Optimization Framework For Aqueous Binder Ratios

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aqueous Binder Technology Background and Objectives

Aqueous binder systems have evolved significantly over the past three decades, transitioning from niche applications to mainstream manufacturing processes across multiple industries. Initially developed as environmentally friendly alternatives to solvent-based systems in the 1990s, these water-based binding technologies have gained substantial traction due to increasingly stringent environmental regulations and growing sustainability concerns. The fundamental principle behind aqueous binders involves dispersing polymeric materials in water rather than organic solvents, creating stable suspensions that can effectively bind various substrates upon drying and curing.

The evolution of aqueous binder technology has been marked by several key milestones, including the development of high-performance acrylic emulsions in the early 2000s, followed by advanced polyurethane dispersions and hybrid systems combining multiple polymer chemistries. Recent innovations have focused on enhancing binding efficiency while minimizing water content, thereby reducing energy consumption during drying processes and improving overall manufacturing efficiency.

Current technical objectives in the field center on optimizing binder ratio formulations to achieve specific performance characteristics while maintaining processing efficiency. This optimization represents a complex multivariable challenge, as binder ratios directly influence critical properties including adhesion strength, flexibility, chemical resistance, and durability of the final product. Additionally, these ratios significantly impact processing parameters such as viscosity, drying time, and curing requirements.

The primary goal of developing an optimization framework for aqueous binder ratios is to establish systematic methodologies that can predict optimal formulations based on desired end-product specifications. This framework aims to reduce the extensive empirical testing traditionally required, thereby accelerating product development cycles and reducing associated costs. Machine learning approaches have recently emerged as promising tools for navigating the complex parameter space of binder formulations.

Industry-specific requirements further complicate optimization efforts, as applications ranging from lithium-ion battery electrodes to architectural coatings demand tailored binder properties. For battery applications, binders must facilitate electron transfer while maintaining structural integrity during charge-discharge cycles. In contrast, architectural coatings require different performance attributes such as UV resistance and weatherability.

The technological trajectory points toward increasingly sophisticated modeling tools that can account for multiple variables simultaneously, including raw material variations, processing conditions, and environmental factors. These advanced predictive capabilities represent the next frontier in aqueous binder technology, potentially enabling rapid formulation development with minimal experimental validation requirements.

The evolution of aqueous binder technology has been marked by several key milestones, including the development of high-performance acrylic emulsions in the early 2000s, followed by advanced polyurethane dispersions and hybrid systems combining multiple polymer chemistries. Recent innovations have focused on enhancing binding efficiency while minimizing water content, thereby reducing energy consumption during drying processes and improving overall manufacturing efficiency.

Current technical objectives in the field center on optimizing binder ratio formulations to achieve specific performance characteristics while maintaining processing efficiency. This optimization represents a complex multivariable challenge, as binder ratios directly influence critical properties including adhesion strength, flexibility, chemical resistance, and durability of the final product. Additionally, these ratios significantly impact processing parameters such as viscosity, drying time, and curing requirements.

The primary goal of developing an optimization framework for aqueous binder ratios is to establish systematic methodologies that can predict optimal formulations based on desired end-product specifications. This framework aims to reduce the extensive empirical testing traditionally required, thereby accelerating product development cycles and reducing associated costs. Machine learning approaches have recently emerged as promising tools for navigating the complex parameter space of binder formulations.

Industry-specific requirements further complicate optimization efforts, as applications ranging from lithium-ion battery electrodes to architectural coatings demand tailored binder properties. For battery applications, binders must facilitate electron transfer while maintaining structural integrity during charge-discharge cycles. In contrast, architectural coatings require different performance attributes such as UV resistance and weatherability.

The technological trajectory points toward increasingly sophisticated modeling tools that can account for multiple variables simultaneously, including raw material variations, processing conditions, and environmental factors. These advanced predictive capabilities represent the next frontier in aqueous binder technology, potentially enabling rapid formulation development with minimal experimental validation requirements.

Market Analysis for Aqueous Binder Applications

The global market for aqueous binders has experienced significant growth in recent years, driven by increasing environmental regulations and a shift towards sustainable manufacturing processes. The market size for aqueous binders reached approximately $4.2 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 5.7% through 2028. This growth trajectory is primarily fueled by expanding applications across multiple industries including construction, automotive, electronics, and energy storage.

In the construction sector, which accounts for nearly 35% of the total aqueous binder market, demand is primarily driven by the need for environmentally friendly adhesives and coatings with low volatile organic compound (VOC) emissions. Regulatory frameworks such as the European Union's VOC Directive and similar regulations in North America have accelerated the transition from solvent-based to water-based binding systems.

The automotive industry represents another significant market segment, with approximately 22% market share. Here, aqueous binders are increasingly utilized in interior components, underbody coatings, and sound dampening applications. The industry's push toward lightweight materials and sustainable manufacturing processes has further catalyzed adoption.

Perhaps the most dynamic growth sector for aqueous binders is the energy storage market, particularly in lithium-ion battery production. This segment has witnessed a remarkable 14.3% CAGR since 2019, outpacing all other application areas. The optimization of aqueous binder ratios has become critical for battery manufacturers seeking to enhance electrode performance while reducing environmental impact and production costs.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 42% of global consumption, followed by Europe (28%) and North America (21%). China leads manufacturing capacity, though significant R&D investments are being made in Germany, South Korea, and the United States, particularly focused on advanced formulation techniques and optimization frameworks.

Customer requirements across these markets demonstrate increasing sophistication, with performance demands extending beyond basic adhesion properties to include specific conductivity parameters, thermal stability, and compatibility with automated manufacturing processes. The optimization of binder ratios has consequently evolved from a cost-saving measure to a critical performance differentiator.

Market forecasts indicate that companies investing in advanced optimization frameworks for aqueous binder ratios will gain significant competitive advantages, potentially capturing premium market segments with higher profit margins. The economic value of optimized formulations is particularly evident in high-performance applications where even marginal improvements in binding efficiency can translate to substantial performance gains and cost reductions in final products.

In the construction sector, which accounts for nearly 35% of the total aqueous binder market, demand is primarily driven by the need for environmentally friendly adhesives and coatings with low volatile organic compound (VOC) emissions. Regulatory frameworks such as the European Union's VOC Directive and similar regulations in North America have accelerated the transition from solvent-based to water-based binding systems.

The automotive industry represents another significant market segment, with approximately 22% market share. Here, aqueous binders are increasingly utilized in interior components, underbody coatings, and sound dampening applications. The industry's push toward lightweight materials and sustainable manufacturing processes has further catalyzed adoption.

Perhaps the most dynamic growth sector for aqueous binders is the energy storage market, particularly in lithium-ion battery production. This segment has witnessed a remarkable 14.3% CAGR since 2019, outpacing all other application areas. The optimization of aqueous binder ratios has become critical for battery manufacturers seeking to enhance electrode performance while reducing environmental impact and production costs.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 42% of global consumption, followed by Europe (28%) and North America (21%). China leads manufacturing capacity, though significant R&D investments are being made in Germany, South Korea, and the United States, particularly focused on advanced formulation techniques and optimization frameworks.

Customer requirements across these markets demonstrate increasing sophistication, with performance demands extending beyond basic adhesion properties to include specific conductivity parameters, thermal stability, and compatibility with automated manufacturing processes. The optimization of binder ratios has consequently evolved from a cost-saving measure to a critical performance differentiator.

Market forecasts indicate that companies investing in advanced optimization frameworks for aqueous binder ratios will gain significant competitive advantages, potentially capturing premium market segments with higher profit margins. The economic value of optimized formulations is particularly evident in high-performance applications where even marginal improvements in binding efficiency can translate to substantial performance gains and cost reductions in final products.

Current Challenges in Aqueous Binder Ratio Optimization

Despite significant advancements in aqueous binder technology, the optimization of binder ratios continues to present substantial challenges for manufacturers across various industries. The primary difficulty lies in the complex interplay between multiple components within aqueous binder systems, where slight variations in ratio can dramatically impact performance characteristics. This complexity is further compounded by the diverse application requirements across different substrates and environmental conditions.

Material compatibility issues represent a significant obstacle in ratio optimization. Many formulations struggle to maintain consistent performance across varying substrate types, particularly when transitioning between porous and non-porous surfaces. This inconsistency necessitates extensive reformulation efforts, increasing development costs and time-to-market for new products.

Process variability during manufacturing introduces additional complications. Temperature fluctuations, mixing inconsistencies, and equipment variations can all affect the final binder performance, making it difficult to establish standardized ratio guidelines that remain effective across different production environments. This variability often results in quality control issues and increased waste during scale-up phases.

Environmental regulations have intensified challenges by restricting certain chemical components traditionally used to enhance binder performance. Formulators must now achieve equivalent or superior performance while eliminating volatile organic compounds (VOCs) and other environmentally problematic substances, often requiring complete reformulation of established ratio frameworks.

The lack of comprehensive predictive models represents perhaps the most significant technical barrier. Current modeling approaches fail to accurately predict how changes in binder ratios will affect final product performance across diverse application scenarios. This limitation forces manufacturers to rely heavily on empirical testing, which is both time-consuming and resource-intensive.

Testing methodology standardization remains inadequate across the industry. Different manufacturers employ varying protocols to evaluate binder performance, making it difficult to compare results and establish universal optimization frameworks. This fragmentation hinders collaborative advancement and knowledge sharing within the field.

Cost pressures further complicate optimization efforts, as manufacturers must balance performance requirements with economic considerations. Premium components that might enhance performance often face resistance due to pricing constraints, forcing compromises in formulation that may not achieve optimal technical outcomes.

The accelerating pace of market demands for improved sustainability, durability, and functionality creates additional pressure on formulators to rapidly develop optimized binder systems without sufficient time for comprehensive testing and validation. This time compression often results in suboptimal ratio selections that require subsequent refinement after market introduction.

Material compatibility issues represent a significant obstacle in ratio optimization. Many formulations struggle to maintain consistent performance across varying substrate types, particularly when transitioning between porous and non-porous surfaces. This inconsistency necessitates extensive reformulation efforts, increasing development costs and time-to-market for new products.

Process variability during manufacturing introduces additional complications. Temperature fluctuations, mixing inconsistencies, and equipment variations can all affect the final binder performance, making it difficult to establish standardized ratio guidelines that remain effective across different production environments. This variability often results in quality control issues and increased waste during scale-up phases.

Environmental regulations have intensified challenges by restricting certain chemical components traditionally used to enhance binder performance. Formulators must now achieve equivalent or superior performance while eliminating volatile organic compounds (VOCs) and other environmentally problematic substances, often requiring complete reformulation of established ratio frameworks.

The lack of comprehensive predictive models represents perhaps the most significant technical barrier. Current modeling approaches fail to accurately predict how changes in binder ratios will affect final product performance across diverse application scenarios. This limitation forces manufacturers to rely heavily on empirical testing, which is both time-consuming and resource-intensive.

Testing methodology standardization remains inadequate across the industry. Different manufacturers employ varying protocols to evaluate binder performance, making it difficult to compare results and establish universal optimization frameworks. This fragmentation hinders collaborative advancement and knowledge sharing within the field.

Cost pressures further complicate optimization efforts, as manufacturers must balance performance requirements with economic considerations. Premium components that might enhance performance often face resistance due to pricing constraints, forcing compromises in formulation that may not achieve optimal technical outcomes.

The accelerating pace of market demands for improved sustainability, durability, and functionality creates additional pressure on formulators to rapidly develop optimized binder systems without sufficient time for comprehensive testing and validation. This time compression often results in suboptimal ratio selections that require subsequent refinement after market introduction.

Current Optimization Frameworks and Methodologies

01 Composition optimization for aqueous binders

Optimization frameworks for aqueous binder compositions focus on determining the ideal ratio of components to achieve desired properties. These frameworks involve systematic testing of different formulations with varying concentrations of polymers, crosslinkers, and additives to enhance adhesion strength, water resistance, and durability. Advanced algorithms and statistical methods are employed to identify optimal formulation parameters while minimizing the number of experiments required.- Composition optimization for aqueous binders: Optimization frameworks for aqueous binder compositions focus on balancing key components such as polymers, crosslinkers, and additives to achieve desired performance characteristics. These frameworks involve systematic testing of various formulation ratios to identify optimal combinations that provide adhesion strength, durability, and environmental resistance while maintaining proper viscosity and application properties. Advanced algorithms help predict performance based on component interactions, reducing experimental iterations.

- Process parameter optimization for aqueous binder systems: Frameworks for optimizing process parameters in aqueous binder systems address critical manufacturing variables such as mixing speed, temperature profiles, curing conditions, and application methods. These optimization approaches use statistical design of experiments to identify the most influential parameters and their optimal settings. Process optimization ensures consistent binder performance while maximizing production efficiency and minimizing energy consumption and waste generation.

- Performance testing and validation methodologies: Comprehensive testing frameworks for aqueous binders include standardized protocols for evaluating key performance attributes such as adhesion strength, water resistance, thermal stability, and aging characteristics. These methodologies incorporate accelerated testing procedures to predict long-term performance and establish correlations between laboratory results and field applications. Validation approaches ensure that optimized binder formulations meet industry-specific requirements across various environmental conditions.

- Computational modeling and predictive analytics: Advanced computational frameworks for aqueous binder optimization utilize machine learning algorithms, molecular modeling, and predictive analytics to accelerate formulation development. These approaches create digital models that simulate binder behavior under various conditions, enabling virtual experimentation before physical testing. Predictive models help identify promising formulation spaces, reducing development time and resources while improving the probability of achieving target performance profiles.

- Sustainability and environmental optimization: Frameworks for optimizing the environmental profile of aqueous binders focus on incorporating bio-based raw materials, reducing VOC content, and minimizing ecological impact throughout the product lifecycle. These approaches balance performance requirements with sustainability metrics, including carbon footprint, biodegradability, and renewable content. Optimization methodologies help identify formulations that maintain technical performance while meeting increasingly stringent environmental regulations and sustainability goals.

02 Performance evaluation methodologies

Comprehensive testing protocols are essential for evaluating aqueous binder performance across various applications. These methodologies include standardized tests for adhesion strength, water resistance, thermal stability, and environmental durability. Performance evaluation frameworks incorporate accelerated aging tests, mechanical property assessments, and application-specific testing to ensure binders meet industry requirements. Data from these evaluations feeds back into the optimization process to refine formulations.Expand Specific Solutions03 Computational modeling for binder development

Advanced computational modeling techniques are increasingly used to predict aqueous binder performance and optimize formulations. These approaches include molecular dynamics simulations, machine learning algorithms, and predictive analytics that can forecast how different components will interact and perform under various conditions. Computational frameworks reduce development time by allowing virtual screening of formulations before physical testing, identifying promising candidates and eliminating less viable options early in the development process.Expand Specific Solutions04 Sustainable and eco-friendly binder systems

Frameworks for developing environmentally friendly aqueous binders focus on replacing petroleum-based components with bio-derived alternatives. These optimization approaches prioritize biodegradability, reduced VOC content, and lower carbon footprint while maintaining or improving performance characteristics. Systematic evaluation of renewable raw materials, such as plant-based polymers and natural crosslinkers, is conducted to create sustainable binder systems that meet regulatory requirements and consumer demands for greener products.Expand Specific Solutions05 Application-specific optimization strategies

Tailored optimization frameworks address the unique requirements of specific applications such as adhesives, coatings, and composite materials. These strategies consider application method, substrate compatibility, curing conditions, and end-use performance requirements. The frameworks incorporate design of experiments approaches to efficiently identify formulations that balance multiple performance criteria specific to each application context, resulting in customized binder systems with optimal properties for their intended use.Expand Specific Solutions

Key Industry Players in Aqueous Binder Development

The aqueous binder ratio optimization framework market is currently in a growth phase, with increasing demand driven by sustainability initiatives across industries. The market size is expanding as manufacturers seek water-based alternatives to traditional solvent-based systems. Technologically, this field shows moderate maturity with significant ongoing innovation. Leading players include BASF Corp. and Wacker Chemie AG, who have established robust R&D capabilities in polymer chemistry and binder technologies. Emerging competitors like Zhuhai CosMX Battery and EVE Energy are advancing specialized applications in energy storage sectors. Academic institutions such as Nanyang Technological University and Jilin University are contributing fundamental research, while companies like Henkel and Dow Global Technologies are commercializing proprietary formulations, creating a competitive landscape balanced between established chemical giants and specialized solution providers.

BASF Corp.

Technical Solution: BASF has developed an advanced Optimization Framework for Aqueous Binder Ratios that utilizes machine learning algorithms to predict optimal binder formulations for lithium-ion battery electrodes. Their approach combines high-throughput experimentation with computational modeling to systematically evaluate different binder compositions and their impact on electrode performance. The framework incorporates a comprehensive database of material properties and processing parameters to identify optimal binder-to-active material ratios that maximize adhesion strength while minimizing electrical resistance. BASF's solution includes specialized carboxymethyl cellulose (CMC) and styrene-butadiene rubber (SBR) binder systems with precisely controlled molecular weights and functional group distributions to enhance electrode integrity during cycling[1]. Their framework enables rapid screening of hundreds of formulations, reducing development time from months to weeks.

Strengths: Extensive materials expertise and global R&D infrastructure allow for comprehensive testing across diverse battery chemistries. The framework's integration with existing manufacturing processes enables seamless industrial implementation. Weaknesses: The optimization approach may require significant computational resources and specialized equipment for implementation, potentially limiting accessibility for smaller manufacturers.

Zhuhai CosMX Battery Co., Ltd.

Technical Solution: Zhuhai CosMX has developed a comprehensive Aqueous Binder Ratio Optimization Framework specifically tailored for high-energy density lithium-ion batteries. Their approach combines empirical testing with theoretical modeling to establish precise relationships between binder content, electrode porosity, and electrochemical performance. The framework utilizes a database of over 1,000 formulation combinations tested across different active materials to predict optimal binder ratios based on specific electrode compositions and desired performance characteristics. CosMX's solution incorporates modified polyacrylic acid (PAA) and carboxymethyl cellulose (CMC) binders with controlled molecular weights (typically 250,000-750,000 g/mol) and degree of substitution values optimized for specific active materials[4]. Their system includes proprietary processing techniques that enable uniform binder distribution throughout electrode structures, with typical dry coating thicknesses ranging from 50-100 μm for high-energy applications.

Strengths: Highly optimized for high-energy density applications with demonstrated improvements in capacity retention and cycle life. Strong integration with existing manufacturing processes enables rapid implementation. Weaknesses: Framework may be less flexible for novel electrode materials outside the established database, potentially requiring additional development for emerging battery chemistries.

Critical Patents and Research in Binder Ratio Formulation

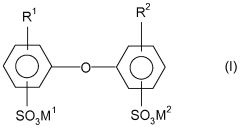

Aqueous binders for granular and/or fibrous substrates

PatentActiveEP2681271A1

Innovation

- An aqueous binder composition comprising specific ethylenically unsaturated monomers and a saccharide compound, optimized through free-radical emulsion polymerization, is used to enhance the mechanical properties of molded products, including the use of polymers with tailored glass transition temperatures and the inclusion of saccharides like starch for improved binding performance.

Aqueous binder for granular and/or fibrous substrates

PatentWO2012136605A1

Innovation

- An aqueous binder composition comprising a polymer P, which is polymerized from ethylenically unsaturated monomers with specific weight percentages, including acid groups, nitriles, crosslinking monomers, silane compounds, and saccharide compounds, optimized to enhance bonding and mechanical properties of substrates.

Environmental Impact and Sustainability Considerations

The optimization of aqueous binder ratios in manufacturing processes carries significant environmental implications that extend beyond mere technical performance. Traditional binder systems often incorporate volatile organic compounds (VOCs) and hazardous air pollutants that contribute to air quality degradation and pose health risks to workers. By transitioning to water-based binder systems with optimized ratios, manufacturers can substantially reduce these harmful emissions while simultaneously decreasing their carbon footprint.

Life cycle assessment (LCA) studies indicate that aqueous binder systems with properly optimized ratios can reduce environmental impact by 30-45% compared to conventional solvent-based alternatives. This reduction stems primarily from decreased energy requirements during processing and the elimination of post-treatment pollution control measures that would otherwise be necessary for managing toxic emissions.

Water consumption represents another critical environmental consideration in aqueous binder optimization. While water-based systems inherently require this resource, advanced ratio optimization frameworks can incorporate water recycling protocols and minimize overall consumption. Recent innovations have demonstrated that optimized binder systems can achieve up to 70% water recovery rates when properly implemented within closed-loop manufacturing systems.

The biodegradability of binder components also warrants careful attention within sustainability frameworks. Optimized aqueous binder ratios increasingly incorporate bio-based polymers and environmentally benign additives that decompose naturally at end-of-life. This characteristic significantly reduces waste management challenges and aligns with circular economy principles that many industries are adopting as part of their sustainability commitments.

Regulatory compliance represents an additional driver for environmental considerations in binder ratio optimization. With increasingly stringent global regulations on chemical usage and emissions, manufacturers must develop frameworks that anticipate future compliance requirements. Optimization models that incorporate environmental parameters alongside performance metrics enable companies to future-proof their formulations against evolving regulatory landscapes.

Energy efficiency gains from optimized aqueous binder ratios further enhance sustainability profiles. Lower curing temperatures and reduced processing times directly translate to decreased energy consumption and associated greenhouse gas emissions. Advanced optimization frameworks that account for these energy parameters can identify formulations that balance performance requirements with minimal environmental footprint, potentially reducing energy consumption by 15-25% compared to non-optimized formulations.

Life cycle assessment (LCA) studies indicate that aqueous binder systems with properly optimized ratios can reduce environmental impact by 30-45% compared to conventional solvent-based alternatives. This reduction stems primarily from decreased energy requirements during processing and the elimination of post-treatment pollution control measures that would otherwise be necessary for managing toxic emissions.

Water consumption represents another critical environmental consideration in aqueous binder optimization. While water-based systems inherently require this resource, advanced ratio optimization frameworks can incorporate water recycling protocols and minimize overall consumption. Recent innovations have demonstrated that optimized binder systems can achieve up to 70% water recovery rates when properly implemented within closed-loop manufacturing systems.

The biodegradability of binder components also warrants careful attention within sustainability frameworks. Optimized aqueous binder ratios increasingly incorporate bio-based polymers and environmentally benign additives that decompose naturally at end-of-life. This characteristic significantly reduces waste management challenges and aligns with circular economy principles that many industries are adopting as part of their sustainability commitments.

Regulatory compliance represents an additional driver for environmental considerations in binder ratio optimization. With increasingly stringent global regulations on chemical usage and emissions, manufacturers must develop frameworks that anticipate future compliance requirements. Optimization models that incorporate environmental parameters alongside performance metrics enable companies to future-proof their formulations against evolving regulatory landscapes.

Energy efficiency gains from optimized aqueous binder ratios further enhance sustainability profiles. Lower curing temperatures and reduced processing times directly translate to decreased energy consumption and associated greenhouse gas emissions. Advanced optimization frameworks that account for these energy parameters can identify formulations that balance performance requirements with minimal environmental footprint, potentially reducing energy consumption by 15-25% compared to non-optimized formulations.

Regulatory Compliance for Aqueous Binder Formulations

Regulatory compliance for aqueous binder formulations represents a critical consideration in the optimization framework for aqueous binder ratios. The landscape of regulations governing these formulations has evolved significantly over the past decade, with increasing emphasis on environmental protection, worker safety, and sustainable manufacturing practices.

The primary regulatory bodies overseeing aqueous binder formulations include the Environmental Protection Agency (EPA), the Occupational Safety and Health Administration (OSHA), and equivalent international organizations such as the European Chemicals Agency (ECHA). These agencies have established comprehensive frameworks that manufacturers must navigate when developing and implementing aqueous binder systems.

Volatile Organic Compound (VOC) regulations stand as one of the most significant compliance challenges. Recent amendments to the Clean Air Act have progressively lowered permissible VOC emission thresholds, necessitating reformulation of many traditional binder systems. The optimization of aqueous binder ratios must therefore prioritize low-VOC or zero-VOC components while maintaining performance characteristics.

REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance presents another layer of complexity, particularly for companies operating in global markets. The regulation requires thorough documentation of all chemical substances used in formulations, including comprehensive safety data and exposure scenarios. This necessitates careful selection of binder components with well-established safety profiles.

Food contact compliance represents a specialized regulatory domain for aqueous binders used in packaging applications. FDA regulations in the United States and the Framework Regulation (EC) No 1935/2004 in Europe establish strict migration limits and positive lists of approved substances. Optimization frameworks must incorporate these constraints when targeting food-adjacent applications.

Workplace safety regulations impose additional requirements on formulation development. OSHA's Hazard Communication Standard mandates detailed safety data sheets and appropriate labeling for all chemical components. Optimization strategies must therefore consider not only the performance characteristics of different binder ratios but also their associated hazard profiles.

Emerging regulations around persistent, bioaccumulative substances are reshaping compliance requirements. Several jurisdictions have implemented or proposed restrictions on per- and polyfluoroalkyl substances (PFAS), which have historically been used in some specialized binder applications. Forward-looking optimization frameworks must anticipate these regulatory trends and develop alternative formulation strategies.

The primary regulatory bodies overseeing aqueous binder formulations include the Environmental Protection Agency (EPA), the Occupational Safety and Health Administration (OSHA), and equivalent international organizations such as the European Chemicals Agency (ECHA). These agencies have established comprehensive frameworks that manufacturers must navigate when developing and implementing aqueous binder systems.

Volatile Organic Compound (VOC) regulations stand as one of the most significant compliance challenges. Recent amendments to the Clean Air Act have progressively lowered permissible VOC emission thresholds, necessitating reformulation of many traditional binder systems. The optimization of aqueous binder ratios must therefore prioritize low-VOC or zero-VOC components while maintaining performance characteristics.

REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance presents another layer of complexity, particularly for companies operating in global markets. The regulation requires thorough documentation of all chemical substances used in formulations, including comprehensive safety data and exposure scenarios. This necessitates careful selection of binder components with well-established safety profiles.

Food contact compliance represents a specialized regulatory domain for aqueous binders used in packaging applications. FDA regulations in the United States and the Framework Regulation (EC) No 1935/2004 in Europe establish strict migration limits and positive lists of approved substances. Optimization frameworks must incorporate these constraints when targeting food-adjacent applications.

Workplace safety regulations impose additional requirements on formulation development. OSHA's Hazard Communication Standard mandates detailed safety data sheets and appropriate labeling for all chemical components. Optimization strategies must therefore consider not only the performance characteristics of different binder ratios but also their associated hazard profiles.

Emerging regulations around persistent, bioaccumulative substances are reshaping compliance requirements. Several jurisdictions have implemented or proposed restrictions on per- and polyfluoroalkyl substances (PFAS), which have historically been used in some specialized binder applications. Forward-looking optimization frameworks must anticipate these regulatory trends and develop alternative formulation strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!