Silicon anode prelithiation methods: gas, electrochemical, and sacrificial

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Anode Prelithiation Background and Objectives

Silicon anode technology has emerged as a promising avenue for next-generation lithium-ion batteries due to its theoretical capacity of 3,579 mAh/g, nearly ten times that of conventional graphite anodes (372 mAh/g). This significant capacity advantage positions silicon as a critical material for addressing the growing demand for higher energy density batteries in electric vehicles, portable electronics, and renewable energy storage systems. The evolution of silicon anode technology can be traced back to the early 2000s, when researchers began exploring alternatives to graphite to overcome energy density limitations.

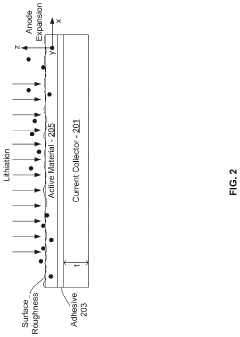

Despite its theoretical advantages, silicon anodes face substantial challenges, primarily the massive volume expansion (up to 300%) during lithiation, leading to mechanical degradation, continuous solid-electrolyte interphase (SEI) formation, and rapid capacity fading. These issues have historically limited the commercial viability of silicon anodes. The technological trajectory has progressed from initial pure silicon structures to silicon-carbon composites, silicon nanomaterials, and most recently, prelithiation strategies to compensate for irreversible capacity loss.

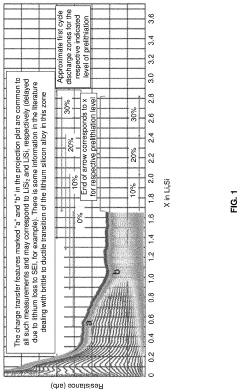

Prelithiation has emerged as a critical enabling technology for silicon anodes, addressing the substantial first-cycle irreversible capacity loss (typically 15-45%) caused by SEI formation and lithium trapping. This process involves introducing lithium into the anode before battery assembly or during the initial cycles, effectively compensating for lithium loss and improving initial Coulombic efficiency. The development of prelithiation techniques represents a significant technological milestone in silicon anode commercialization.

The primary objective of silicon anode prelithiation research is to develop scalable, cost-effective, and industrially viable methods that can compensate for first-cycle capacity loss while maintaining long-term cycling stability. Current prelithiation approaches fall into three main categories: gas-based methods utilizing lithium-containing atmospheres, electrochemical techniques applying controlled potential to introduce lithium, and sacrificial lithium-containing additives that release lithium during initial cycling.

Future technological goals include developing prelithiation methods compatible with existing manufacturing processes, ensuring safety during implementation, extending the shelf life of prelithiated materials, and reducing the cost of prelithiation to make silicon anodes commercially competitive. Additionally, researchers aim to optimize the degree of prelithiation to balance initial capacity with long-term stability, as excessive prelithiation can lead to other degradation mechanisms.

The convergence of silicon anode technology with effective prelithiation strategies represents a critical pathway toward next-generation high-energy-density batteries, potentially enabling electric vehicles with longer ranges, consumer electronics with extended usage times, and more efficient renewable energy storage systems.

Despite its theoretical advantages, silicon anodes face substantial challenges, primarily the massive volume expansion (up to 300%) during lithiation, leading to mechanical degradation, continuous solid-electrolyte interphase (SEI) formation, and rapid capacity fading. These issues have historically limited the commercial viability of silicon anodes. The technological trajectory has progressed from initial pure silicon structures to silicon-carbon composites, silicon nanomaterials, and most recently, prelithiation strategies to compensate for irreversible capacity loss.

Prelithiation has emerged as a critical enabling technology for silicon anodes, addressing the substantial first-cycle irreversible capacity loss (typically 15-45%) caused by SEI formation and lithium trapping. This process involves introducing lithium into the anode before battery assembly or during the initial cycles, effectively compensating for lithium loss and improving initial Coulombic efficiency. The development of prelithiation techniques represents a significant technological milestone in silicon anode commercialization.

The primary objective of silicon anode prelithiation research is to develop scalable, cost-effective, and industrially viable methods that can compensate for first-cycle capacity loss while maintaining long-term cycling stability. Current prelithiation approaches fall into three main categories: gas-based methods utilizing lithium-containing atmospheres, electrochemical techniques applying controlled potential to introduce lithium, and sacrificial lithium-containing additives that release lithium during initial cycling.

Future technological goals include developing prelithiation methods compatible with existing manufacturing processes, ensuring safety during implementation, extending the shelf life of prelithiated materials, and reducing the cost of prelithiation to make silicon anodes commercially competitive. Additionally, researchers aim to optimize the degree of prelithiation to balance initial capacity with long-term stability, as excessive prelithiation can lead to other degradation mechanisms.

The convergence of silicon anode technology with effective prelithiation strategies represents a critical pathway toward next-generation high-energy-density batteries, potentially enabling electric vehicles with longer ranges, consumer electronics with extended usage times, and more efficient renewable energy storage systems.

Market Analysis for Prelithiated Silicon Anodes

The global market for prelithiated silicon anodes is experiencing significant growth, driven by the increasing demand for high-energy-density batteries in electric vehicles, consumer electronics, and energy storage systems. Current market projections indicate that the silicon anode battery market is expected to reach $2.1 billion by 2027, growing at a CAGR of 25.7% from 2022 to 2027. Within this broader market, prelithiated silicon anodes represent an emerging segment with substantial growth potential.

The primary market drivers for prelithiated silicon anodes include the push for higher energy density batteries, longer cycle life, and faster charging capabilities. Electric vehicle manufacturers are particularly interested in this technology as it addresses the range anxiety concerns while potentially reducing battery costs in the long term. Tesla, BMW, and Volkswagen have all announced investments in silicon anode technology for their next-generation battery systems.

Consumer electronics represents another significant market segment, with smartphone and laptop manufacturers seeking batteries that offer longer usage time without increasing device size. Apple has reportedly been working with silicon anode technology suppliers to enhance battery performance in future iPhone models.

Regional analysis shows that Asia-Pacific currently dominates the market, with Japan, South Korea, and China leading in both research and commercialization efforts. North America follows closely, with significant investments from both government agencies and private companies. The European market is growing rapidly, supported by stringent environmental regulations and substantial investments in electric mobility.

Market challenges include the high cost of prelithiation processes, scalability issues, and competition from alternative battery technologies. The cost premium for prelithiated silicon anodes currently ranges from 30-40% compared to conventional graphite anodes, presenting a significant barrier to mass adoption. However, this premium is expected to decrease as manufacturing processes mature and economies of scale are achieved.

Industry analysts predict that gas-phase prelithiation methods will capture the largest market share initially due to their compatibility with existing manufacturing infrastructure. Electrochemical prelithiation is expected to gain traction in specialized applications requiring precise control, while sacrificial lithium methods show promise for cost-effective mass production in the medium term.

The competitive landscape features established battery manufacturers expanding into silicon anode technology alongside specialized startups focused exclusively on silicon anode innovations. Strategic partnerships between material suppliers, battery manufacturers, and end-users are becoming increasingly common as the industry works to overcome technical challenges and accelerate commercialization.

The primary market drivers for prelithiated silicon anodes include the push for higher energy density batteries, longer cycle life, and faster charging capabilities. Electric vehicle manufacturers are particularly interested in this technology as it addresses the range anxiety concerns while potentially reducing battery costs in the long term. Tesla, BMW, and Volkswagen have all announced investments in silicon anode technology for their next-generation battery systems.

Consumer electronics represents another significant market segment, with smartphone and laptop manufacturers seeking batteries that offer longer usage time without increasing device size. Apple has reportedly been working with silicon anode technology suppliers to enhance battery performance in future iPhone models.

Regional analysis shows that Asia-Pacific currently dominates the market, with Japan, South Korea, and China leading in both research and commercialization efforts. North America follows closely, with significant investments from both government agencies and private companies. The European market is growing rapidly, supported by stringent environmental regulations and substantial investments in electric mobility.

Market challenges include the high cost of prelithiation processes, scalability issues, and competition from alternative battery technologies. The cost premium for prelithiated silicon anodes currently ranges from 30-40% compared to conventional graphite anodes, presenting a significant barrier to mass adoption. However, this premium is expected to decrease as manufacturing processes mature and economies of scale are achieved.

Industry analysts predict that gas-phase prelithiation methods will capture the largest market share initially due to their compatibility with existing manufacturing infrastructure. Electrochemical prelithiation is expected to gain traction in specialized applications requiring precise control, while sacrificial lithium methods show promise for cost-effective mass production in the medium term.

The competitive landscape features established battery manufacturers expanding into silicon anode technology alongside specialized startups focused exclusively on silicon anode innovations. Strategic partnerships between material suppliers, battery manufacturers, and end-users are becoming increasingly common as the industry works to overcome technical challenges and accelerate commercialization.

Current Prelithiation Technologies and Barriers

Prelithiation technologies have emerged as critical solutions to address the first-cycle capacity loss in silicon anodes for lithium-ion batteries. Currently, three main prelithiation approaches dominate the field: gas-phase, electrochemical, and sacrificial lithium methods. Each offers distinct advantages while facing specific implementation challenges.

Gas-phase prelithiation involves exposing silicon anodes to lithium-containing gases such as lithium vapor or n-butyllithium under controlled conditions. This method achieves uniform lithium distribution throughout the electrode structure and can be integrated into existing manufacturing processes. However, it requires specialized equipment for handling reactive lithium gases, strict environmental controls to prevent moisture and oxygen contamination, and precise process parameters to ensure consistent lithiation levels.

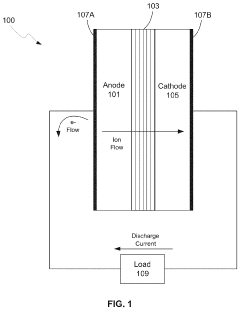

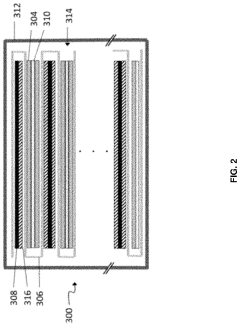

Electrochemical prelithiation utilizes direct current to drive lithium ions into silicon anodes before cell assembly. This approach offers precise control over the degree of lithiation and can be monitored in real-time through voltage measurements. The method is compatible with conventional battery manufacturing equipment with minimal modifications. Despite these advantages, electrochemical prelithiation significantly increases production time, requires additional processing steps, and faces challenges in achieving uniform lithiation across thick electrodes.

Sacrificial lithium methods incorporate additional lithium-containing materials that release lithium ions during initial cycling. These include stabilized lithium metal powder (SLMP), lithium-rich compounds, and lithium alloys. This approach can be integrated into standard electrode manufacturing processes and provides a reservoir of lithium to compensate for losses. However, the uniform distribution of sacrificial materials remains challenging, and many sacrificial compounds exhibit poor stability during storage and handling.

A significant barrier across all prelithiation technologies is scalability for mass production. Laboratory-scale demonstrations have shown promising results, but translating these processes to industrial scales introduces complications in uniformity, throughput, and quality control. Additionally, safety concerns persist due to the reactive nature of lithiated materials, requiring specialized handling protocols and equipment.

Cost considerations also present substantial barriers to widespread adoption. Prelithiation adds manufacturing complexity and requires additional materials and processing steps, increasing production costs. The economic viability depends on balancing these increased costs against performance improvements and potential reductions in overall battery material requirements.

Environmental stability represents another critical challenge, as prelithiated materials typically exhibit high reactivity with atmospheric components. This necessitates controlled manufacturing environments and specialized packaging solutions to maintain electrode integrity from production through cell assembly.

Gas-phase prelithiation involves exposing silicon anodes to lithium-containing gases such as lithium vapor or n-butyllithium under controlled conditions. This method achieves uniform lithium distribution throughout the electrode structure and can be integrated into existing manufacturing processes. However, it requires specialized equipment for handling reactive lithium gases, strict environmental controls to prevent moisture and oxygen contamination, and precise process parameters to ensure consistent lithiation levels.

Electrochemical prelithiation utilizes direct current to drive lithium ions into silicon anodes before cell assembly. This approach offers precise control over the degree of lithiation and can be monitored in real-time through voltage measurements. The method is compatible with conventional battery manufacturing equipment with minimal modifications. Despite these advantages, electrochemical prelithiation significantly increases production time, requires additional processing steps, and faces challenges in achieving uniform lithiation across thick electrodes.

Sacrificial lithium methods incorporate additional lithium-containing materials that release lithium ions during initial cycling. These include stabilized lithium metal powder (SLMP), lithium-rich compounds, and lithium alloys. This approach can be integrated into standard electrode manufacturing processes and provides a reservoir of lithium to compensate for losses. However, the uniform distribution of sacrificial materials remains challenging, and many sacrificial compounds exhibit poor stability during storage and handling.

A significant barrier across all prelithiation technologies is scalability for mass production. Laboratory-scale demonstrations have shown promising results, but translating these processes to industrial scales introduces complications in uniformity, throughput, and quality control. Additionally, safety concerns persist due to the reactive nature of lithiated materials, requiring specialized handling protocols and equipment.

Cost considerations also present substantial barriers to widespread adoption. Prelithiation adds manufacturing complexity and requires additional materials and processing steps, increasing production costs. The economic viability depends on balancing these increased costs against performance improvements and potential reductions in overall battery material requirements.

Environmental stability represents another critical challenge, as prelithiated materials typically exhibit high reactivity with atmospheric components. This necessitates controlled manufacturing environments and specialized packaging solutions to maintain electrode integrity from production through cell assembly.

Comparative Analysis of Gas, Electrochemical, and Sacrificial Methods

01 Chemical prelithiation methods for silicon anodes

Chemical prelithiation involves treating silicon anodes with lithium-containing compounds to introduce lithium ions before battery assembly. This process typically uses lithium-containing solutions or reactive lithium compounds that can transfer lithium to silicon particles. Chemical methods are advantageous for their scalability and ability to achieve uniform lithiation. These approaches help compensate for initial capacity loss and improve the first cycle efficiency of silicon anodes in lithium-ion batteries.- Chemical prelithiation methods for silicon anodes: Chemical prelithiation involves treating silicon anodes with lithium-containing compounds to introduce lithium ions before battery assembly. This process typically uses lithium-containing solutions or reagents that react with silicon to form lithiated silicon compounds. Chemical methods offer advantages such as scalability and compatibility with existing manufacturing processes. These techniques help compensate for initial lithium loss during the formation of the solid electrolyte interphase (SEI) layer, thereby improving first cycle efficiency and overall battery performance.

- Electrochemical prelithiation techniques: Electrochemical prelithiation involves applying an electrical current to drive lithium ions into silicon anodes before battery assembly. This can be achieved through direct contact with lithium metal or through an electrolyte solution containing lithium ions. The process can be controlled by adjusting parameters such as current density, duration, and temperature. Electrochemical methods allow for precise control of the lithiation degree and can be integrated into existing battery manufacturing lines. This approach significantly improves first-cycle coulombic efficiency and overall battery capacity.

- Physical contact prelithiation methods: Physical contact prelithiation involves direct contact between silicon anodes and lithium sources under controlled conditions. This can include pressing lithium metal against silicon electrodes, using lithium powder dispersions, or applying lithium-containing films to the anode surface. The process may be enhanced by applying pressure, heat, or both to facilitate lithium diffusion into the silicon structure. Physical contact methods are often simpler than other approaches but require careful handling of reactive lithium materials. These techniques effectively introduce lithium into silicon anodes while minimizing side reactions.

- Composite prelithiation additives and stabilizers: This approach involves incorporating lithium-containing additives or stabilizers into silicon anode materials during electrode fabrication. These additives can include lithium powders, lithium alloys, or lithium compounds that release lithium ions during initial battery cycling. Some formulations use protective coatings or encapsulation techniques to prevent premature reaction of the lithium source with air or electrolytes. Composite additives can be designed to release lithium gradually during cycling, providing continuous compensation for lithium loss. This method improves battery performance while enhancing manufacturing safety compared to handling pure lithium metal.

- Advanced manufacturing processes for prelithiated silicon anodes: Advanced manufacturing processes focus on integrating prelithiation steps into industrial-scale production of silicon anodes. These include specialized coating techniques, roll-to-roll processing methods, and automated assembly systems designed to handle reactive lithium materials safely. Some approaches use controlled atmosphere environments to prevent unwanted reactions during prelithiation. Others employ novel drying and curing processes to stabilize prelithiated materials. These manufacturing innovations address challenges related to scalability, safety, and cost-effectiveness of prelithiation techniques, making them more viable for commercial battery production.

02 Electrochemical prelithiation techniques

Electrochemical prelithiation involves applying an external current to drive lithium ions into silicon anodes before battery assembly. This can be achieved through direct contact with lithium metal or through an electrolyte solution containing lithium ions. The process allows for precise control of the lithiation level by adjusting current density and treatment time. Electrochemical methods can effectively reduce first-cycle irreversible capacity loss and improve overall battery performance when using silicon anodes.Expand Specific Solutions03 Physical contact prelithiation approaches

Physical contact prelithiation involves direct contact between silicon anodes and lithium sources under controlled conditions. This can include methods such as pressing lithium metal against silicon electrodes, using lithium powder dispersion, or creating temporary lithium-silicon composites. These approaches often require specific pressure, temperature, and environmental controls to ensure effective lithium transfer. Physical contact methods are valued for their simplicity and potential for integration into existing manufacturing processes.Expand Specific Solutions04 Composite additives for silicon anode prelithiation

Composite additives incorporate lithium-containing materials directly into silicon anode formulations to provide an internal source of lithium. These additives can include stabilized lithium metal particles, lithium-silicon alloys, or lithium compounds embedded in protective matrices. During initial battery cycling, these additives release lithium ions to compensate for irreversible capacity loss. This approach allows for prelithiation to occur naturally during the first few battery cycles without requiring separate processing steps.Expand Specific Solutions05 Manufacturing process integration for prelithiation

Integration of prelithiation into manufacturing processes involves developing methods that can be efficiently incorporated into existing battery production lines. This includes designing specialized equipment for controlled lithiation, developing dry-room compatible techniques, and creating in-line prelithiation stations. These approaches focus on minimizing additional production costs while ensuring consistent prelithiation results. Manufacturing integration considerations also address safety concerns related to handling reactive lithium materials in production environments.Expand Specific Solutions

Leading Companies and Research Institutions in Prelithiation

Silicon anode prelithiation technology is currently in the early commercialization phase, with the global market expected to grow significantly as electric vehicle adoption accelerates. The technology addresses critical challenges in lithium-ion battery performance, particularly first-cycle capacity loss. Among the three main prelithiation methods (gas, electrochemical, and sacrificial), electrochemical approaches are gaining traction due to scalability advantages. Companies like BTR New Material Group and LG Energy Solution are leading commercial implementation, while research institutions such as Northwestern Polytechnical University and Caltech continue advancing fundamental innovations. Emerging players including Farasis Energy and Guangdong Kaijin are developing proprietary prelithiation technologies, while established manufacturers like Bosch and Infineon are integrating these solutions into broader battery management systems.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced prelithiation methods for silicon anodes, focusing on electrochemical approaches. Their technology involves a controlled pre-insertion of lithium ions into silicon anodes before cell assembly, using proprietary electrolyte formulations that enhance the initial coulombic efficiency. The company employs a two-stage electrochemical prelithiation process where silicon anodes are first partially lithiated in a controlled environment and then undergo a secondary stabilization phase to form an optimized SEI layer[1]. This approach allows for precise control of the lithiation level, typically achieving 30-40% prelithiation capacity. LG Energy Solution has also developed specialized manufacturing equipment that enables large-scale prelithiation processes compatible with their existing production lines, allowing for seamless integration into commercial battery manufacturing[3].

Strengths: Precise control over lithiation levels, scalable manufacturing process integration, improved first-cycle efficiency by approximately 15-20%. Weaknesses: Electrochemical prelithiation requires additional processing time and specialized equipment, potentially increasing production costs and complexity compared to alternative methods.

Nanotek Instruments, Inc.

Technical Solution: Nanotek Instruments has developed a proprietary sacrificial lithium source technology for silicon anode prelithiation. Their approach utilizes specially designed lithium-containing compounds that are incorporated directly into the silicon anode matrix during electrode manufacturing. These compounds release lithium ions during the initial charging cycles, compensating for the lithium loss due to SEI formation. The company's patented SLMP (Stabilized Lithium Metal Powder) technology involves coating silicon particles with lithium-rich materials that are protected by a thin polymer layer, which dissolves in the electrolyte during battery activation[1][5]. This method achieves prelithiation levels of 15-25% without requiring separate processing steps. Nanotek has also developed advanced manufacturing techniques that allow for the safe handling of these reactive materials in ambient conditions, solving a major challenge in sacrificial prelithiation implementation[6].

Strengths: Simplified manufacturing process that integrates with existing electrode production lines, no need for separate prelithiation equipment, good scalability potential. Weaknesses: Lower prelithiation capacity compared to direct methods, potential for non-uniform lithium distribution, challenges in long-term stability of the sacrificial lithium sources during battery storage.

Key Patents and Scientific Breakthroughs in Prelithiation

Prelithiation of free-standing silicon dominant anode batteries

PatentActiveUS12051806B2

Innovation

- Prelithiation of silicon-dominant anodes using Li-organic compound complex solutions, such as lithium naphthalenide in tetrahydrofuran or lithium biphenyl in dimethoxyethane, to compensate for active lithium losses and enhance energy density by pre-doping lithium ions before charge/discharge cycling.

Prelithiated And Methods For Prelithiating An Energy Storage Device

PatentPendingUS20230231119A1

Innovation

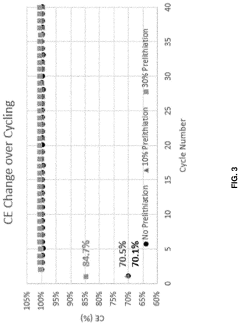

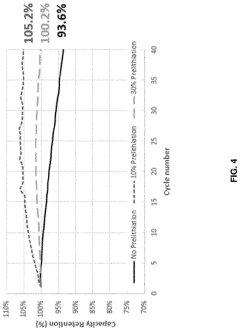

- The development of prelithiated silicon-based electrodes with a prelithiation level of 0% to 30% and the use of a self-supporting composite material film with a carbonized polymer as a current collector, eliminating the need for metal foil and enhancing cycle life, combined with an electrolyte containing fluoroethylene carbonate (FEC) to stabilize the SEI.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability and cost analysis of silicon anode prelithiation methods represents a critical factor in their commercial viability. Gas-based prelithiation methods offer significant advantages in terms of scalability, as they can be integrated into existing battery manufacturing lines with relatively minor modifications. The process typically involves exposing silicon anodes to lithium-containing gases in controlled environments, which can be implemented as a continuous process. However, the specialized equipment required for handling reactive gases safely adds considerable capital expenditure, estimated between $2-5 million for production-scale implementation.

Electrochemical prelithiation demonstrates moderate scalability potential with established electrochemical processing techniques. This method can be integrated as an additional step in existing manufacturing flows, utilizing equipment similar to that already employed in battery production. The primary challenge lies in maintaining process uniformity across large electrode areas and ensuring consistent lithiation levels. Current cost estimates suggest an additional $0.8-1.5 per kWh to battery production costs when implementing electrochemical prelithiation at scale.

Sacrificial lithium source methods present varying degrees of scalability depending on the specific approach. Additive-based techniques that incorporate lithium-containing compounds directly into electrode materials show excellent compatibility with existing manufacturing processes. However, methods requiring physical contact between lithium metal and silicon anodes face significant engineering challenges for high-volume production. The cost impact ranges from $0.5-2.0 per kWh, with material costs constituting 60-75% of this increase.

A comparative analysis of production throughput reveals that gas-based methods can achieve the highest processing speeds (potentially exceeding 30 m²/min), followed by certain sacrificial approaches (10-25 m²/min), with electrochemical methods currently limited to lower rates (5-15 m²/min) due to the time required for ion diffusion.

Energy consumption metrics further differentiate these approaches, with electrochemical methods requiring 1.2-1.8 kWh per kWh of battery capacity produced, compared to gas-based methods at 0.8-1.3 kWh. This energy requirement significantly impacts the overall carbon footprint and operating expenses in large-scale production environments.

For market adoption, manufacturers must consider the balance between initial capital investment and long-term operational costs. Gas-based methods typically require higher upfront investment but offer lower per-unit costs at scale, while sacrificial approaches often present lower barriers to entry but potentially higher material costs over time. These economic considerations ultimately determine which prelithiation technologies will achieve widespread commercial implementation.

Electrochemical prelithiation demonstrates moderate scalability potential with established electrochemical processing techniques. This method can be integrated as an additional step in existing manufacturing flows, utilizing equipment similar to that already employed in battery production. The primary challenge lies in maintaining process uniformity across large electrode areas and ensuring consistent lithiation levels. Current cost estimates suggest an additional $0.8-1.5 per kWh to battery production costs when implementing electrochemical prelithiation at scale.

Sacrificial lithium source methods present varying degrees of scalability depending on the specific approach. Additive-based techniques that incorporate lithium-containing compounds directly into electrode materials show excellent compatibility with existing manufacturing processes. However, methods requiring physical contact between lithium metal and silicon anodes face significant engineering challenges for high-volume production. The cost impact ranges from $0.5-2.0 per kWh, with material costs constituting 60-75% of this increase.

A comparative analysis of production throughput reveals that gas-based methods can achieve the highest processing speeds (potentially exceeding 30 m²/min), followed by certain sacrificial approaches (10-25 m²/min), with electrochemical methods currently limited to lower rates (5-15 m²/min) due to the time required for ion diffusion.

Energy consumption metrics further differentiate these approaches, with electrochemical methods requiring 1.2-1.8 kWh per kWh of battery capacity produced, compared to gas-based methods at 0.8-1.3 kWh. This energy requirement significantly impacts the overall carbon footprint and operating expenses in large-scale production environments.

For market adoption, manufacturers must consider the balance between initial capital investment and long-term operational costs. Gas-based methods typically require higher upfront investment but offer lower per-unit costs at scale, while sacrificial approaches often present lower barriers to entry but potentially higher material costs over time. These economic considerations ultimately determine which prelithiation technologies will achieve widespread commercial implementation.

Safety and Environmental Considerations

The implementation of silicon anode prelithiation methods necessitates careful consideration of safety and environmental impacts throughout the entire lifecycle. Gas-phase prelithiation processes often involve highly reactive lithium compounds such as lithium vapor or lithium-containing gases, which present significant fire and explosion hazards when exposed to moisture or air. These processes require specialized containment systems, inert atmospheres, and rigorous handling protocols to minimize risks to personnel and facilities.

Electrochemical prelithiation methods generally present lower immediate safety risks compared to gas-phase approaches, but still involve potentially hazardous electrolytes and lithium salts. The organic solvents commonly used in these processes may be flammable and toxic, requiring proper ventilation systems and personal protective equipment. Additionally, the electrical systems used must incorporate appropriate safeguards against short circuits and thermal runaway events.

Sacrificial lithium source methods introduce their own safety considerations, particularly when utilizing metallic lithium or lithium-rich compounds. These materials remain highly reactive and require careful handling to prevent unintended reactions. The stabilization additives used in these processes may also present toxicity concerns that must be addressed through proper industrial hygiene practices.

From an environmental perspective, all prelithiation methods generate waste streams that require appropriate management. Gas-phase processes may release lithium-containing emissions that need capture and treatment systems to prevent atmospheric release. The production and disposal of spent electrolytes from electrochemical methods raise concerns regarding groundwater contamination and resource recovery, particularly for fluorinated compounds that persist in the environment.

Life cycle assessment studies indicate that while silicon anode batteries with prelithiation offer environmental benefits through extended battery life and improved energy density, the manufacturing processes themselves may carry higher environmental burdens than conventional electrode production. The energy-intensive nature of some prelithiation techniques, particularly those requiring high temperatures or vacuum conditions, contributes significantly to their carbon footprint.

Regulatory frameworks governing these processes continue to evolve, with increasing emphasis on chemical registration, workplace exposure limits, and waste classification. Companies implementing prelithiation technologies must navigate complex compliance requirements that vary by jurisdiction, often necessitating comprehensive environmental management systems and safety protocols that exceed standard battery manufacturing practices.

Electrochemical prelithiation methods generally present lower immediate safety risks compared to gas-phase approaches, but still involve potentially hazardous electrolytes and lithium salts. The organic solvents commonly used in these processes may be flammable and toxic, requiring proper ventilation systems and personal protective equipment. Additionally, the electrical systems used must incorporate appropriate safeguards against short circuits and thermal runaway events.

Sacrificial lithium source methods introduce their own safety considerations, particularly when utilizing metallic lithium or lithium-rich compounds. These materials remain highly reactive and require careful handling to prevent unintended reactions. The stabilization additives used in these processes may also present toxicity concerns that must be addressed through proper industrial hygiene practices.

From an environmental perspective, all prelithiation methods generate waste streams that require appropriate management. Gas-phase processes may release lithium-containing emissions that need capture and treatment systems to prevent atmospheric release. The production and disposal of spent electrolytes from electrochemical methods raise concerns regarding groundwater contamination and resource recovery, particularly for fluorinated compounds that persist in the environment.

Life cycle assessment studies indicate that while silicon anode batteries with prelithiation offer environmental benefits through extended battery life and improved energy density, the manufacturing processes themselves may carry higher environmental burdens than conventional electrode production. The energy-intensive nature of some prelithiation techniques, particularly those requiring high temperatures or vacuum conditions, contributes significantly to their carbon footprint.

Regulatory frameworks governing these processes continue to evolve, with increasing emphasis on chemical registration, workplace exposure limits, and waste classification. Companies implementing prelithiation technologies must navigate complex compliance requirements that vary by jurisdiction, often necessitating comprehensive environmental management systems and safety protocols that exceed standard battery manufacturing practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!