Electrode Porosity Control In Solvent-Free Processes

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solvent-Free Electrode Manufacturing Background and Objectives

The evolution of lithium-ion battery technology has been marked by continuous efforts to enhance energy density, safety, and manufacturing efficiency. Traditional electrode manufacturing processes heavily rely on solvent-based slurry coating methods, which have been the industry standard for decades. These conventional approaches involve dissolving active materials, conductive additives, and binders in organic solvents, followed by coating, drying, and calendering steps. However, these solvent-based processes present significant environmental, economic, and technical challenges.

Solvent-free electrode manufacturing has emerged as a promising alternative pathway, aiming to eliminate the use of environmentally harmful organic solvents such as N-Methyl-2-pyrrolidone (NMP) and reduce energy consumption associated with solvent evaporation and recovery. This technological shift began gaining momentum in the early 2010s, with pioneering research focusing on dry powder coating, electrostatic spraying, and various pressing techniques.

The primary objective of solvent-free electrode manufacturing research is to develop commercially viable processes that can produce high-performance electrodes without compromising energy density, cycle life, or rate capability. A critical aspect of this objective is achieving precise control over electrode porosity—a parameter that significantly influences ion transport, electrolyte wetting, and ultimately battery performance.

Porosity control in solvent-free processes presents unique challenges compared to traditional methods. Without liquid solvents to facilitate particle distribution and binding, alternative mechanisms must be developed to create and maintain optimal pore structures. The target porosity typically ranges from 20-40%, depending on the specific cell chemistry and application requirements.

Recent technological advancements have demonstrated promising results in controlling electrode porosity through various approaches, including particle size engineering, pressure modulation during compaction, and innovative binder systems specifically designed for dry processing. These developments have been driven by both academic research and industrial R&D efforts, particularly from major battery manufacturers and automotive companies seeking more sustainable production methods.

The trajectory of solvent-free electrode manufacturing technology indicates a gradual but steady progression toward commercial implementation. Current research focuses on scaling these processes while maintaining precise control over microstructural parameters, including porosity. The ultimate goal is to establish manufacturing protocols that can be integrated into existing production lines with minimal disruption while offering substantial benefits in terms of cost reduction, environmental impact, and potentially enhanced battery performance.

As global battery production continues to scale dramatically to meet the demands of electric vehicles and renewable energy storage, the importance of developing more sustainable manufacturing methods becomes increasingly critical. Electrode porosity control in solvent-free processes represents a key technological challenge that, when successfully addressed, could significantly contribute to the next generation of more sustainable and efficient battery production.

Solvent-free electrode manufacturing has emerged as a promising alternative pathway, aiming to eliminate the use of environmentally harmful organic solvents such as N-Methyl-2-pyrrolidone (NMP) and reduce energy consumption associated with solvent evaporation and recovery. This technological shift began gaining momentum in the early 2010s, with pioneering research focusing on dry powder coating, electrostatic spraying, and various pressing techniques.

The primary objective of solvent-free electrode manufacturing research is to develop commercially viable processes that can produce high-performance electrodes without compromising energy density, cycle life, or rate capability. A critical aspect of this objective is achieving precise control over electrode porosity—a parameter that significantly influences ion transport, electrolyte wetting, and ultimately battery performance.

Porosity control in solvent-free processes presents unique challenges compared to traditional methods. Without liquid solvents to facilitate particle distribution and binding, alternative mechanisms must be developed to create and maintain optimal pore structures. The target porosity typically ranges from 20-40%, depending on the specific cell chemistry and application requirements.

Recent technological advancements have demonstrated promising results in controlling electrode porosity through various approaches, including particle size engineering, pressure modulation during compaction, and innovative binder systems specifically designed for dry processing. These developments have been driven by both academic research and industrial R&D efforts, particularly from major battery manufacturers and automotive companies seeking more sustainable production methods.

The trajectory of solvent-free electrode manufacturing technology indicates a gradual but steady progression toward commercial implementation. Current research focuses on scaling these processes while maintaining precise control over microstructural parameters, including porosity. The ultimate goal is to establish manufacturing protocols that can be integrated into existing production lines with minimal disruption while offering substantial benefits in terms of cost reduction, environmental impact, and potentially enhanced battery performance.

As global battery production continues to scale dramatically to meet the demands of electric vehicles and renewable energy storage, the importance of developing more sustainable manufacturing methods becomes increasingly critical. Electrode porosity control in solvent-free processes represents a key technological challenge that, when successfully addressed, could significantly contribute to the next generation of more sustainable and efficient battery production.

Market Demand Analysis for Sustainable Battery Production

The global battery market is experiencing unprecedented growth driven by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. This growth trajectory has created a substantial demand for more sustainable battery production methods, with electrode porosity control in solvent-free processes emerging as a critical technological focus area. Current market projections indicate the global lithium-ion battery market will reach approximately $129 billion by 2027, with a compound annual growth rate exceeding 18% from 2022.

Sustainability concerns are reshaping market demands across the battery value chain. Traditional electrode manufacturing processes rely heavily on toxic N-Methyl-2-pyrrolidone (NMP) solvents, generating significant environmental hazards and requiring extensive energy consumption for solvent recovery. This has created a market pull for solvent-free electrode manufacturing technologies, with major battery manufacturers and automotive companies committing billions to sustainable production methods.

Consumer electronics manufacturers are increasingly prioritizing green credentials in their supply chains, creating additional market pressure for sustainable battery components. Market research indicates that 67% of consumers consider environmental impact when making purchasing decisions, translating to tangible market advantages for companies employing sustainable manufacturing processes.

Regulatory frameworks worldwide are accelerating this market shift. The European Union's Battery Directive revision and similar regulations in North America and Asia are establishing stringent environmental standards for battery production. These regulations often include specific provisions regarding solvent usage, carbon footprint, and manufacturing waste, creating immediate market incentives for solvent-free electrode technologies.

Industrial stakeholders across the battery ecosystem are responding to these market signals. Major cell manufacturers have announced investments totaling over $45 billion in new production facilities incorporating sustainable manufacturing technologies. Automotive OEMs have similarly committed substantial resources to securing supply chains featuring environmentally responsible battery production.

The market for electrode manufacturing equipment is particularly responsive to these trends. Equipment suppliers report growing demand for dry electrode coating technologies, with order backlogs extending 12-18 months for advanced systems capable of precise porosity control without solvents. This equipment segment is projected to grow at 25% annually through 2026, outpacing the broader battery market.

Energy density requirements from end-users create additional market pressure for advanced porosity control. EV manufacturers specifically demand batteries with higher energy density to extend vehicle range, creating market pull for electrode technologies that can precisely engineer porosity to optimize both energy density and power capabilities.

Sustainability concerns are reshaping market demands across the battery value chain. Traditional electrode manufacturing processes rely heavily on toxic N-Methyl-2-pyrrolidone (NMP) solvents, generating significant environmental hazards and requiring extensive energy consumption for solvent recovery. This has created a market pull for solvent-free electrode manufacturing technologies, with major battery manufacturers and automotive companies committing billions to sustainable production methods.

Consumer electronics manufacturers are increasingly prioritizing green credentials in their supply chains, creating additional market pressure for sustainable battery components. Market research indicates that 67% of consumers consider environmental impact when making purchasing decisions, translating to tangible market advantages for companies employing sustainable manufacturing processes.

Regulatory frameworks worldwide are accelerating this market shift. The European Union's Battery Directive revision and similar regulations in North America and Asia are establishing stringent environmental standards for battery production. These regulations often include specific provisions regarding solvent usage, carbon footprint, and manufacturing waste, creating immediate market incentives for solvent-free electrode technologies.

Industrial stakeholders across the battery ecosystem are responding to these market signals. Major cell manufacturers have announced investments totaling over $45 billion in new production facilities incorporating sustainable manufacturing technologies. Automotive OEMs have similarly committed substantial resources to securing supply chains featuring environmentally responsible battery production.

The market for electrode manufacturing equipment is particularly responsive to these trends. Equipment suppliers report growing demand for dry electrode coating technologies, with order backlogs extending 12-18 months for advanced systems capable of precise porosity control without solvents. This equipment segment is projected to grow at 25% annually through 2026, outpacing the broader battery market.

Energy density requirements from end-users create additional market pressure for advanced porosity control. EV manufacturers specifically demand batteries with higher energy density to extend vehicle range, creating market pull for electrode technologies that can precisely engineer porosity to optimize both energy density and power capabilities.

Current Challenges in Porosity Control Technologies

Despite significant advancements in solvent-free electrode manufacturing processes, achieving precise control over electrode porosity remains a formidable challenge. Current technologies struggle with several fundamental limitations that hinder optimal performance in battery production. The primary challenge lies in the inherent trade-off between mechanical integrity and porosity - higher porosity typically results in reduced mechanical strength, creating a delicate balancing act for manufacturers.

Temperature management during dry processing presents another significant obstacle. Unlike solvent-based methods where evaporation provides natural cooling, solvent-free processes generate considerable heat through mechanical friction. This heat can lead to uneven particle distribution and inconsistent pore formation, particularly in large-scale production environments where heat dissipation becomes increasingly problematic.

The absence of liquid-phase intermediates eliminates the traditional pore-forming mechanisms relied upon in conventional electrode manufacturing. Without solvents to create temporary spaces that become pores after evaporation, alternative porosity generation methods must be employed, often with less predictable results. This unpredictability translates to higher variability in final electrode properties, complicating quality control efforts.

Current dry processing equipment also demonstrates limitations in achieving uniform particle distribution throughout the electrode structure. Agglomeration of active materials and conductive additives frequently occurs, creating density variations that lead to uneven porosity profiles. These heterogeneities can significantly impact electrode performance, particularly in high-power applications where uniform ion transport pathways are critical.

Real-time monitoring and control systems for porosity in solvent-free processes remain underdeveloped compared to their wet-processing counterparts. The lack of sophisticated in-line measurement techniques makes it difficult to implement closed-loop control systems that could adjust processing parameters dynamically to maintain target porosity specifications.

Scale-up challenges further complicate porosity control in industrial settings. Laboratory-scale successes often fail to translate directly to production environments due to differences in equipment dynamics, material handling characteristics, and process control capabilities. The physics of particle interaction changes significantly with increasing batch sizes, requiring substantial process reengineering during commercialization.

Additionally, the limited understanding of the relationship between processing parameters and resulting pore structures hampers systematic optimization efforts. Current models inadequately capture the complex interplay between mechanical forces, material properties, and environmental conditions that collectively determine electrode microstructure in dry processing environments.

Temperature management during dry processing presents another significant obstacle. Unlike solvent-based methods where evaporation provides natural cooling, solvent-free processes generate considerable heat through mechanical friction. This heat can lead to uneven particle distribution and inconsistent pore formation, particularly in large-scale production environments where heat dissipation becomes increasingly problematic.

The absence of liquid-phase intermediates eliminates the traditional pore-forming mechanisms relied upon in conventional electrode manufacturing. Without solvents to create temporary spaces that become pores after evaporation, alternative porosity generation methods must be employed, often with less predictable results. This unpredictability translates to higher variability in final electrode properties, complicating quality control efforts.

Current dry processing equipment also demonstrates limitations in achieving uniform particle distribution throughout the electrode structure. Agglomeration of active materials and conductive additives frequently occurs, creating density variations that lead to uneven porosity profiles. These heterogeneities can significantly impact electrode performance, particularly in high-power applications where uniform ion transport pathways are critical.

Real-time monitoring and control systems for porosity in solvent-free processes remain underdeveloped compared to their wet-processing counterparts. The lack of sophisticated in-line measurement techniques makes it difficult to implement closed-loop control systems that could adjust processing parameters dynamically to maintain target porosity specifications.

Scale-up challenges further complicate porosity control in industrial settings. Laboratory-scale successes often fail to translate directly to production environments due to differences in equipment dynamics, material handling characteristics, and process control capabilities. The physics of particle interaction changes significantly with increasing batch sizes, requiring substantial process reengineering during commercialization.

Additionally, the limited understanding of the relationship between processing parameters and resulting pore structures hampers systematic optimization efforts. Current models inadequately capture the complex interplay between mechanical forces, material properties, and environmental conditions that collectively determine electrode microstructure in dry processing environments.

Current Porosity Control Methods in Dry Processing

01 Porous electrode manufacturing through sintering processes

Sintering is a key manufacturing process for creating porous electrodes. This thermal treatment process involves heating powdered materials below their melting point, causing particles to bond together while maintaining controlled porosity. The sintering parameters such as temperature, time, and atmosphere can be adjusted to achieve desired porosity levels in the electrode structure, which directly impacts the electrode's performance characteristics including ion transport and electrical conductivity.- Porosity control through material selection: The porosity of electrodes can be controlled through careful selection of materials. Different materials, such as specific metal alloys or carbon-based compounds, can be used to achieve desired porosity levels in electrode manufacturing. The selection of materials with specific particle sizes and shapes can influence the pore structure and distribution within the electrode, affecting its performance characteristics and electrochemical properties.

- Thermal processing techniques for porosity management: Thermal processing techniques, including sintering, annealing, and heat treatment, are employed to manage electrode porosity. These processes can be controlled to create specific pore structures by manipulating temperature profiles, heating rates, and cooling conditions. Thermal processing affects the microstructure development and can be used to either increase porosity through controlled decomposition of certain components or decrease porosity through densification.

- Pore-forming additives and sacrificial templates: Pore-forming additives and sacrificial templates are incorporated into electrode formulations to create controlled porosity. These additives, which can include organic compounds, polymers, or salts, are removed during subsequent processing steps through thermal decomposition or dissolution, leaving behind a porous structure. The size, amount, and distribution of these additives can be tailored to achieve specific porosity characteristics in the final electrode.

- Advanced manufacturing techniques for porosity control: Advanced manufacturing techniques such as freeze-casting, 3D printing, electrospinning, and laser processing are employed to create electrodes with precisely controlled porosity. These techniques allow for the fabrication of complex pore architectures and hierarchical structures that can enhance electrode performance. By controlling processing parameters in these advanced techniques, manufacturers can tailor porosity gradients and pore connectivity for specific applications.

- Porosity characterization and quality control methods: Various methods are used for characterizing and controlling the porosity of manufactured electrodes. These include mercury intrusion porosimetry, gas adsorption analysis, scanning electron microscopy, X-ray tomography, and electrochemical impedance spectroscopy. These techniques help in measuring pore size distribution, total porosity, pore connectivity, and tortuosity, which are critical parameters for ensuring consistent electrode performance and quality control during manufacturing.

02 Porosity control through particle size and distribution

The size and distribution of particles used in electrode manufacturing significantly influence the final porosity of the electrode. By carefully selecting particle sizes and controlling their distribution, manufacturers can engineer electrodes with specific pore sizes and porosity levels. Techniques such as ball milling, spray drying, and classification are employed to achieve the desired particle characteristics, which ultimately determine the electrode's surface area, electrolyte penetration, and overall electrochemical performance.Expand Specific Solutions03 Porosity enhancement through template and pore-forming agents

Template-based methods and pore-forming agents are advanced techniques for creating controlled porosity in electrodes. These approaches involve incorporating sacrificial materials or templates during electrode formation that are subsequently removed through thermal decomposition or chemical dissolution, leaving behind a precisely engineered porous structure. Common pore-forming agents include polymeric materials, salts, and carbonaceous compounds that can be tailored to create specific pore architectures optimized for electrochemical performance.Expand Specific Solutions04 Porosity optimization through coating and deposition techniques

Various coating and deposition methods are employed to control electrode porosity during manufacturing. Techniques such as spray coating, electrodeposition, vapor deposition, and solution casting allow for precise control over the electrode microstructure. These processes can be fine-tuned to create gradient porosity, layered structures, or uniform pore distribution throughout the electrode, enhancing properties such as ion diffusion, mechanical stability, and electrochemical activity.Expand Specific Solutions05 Porosity characterization and quality control in electrode manufacturing

Advanced characterization techniques are essential for measuring and controlling porosity in electrode manufacturing processes. Methods such as mercury intrusion porosimetry, gas adsorption analysis, scanning electron microscopy, and X-ray tomography are used to quantify porosity parameters including pore size distribution, total porosity, and tortuosity. These measurements enable manufacturers to implement quality control procedures that ensure consistent electrode performance and facilitate process optimization for specific electrochemical applications.Expand Specific Solutions

Key Industry Players in Solvent-Free Electrode Production

The electrode porosity control in solvent-free processes market is currently in an early growth phase, with increasing adoption driven by sustainability demands in battery manufacturing. The global market size is expanding rapidly, projected to reach significant value as electric vehicle production scales up. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include established automotive manufacturers (BMW, Honda, GM) investing heavily in this technology, battery specialists (LG Chem, Saft Groupe, Automotive Cells Company), and research institutions (MIT, Lawrence Berkeley National Laboratory). Companies like 24M Technologies and PowerCo are developing proprietary solvent-free electrode manufacturing processes, while traditional equipment manufacturers like Robert Bosch are adapting their offerings to support this emerging production method.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed an advanced solvent-free electrode manufacturing technology that precisely controls porosity through innovative material processing techniques. Their approach utilizes a proprietary dry mixing and calendering process that creates engineered pore structures without traditional NMP or water-based solvents. The technology incorporates specially formulated binder systems that activate under controlled temperature and pressure conditions, forming cohesive electrode structures with optimized porosity networks. Bosch's process employs a multi-stage calendering system with variable pressure zones and temperature profiles that enables gradient porosity distribution across the electrode thickness. This results in electrodes with customizable porosity ranges (typically 20-40%) that can be tailored for specific applications from high-power to high-energy cells. The company has implemented advanced in-line monitoring systems using laser diffraction and impedance techniques to provide real-time feedback on porosity development during manufacturing, enabling adaptive process control to maintain consistent quality across production batches.

Strengths: Eliminates environmental concerns associated with solvent handling and recovery, reduces energy consumption by approximately 35%, and enables faster production cycles. Weaknesses: May require more precise control of raw material properties and processing parameters compared to traditional methods, potentially limiting flexibility with certain active materials.

Automotive Cells Co. SE

Technical Solution: Automotive Cells Company (ACC) has developed a proprietary solvent-free electrode manufacturing process that precisely controls porosity through innovative material formulation and processing techniques. Their technology utilizes specially engineered binder systems that create controlled microporous structures when subjected to specific temperature and pressure conditions. ACC's process incorporates a multi-stage compaction approach where electrode materials undergo sequential compression steps with varying force profiles, creating engineered pore networks optimized for electrolyte penetration and ion transport. The company has implemented advanced real-time monitoring systems using ultrasonic and optical techniques to measure porosity development during processing, enabling closed-loop control of manufacturing parameters. This approach achieves electrodes with porosity ranges of 25-35% that can be adjusted based on specific cell design requirements. ACC has reported manufacturing energy savings of approximately 30-40% compared to conventional solvent-based processes while maintaining comparable electrochemical performance metrics.

Strengths: Eliminates solvent recovery systems, reduces manufacturing footprint and energy consumption, and enables rapid production cycles. Weaknesses: May require more specialized equipment for handling dry materials and could have limitations with certain high-nickel cathode chemistries that are sensitive to mechanical processing.

Critical Patents in Electrode Porosity Engineering

Process for Solvent-Free Electrode Production and Electrode

PatentPendingUS20250062309A1

Innovation

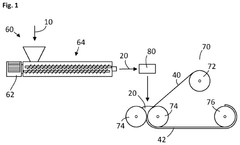

- A solvent-free electrode production process using a multi-screw extruder to fibrillate a binder material, allowing for continuous mixing and precise adjustment of particle size and fibril formation, followed by application to a carrier foil using a roll apparatus.

Method for producing porous electrodes for electrochemical cells

PatentWO2019219719A1

Innovation

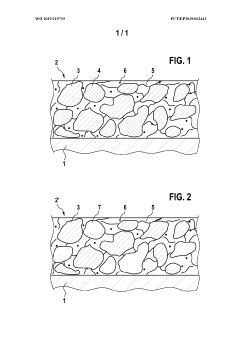

- A solvent-free process involving a homogeneous mixture of particulate active material, binder, and pore former, which is formed into a compact electrode and then heated or contacted with a liquid electrolyte to dissolve the pore former, creating a porous structure and improving accessibility for charge carriers.

Environmental Impact Assessment of Solvent-Free Technologies

The transition to solvent-free electrode manufacturing processes represents a significant advancement in sustainable battery production. Traditional electrode manufacturing relies heavily on N-Methyl-2-pyrrolidone (NMP) and other organic solvents, which pose substantial environmental hazards including air pollution, water contamination, and greenhouse gas emissions. Solvent-free technologies dramatically reduce these environmental impacts by eliminating the need for toxic solvent recovery systems and energy-intensive drying processes.

Life cycle assessment (LCA) studies indicate that solvent-free electrode manufacturing can reduce the carbon footprint of battery production by 40-60% compared to conventional methods. This reduction stems primarily from lower energy consumption during processing and the elimination of solvent recovery operations. Additionally, the absence of volatile organic compounds (VOCs) significantly improves air quality in manufacturing facilities and surrounding communities, reducing respiratory health risks for workers and local populations.

Water conservation represents another critical environmental benefit of solvent-free processes. Conventional electrode manufacturing consumes substantial quantities of water for solvent recovery and purification. By eliminating these requirements, solvent-free technologies can reduce water usage by up to 80%, a particularly valuable advantage in water-stressed regions where battery manufacturing is expanding rapidly.

The waste profile of solvent-free electrode production also demonstrates marked improvements. Without solvent recovery and treatment processes, hazardous waste generation decreases by approximately 70%. This reduction translates to lower disposal costs and diminished risks of soil and groundwater contamination from improper waste management practices.

From a regulatory compliance perspective, solvent-free technologies offer significant advantages as environmental regulations continue to tighten globally. Manufacturers implementing these processes face fewer compliance challenges related to emissions permits, hazardous material handling, and waste disposal requirements. This regulatory simplification can accelerate facility permitting and reduce compliance monitoring costs.

Energy efficiency analyses reveal that dry electrode manufacturing processes typically consume 30-50% less energy than solvent-based methods, primarily due to the elimination of energy-intensive drying steps. This efficiency translates directly to reduced greenhouse gas emissions and lower production costs, enhancing both environmental sustainability and economic viability.

As battery production scales globally to meet growing demand for electric vehicles and energy storage systems, the cumulative environmental benefits of widespread adoption of solvent-free electrode manufacturing could be substantial, potentially preventing millions of tons of carbon emissions and conserving billions of gallons of water annually.

Life cycle assessment (LCA) studies indicate that solvent-free electrode manufacturing can reduce the carbon footprint of battery production by 40-60% compared to conventional methods. This reduction stems primarily from lower energy consumption during processing and the elimination of solvent recovery operations. Additionally, the absence of volatile organic compounds (VOCs) significantly improves air quality in manufacturing facilities and surrounding communities, reducing respiratory health risks for workers and local populations.

Water conservation represents another critical environmental benefit of solvent-free processes. Conventional electrode manufacturing consumes substantial quantities of water for solvent recovery and purification. By eliminating these requirements, solvent-free technologies can reduce water usage by up to 80%, a particularly valuable advantage in water-stressed regions where battery manufacturing is expanding rapidly.

The waste profile of solvent-free electrode production also demonstrates marked improvements. Without solvent recovery and treatment processes, hazardous waste generation decreases by approximately 70%. This reduction translates to lower disposal costs and diminished risks of soil and groundwater contamination from improper waste management practices.

From a regulatory compliance perspective, solvent-free technologies offer significant advantages as environmental regulations continue to tighten globally. Manufacturers implementing these processes face fewer compliance challenges related to emissions permits, hazardous material handling, and waste disposal requirements. This regulatory simplification can accelerate facility permitting and reduce compliance monitoring costs.

Energy efficiency analyses reveal that dry electrode manufacturing processes typically consume 30-50% less energy than solvent-based methods, primarily due to the elimination of energy-intensive drying steps. This efficiency translates directly to reduced greenhouse gas emissions and lower production costs, enhancing both environmental sustainability and economic viability.

As battery production scales globally to meet growing demand for electric vehicles and energy storage systems, the cumulative environmental benefits of widespread adoption of solvent-free electrode manufacturing could be substantial, potentially preventing millions of tons of carbon emissions and conserving billions of gallons of water annually.

Scale-up Considerations for Industrial Implementation

Scaling up solvent-free electrode manufacturing processes from laboratory to industrial scale presents significant challenges that require careful consideration. The transition demands meticulous planning to maintain consistent electrode porosity while increasing production volume. Equipment selection becomes a critical factor, as industrial-scale machinery must replicate the precise porosity control achieved in laboratory settings. Specialized calendering equipment with advanced pressure distribution systems and temperature control mechanisms are essential for maintaining uniform porosity across larger electrode sheets.

Process parameter optimization requires substantial adjustment when scaling up. Variables such as compression force, processing temperature, and line speed must be recalibrated to accommodate larger production volumes while maintaining target porosity specifications. Manufacturers typically employ statistical process control methods and design of experiments approaches to establish robust operating windows that ensure consistent porosity across production batches.

Quality control systems must evolve to handle increased production volumes. In-line porosity measurement technologies, including laser-based thickness gauges and optical inspection systems, become necessary for real-time monitoring. These systems should be integrated with automated feedback loops that can make immediate adjustments to process parameters when porosity deviations are detected, minimizing waste and ensuring product consistency.

Material handling considerations also change dramatically at industrial scale. The movement of dry electrode materials requires specialized conveying systems that prevent segregation of components and maintain homogeneity. Electrostatic discharge protection becomes more critical as larger volumes of dry materials increase the risk of particle agglomeration and uneven distribution, which directly impacts final electrode porosity.

Environmental controls present another scaling challenge. Temperature and humidity fluctuations can significantly affect dry powder behavior and subsequent electrode porosity. Industrial facilities must implement comprehensive environmental management systems with zoned climate control to maintain optimal conditions throughout the manufacturing process.

Cost-benefit analysis must guide implementation decisions. While solvent-free processes eliminate expensive solvent recovery systems and reduce energy consumption associated with drying, they require significant capital investment in specialized equipment. Manufacturers must carefully evaluate production volume thresholds at which solvent-free processes become economically advantageous, considering factors such as equipment costs, energy savings, and reduced environmental compliance expenses.

Process parameter optimization requires substantial adjustment when scaling up. Variables such as compression force, processing temperature, and line speed must be recalibrated to accommodate larger production volumes while maintaining target porosity specifications. Manufacturers typically employ statistical process control methods and design of experiments approaches to establish robust operating windows that ensure consistent porosity across production batches.

Quality control systems must evolve to handle increased production volumes. In-line porosity measurement technologies, including laser-based thickness gauges and optical inspection systems, become necessary for real-time monitoring. These systems should be integrated with automated feedback loops that can make immediate adjustments to process parameters when porosity deviations are detected, minimizing waste and ensuring product consistency.

Material handling considerations also change dramatically at industrial scale. The movement of dry electrode materials requires specialized conveying systems that prevent segregation of components and maintain homogeneity. Electrostatic discharge protection becomes more critical as larger volumes of dry materials increase the risk of particle agglomeration and uneven distribution, which directly impacts final electrode porosity.

Environmental controls present another scaling challenge. Temperature and humidity fluctuations can significantly affect dry powder behavior and subsequent electrode porosity. Industrial facilities must implement comprehensive environmental management systems with zoned climate control to maintain optimal conditions throughout the manufacturing process.

Cost-benefit analysis must guide implementation decisions. While solvent-free processes eliminate expensive solvent recovery systems and reduce energy consumption associated with drying, they require significant capital investment in specialized equipment. Manufacturers must carefully evaluate production volume thresholds at which solvent-free processes become economically advantageous, considering factors such as equipment costs, energy savings, and reduced environmental compliance expenses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!