Adhesion Testing Standardization For Dry Films

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dry Film Adhesion Testing Background and Objectives

Dry film adhesion testing has evolved significantly over the past several decades, transitioning from rudimentary qualitative assessments to sophisticated quantitative methodologies. The development of this testing domain has been primarily driven by the expanding applications of dry films across multiple industries including electronics, automotive, aerospace, and medical devices. Initially, adhesion testing was largely subjective, relying on visual inspection and basic mechanical tests that provided limited reproducibility and comparability across different testing environments.

The evolution of microelectronics and the increasing miniaturization of components have placed greater demands on the performance and reliability of dry films, particularly in harsh operating conditions. This has necessitated more precise and standardized testing protocols to ensure consistent quality and performance across global supply chains. The industry has witnessed a gradual shift from proprietary testing methods to internationally recognized standards, though significant fragmentation still exists.

Current technological objectives in dry film adhesion testing center around developing universally accepted standardization protocols that can accurately predict field performance while accommodating the diverse range of substrate materials, film compositions, and application environments. These standards must balance practical implementation with scientific rigor to gain widespread industry adoption.

A key challenge in this standardization effort is the complex interplay between chemical bonding mechanisms, mechanical interlocking, and surface energy phenomena that collectively determine adhesion strength. Different industries prioritize different aspects of adhesion performance, further complicating the development of unified testing approaches. For example, while the electronics industry may focus on thermal cycling resistance, the automotive sector might emphasize chemical and environmental durability.

The technological trajectory points toward multi-parameter testing methodologies that can comprehensively characterize adhesion properties under various stress conditions. Advanced instrumentation incorporating real-time monitoring capabilities and automated analysis systems represents the cutting edge of this field. These developments aim to reduce operator dependency and enhance test reproducibility across different facilities and geographic regions.

Recent research has increasingly focused on non-destructive testing methods that can be integrated into production lines for continuous quality monitoring. This trend aligns with broader industry movements toward smart manufacturing and real-time process control, potentially enabling predictive maintenance and early detection of adhesion failures before they manifest in finished products.

The ultimate goal of current standardization efforts is to establish globally recognized testing protocols that can reliably predict the long-term performance of dry film adhesion across diverse applications and operating environments, thereby reducing field failures and enhancing product reliability.

The evolution of microelectronics and the increasing miniaturization of components have placed greater demands on the performance and reliability of dry films, particularly in harsh operating conditions. This has necessitated more precise and standardized testing protocols to ensure consistent quality and performance across global supply chains. The industry has witnessed a gradual shift from proprietary testing methods to internationally recognized standards, though significant fragmentation still exists.

Current technological objectives in dry film adhesion testing center around developing universally accepted standardization protocols that can accurately predict field performance while accommodating the diverse range of substrate materials, film compositions, and application environments. These standards must balance practical implementation with scientific rigor to gain widespread industry adoption.

A key challenge in this standardization effort is the complex interplay between chemical bonding mechanisms, mechanical interlocking, and surface energy phenomena that collectively determine adhesion strength. Different industries prioritize different aspects of adhesion performance, further complicating the development of unified testing approaches. For example, while the electronics industry may focus on thermal cycling resistance, the automotive sector might emphasize chemical and environmental durability.

The technological trajectory points toward multi-parameter testing methodologies that can comprehensively characterize adhesion properties under various stress conditions. Advanced instrumentation incorporating real-time monitoring capabilities and automated analysis systems represents the cutting edge of this field. These developments aim to reduce operator dependency and enhance test reproducibility across different facilities and geographic regions.

Recent research has increasingly focused on non-destructive testing methods that can be integrated into production lines for continuous quality monitoring. This trend aligns with broader industry movements toward smart manufacturing and real-time process control, potentially enabling predictive maintenance and early detection of adhesion failures before they manifest in finished products.

The ultimate goal of current standardization efforts is to establish globally recognized testing protocols that can reliably predict the long-term performance of dry film adhesion across diverse applications and operating environments, thereby reducing field failures and enhancing product reliability.

Market Requirements for Standardized Adhesion Testing

The global dry film market has witnessed significant growth in recent years, with applications spanning across printed circuit boards, semiconductor packaging, and various industrial coatings. This expansion has intensified the demand for standardized adhesion testing methodologies that can ensure consistent quality and reliability across different manufacturing environments and applications. Industry stakeholders, including manufacturers, end-users, and regulatory bodies, have articulated several key requirements for standardized adhesion testing protocols.

Primary among these requirements is the need for reproducibility and repeatability across different testing environments. Manufacturers operating in multiple locations require testing standards that yield consistent results regardless of geographical location, equipment variations, or operator expertise. This consistency is crucial for maintaining quality control and facilitating meaningful comparisons between different production batches and facilities.

Another critical market requirement is the development of testing protocols that accurately simulate real-world conditions. Dry films in various applications are subjected to different environmental stresses, including temperature fluctuations, humidity, chemical exposure, and mechanical stress. Standardized tests must reflect these conditions to provide meaningful predictions of product performance and longevity in actual use scenarios.

The market also demands testing standards that accommodate the diverse range of dry film formulations and substrates currently in use. With continuous innovation in material science leading to new film compositions and applications, testing methodologies must be flexible enough to remain relevant across this evolving landscape while still providing comparable results.

Cost-effectiveness and efficiency represent another significant market requirement. Industry stakeholders seek testing protocols that minimize resource utilization, reduce testing time, and lower overall quality assurance costs without compromising reliability. This includes considerations for equipment investment, operator training, and ongoing operational expenses.

Regulatory compliance is increasingly shaping market requirements for adhesion testing. As global regulations regarding product safety, environmental impact, and performance standards become more stringent, manufacturers require testing methodologies that align with these regulatory frameworks and can support certification processes across different markets.

Finally, there is growing demand for testing standards that incorporate digital documentation and data analysis capabilities. Modern manufacturing environments increasingly rely on data-driven decision-making and quality control systems, creating a need for testing protocols that generate quantifiable, analyzable results that can be integrated into broader quality management systems and Industry 4.0 frameworks.

Primary among these requirements is the need for reproducibility and repeatability across different testing environments. Manufacturers operating in multiple locations require testing standards that yield consistent results regardless of geographical location, equipment variations, or operator expertise. This consistency is crucial for maintaining quality control and facilitating meaningful comparisons between different production batches and facilities.

Another critical market requirement is the development of testing protocols that accurately simulate real-world conditions. Dry films in various applications are subjected to different environmental stresses, including temperature fluctuations, humidity, chemical exposure, and mechanical stress. Standardized tests must reflect these conditions to provide meaningful predictions of product performance and longevity in actual use scenarios.

The market also demands testing standards that accommodate the diverse range of dry film formulations and substrates currently in use. With continuous innovation in material science leading to new film compositions and applications, testing methodologies must be flexible enough to remain relevant across this evolving landscape while still providing comparable results.

Cost-effectiveness and efficiency represent another significant market requirement. Industry stakeholders seek testing protocols that minimize resource utilization, reduce testing time, and lower overall quality assurance costs without compromising reliability. This includes considerations for equipment investment, operator training, and ongoing operational expenses.

Regulatory compliance is increasingly shaping market requirements for adhesion testing. As global regulations regarding product safety, environmental impact, and performance standards become more stringent, manufacturers require testing methodologies that align with these regulatory frameworks and can support certification processes across different markets.

Finally, there is growing demand for testing standards that incorporate digital documentation and data analysis capabilities. Modern manufacturing environments increasingly rely on data-driven decision-making and quality control systems, creating a need for testing protocols that generate quantifiable, analyzable results that can be integrated into broader quality management systems and Industry 4.0 frameworks.

Current Challenges in Dry Film Adhesion Evaluation

Despite significant advancements in dry film technology, the adhesion testing landscape remains fragmented and inconsistent across industries. The lack of universally accepted standardization creates substantial challenges for manufacturers, researchers, and end-users alike. Current evaluation methods vary widely in methodology, equipment specifications, and result interpretation, making cross-comparison between different studies or products nearly impossible.

A primary challenge lies in the diversity of substrate materials used with dry films. Each substrate—whether metal, polymer, ceramic, or composite—presents unique surface characteristics that significantly influence adhesion properties. This variability necessitates different testing approaches, yet current standards rarely account for these substrate-specific considerations in a comprehensive manner.

Environmental conditioning represents another critical obstacle in adhesion evaluation. Dry films in real-world applications face varying temperature, humidity, UV exposure, and chemical environments that can dramatically alter adhesion performance over time. Current testing protocols often fail to adequately simulate these conditions or standardize the aging processes, leading to poor correlation between laboratory results and field performance.

The quantification metrics themselves lack consistency across the industry. Some methods rely on qualitative assessments (e.g., visual inspection after cross-hatch testing), while others attempt quantitative measurements (e.g., pull-off strength in MPa). This disparity creates significant barriers when attempting to establish minimum performance thresholds or compare competing products objectively.

Test equipment calibration and operator training introduce additional variability. Even when following identical protocols, different laboratories often produce divergent results due to equipment variations, maintenance schedules, or technician experience levels. The absence of robust inter-laboratory validation studies compounds this problem, undermining confidence in test results.

Digital documentation and result reporting formats vary widely, hindering data sharing and meta-analysis opportunities. The lack of standardized reporting templates makes it difficult to build comprehensive databases that could advance understanding of adhesion mechanisms and accelerate innovation in dry film formulations.

Emerging applications in electronics, medical devices, and advanced manufacturing have introduced new performance requirements that outpace existing testing methodologies. Miniaturization trends demand adhesion evaluation at micro and nano scales, while increasing regulatory scrutiny requires more precise correlation between test results and in-service performance predictions.

These challenges collectively highlight the urgent need for a harmonized approach to dry film adhesion testing that addresses substrate diversity, environmental factors, quantification methods, equipment standardization, and evolving application requirements.

A primary challenge lies in the diversity of substrate materials used with dry films. Each substrate—whether metal, polymer, ceramic, or composite—presents unique surface characteristics that significantly influence adhesion properties. This variability necessitates different testing approaches, yet current standards rarely account for these substrate-specific considerations in a comprehensive manner.

Environmental conditioning represents another critical obstacle in adhesion evaluation. Dry films in real-world applications face varying temperature, humidity, UV exposure, and chemical environments that can dramatically alter adhesion performance over time. Current testing protocols often fail to adequately simulate these conditions or standardize the aging processes, leading to poor correlation between laboratory results and field performance.

The quantification metrics themselves lack consistency across the industry. Some methods rely on qualitative assessments (e.g., visual inspection after cross-hatch testing), while others attempt quantitative measurements (e.g., pull-off strength in MPa). This disparity creates significant barriers when attempting to establish minimum performance thresholds or compare competing products objectively.

Test equipment calibration and operator training introduce additional variability. Even when following identical protocols, different laboratories often produce divergent results due to equipment variations, maintenance schedules, or technician experience levels. The absence of robust inter-laboratory validation studies compounds this problem, undermining confidence in test results.

Digital documentation and result reporting formats vary widely, hindering data sharing and meta-analysis opportunities. The lack of standardized reporting templates makes it difficult to build comprehensive databases that could advance understanding of adhesion mechanisms and accelerate innovation in dry film formulations.

Emerging applications in electronics, medical devices, and advanced manufacturing have introduced new performance requirements that outpace existing testing methodologies. Miniaturization trends demand adhesion evaluation at micro and nano scales, while increasing regulatory scrutiny requires more precise correlation between test results and in-service performance predictions.

These challenges collectively highlight the urgent need for a harmonized approach to dry film adhesion testing that addresses substrate diversity, environmental factors, quantification methods, equipment standardization, and evolving application requirements.

Established Adhesion Testing Protocols and Methods

01 Adhesion enhancement in semiconductor applications

Various methods are employed to improve the adhesion of dry films in semiconductor manufacturing processes. These include surface treatments, specialized adhesion promoters, and modified deposition techniques that enhance the bonding between the film and substrate. These approaches are particularly important in microelectronics where reliable adhesion is critical for device performance and durability.- Adhesion enhancement in photoresist dry films: Various methods and compositions are used to enhance the adhesion of photoresist dry films to substrates, particularly in semiconductor manufacturing. These include surface treatments, adhesion promoters, and specialized coating techniques that improve the interfacial bonding between the dry film and the substrate surface. Enhanced adhesion is critical for preventing delamination during subsequent processing steps and ensuring pattern fidelity in microelectronic applications.

- Dry film adhesives for electronic applications: Specialized dry film adhesives have been developed for electronic and semiconductor applications. These films provide reliable bonding while meeting stringent requirements for thermal stability, electrical insulation, and chemical resistance. The formulations often include specific polymers, crosslinking agents, and fillers that contribute to the overall performance characteristics needed in modern electronic devices and circuit boards.

- Surface preparation techniques for dry film adhesion: Proper surface preparation is essential for achieving optimal adhesion of dry films. Various techniques including plasma treatment, chemical cleaning, mechanical roughening, and application of primers can significantly improve the adhesion properties. These preparation methods remove contaminants, increase surface energy, and create anchor points for better mechanical interlocking between the dry film and the substrate.

- Adhesion testing and evaluation methods for dry films: Standardized methods for testing and evaluating the adhesion of dry films have been developed to ensure reliability in various applications. These include peel tests, cross-hatch tests, and environmental stress testing that simulate real-world conditions. Advanced analytical techniques are also employed to characterize the interface between dry films and substrates, providing insights into adhesion mechanisms and failure modes.

- Novel materials for improved dry film adhesion: Research has led to the development of novel materials specifically designed to enhance dry film adhesion. These include functionalized polymers, nanocomposites, and hybrid organic-inorganic materials that provide superior adhesion properties while maintaining other required characteristics such as flexibility, transparency, or chemical resistance. These innovative materials address challenges in advanced applications where conventional adhesion solutions are inadequate.

02 Polymer-based adhesion solutions

Polymer formulations play a significant role in improving dry film adhesion across various applications. These formulations may include specialized copolymers, adhesion-promoting additives, and surface-active agents that modify the interfacial properties between the film and substrate. The polymer chemistry can be tailored to specific substrate materials to optimize adhesion performance.Expand Specific Solutions03 Electrochemical and plating adhesion techniques

Electrochemical processes and plating technologies offer effective methods for enhancing dry film adhesion. These techniques involve surface preparation, specialized electrolyte formulations, and controlled deposition parameters to create strong interfacial bonds. Such approaches are commonly used in printed circuit board manufacturing and metal finishing industries.Expand Specific Solutions04 Novel material compositions for improved adhesion

Innovative material compositions have been developed specifically to address dry film adhesion challenges. These include composite materials, nanostructured surfaces, and specialized chemical treatments that modify surface energy and promote strong adhesion. The compositions often incorporate multiple functional components that work synergistically to enhance bonding properties.Expand Specific Solutions05 Manufacturing process optimization for adhesion control

Optimizing manufacturing processes is crucial for achieving consistent dry film adhesion. This includes controlling environmental parameters, developing precise application techniques, and implementing quality control measures. Process innovations focus on temperature management, pressure control, and curing conditions that significantly impact the final adhesion properties of dry films.Expand Specific Solutions

Leading Organizations and Companies in Adhesion Testing

The adhesion testing standardization for dry films market is currently in a growth phase, driven by increasing demand for reliable quality control in electronics, automotive, and packaging industries. The global market size is estimated to reach $1.2 billion by 2025, with a CAGR of 5.8%. Regarding technical maturity, industry leaders like 3M Innovative Properties, DuPont de Nemours, and Nitto Denko have established advanced testing protocols, while companies such as Resonac Corp., LG Chem, and Sumitomo Bakelite are investing heavily in R&D to develop proprietary standardization methods. Samsung Electronics and FUJIFILM are focusing on application-specific testing standards, particularly for semiconductor and display technologies, creating a competitive landscape where standardization efforts are becoming a key differentiator in the high-performance dry film segment.

Resonac Corp.

Technical Solution: Resonac (formerly Showa Denko) has developed a comprehensive adhesion testing standardization system for dry films used in semiconductor packaging and electronic applications. Their methodology incorporates both qualitative and quantitative testing approaches, including modified versions of ASTM D3359 (cross-hatch) with standardized scoring systems and automated image analysis to reduce subjective interpretation. Resonac's testing protocol includes specialized thermal stress testing that simulates the rapid temperature changes experienced during semiconductor manufacturing processes, with particular attention to the effects of thermal expansion coefficient mismatches between materials. The company has pioneered the use of nano-indentation and nano-scratch testing techniques to evaluate adhesion at microscopic scales relevant to modern microelectronics. Their approach includes chemical compatibility testing to evaluate how adhesion performance is affected by exposure to process chemicals commonly used in semiconductor manufacturing. Resonac has also established standardized reporting formats that include not only pass/fail results but detailed characterization of failure modes and mechanisms to guide material improvement.

Strengths: Specialized protocols for semiconductor applications address industry-specific challenges; combination of macro and nano-scale testing provides comprehensive evaluation across relevant dimensions; standardized reporting formats improve communication of results. Weaknesses: Heavy focus on semiconductor applications may limit applicability to other industries; nano-scale testing requires specialized equipment and expertise that may not be widely available.

Nitto Denko Corp.

Technical Solution: Nitto Denko has developed a multi-tiered adhesion testing standardization system for dry films that addresses both immediate adhesion performance and long-term reliability. Their approach includes standardized 90° and 180° peel testing methods with controlled peel rates and environmental conditions, complemented by shear adhesion testing to evaluate performance under lateral forces. Nitto's methodology incorporates specialized surface analysis techniques including X-ray photoelectron spectroscopy (XPS) and time-of-flight secondary ion mass spectrometry (ToF-SIMS) to characterize the chemical interactions at adhesive interfaces before and after testing. The company has established accelerated aging protocols that combine temperature, humidity, and mechanical stress to predict long-term adhesion performance, with validation against real-world performance data collected over decades. Their testing standards include application-specific modifications for industries ranging from electronics to automotive to medical, recognizing that adhesion requirements vary significantly across use cases.

Strengths: Comprehensive approach combining mechanical testing with advanced surface analysis provides deeper understanding of adhesion mechanisms; extensive validation against real-world performance data enhances reliability of predictions; application-specific test modifications increase relevance. Weaknesses: Advanced surface analysis techniques require specialized equipment and expertise; multiple testing methodologies may increase testing time and costs compared to simpler approaches.

Key Technical Standards and Research Publications

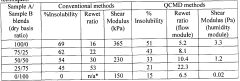

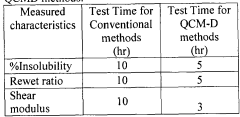

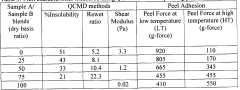

Methods of measuring a characteristic of a creping adhesive film and methods of modifying the creping adhesive film

PatentWO2013142244A1

Innovation

- The use of Quartz Crystal Microbalance (QCM) and Quartz Crystal Microbalance with Dissipation (QCMD) techniques to measure the oscillation frequency and dissipation of creping adhesive films disposed on a sensor substrate, allowing for real-time characterization and modification of the adhesive film composition based on determined characteristics.

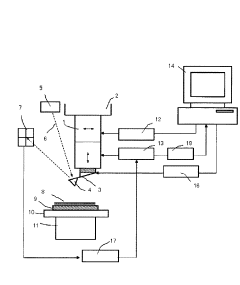

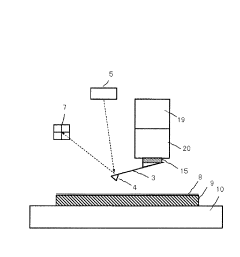

Adhesion tester

PatentInactiveJP2012202840A

Innovation

- An adhesion tester employing a leaf spring-like elastic arm with a minute probe, displacement detection, and scanning means to apply controlled vertical loads and scan the film surface, coupled with a cantilever for precise load measurement and high-magnification observation.

Interlaboratory Comparison and Validation Approaches

Interlaboratory comparison studies represent a cornerstone methodology for establishing the reliability and reproducibility of adhesion testing methods for dry films. These collaborative exercises involve multiple laboratories performing identical tests on homogeneous sample materials under controlled conditions, following standardized protocols. The statistical analysis of results across different facilities provides crucial insights into method variability and reproducibility.

The ASTM E691 standard serves as a primary framework for conducting interlaboratory studies, offering guidelines for participant selection, sample preparation, data collection, and statistical analysis. For dry film adhesion testing, these studies typically involve 8-15 laboratories to ensure statistical significance while maintaining practical feasibility. Participant selection criteria emphasize technical competence, equipment calibration status, and geographic distribution to account for environmental variables.

Sample homogeneity represents a critical factor in these studies, as variations in substrate properties, film thickness, or curing conditions can significantly impact adhesion test results. Advanced sample preparation techniques, including controlled environmental conditioning and precise application methods, help minimize these variables. Each participating laboratory receives identical sample sets with comprehensive testing instructions to ensure procedural uniformity.

Statistical validation approaches for interlaboratory studies typically employ analysis of variance (ANOVA) techniques to quantify within-laboratory repeatability and between-laboratory reproducibility. The calculation of precision statistics such as repeatability standard deviation (sr), reproducibility standard deviation (sR), and reproducibility limit (R) provides quantitative measures of method reliability. These metrics enable the establishment of acceptance criteria for future testing and facilitate method comparison across different adhesion testing techniques.

Recent innovations in validation approaches include digital image analysis for quantitative assessment of adhesion failure patterns and machine learning algorithms for identifying variables that contribute to result variability. These technological advancements enhance the objectivity of traditionally subjective visual assessments in tests like cross-hatch and tape pull methods.

Successful interlaboratory studies have led to significant improvements in adhesion testing standards for dry films, including the refinement of ASTM D3359 and ISO 2409 methods. These collaborative efforts have resulted in more precise test parameters, clearer failure mode classifications, and improved correlation between laboratory and field performance. The continuous validation process ensures that standardized methods remain relevant as coating technologies and application requirements evolve in various industries.

The ASTM E691 standard serves as a primary framework for conducting interlaboratory studies, offering guidelines for participant selection, sample preparation, data collection, and statistical analysis. For dry film adhesion testing, these studies typically involve 8-15 laboratories to ensure statistical significance while maintaining practical feasibility. Participant selection criteria emphasize technical competence, equipment calibration status, and geographic distribution to account for environmental variables.

Sample homogeneity represents a critical factor in these studies, as variations in substrate properties, film thickness, or curing conditions can significantly impact adhesion test results. Advanced sample preparation techniques, including controlled environmental conditioning and precise application methods, help minimize these variables. Each participating laboratory receives identical sample sets with comprehensive testing instructions to ensure procedural uniformity.

Statistical validation approaches for interlaboratory studies typically employ analysis of variance (ANOVA) techniques to quantify within-laboratory repeatability and between-laboratory reproducibility. The calculation of precision statistics such as repeatability standard deviation (sr), reproducibility standard deviation (sR), and reproducibility limit (R) provides quantitative measures of method reliability. These metrics enable the establishment of acceptance criteria for future testing and facilitate method comparison across different adhesion testing techniques.

Recent innovations in validation approaches include digital image analysis for quantitative assessment of adhesion failure patterns and machine learning algorithms for identifying variables that contribute to result variability. These technological advancements enhance the objectivity of traditionally subjective visual assessments in tests like cross-hatch and tape pull methods.

Successful interlaboratory studies have led to significant improvements in adhesion testing standards for dry films, including the refinement of ASTM D3359 and ISO 2409 methods. These collaborative efforts have resulted in more precise test parameters, clearer failure mode classifications, and improved correlation between laboratory and field performance. The continuous validation process ensures that standardized methods remain relevant as coating technologies and application requirements evolve in various industries.

Environmental Factors Affecting Adhesion Test Results

Environmental factors play a critical role in the reliability and reproducibility of adhesion testing for dry films. Temperature variations significantly impact test results, as higher temperatures can increase polymer chain mobility, potentially enhancing adhesion in some systems while causing thermal expansion mismatches in others. Research indicates that for every 10°C increase, adhesion strength measurements may vary by 5-15% depending on the substrate-film combination.

Humidity represents another crucial variable, with relative humidity levels directly affecting both the substrate surface properties and the film's mechanical characteristics. Studies have demonstrated that moisture absorption can plasticize certain dry films, reducing their cohesive strength and consequently altering adhesion test outcomes. In environments exceeding 65% relative humidity, measurement deviations of up to 20% have been documented compared to standard conditions.

Atmospheric contaminants, including airborne particulates and volatile organic compounds, can interfere with adhesion mechanisms by creating barrier layers between the substrate and film. Industrial settings with high particulate counts have shown consistently lower adhesion values compared to controlled laboratory environments, with differences sometimes exceeding 30% for identical material combinations.

Light exposure, particularly UV radiation, introduces another variable by potentially degrading polymer structures through photo-oxidation processes. Long-term exposure can significantly alter the chemical bonding at the interface, with some acrylic-based dry films showing adhesion reductions of 25-40% after 500 hours of accelerated weathering tests.

Barometric pressure variations, though often overlooked, can influence solvent evaporation rates during film formation and curing, affecting the development of interfacial bonds. This becomes particularly relevant when comparing test results from facilities at different elevations or during significant weather pattern changes.

Standardization efforts must therefore incorporate environmental conditioning protocols that specify pre-test equilibration periods (minimum 24 hours recommended), tight control parameters (±2°C, ±5% RH), and detailed documentation of environmental conditions during testing. Multi-laboratory studies have confirmed that implementing such standardized environmental controls can reduce measurement variability from 25-30% to below 10% across different testing facilities.

Advanced testing facilities are increasingly implementing environmental monitoring systems that continuously record conditions throughout the testing process, allowing for post-test data normalization and more meaningful cross-comparison of results across different geographical locations and seasonal variations.

Humidity represents another crucial variable, with relative humidity levels directly affecting both the substrate surface properties and the film's mechanical characteristics. Studies have demonstrated that moisture absorption can plasticize certain dry films, reducing their cohesive strength and consequently altering adhesion test outcomes. In environments exceeding 65% relative humidity, measurement deviations of up to 20% have been documented compared to standard conditions.

Atmospheric contaminants, including airborne particulates and volatile organic compounds, can interfere with adhesion mechanisms by creating barrier layers between the substrate and film. Industrial settings with high particulate counts have shown consistently lower adhesion values compared to controlled laboratory environments, with differences sometimes exceeding 30% for identical material combinations.

Light exposure, particularly UV radiation, introduces another variable by potentially degrading polymer structures through photo-oxidation processes. Long-term exposure can significantly alter the chemical bonding at the interface, with some acrylic-based dry films showing adhesion reductions of 25-40% after 500 hours of accelerated weathering tests.

Barometric pressure variations, though often overlooked, can influence solvent evaporation rates during film formation and curing, affecting the development of interfacial bonds. This becomes particularly relevant when comparing test results from facilities at different elevations or during significant weather pattern changes.

Standardization efforts must therefore incorporate environmental conditioning protocols that specify pre-test equilibration periods (minimum 24 hours recommended), tight control parameters (±2°C, ±5% RH), and detailed documentation of environmental conditions during testing. Multi-laboratory studies have confirmed that implementing such standardized environmental controls can reduce measurement variability from 25-30% to below 10% across different testing facilities.

Advanced testing facilities are increasingly implementing environmental monitoring systems that continuously record conditions throughout the testing process, allowing for post-test data normalization and more meaningful cross-comparison of results across different geographical locations and seasonal variations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!