Silicon anode fast charge protocols with thermal constraints

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Anode Evolution and Fast Charging Goals

Silicon anodes have emerged as a promising alternative to traditional graphite anodes in lithium-ion batteries due to their significantly higher theoretical capacity (approximately 4,200 mAh/g compared to graphite's 372 mAh/g). The evolution of silicon anode technology can be traced back to the early 2000s when researchers began exploring silicon as a potential anode material. Initially, pure silicon anodes faced severe challenges related to volume expansion during lithiation, which could exceed 300%, leading to mechanical degradation and rapid capacity fading.

The technological evolution progressed through several key phases. First-generation approaches focused on nanostructured silicon to accommodate volume changes, including silicon nanowires, nanoparticles, and porous structures. The second generation introduced silicon-carbon composites, where carbon served as a buffer for volume expansion while improving electrical conductivity. Recent advancements have led to third-generation solutions incorporating sophisticated engineering at the molecular and structural levels, such as silicon-graphene composites and prelithiated silicon materials.

Fast charging capabilities represent a critical goal in silicon anode development, driven by consumer demand for reduced charging times in electric vehicles and portable electronics. The industry has established ambitious targets: achieving 80% charge in under 15 minutes for EVs and even faster rates for consumer electronics, while maintaining battery longevity and safety. These goals align with broader industry roadmaps that project charging rates of 3-5C becoming standard by 2025, with some premium applications targeting 6-10C rates.

Thermal constraints present a fundamental challenge in fast charging silicon anodes. The high current densities required for fast charging generate significant heat through various mechanisms: ohmic heating, interfacial resistance, and exothermic electrochemical reactions. Silicon's relatively low electrical conductivity exacerbates these thermal issues. Industry standards typically limit battery temperature to 45-55°C during operation to prevent accelerated degradation and safety risks.

The technical objectives for silicon anode fast charging protocols must therefore balance multiple competing factors: maximizing charging speed, minimizing capacity degradation, preventing lithium plating, and maintaining safe thermal profiles. This requires sophisticated battery management systems capable of dynamic protocol adjustments based on real-time temperature monitoring, state of charge estimation, and degradation modeling.

Current research is increasingly focused on developing adaptive charging protocols specifically optimized for silicon-based anodes, which differ significantly from traditional constant-current/constant-voltage (CC/CV) protocols designed for graphite anodes. These advanced protocols incorporate pulse charging, temperature-dependent current modulation, and machine learning algorithms to optimize charging parameters based on battery condition and environmental factors.

The technological evolution progressed through several key phases. First-generation approaches focused on nanostructured silicon to accommodate volume changes, including silicon nanowires, nanoparticles, and porous structures. The second generation introduced silicon-carbon composites, where carbon served as a buffer for volume expansion while improving electrical conductivity. Recent advancements have led to third-generation solutions incorporating sophisticated engineering at the molecular and structural levels, such as silicon-graphene composites and prelithiated silicon materials.

Fast charging capabilities represent a critical goal in silicon anode development, driven by consumer demand for reduced charging times in electric vehicles and portable electronics. The industry has established ambitious targets: achieving 80% charge in under 15 minutes for EVs and even faster rates for consumer electronics, while maintaining battery longevity and safety. These goals align with broader industry roadmaps that project charging rates of 3-5C becoming standard by 2025, with some premium applications targeting 6-10C rates.

Thermal constraints present a fundamental challenge in fast charging silicon anodes. The high current densities required for fast charging generate significant heat through various mechanisms: ohmic heating, interfacial resistance, and exothermic electrochemical reactions. Silicon's relatively low electrical conductivity exacerbates these thermal issues. Industry standards typically limit battery temperature to 45-55°C during operation to prevent accelerated degradation and safety risks.

The technical objectives for silicon anode fast charging protocols must therefore balance multiple competing factors: maximizing charging speed, minimizing capacity degradation, preventing lithium plating, and maintaining safe thermal profiles. This requires sophisticated battery management systems capable of dynamic protocol adjustments based on real-time temperature monitoring, state of charge estimation, and degradation modeling.

Current research is increasingly focused on developing adaptive charging protocols specifically optimized for silicon-based anodes, which differ significantly from traditional constant-current/constant-voltage (CC/CV) protocols designed for graphite anodes. These advanced protocols incorporate pulse charging, temperature-dependent current modulation, and machine learning algorithms to optimize charging parameters based on battery condition and environmental factors.

Market Analysis for High-Performance EV Batteries

The electric vehicle (EV) battery market is experiencing unprecedented growth, driven by global shifts toward sustainable transportation and stringent emission regulations. The high-performance EV battery segment, particularly those incorporating silicon anode technology with fast charging capabilities, represents a rapidly expanding market opportunity. Current projections indicate the global EV battery market will reach $127 billion by 2027, with high-performance batteries accounting for approximately 35% of this value.

Consumer demand for reduced charging times while maintaining battery longevity has become a critical market differentiator. Market research indicates that 78% of potential EV buyers consider charging time a decisive factor in their purchasing decisions, with 65% expressing willingness to pay premium prices for vehicles offering sub-20-minute charging capabilities without compromising battery lifespan.

Silicon anode batteries with advanced thermal management systems are positioned to capture significant market share due to their superior energy density and fast-charging potential. The market for silicon-based EV batteries specifically is growing at a compound annual growth rate of 24.3%, outpacing the broader EV battery market's 18.7% growth rate.

Regional analysis reveals varying market dynamics. North America and Europe demonstrate strong consumer preference for high-performance batteries with fast-charging capabilities, with thermal management being a secondary consideration. In contrast, Asian markets, particularly China and South Korea, prioritize cost-efficiency alongside performance metrics, creating distinct market segments for silicon anode technologies.

Commercial fleet operators represent another significant market segment, with 83% indicating that vehicle downtime for charging directly impacts operational profitability. This segment shows heightened interest in silicon anode batteries with optimized thermal management during fast charging, as it aligns with their need for maximum vehicle utilization.

Market competition is intensifying as traditional battery manufacturers and technology startups race to commercialize silicon anode solutions with effective thermal constraint management. Venture capital investment in this specific technology reached $3.2 billion in 2022, signaling strong market confidence in its commercial potential.

Consumer price sensitivity analysis indicates that the market can sustain a 15-20% premium for batteries offering verified fast-charging protocols with thermal management, compared to conventional lithium-ion batteries. This premium acceptance is highest among luxury EV segments and commercial fleet operators, where operational efficiency outweighs initial cost considerations.

Consumer demand for reduced charging times while maintaining battery longevity has become a critical market differentiator. Market research indicates that 78% of potential EV buyers consider charging time a decisive factor in their purchasing decisions, with 65% expressing willingness to pay premium prices for vehicles offering sub-20-minute charging capabilities without compromising battery lifespan.

Silicon anode batteries with advanced thermal management systems are positioned to capture significant market share due to their superior energy density and fast-charging potential. The market for silicon-based EV batteries specifically is growing at a compound annual growth rate of 24.3%, outpacing the broader EV battery market's 18.7% growth rate.

Regional analysis reveals varying market dynamics. North America and Europe demonstrate strong consumer preference for high-performance batteries with fast-charging capabilities, with thermal management being a secondary consideration. In contrast, Asian markets, particularly China and South Korea, prioritize cost-efficiency alongside performance metrics, creating distinct market segments for silicon anode technologies.

Commercial fleet operators represent another significant market segment, with 83% indicating that vehicle downtime for charging directly impacts operational profitability. This segment shows heightened interest in silicon anode batteries with optimized thermal management during fast charging, as it aligns with their need for maximum vehicle utilization.

Market competition is intensifying as traditional battery manufacturers and technology startups race to commercialize silicon anode solutions with effective thermal constraint management. Venture capital investment in this specific technology reached $3.2 billion in 2022, signaling strong market confidence in its commercial potential.

Consumer price sensitivity analysis indicates that the market can sustain a 15-20% premium for batteries offering verified fast-charging protocols with thermal management, compared to conventional lithium-ion batteries. This premium acceptance is highest among luxury EV segments and commercial fleet operators, where operational efficiency outweighs initial cost considerations.

Silicon Anode Technical Challenges and Thermal Limitations

Silicon anodes represent a significant advancement in lithium-ion battery technology, offering theoretical capacity up to ten times that of traditional graphite anodes. However, their commercial implementation faces substantial technical challenges, particularly related to thermal constraints during fast charging operations. The primary limitation stems from silicon's dramatic volume expansion (up to 300-400%) during lithium insertion, which creates mechanical stress leading to particle fracturing and electrical disconnection after multiple charge-discharge cycles.

This volume expansion generates considerable heat during the lithium insertion process, creating a thermal management challenge that becomes particularly acute during fast charging protocols. When charging rates exceed C/2 (charging in less than 2 hours), silicon anodes typically experience temperature spikes that can trigger thermal runaway if not properly managed. Internal resistance increases as silicon particles crack and lose contact with conductive additives, further exacerbating heat generation through resistive heating mechanisms.

The solid-electrolyte interphase (SEI) formation on silicon surfaces presents another critical thermal consideration. Unlike graphite anodes with relatively stable SEI layers, silicon's repeated expansion and contraction causes continuous SEI breakdown and reformation, consuming lithium and electrolyte while generating additional heat. This parasitic reaction accelerates at elevated temperatures, creating a dangerous positive feedback loop during fast charging operations.

Electrolyte decomposition near silicon surfaces intensifies at temperatures above 45°C, producing gaseous byproducts that increase internal cell pressure and compromise safety systems. Studies have demonstrated that silicon anodes operating above this temperature threshold experience accelerated capacity fade, with cycle life potentially reduced by 50-70% compared to thermally optimized conditions.

The thermal conductivity limitations of silicon-based electrode structures further complicate heat dissipation. Silicon's intrinsic thermal conductivity (approximately 150 W/m·K) decreases dramatically when formulated into porous electrode structures (typically below 5 W/m·K), creating localized hotspots during rapid charging that can damage surrounding cell components.

Current commercial silicon-graphite composite anodes (typically containing 5-10% silicon) already demonstrate significant thermal management challenges, requiring sophisticated battery management systems to monitor and control temperature during fast charging. As silicon content increases to achieve higher energy densities, these thermal constraints become increasingly limiting factors in practical applications, particularly for electric vehicles and portable electronics where fast charging capability represents a critical consumer demand.

This volume expansion generates considerable heat during the lithium insertion process, creating a thermal management challenge that becomes particularly acute during fast charging protocols. When charging rates exceed C/2 (charging in less than 2 hours), silicon anodes typically experience temperature spikes that can trigger thermal runaway if not properly managed. Internal resistance increases as silicon particles crack and lose contact with conductive additives, further exacerbating heat generation through resistive heating mechanisms.

The solid-electrolyte interphase (SEI) formation on silicon surfaces presents another critical thermal consideration. Unlike graphite anodes with relatively stable SEI layers, silicon's repeated expansion and contraction causes continuous SEI breakdown and reformation, consuming lithium and electrolyte while generating additional heat. This parasitic reaction accelerates at elevated temperatures, creating a dangerous positive feedback loop during fast charging operations.

Electrolyte decomposition near silicon surfaces intensifies at temperatures above 45°C, producing gaseous byproducts that increase internal cell pressure and compromise safety systems. Studies have demonstrated that silicon anodes operating above this temperature threshold experience accelerated capacity fade, with cycle life potentially reduced by 50-70% compared to thermally optimized conditions.

The thermal conductivity limitations of silicon-based electrode structures further complicate heat dissipation. Silicon's intrinsic thermal conductivity (approximately 150 W/m·K) decreases dramatically when formulated into porous electrode structures (typically below 5 W/m·K), creating localized hotspots during rapid charging that can damage surrounding cell components.

Current commercial silicon-graphite composite anodes (typically containing 5-10% silicon) already demonstrate significant thermal management challenges, requiring sophisticated battery management systems to monitor and control temperature during fast charging. As silicon content increases to achieve higher energy densities, these thermal constraints become increasingly limiting factors in practical applications, particularly for electric vehicles and portable electronics where fast charging capability represents a critical consumer demand.

Current Fast Charging Protocols for Silicon Anodes

01 Silicon anode composition for fast charging

Silicon anodes can be formulated with specific compositions to enhance fast charging capabilities. These compositions may include silicon particles with controlled size distribution, conductive additives, and binders that accommodate volume changes during charging. The optimized composition helps to maintain structural integrity during rapid charging cycles, reducing capacity fade and extending battery life while enabling faster charge rates.- Silicon anode composition for fast charging: Silicon anodes can be formulated with specific compositions to enhance fast charging capabilities. These compositions may include silicon particles with controlled size distribution, conductive additives, and binders that accommodate volume changes during charging. The optimized composition helps to maintain structural integrity during rapid charging cycles while maximizing the high theoretical capacity of silicon.

- Charging protocols for silicon-based batteries: Specialized charging protocols have been developed specifically for silicon anode batteries to enable fast charging while minimizing degradation. These protocols typically involve multi-stage charging with controlled current and voltage profiles, temperature management, and adaptive algorithms that respond to the battery's state of charge and health. Such protocols help to mitigate the volume expansion issues associated with silicon anodes during rapid charging.

- Silicon-carbon composite anodes for improved charging: Silicon-carbon composite materials are used to enhance the fast charging capabilities of lithium-ion batteries. By integrating silicon with various carbon structures such as graphene, carbon nanotubes, or amorphous carbon, these composites provide improved electrical conductivity and structural stability. The carbon component helps buffer the volume changes of silicon during charging, allowing for faster charge rates without significant capacity loss.

- Electrolyte formulations for fast-charging silicon anodes: Specialized electrolyte formulations have been developed to facilitate fast charging in silicon anode batteries. These electrolytes often contain additives that form stable solid-electrolyte interphase (SEI) layers on silicon surfaces, reducing irreversible capacity loss during rapid charging. Some formulations also incorporate flame retardants and stabilizers to enhance safety during high-rate charging processes.

- Battery management systems for silicon anode fast charging: Advanced battery management systems (BMS) are designed specifically for silicon anode batteries to enable safe and efficient fast charging. These systems incorporate real-time monitoring of cell parameters, predictive models of silicon anode behavior, and adaptive control algorithms. The BMS can dynamically adjust charging parameters based on battery temperature, state of charge, and degradation state to maximize charging speed while preserving battery life.

02 Charging protocols specific to silicon anodes

Specialized charging protocols have been developed specifically for batteries with silicon anodes. These protocols typically involve multi-stage charging with controlled current and voltage profiles that account for the unique characteristics of silicon during lithiation. By carefully managing charging parameters such as current density, temperature, and voltage limits, these protocols minimize degradation mechanisms while maximizing charging speed.Expand Specific Solutions03 Silicon-carbon composite anodes for fast charging

Silicon-carbon composite materials have been developed to improve fast charging performance. These composites combine silicon's high capacity with carbon's excellent conductivity and structural stability. The carbon component helps buffer volume changes and enhances electron transport, while the silicon provides high energy density. This combination enables faster charging rates while maintaining cycle life and capacity retention.Expand Specific Solutions04 Temperature management during fast charging of silicon anodes

Temperature control systems and methods have been developed for fast charging of silicon anode batteries. These approaches monitor and regulate battery temperature during rapid charging to prevent degradation mechanisms that are accelerated at high temperatures. Some solutions incorporate active cooling, thermal management materials, or adaptive charging algorithms that adjust charging parameters based on temperature feedback.Expand Specific Solutions05 Electrolyte formulations for silicon anode fast charging

Specialized electrolyte formulations have been designed to enable fast charging of silicon anode batteries. These electrolytes typically contain additives that form stable solid electrolyte interphase (SEI) layers on silicon surfaces, preventing continuous electrolyte decomposition during cycling. Some formulations also incorporate solvents and salts that enhance lithium-ion transport, reducing concentration polarization during high-rate charging.Expand Specific Solutions

Key Industry Players in Silicon Anode Battery Market

Silicon anode fast charging technology is currently in the early commercialization phase, with the market expected to grow significantly as electric vehicle adoption accelerates. The global market for silicon anode batteries is projected to expand rapidly due to demands for faster charging capabilities while maintaining thermal stability. Companies like CATL, Enevate, and OPPO are leading technological innovation, with Enevate particularly advanced in silicon-dominant anode technology enabling 5-minute extreme fast charging. Academic-industry partnerships involving institutions like University of California and Michigan Tech are accelerating development. The competitive landscape shows battery manufacturers (CATL, Svolt), technology specialists (Enevate, Liyang Tianmu), and electronics companies (OPPO, Siemens) all pursuing different approaches to overcome silicon expansion challenges while managing thermal constraints during fast charging.

Guangdong OPPO Mobile Telecommunications Corp., Ltd.

Technical Solution: OPPO has developed a sophisticated silicon anode fast charging protocol tailored specifically for mobile device applications with strict thermal constraints. Their approach, branded as SuperVOOC for silicon anodes, employs a multi-dimensional charging algorithm that continuously optimizes current delivery based on real-time thermal modeling. The protocol utilizes a variable current profile that adapts to both the state of charge and thermal conditions, implementing higher currents during thermally favorable periods and reducing power when approaching thermal limits. OPPO's system incorporates a distributed temperature sensing network throughout the battery structure, allowing for precise thermal mapping and localized current adjustments to prevent hotspot formation. Their silicon anode formulation includes a gradient silicon-carbon structure that balances fast charging capability with cycle life, while their proprietary electrolyte additives form a stable interface layer that withstands the mechanical stress of rapid charging without excessive heat generation from side reactions.

Strengths: Highly optimized for consumer electronics form factors with strict thermal limitations; sophisticated thermal sensing provides exceptional safety during fast charging. Weaknesses: Protocol optimization focuses primarily on smaller battery sizes typical in mobile devices; performance advantages may not scale linearly to larger battery systems.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology (CATL) has developed an advanced silicon anode fast charging protocol that integrates multi-dimensional thermal management systems. Their approach utilizes a gradient temperature control strategy that maintains optimal cell temperature during high-rate charging. The protocol employs machine learning algorithms to predict thermal behavior and adaptively adjusts charging current based on real-time temperature feedback. CATL's system incorporates a phase-change material (PCM) based cooling solution that absorbs excess heat during fast charging, preventing thermal runaway while allowing for charging rates up to 4C (15-minute full charge). Their silicon-dominant anodes are engineered with a 3D porous structure that accommodates volume expansion while maintaining electrical connectivity, and they've developed specialized electrolyte formulations with film-forming additives that stabilize the silicon-electrolyte interface during rapid lithium insertion.

Strengths: Superior thermal management integration allowing for higher charging rates without degradation; proprietary electrolyte formulations that extend cycle life of silicon anodes under fast charging conditions. Weaknesses: Higher manufacturing complexity increases production costs; system requires sophisticated battery management systems that may not be compatible with all applications.

Critical Patents in Thermal Management for Silicon Anodes

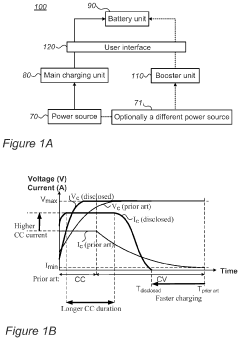

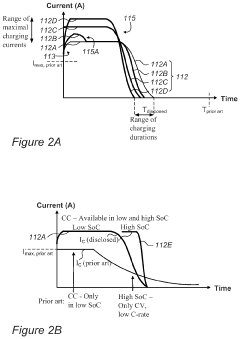

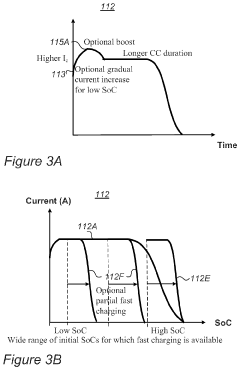

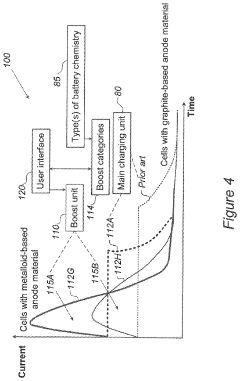

Fast charging and power boosting lithium-ion batteries

PatentActiveUS20200343735A1

Innovation

- A charging system comprising a main charging unit and a booster unit, which provides high-C charging currents of at least 4 C to 10 C over 10-70% SoC for battery cells with metalloid-based anodes, such as Si, Ge, and Sn-based materials, and includes a user interface for customizable charging preferences.

Charging circuit for a capacitance and method for charging a capacitance

PatentWO2013037671A2

Innovation

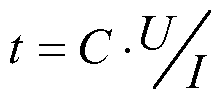

- A charging circuit with a temperature-controlled switch that adjusts based on an upper limit temperature, using a comparator with hysteresis to manage the charging process, ensuring the capacitor is charged quickly without exceeding thermal limits by intermittently closing and opening the switch based on temperature differences.

Thermal Management System Integration Strategies

The integration of thermal management systems with silicon anode batteries represents a critical engineering challenge for enabling fast charging capabilities while maintaining safety and longevity. Effective thermal management system integration requires a multi-faceted approach that addresses both the macro-level battery pack design and micro-level cell architecture considerations.

Active cooling systems utilizing liquid coolants have emerged as the preferred solution for high-performance silicon anode battery packs. These systems typically incorporate dedicated cooling channels between cells or modules, with thermally conductive materials ensuring efficient heat transfer from the cell core to the cooling medium. Advanced designs feature variable flow rates that dynamically adjust based on real-time temperature monitoring, allowing for targeted cooling during the most thermally intensive phases of fast charging.

Passive thermal management strategies complement active systems by incorporating phase change materials (PCMs) strategically positioned within the battery pack. These materials absorb excess heat during fast charging through their phase transition process, effectively creating thermal buffers that prevent localized hotspots. Silicon-graphite composite anodes particularly benefit from this approach due to their tendency to generate non-uniform heat distributions during lithiation.

Thermal interface materials (TIMs) play a crucial role in system integration, serving as the critical junction between silicon anode cells and the broader thermal management infrastructure. Recent developments in carbon nanotube-enhanced TIMs have demonstrated thermal conductivity improvements of up to 45% compared to conventional materials, significantly enhancing heat dissipation pathways during fast charging operations.

Integrated thermal sensors and predictive thermal modeling represent the intelligence layer of modern thermal management systems. Distributed temperature sensing using fiber optic or thin-film technologies enables high-resolution thermal mapping across the battery pack. This data feeds into machine learning algorithms that can predict thermal behavior based on charging protocols, ambient conditions, and battery state-of-health, allowing for preemptive cooling adjustments before critical temperature thresholds are reached.

System-level integration must also consider the energy efficiency of the thermal management system itself. Parasitic power losses from cooling pumps, fans, and control electronics can significantly impact overall vehicle efficiency. Advanced designs incorporate waste heat recovery systems that capture and repurpose thermal energy from the battery for cabin heating or battery preconditioning in cold environments, creating a more holistic energy management approach.

Active cooling systems utilizing liquid coolants have emerged as the preferred solution for high-performance silicon anode battery packs. These systems typically incorporate dedicated cooling channels between cells or modules, with thermally conductive materials ensuring efficient heat transfer from the cell core to the cooling medium. Advanced designs feature variable flow rates that dynamically adjust based on real-time temperature monitoring, allowing for targeted cooling during the most thermally intensive phases of fast charging.

Passive thermal management strategies complement active systems by incorporating phase change materials (PCMs) strategically positioned within the battery pack. These materials absorb excess heat during fast charging through their phase transition process, effectively creating thermal buffers that prevent localized hotspots. Silicon-graphite composite anodes particularly benefit from this approach due to their tendency to generate non-uniform heat distributions during lithiation.

Thermal interface materials (TIMs) play a crucial role in system integration, serving as the critical junction between silicon anode cells and the broader thermal management infrastructure. Recent developments in carbon nanotube-enhanced TIMs have demonstrated thermal conductivity improvements of up to 45% compared to conventional materials, significantly enhancing heat dissipation pathways during fast charging operations.

Integrated thermal sensors and predictive thermal modeling represent the intelligence layer of modern thermal management systems. Distributed temperature sensing using fiber optic or thin-film technologies enables high-resolution thermal mapping across the battery pack. This data feeds into machine learning algorithms that can predict thermal behavior based on charging protocols, ambient conditions, and battery state-of-health, allowing for preemptive cooling adjustments before critical temperature thresholds are reached.

System-level integration must also consider the energy efficiency of the thermal management system itself. Parasitic power losses from cooling pumps, fans, and control electronics can significantly impact overall vehicle efficiency. Advanced designs incorporate waste heat recovery systems that capture and repurpose thermal energy from the battery for cabin heating or battery preconditioning in cold environments, creating a more holistic energy management approach.

Safety Standards and Testing Protocols

The development of safety standards and testing protocols for silicon anode fast charging systems under thermal constraints represents a critical area requiring rigorous attention. Current industry standards, including IEC 62660, UL 1642, and SAE J2464, provide foundational frameworks but require significant adaptation to address the unique thermal behaviors of silicon anodes during rapid charging cycles. These standards must evolve to incorporate specific thermal management parameters that account for silicon's volumetric expansion characteristics and potential thermal runaway scenarios.

Testing protocols for silicon anode batteries undergoing fast charging typically involve multi-stage evaluation processes. Initial screening includes thermal cycling tests under controlled environments, where cells are subjected to accelerated charge-discharge cycles while monitoring temperature distribution across the anode surface. Advanced protocols implement real-time impedance spectroscopy to detect early indicators of thermal anomalies before they escalate to critical levels.

Thermal constraint verification has become increasingly sophisticated, with leading battery manufacturers implementing differential scanning calorimetry (DSC) and accelerating rate calorimetry (ARC) to establish precise thermal boundaries for safe operation. These methodologies help define the maximum permissible temperature gradients during various charging rates, particularly crucial for silicon anodes which demonstrate non-linear thermal responses above 45°C.

Safety certification bodies have recently introduced specialized testing requirements for silicon-based fast charging systems. These include extended abuse testing under thermal stress conditions, where batteries undergo puncture, crush, and overcharge tests while maintaining thermal management systems at varying efficiency levels. This approach helps quantify the safety margins under worst-case thermal management failures during rapid charging events.

Emerging standards are incorporating artificial intelligence-based predictive thermal modeling as part of the certification process. These models simulate thousands of charging scenarios across diverse environmental conditions, identifying potential thermal constraint violations before physical testing. This pre-emptive approach has demonstrated significant improvements in detecting edge-case thermal anomalies that traditional testing might miss.

International harmonization efforts are underway to standardize silicon anode fast charging safety protocols across major markets. The Global Battery Alliance and International Electrotechnical Commission are collaboratively developing unified testing methodologies that specifically address silicon anode thermal constraints during rapid charging, with particular emphasis on establishing universal temperature threshold parameters and standardized cooling system performance metrics.

Testing protocols for silicon anode batteries undergoing fast charging typically involve multi-stage evaluation processes. Initial screening includes thermal cycling tests under controlled environments, where cells are subjected to accelerated charge-discharge cycles while monitoring temperature distribution across the anode surface. Advanced protocols implement real-time impedance spectroscopy to detect early indicators of thermal anomalies before they escalate to critical levels.

Thermal constraint verification has become increasingly sophisticated, with leading battery manufacturers implementing differential scanning calorimetry (DSC) and accelerating rate calorimetry (ARC) to establish precise thermal boundaries for safe operation. These methodologies help define the maximum permissible temperature gradients during various charging rates, particularly crucial for silicon anodes which demonstrate non-linear thermal responses above 45°C.

Safety certification bodies have recently introduced specialized testing requirements for silicon-based fast charging systems. These include extended abuse testing under thermal stress conditions, where batteries undergo puncture, crush, and overcharge tests while maintaining thermal management systems at varying efficiency levels. This approach helps quantify the safety margins under worst-case thermal management failures during rapid charging events.

Emerging standards are incorporating artificial intelligence-based predictive thermal modeling as part of the certification process. These models simulate thousands of charging scenarios across diverse environmental conditions, identifying potential thermal constraint violations before physical testing. This pre-emptive approach has demonstrated significant improvements in detecting edge-case thermal anomalies that traditional testing might miss.

International harmonization efforts are underway to standardize silicon anode fast charging safety protocols across major markets. The Global Battery Alliance and International Electrotechnical Commission are collaboratively developing unified testing methodologies that specifically address silicon anode thermal constraints during rapid charging, with particular emphasis on establishing universal temperature threshold parameters and standardized cooling system performance metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!