi-parameter characterization. Their proprietary methodology combines electron microscopy with tomographic reconstruction to accurately measure silicon anode thickness variations during cycling. For porosity assessment, they employ mercury intrusion porosimetry alongside BET surface area analysis to quantify pore size distribution and volume changes. Residual lithium detection is achieved through their innovative titration-based analytical protocol that can detect sub-ppm levels of unreacted lithium. Nexeon's diagnostic suite includes in-situ monitoring capabilities that track real-time changes in silicon microstructure during lithiation/delithiation cycles, providing crucial data on performance degradation mechanisms.

Strengths: Exceptional precision in thickness measurement (±2nm resolution); comprehensive porosity characterization across multiple length scales; industry-leading sensitivity for residual lithium detection. Weaknesses: Diagnostic equipment requires specialized training; time-intensive analysis process; higher implementation cost compared to conventional electrode characterization methods.

Key Measurement Techniques for Thickness, Porosity and Lithium

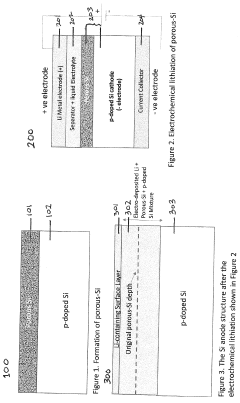

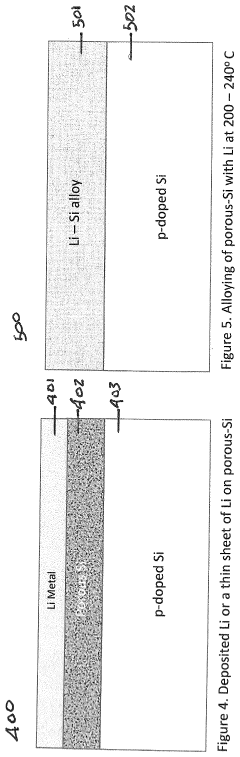

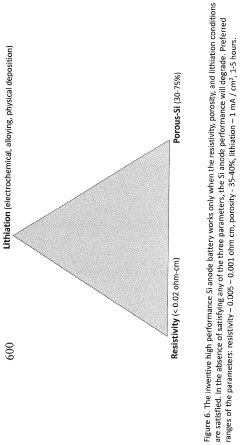

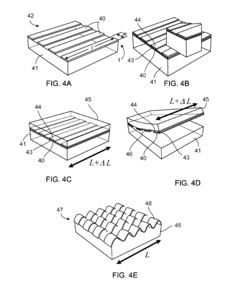

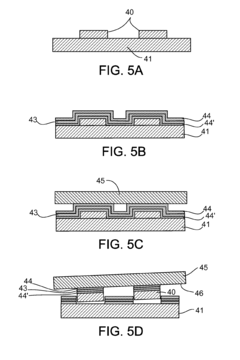

LITHIATION OF POROUS-Si FOR HIGH PERFORMANCE ANODE

PatentPendingUS20240102201A1

Innovation

- A single crystal porous-Si/p-Si anode with a wide range of porosities and low resistivity, achieved through lithiation, is developed, allowing for a robust anode structure that outperforms traditional graphite or lithium metal anodes by maintaining mechanical integrity and preventing dendrite formation.

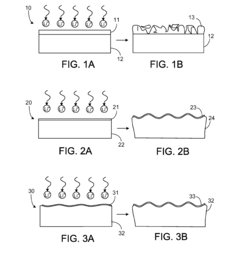

Buckled silicon nanostructures on elastomeric substrates for rechargeable lithium ion batteries

PatentInactiveUS20130115512A1

Innovation

- A flexible silicon anode is created by adhering a thin silicon layer to a flexible substrate, allowing for buckling and stress relief during charge-discharge cycles, which extends the cycle life and maintains functionality under high strain.

Manufacturing Scale-up Considerations

Scaling up silicon anode manufacturing from laboratory to industrial production presents significant challenges that require careful consideration of diagnostic parameters. The transition demands robust quality control systems capable of monitoring thickness, porosity, and residual lithium content with high precision across large production volumes.

Production equipment for silicon anodes must incorporate advanced in-line measurement technologies to ensure consistent thickness control. Optical methods such as laser triangulation and interferometry can be adapted for continuous monitoring during roll-to-roll processing, while X-ray techniques offer deeper insights into material uniformity. These systems must operate at speeds compatible with industrial throughput requirements while maintaining nanometer-scale precision.

Porosity monitoring presents unique challenges at scale, as traditional laboratory techniques like BET analysis and mercury intrusion porosimetry are typically offline and time-consuming. Development of real-time porosity assessment tools based on acoustic or electrical impedance measurements could enable continuous quality assurance during manufacturing. Correlation studies between these rapid techniques and established methods are essential for validation.

Residual lithium detection becomes increasingly critical at industrial scale due to safety implications. Automated systems utilizing techniques such as titration, ICP-MS, or specialized spectroscopic methods must be integrated into production lines. These systems should feature appropriate safety controls and isolation protocols to manage the reactivity of lithium compounds during high-volume manufacturing.

Data management infrastructure represents another crucial consideration, as the volume of diagnostic information increases exponentially with production scale. Implementation of advanced analytics platforms capable of processing multivariate data from thickness, porosity, and lithium content measurements can identify subtle correlations between manufacturing parameters and anode performance.

Environmental controls must be more stringent in scaled production environments, particularly regarding moisture and oxygen levels that can affect residual lithium compounds. Specialized dry rooms or inert atmosphere processing lines with continuous monitoring capabilities are necessary investments for maintaining product quality and safety.

Cost-benefit analysis of various diagnostic approaches becomes increasingly important at scale. While comprehensive characterization of every anode would provide maximum quality assurance, practical manufacturing economics necessitate strategic sampling plans and statistical process control methodologies that balance thoroughness with production efficiency.

Production equipment for silicon anodes must incorporate advanced in-line measurement technologies to ensure consistent thickness control. Optical methods such as laser triangulation and interferometry can be adapted for continuous monitoring during roll-to-roll processing, while X-ray techniques offer deeper insights into material uniformity. These systems must operate at speeds compatible with industrial throughput requirements while maintaining nanometer-scale precision.

Porosity monitoring presents unique challenges at scale, as traditional laboratory techniques like BET analysis and mercury intrusion porosimetry are typically offline and time-consuming. Development of real-time porosity assessment tools based on acoustic or electrical impedance measurements could enable continuous quality assurance during manufacturing. Correlation studies between these rapid techniques and established methods are essential for validation.

Residual lithium detection becomes increasingly critical at industrial scale due to safety implications. Automated systems utilizing techniques such as titration, ICP-MS, or specialized spectroscopic methods must be integrated into production lines. These systems should feature appropriate safety controls and isolation protocols to manage the reactivity of lithium compounds during high-volume manufacturing.

Data management infrastructure represents another crucial consideration, as the volume of diagnostic information increases exponentially with production scale. Implementation of advanced analytics platforms capable of processing multivariate data from thickness, porosity, and lithium content measurements can identify subtle correlations between manufacturing parameters and anode performance.

Environmental controls must be more stringent in scaled production environments, particularly regarding moisture and oxygen levels that can affect residual lithium compounds. Specialized dry rooms or inert atmosphere processing lines with continuous monitoring capabilities are necessary investments for maintaining product quality and safety.

Cost-benefit analysis of various diagnostic approaches becomes increasingly important at scale. While comprehensive characterization of every anode would provide maximum quality assurance, practical manufacturing economics necessitate strategic sampling plans and statistical process control methodologies that balance thoroughness with production efficiency.

Environmental Impact and Sustainability Assessment

The development of silicon anode technology, while promising for energy storage advancements, raises significant environmental and sustainability concerns that warrant careful assessment. Silicon anode production processes, particularly those involving thickness control, porosity engineering, and residual lithium management, consume substantial energy and resources. The extraction of silicon precursors often involves mining operations that can lead to habitat disruption, soil erosion, and water pollution if not properly managed.

Manufacturing processes for silicon anodes typically require high temperatures and energy-intensive conditions, contributing to considerable carbon emissions. The diagnostic techniques used to measure thickness and porosity, such as electron microscopy and X-ray tomography, also have associated energy costs and potential chemical waste streams that must be properly handled and disposed of.

Residual lithium compounds present particular environmental challenges due to their high reactivity with water and air. Improper handling or disposal can lead to hazardous reactions, contamination of water sources, and potential fire risks. Current diagnostic methods for detecting residual lithium often involve solvents and chemicals that may themselves pose environmental hazards if released untreated.

From a life-cycle perspective, silicon anodes offer potential sustainability benefits through improved battery longevity and energy density, potentially reducing overall resource consumption compared to traditional graphite anodes. However, end-of-life considerations remain problematic, as the complex composite structures of silicon anodes with various binders and additives complicate recycling efforts.

Water usage represents another critical environmental factor, as silicon processing and diagnostic procedures often require significant quantities of ultra-pure water. In regions facing water scarcity, this consumption pattern raises sustainability concerns that must be addressed through water recycling systems and process optimization.

Emerging green manufacturing approaches for silicon anodes show promise for reducing environmental impact. These include room-temperature synthesis methods, water-based processing, and the use of bio-derived binders and templates. Additionally, non-destructive diagnostic techniques that minimize chemical waste generation are being developed to reduce the environmental footprint of quality control processes.

Regulatory frameworks worldwide are increasingly demanding life-cycle assessments for battery technologies, placing greater emphasis on sustainable production methods and recyclability. Companies developing silicon anode technologies must therefore integrate environmental considerations into their diagnostic and manufacturing protocols to ensure market acceptance and regulatory compliance.

Manufacturing processes for silicon anodes typically require high temperatures and energy-intensive conditions, contributing to considerable carbon emissions. The diagnostic techniques used to measure thickness and porosity, such as electron microscopy and X-ray tomography, also have associated energy costs and potential chemical waste streams that must be properly handled and disposed of.

Residual lithium compounds present particular environmental challenges due to their high reactivity with water and air. Improper handling or disposal can lead to hazardous reactions, contamination of water sources, and potential fire risks. Current diagnostic methods for detecting residual lithium often involve solvents and chemicals that may themselves pose environmental hazards if released untreated.

From a life-cycle perspective, silicon anodes offer potential sustainability benefits through improved battery longevity and energy density, potentially reducing overall resource consumption compared to traditional graphite anodes. However, end-of-life considerations remain problematic, as the complex composite structures of silicon anodes with various binders and additives complicate recycling efforts.

Water usage represents another critical environmental factor, as silicon processing and diagnostic procedures often require significant quantities of ultra-pure water. In regions facing water scarcity, this consumption pattern raises sustainability concerns that must be addressed through water recycling systems and process optimization.

Emerging green manufacturing approaches for silicon anodes show promise for reducing environmental impact. These include room-temperature synthesis methods, water-based processing, and the use of bio-derived binders and templates. Additionally, non-destructive diagnostic techniques that minimize chemical waste generation are being developed to reduce the environmental footprint of quality control processes.

Regulatory frameworks worldwide are increasingly demanding life-cycle assessments for battery technologies, placing greater emphasis on sustainable production methods and recyclability. Companies developing silicon anode technologies must therefore integrate environmental considerations into their diagnostic and manufacturing protocols to ensure market acceptance and regulatory compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!