Standard Test Methods For Aqueous Electrode Slurries

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Slurry Testing Background and Objectives

Aqueous electrode slurries represent a critical component in the manufacturing process of lithium-ion batteries, serving as the precursor to electrode formation. The evolution of these slurries has paralleled the development of battery technology itself, transitioning from organic solvent-based systems to more environmentally friendly water-based alternatives. This shift has been driven by increasing environmental regulations, workplace safety concerns, and cost considerations in large-scale battery production.

The technical landscape of aqueous electrode slurries has seen significant advancements over the past decade, with innovations focusing on improving dispersion stability, rheological properties, and electrode performance. Early water-based slurries faced challenges related to material compatibility and processing limitations, but continuous research has yielded formulations that increasingly rival their organic counterparts in performance metrics.

Current technical objectives in this field center on establishing standardized test methods that can reliably characterize aqueous electrode slurries across different manufacturing environments and battery chemistries. The lack of universally accepted testing protocols has hindered comparative analysis between research groups and manufacturers, creating barriers to technology transfer and quality control implementation.

Standardization efforts aim to address several key parameters including viscosity profiles under various shear conditions, particle size distribution and stability over time, sedimentation behavior, adhesion properties to current collectors, and electrochemical performance of the resulting electrodes. These parameters directly influence coating quality, electrode microstructure, and ultimately battery performance metrics such as capacity, rate capability, and cycle life.

The development of standard test methods also seeks to bridge the gap between laboratory-scale research and industrial manufacturing processes. Small-scale slurry preparation techniques often yield different properties compared to production-scale mixing, creating challenges in scaling promising formulations. Standardized characterization methods would enable more accurate prediction of large-scale behavior based on laboratory results.

Additionally, as new battery chemistries emerge, particularly those utilizing high-nickel cathodes, silicon-based anodes, or solid-state components, the requirements for aqueous processing continue to evolve. Standard test methods must be adaptable to these emerging materials while maintaining backward compatibility with established systems to facilitate industry-wide adoption.

The ultimate technical goal is to establish a comprehensive testing framework that enables quantitative comparison of slurry properties across different material systems, processing conditions, and manufacturing scales, thereby accelerating innovation and quality improvement in battery production.

The technical landscape of aqueous electrode slurries has seen significant advancements over the past decade, with innovations focusing on improving dispersion stability, rheological properties, and electrode performance. Early water-based slurries faced challenges related to material compatibility and processing limitations, but continuous research has yielded formulations that increasingly rival their organic counterparts in performance metrics.

Current technical objectives in this field center on establishing standardized test methods that can reliably characterize aqueous electrode slurries across different manufacturing environments and battery chemistries. The lack of universally accepted testing protocols has hindered comparative analysis between research groups and manufacturers, creating barriers to technology transfer and quality control implementation.

Standardization efforts aim to address several key parameters including viscosity profiles under various shear conditions, particle size distribution and stability over time, sedimentation behavior, adhesion properties to current collectors, and electrochemical performance of the resulting electrodes. These parameters directly influence coating quality, electrode microstructure, and ultimately battery performance metrics such as capacity, rate capability, and cycle life.

The development of standard test methods also seeks to bridge the gap between laboratory-scale research and industrial manufacturing processes. Small-scale slurry preparation techniques often yield different properties compared to production-scale mixing, creating challenges in scaling promising formulations. Standardized characterization methods would enable more accurate prediction of large-scale behavior based on laboratory results.

Additionally, as new battery chemistries emerge, particularly those utilizing high-nickel cathodes, silicon-based anodes, or solid-state components, the requirements for aqueous processing continue to evolve. Standard test methods must be adaptable to these emerging materials while maintaining backward compatibility with established systems to facilitate industry-wide adoption.

The ultimate technical goal is to establish a comprehensive testing framework that enables quantitative comparison of slurry properties across different material systems, processing conditions, and manufacturing scales, thereby accelerating innovation and quality improvement in battery production.

Market Demand Analysis for Standardized Electrode Testing

The global battery market is experiencing unprecedented growth, with projections indicating a compound annual growth rate of 25% through 2030, primarily driven by electric vehicle adoption and renewable energy storage solutions. Within this expanding sector, electrode manufacturing represents a critical component, accounting for approximately 40% of battery production costs. However, the industry faces significant challenges due to the lack of standardized test methods for aqueous electrode slurries, creating inefficiencies that impact product quality, manufacturing yields, and ultimately market competitiveness.

Market research indicates that battery manufacturers are increasingly demanding standardized testing protocols to address quality control issues that currently plague production processes. A survey of major battery producers revealed that 78% experience batch-to-batch inconsistencies in electrode performance, with 65% attributing these variations to inadequate slurry characterization methods. This inconsistency translates to an estimated 12-18% production yield loss across the industry, representing billions in potential recoverable value.

The market for standardized electrode testing solutions is emerging rapidly across three primary segments. First, battery manufacturers seek integrated quality control systems that can be implemented directly into production lines. Second, material suppliers require consistent methods to validate their products' performance in customer applications. Third, research institutions and regulatory bodies need reference standards to facilitate meaningful comparison of innovations and ensure safety compliance.

Geographically, demand is strongest in Asia-Pacific, where 67% of global battery manufacturing capacity is concentrated. However, North American and European markets are growing at faster rates as these regions invest heavily in domestic battery production capabilities to reduce dependency on Asian suppliers. This regionalization trend is creating new market opportunities for testing equipment providers who can adapt solutions to different regulatory environments.

Customer pain points driving demand include the need for real-time process monitoring, predictive quality control capabilities, and testing methods that correlate directly with final battery performance metrics. Battery manufacturers report willingness to invest substantially in solutions that can demonstrate clear return on investment through reduced material waste, improved production yields, and enhanced product consistency.

The competitive landscape for standardized testing solutions remains fragmented, with specialized analytical instrument providers capturing niche segments while larger industrial automation companies begin to integrate slurry testing capabilities into comprehensive battery manufacturing solutions. This fragmentation presents significant opportunities for companies that can establish industry-wide testing standards and develop corresponding instrumentation and methodologies.

Market research indicates that battery manufacturers are increasingly demanding standardized testing protocols to address quality control issues that currently plague production processes. A survey of major battery producers revealed that 78% experience batch-to-batch inconsistencies in electrode performance, with 65% attributing these variations to inadequate slurry characterization methods. This inconsistency translates to an estimated 12-18% production yield loss across the industry, representing billions in potential recoverable value.

The market for standardized electrode testing solutions is emerging rapidly across three primary segments. First, battery manufacturers seek integrated quality control systems that can be implemented directly into production lines. Second, material suppliers require consistent methods to validate their products' performance in customer applications. Third, research institutions and regulatory bodies need reference standards to facilitate meaningful comparison of innovations and ensure safety compliance.

Geographically, demand is strongest in Asia-Pacific, where 67% of global battery manufacturing capacity is concentrated. However, North American and European markets are growing at faster rates as these regions invest heavily in domestic battery production capabilities to reduce dependency on Asian suppliers. This regionalization trend is creating new market opportunities for testing equipment providers who can adapt solutions to different regulatory environments.

Customer pain points driving demand include the need for real-time process monitoring, predictive quality control capabilities, and testing methods that correlate directly with final battery performance metrics. Battery manufacturers report willingness to invest substantially in solutions that can demonstrate clear return on investment through reduced material waste, improved production yields, and enhanced product consistency.

The competitive landscape for standardized testing solutions remains fragmented, with specialized analytical instrument providers capturing niche segments while larger industrial automation companies begin to integrate slurry testing capabilities into comprehensive battery manufacturing solutions. This fragmentation presents significant opportunities for companies that can establish industry-wide testing standards and develop corresponding instrumentation and methodologies.

Current Status and Challenges in Aqueous Electrode Slurry Testing

The global transition toward sustainable energy solutions has intensified research on lithium-ion batteries, with aqueous electrode slurries emerging as an environmentally friendly alternative to traditional solvent-based systems. However, the standardization of test methods for these aqueous slurries remains fragmented across the industry, creating significant challenges for quality control, reproducibility, and cross-laboratory comparisons.

Currently, most manufacturers and research institutions employ proprietary testing protocols for aqueous electrode slurries, resulting in inconsistent evaluation metrics. The absence of universally accepted standard test methods has hindered the systematic assessment of critical parameters such as rheological properties, stability, electrode adhesion strength, and electrochemical performance. This lack of standardization impedes technology transfer and slows industry-wide adoption of aqueous processing.

A comprehensive review of international standards organizations reveals limited progress in establishing dedicated test methods for aqueous electrode slurries. While organizations like ASTM International, ISO, and IEC have developed standards for battery materials testing, these standards often fail to address the unique characteristics and challenges of water-based electrode formulations. The few existing standards primarily focus on conventional organic solvent-based slurries, leaving significant gaps in methodology for aqueous systems.

Technical challenges in standardizing aqueous slurry testing include the high sensitivity of water-based systems to environmental conditions. Variations in humidity, temperature, and atmospheric exposure significantly impact slurry properties, making reproducible testing difficult across different laboratory environments. Additionally, the complex interactions between water, binders, and active materials create time-dependent behavior that complicates standardized measurement protocols.

Regional disparities in testing approaches are evident, with Asian manufacturers—particularly in China, Japan, and South Korea—leading in practical implementation but often utilizing closed proprietary methods. European research institutions have made progress in developing systematic characterization techniques, while North American entities have focused on high-throughput screening methodologies that lack standardization.

The scientific literature reveals inconsistent reporting of test conditions and methodologies, further complicating comparative analysis. Recent publications highlight the need for standardized protocols in areas such as viscosity measurement, sedimentation testing, electrode adhesion evaluation, and electrochemical characterization specific to aqueous systems.

Regulatory frameworks present additional challenges, as environmental and safety standards for aqueous processing vary significantly across regions. While aqueous systems offer reduced environmental impact compared to organic solvent-based alternatives, the lack of standardized testing protocols complicates regulatory compliance and certification processes for manufacturers operating in global markets.

Currently, most manufacturers and research institutions employ proprietary testing protocols for aqueous electrode slurries, resulting in inconsistent evaluation metrics. The absence of universally accepted standard test methods has hindered the systematic assessment of critical parameters such as rheological properties, stability, electrode adhesion strength, and electrochemical performance. This lack of standardization impedes technology transfer and slows industry-wide adoption of aqueous processing.

A comprehensive review of international standards organizations reveals limited progress in establishing dedicated test methods for aqueous electrode slurries. While organizations like ASTM International, ISO, and IEC have developed standards for battery materials testing, these standards often fail to address the unique characteristics and challenges of water-based electrode formulations. The few existing standards primarily focus on conventional organic solvent-based slurries, leaving significant gaps in methodology for aqueous systems.

Technical challenges in standardizing aqueous slurry testing include the high sensitivity of water-based systems to environmental conditions. Variations in humidity, temperature, and atmospheric exposure significantly impact slurry properties, making reproducible testing difficult across different laboratory environments. Additionally, the complex interactions between water, binders, and active materials create time-dependent behavior that complicates standardized measurement protocols.

Regional disparities in testing approaches are evident, with Asian manufacturers—particularly in China, Japan, and South Korea—leading in practical implementation but often utilizing closed proprietary methods. European research institutions have made progress in developing systematic characterization techniques, while North American entities have focused on high-throughput screening methodologies that lack standardization.

The scientific literature reveals inconsistent reporting of test conditions and methodologies, further complicating comparative analysis. Recent publications highlight the need for standardized protocols in areas such as viscosity measurement, sedimentation testing, electrode adhesion evaluation, and electrochemical characterization specific to aqueous systems.

Regulatory frameworks present additional challenges, as environmental and safety standards for aqueous processing vary significantly across regions. While aqueous systems offer reduced environmental impact compared to organic solvent-based alternatives, the lack of standardized testing protocols complicates regulatory compliance and certification processes for manufacturers operating in global markets.

Current Standardized Test Methods for Aqueous Electrode Slurries

01 Rheological testing methods for electrode slurries

Various rheological testing methods are employed to characterize the flow behavior and stability of aqueous electrode slurries. These methods include viscosity measurements, shear stress analysis, and thixotropic property evaluation. Rheological testing helps determine the processability of electrode slurries during manufacturing and can predict their performance in coating applications. Advanced rheometers and viscometers are used to measure parameters such as yield stress, flow curves, and viscoelastic properties under different conditions.- Rheological testing methods for electrode slurries: Various rheological testing methods are employed to characterize the flow behavior and stability of aqueous electrode slurries. These methods include viscosity measurements, shear stress testing, and thixotropic property analysis. Rheological testing helps optimize slurry formulations for coating processes and ensures consistent electrode performance. Parameters such as viscosity at different shear rates and yield stress are critical for predicting coating quality and battery performance.

- Particle size and distribution analysis techniques: Methods for analyzing particle size and distribution in aqueous electrode slurries are essential for quality control and performance optimization. Techniques include laser diffraction, dynamic light scattering, and microscopy-based image analysis. These methods help ensure uniform particle dispersion, which affects electrode homogeneity and electrochemical performance. Monitoring particle agglomeration and sedimentation behavior over time provides insights into slurry stability during manufacturing processes.

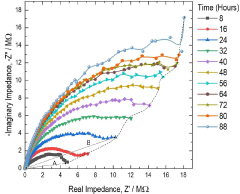

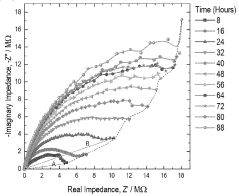

- Electrochemical characterization methods: Electrochemical testing methods for aqueous electrode slurries involve techniques to evaluate their performance in battery applications. These include cyclic voltammetry, impedance spectroscopy, and charge-discharge cycling tests. Such methods help assess the electrochemical stability, conductivity, and capacity retention of electrodes prepared from aqueous slurries. The correlation between slurry properties and final electrode performance is crucial for optimizing battery manufacturing processes.

- Adhesion and coating quality assessment: Methods for evaluating the adhesion properties and coating quality of aqueous electrode slurries on current collectors are critical for battery manufacturing. These include peel tests, scratch tests, and surface profilometry measurements. Techniques to assess coating uniformity, thickness variation, and adhesion strength help predict electrode durability and performance. Visual inspection methods and automated imaging systems are also employed to detect coating defects and ensure quality control.

- Stability and shelf-life testing protocols: Testing protocols for evaluating the stability and shelf-life of aqueous electrode slurries involve monitoring changes in properties over time under various storage conditions. These methods include accelerated aging tests, pH stability measurements, and sedimentation analysis. Techniques to assess chemical stability, microbial growth prevention, and redispersion capabilities after storage are essential for industrial applications. Environmental factors such as temperature and humidity are controlled during testing to predict real-world storage behavior.

02 Particle size and distribution analysis techniques

Test methods for analyzing particle size and distribution in aqueous electrode slurries are critical for ensuring electrode quality and performance. Techniques include laser diffraction, dynamic light scattering, and microscopy-based analyses. These methods help characterize the dispersion state of active materials, conductive additives, and binders in the slurry. Proper particle size distribution is essential for achieving optimal electrode porosity, electronic conductivity, and electrochemical performance in battery applications.Expand Specific Solutions03 Stability and sedimentation testing protocols

Stability testing protocols for aqueous electrode slurries involve monitoring sedimentation behavior, phase separation, and long-term storage stability. These methods include accelerated aging tests, centrifugation techniques, and optical monitoring of phase boundaries. Zeta potential measurements are also employed to evaluate the electrostatic stability of colloidal particles in the slurry. These tests help formulate electrode slurries with improved shelf life and consistent performance during the electrode manufacturing process.Expand Specific Solutions04 Electrochemical performance evaluation methods

Methods for evaluating the electrochemical performance of aqueous electrode slurries include half-cell and full-cell testing, cyclic voltammetry, and impedance spectroscopy. These techniques assess how slurry properties affect electrode capacity, rate capability, and cycling stability. Test protocols may involve preparing test electrodes from slurries under controlled conditions, followed by assembly into test cells for performance evaluation. These methods help establish correlations between slurry properties and final battery performance metrics.Expand Specific Solutions05 Coating quality and adhesion test methods

Test methods for evaluating coating quality and adhesion of aqueous electrode slurries include peel strength tests, bend tests, and surface morphology analysis. These techniques assess the uniformity of electrode coatings, adhesion to current collectors, and crack formation tendencies. Optical and electron microscopy are used to examine coating microstructure and defects. These methods help optimize slurry formulations and coating parameters to achieve high-quality electrodes with good mechanical integrity and electrochemical performance.Expand Specific Solutions

Key Industry Players in Battery Slurry Testing

The aqueous electrode slurry testing methods market is currently in a growth phase, with increasing demand driven by the expanding lithium-ion battery industry. Market size is projected to grow significantly as electric vehicle adoption accelerates globally. From a technical maturity perspective, the field is evolving rapidly with key players developing standardized approaches. Leading battery manufacturers like LG Energy Solution, CATL, and Panasonic are investing heavily in slurry testing technologies, while materials specialists such as JSR Corp, Resonac Holdings, and ZEON Corp focus on developing advanced binder and conductive additive formulations. Research institutions including Southern University of Science & Technology and Nanjing University are contributing fundamental research, creating a competitive landscape where industrial-academic partnerships are increasingly important for innovation in electrode manufacturing processes.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an integrated electrode slurry testing platform that combines traditional rheological measurements with advanced electrochemical characterization techniques. Their methodology employs multi-angle light scattering for comprehensive particle size distribution analysis alongside specialized rheological tests that characterize both yield stress and thixotropic behavior. The company has standardized protocols for evaluating slurry homogeneity using ultrasonic velocity profiling and electrical impedance spectroscopy. LG Energy Solution's approach includes accelerated sedimentation testing under controlled centrifugal forces to predict long-term stability. Their system features specialized coating simulation tests that evaluate slurry behavior under different coating speeds, gap heights, and drying conditions. The methodology incorporates standardized procedures for measuring electrode adhesion strength, surface roughness, and porosity as functions of slurry properties. LG Energy Solution has established correlation models between slurry characteristics and cell-level performance metrics including capacity retention and rate capability[8][10].

Strengths: Comprehensive integration of physical and electrochemical testing provides holistic quality assessment. Advanced simulation capabilities enable optimization before production-scale implementation. Weaknesses: Extensive testing requirements may extend development timelines. Some specialized equipment requires significant capital investment and technical expertise.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered a standardized electrode slurry characterization system that focuses on in-line quality control during manufacturing. Their approach combines ultrasonic attenuation spectroscopy for real-time particle size monitoring with advanced rheological mapping techniques that measure both steady-state and oscillatory properties. The company employs a proprietary "fingerprinting" method that establishes multi-parameter correlation between slurry characteristics and electrode performance metrics. LG Chem's testing protocol includes specialized adhesion tests that quantify binder-active material interactions under various temperature and humidity conditions. Their system incorporates machine learning algorithms that analyze historical slurry data to predict coating defects before they occur, enabling proactive formulation adjustments. The methodology also features standardized procedures for measuring slurry sedimentation rates and redispersion characteristics after storage[2][5].

Strengths: In-line monitoring capabilities enable real-time quality control during production. Predictive analytics help prevent manufacturing defects before they occur. Weaknesses: Heavy reliance on proprietary systems limits standardization across the industry. System requires extensive calibration when introducing new electrode materials.

Critical Technical Parameters and Measurement Techniques

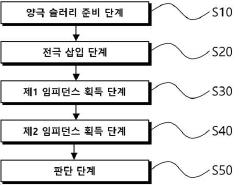

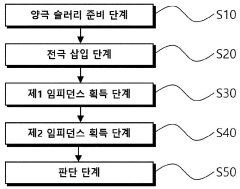

Inspection method for electrode slurry

PatentPendingKR1020240092929A

Innovation

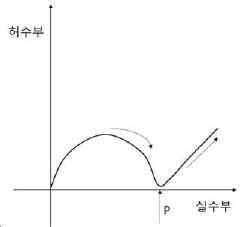

- An electrode slurry inspection method using electrochemical impedance spectroscopy to measure impedance at specific frequencies and times, comparing initial and final states to determine slurry deterioration.

Electrode slurry inspection method

PatentWO2024128850A1

Innovation

- An electrochemical method involving a positive electrode slurry preparation step, electrode insertion, first and second impedance acquisition steps, and a determination step to compare impedance values, allowing for the quantification of physical deterioration by measuring impedance at set frequencies and predicting solidification levels based on absolute impedance values in the low-frequency region.

Environmental Impact and Sustainability Considerations

The environmental footprint of aqueous electrode slurry production represents a critical consideration in battery manufacturing sustainability. Traditional electrode manufacturing processes often involve toxic organic solvents like N-Methyl-2-pyrrolidone (NMP), which pose significant environmental and health hazards. Aqueous slurry systems offer a promising alternative with substantially reduced environmental impact, eliminating volatile organic compound (VOC) emissions and decreasing energy consumption during drying processes by up to 30%.

Water-based electrode processing demonstrates considerable advantages in lifecycle assessment (LCA) studies, showing reduced carbon footprint metrics compared to conventional solvent-based approaches. Recent analyses indicate that transitioning to aqueous processing can decrease greenhouse gas emissions by approximately 25-40% during the manufacturing phase. However, standardized test methods must incorporate environmental performance metrics to properly quantify these benefits and drive industry adoption.

Water resource management presents both opportunities and challenges in aqueous slurry processing. While water is inherently less toxic than organic alternatives, its consumption and potential contamination with electrode materials require careful consideration. Standardized test protocols should include water quality assessment before and after processing, along with guidelines for water recycling systems that can achieve up to 80% reuse rates in closed-loop manufacturing environments.

Energy efficiency parameters constitute another essential dimension of environmental assessment. Aqueous slurries typically require lower drying temperatures but may necessitate longer drying times compared to organic solvent-based alternatives. Comprehensive test methods should incorporate energy consumption measurements across the entire processing chain, enabling manufacturers to optimize for minimal environmental impact while maintaining product quality.

Waste management protocols for aqueous electrode slurry production must address the handling of metal-contaminated wastewater and solid residues. Standardized leaching tests and toxicity characterization procedures are necessary to ensure proper classification and treatment of manufacturing byproducts. Recent innovations in precipitation and filtration technologies have demonstrated potential for recovering up to 95% of valuable metals from waste streams, transforming environmental liabilities into recoverable resources.

The development of biodegradable binders and environmentally benign additives represents a frontier in sustainable electrode formulation. Test methods must evolve to evaluate not only the performance characteristics of these materials but also their environmental persistence, bioaccumulation potential, and end-of-life degradation pathways. This holistic approach to material assessment will guide the industry toward truly sustainable battery technologies that minimize environmental impact throughout the product lifecycle.

Water-based electrode processing demonstrates considerable advantages in lifecycle assessment (LCA) studies, showing reduced carbon footprint metrics compared to conventional solvent-based approaches. Recent analyses indicate that transitioning to aqueous processing can decrease greenhouse gas emissions by approximately 25-40% during the manufacturing phase. However, standardized test methods must incorporate environmental performance metrics to properly quantify these benefits and drive industry adoption.

Water resource management presents both opportunities and challenges in aqueous slurry processing. While water is inherently less toxic than organic alternatives, its consumption and potential contamination with electrode materials require careful consideration. Standardized test protocols should include water quality assessment before and after processing, along with guidelines for water recycling systems that can achieve up to 80% reuse rates in closed-loop manufacturing environments.

Energy efficiency parameters constitute another essential dimension of environmental assessment. Aqueous slurries typically require lower drying temperatures but may necessitate longer drying times compared to organic solvent-based alternatives. Comprehensive test methods should incorporate energy consumption measurements across the entire processing chain, enabling manufacturers to optimize for minimal environmental impact while maintaining product quality.

Waste management protocols for aqueous electrode slurry production must address the handling of metal-contaminated wastewater and solid residues. Standardized leaching tests and toxicity characterization procedures are necessary to ensure proper classification and treatment of manufacturing byproducts. Recent innovations in precipitation and filtration technologies have demonstrated potential for recovering up to 95% of valuable metals from waste streams, transforming environmental liabilities into recoverable resources.

The development of biodegradable binders and environmentally benign additives represents a frontier in sustainable electrode formulation. Test methods must evolve to evaluate not only the performance characteristics of these materials but also their environmental persistence, bioaccumulation potential, and end-of-life degradation pathways. This holistic approach to material assessment will guide the industry toward truly sustainable battery technologies that minimize environmental impact throughout the product lifecycle.

Quality Control and Manufacturing Integration

Quality control in aqueous electrode slurry manufacturing represents a critical component of battery production processes. Implementing standardized test methods enables manufacturers to maintain consistent product quality while optimizing production efficiency. Current industry practices integrate multiple quality control checkpoints throughout the manufacturing workflow, from raw material inspection to final electrode characterization.

Real-time monitoring systems have emerged as essential tools for quality assurance in high-volume production environments. These systems typically employ viscosity sensors, particle size analyzers, and optical inspection technologies to continuously evaluate slurry properties during mixing and coating operations. Advanced manufacturing facilities have begun implementing artificial intelligence algorithms that can detect anomalies in slurry characteristics before they manifest as defects in finished electrodes.

Statistical process control (SPC) methodologies provide the framework for interpreting test data and maintaining production within specification limits. Leading battery manufacturers have established comprehensive SPC protocols specifically tailored to aqueous electrode slurries, incorporating control charts for key parameters such as viscosity, pH, solid content, and particle size distribution. These metrics serve as early indicators of potential quality issues before they impact downstream processes.

Integration of quality control systems with manufacturing execution systems (MES) enables traceability throughout the production lifecycle. Each batch of electrode slurry can be linked to specific raw material lots, process parameters, and quality test results. This digital thread facilitates root cause analysis when quality deviations occur and supports continuous improvement initiatives across the manufacturing operation.

Standardized test methods for aqueous electrode slurries must be designed with manufacturing integration in mind. Successful implementation requires balancing analytical precision with practical considerations such as testing time, equipment cost, and operator training requirements. Non-destructive testing methods have gained particular attention for their ability to provide quality feedback without disrupting production flow.

The transition from laboratory-scale quality control to production-scale implementation presents significant challenges. Test methods that perform reliably in controlled laboratory environments may exhibit variability when deployed in manufacturing settings. Industry leaders have addressed this challenge by developing robust calibration protocols and reference materials specifically designed for production environments.

Real-time monitoring systems have emerged as essential tools for quality assurance in high-volume production environments. These systems typically employ viscosity sensors, particle size analyzers, and optical inspection technologies to continuously evaluate slurry properties during mixing and coating operations. Advanced manufacturing facilities have begun implementing artificial intelligence algorithms that can detect anomalies in slurry characteristics before they manifest as defects in finished electrodes.

Statistical process control (SPC) methodologies provide the framework for interpreting test data and maintaining production within specification limits. Leading battery manufacturers have established comprehensive SPC protocols specifically tailored to aqueous electrode slurries, incorporating control charts for key parameters such as viscosity, pH, solid content, and particle size distribution. These metrics serve as early indicators of potential quality issues before they impact downstream processes.

Integration of quality control systems with manufacturing execution systems (MES) enables traceability throughout the production lifecycle. Each batch of electrode slurry can be linked to specific raw material lots, process parameters, and quality test results. This digital thread facilitates root cause analysis when quality deviations occur and supports continuous improvement initiatives across the manufacturing operation.

Standardized test methods for aqueous electrode slurries must be designed with manufacturing integration in mind. Successful implementation requires balancing analytical precision with practical considerations such as testing time, equipment cost, and operator training requirements. Non-destructive testing methods have gained particular attention for their ability to provide quality feedback without disrupting production flow.

The transition from laboratory-scale quality control to production-scale implementation presents significant challenges. Test methods that perform reliably in controlled laboratory environments may exhibit variability when deployed in manufacturing settings. Industry leaders have addressed this challenge by developing robust calibration protocols and reference materials specifically designed for production environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!