Quality By Design (QbD) For Green Electrode Formulation

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Green Electrode QbD Background and Objectives

The evolution of energy storage technologies has been marked by continuous innovation aimed at enhancing performance while reducing environmental impact. Quality by Design (QbD) for Green Electrode Formulation represents a paradigm shift in how we approach battery manufacturing, particularly in the context of growing environmental concerns. This systematic approach to electrode development integrates quality considerations from the earliest stages of design rather than relying on end-product testing alone.

Historically, electrode formulation has prioritized performance metrics such as energy density, power capability, and cycle life, often at the expense of environmental sustainability. The traditional manufacturing processes typically involve toxic solvents like N-Methyl-2-pyrrolidone (NMP), energy-intensive drying steps, and environmentally harmful materials. As global demand for energy storage solutions continues to surge, driven by electric vehicle adoption and renewable energy integration, the environmental footprint of battery production has become increasingly problematic.

The concept of QbD originated in the pharmaceutical industry but has gained traction in battery manufacturing due to its emphasis on understanding process parameters and their relationship to product quality. When applied to green electrode formulation, QbD aims to systematically identify critical quality attributes and process parameters that influence both performance and environmental impact, establishing a design space where optimal outcomes can be consistently achieved.

The primary objective of implementing QbD for green electrode formulation is to develop manufacturing processes that minimize environmental impact while maintaining or enhancing battery performance. This includes replacing toxic solvents with water-based or bio-derived alternatives, reducing energy consumption during processing, minimizing waste generation, and incorporating materials from sustainable sources or recycled content.

Secondary objectives include improving process robustness and reproducibility, reducing manufacturing costs through process optimization, and establishing a framework for continuous improvement that adapts to evolving environmental regulations and sustainability standards. Additionally, QbD aims to create a knowledge base that facilitates faster development cycles for next-generation green electrode technologies.

Current technological trends in this field include the development of aqueous processing methods, solvent-free dry electrode manufacturing, low-temperature processing techniques, and the incorporation of bio-derived binders and conductive additives. These innovations are complemented by advances in characterization techniques that enable more precise understanding of how formulation parameters affect electrode microstructure and performance.

The successful implementation of QbD principles in green electrode formulation represents a critical step toward sustainable battery manufacturing, aligning with global initiatives to reduce carbon emissions and minimize resource depletion in the transition to a clean energy economy.

Historically, electrode formulation has prioritized performance metrics such as energy density, power capability, and cycle life, often at the expense of environmental sustainability. The traditional manufacturing processes typically involve toxic solvents like N-Methyl-2-pyrrolidone (NMP), energy-intensive drying steps, and environmentally harmful materials. As global demand for energy storage solutions continues to surge, driven by electric vehicle adoption and renewable energy integration, the environmental footprint of battery production has become increasingly problematic.

The concept of QbD originated in the pharmaceutical industry but has gained traction in battery manufacturing due to its emphasis on understanding process parameters and their relationship to product quality. When applied to green electrode formulation, QbD aims to systematically identify critical quality attributes and process parameters that influence both performance and environmental impact, establishing a design space where optimal outcomes can be consistently achieved.

The primary objective of implementing QbD for green electrode formulation is to develop manufacturing processes that minimize environmental impact while maintaining or enhancing battery performance. This includes replacing toxic solvents with water-based or bio-derived alternatives, reducing energy consumption during processing, minimizing waste generation, and incorporating materials from sustainable sources or recycled content.

Secondary objectives include improving process robustness and reproducibility, reducing manufacturing costs through process optimization, and establishing a framework for continuous improvement that adapts to evolving environmental regulations and sustainability standards. Additionally, QbD aims to create a knowledge base that facilitates faster development cycles for next-generation green electrode technologies.

Current technological trends in this field include the development of aqueous processing methods, solvent-free dry electrode manufacturing, low-temperature processing techniques, and the incorporation of bio-derived binders and conductive additives. These innovations are complemented by advances in characterization techniques that enable more precise understanding of how formulation parameters affect electrode microstructure and performance.

The successful implementation of QbD principles in green electrode formulation represents a critical step toward sustainable battery manufacturing, aligning with global initiatives to reduce carbon emissions and minimize resource depletion in the transition to a clean energy economy.

Market Analysis for Sustainable Battery Technologies

The sustainable battery market is experiencing unprecedented growth, driven by increasing environmental awareness and stringent regulations on carbon emissions. The global market for sustainable battery technologies reached approximately $21.4 billion in 2022 and is projected to grow at a CAGR of 14.2% through 2030, potentially reaching $63.7 billion by the end of the decade. This growth trajectory is significantly outpacing traditional battery technologies, which are growing at roughly 5-7% annually.

Electric vehicle adoption serves as the primary catalyst for sustainable battery demand, with the EV market expected to represent over 45% of new vehicle sales in major markets by 2030. This transition is creating substantial demand for green electrode formulations that minimize environmental impact while maintaining or improving performance characteristics.

Consumer electronics represents the second largest application segment, with manufacturers increasingly marketing sustainability as a key differentiator. The industrial energy storage sector is also showing rapid adoption of sustainable battery technologies, particularly for grid-scale applications where lifecycle environmental impact is becoming a critical consideration for utilities and regulators.

Regionally, Europe leads in sustainable battery adoption due to progressive environmental policies and the European Battery Alliance's strategic initiatives. The European sustainable battery market is valued at approximately $7.8 billion and growing at 16.5% annually. Asia-Pacific, particularly China, dominates manufacturing capacity but is increasingly focusing on sustainability to meet export requirements for Western markets.

North America is experiencing accelerated growth following recent legislation including the Inflation Reduction Act, which allocates substantial funding for domestic battery production with environmental considerations. The market is expected to grow at 15.3% annually through 2028.

Key market drivers include regulatory pressures such as the EU Battery Directive mandating carbon footprint declarations and recycled content requirements. Consumer preferences are shifting toward environmentally responsible products, with 68% of consumers in recent surveys indicating willingness to pay premium prices for demonstrably sustainable battery technologies.

Cost remains the primary market barrier, with green electrode formulations typically commanding a 15-30% premium over conventional alternatives. However, this gap is narrowing as economies of scale improve and research advances in Quality by Design methodologies optimize manufacturing processes. Industry analysts project price parity for many green electrode formulations by 2027-2028, which would significantly accelerate market penetration across all segments.

Electric vehicle adoption serves as the primary catalyst for sustainable battery demand, with the EV market expected to represent over 45% of new vehicle sales in major markets by 2030. This transition is creating substantial demand for green electrode formulations that minimize environmental impact while maintaining or improving performance characteristics.

Consumer electronics represents the second largest application segment, with manufacturers increasingly marketing sustainability as a key differentiator. The industrial energy storage sector is also showing rapid adoption of sustainable battery technologies, particularly for grid-scale applications where lifecycle environmental impact is becoming a critical consideration for utilities and regulators.

Regionally, Europe leads in sustainable battery adoption due to progressive environmental policies and the European Battery Alliance's strategic initiatives. The European sustainable battery market is valued at approximately $7.8 billion and growing at 16.5% annually. Asia-Pacific, particularly China, dominates manufacturing capacity but is increasingly focusing on sustainability to meet export requirements for Western markets.

North America is experiencing accelerated growth following recent legislation including the Inflation Reduction Act, which allocates substantial funding for domestic battery production with environmental considerations. The market is expected to grow at 15.3% annually through 2028.

Key market drivers include regulatory pressures such as the EU Battery Directive mandating carbon footprint declarations and recycled content requirements. Consumer preferences are shifting toward environmentally responsible products, with 68% of consumers in recent surveys indicating willingness to pay premium prices for demonstrably sustainable battery technologies.

Cost remains the primary market barrier, with green electrode formulations typically commanding a 15-30% premium over conventional alternatives. However, this gap is narrowing as economies of scale improve and research advances in Quality by Design methodologies optimize manufacturing processes. Industry analysts project price parity for many green electrode formulations by 2027-2028, which would significantly accelerate market penetration across all segments.

Current Green Electrode Formulation Challenges

The current landscape of electrode formulation faces significant challenges in transitioning to greener alternatives while maintaining performance standards. Traditional electrode manufacturing processes rely heavily on toxic N-Methyl-2-pyrrolidone (NMP) as the primary solvent, which poses serious environmental and health risks. Despite regulatory pressures to phase out NMP, particularly under REACH regulations in Europe, finding suitable replacements that maintain electrode performance remains problematic.

Water-based formulations represent the most environmentally friendly alternative but struggle with fundamental issues including poor wetting of active materials, slower drying rates, and increased energy consumption during processing. These formulations often result in electrodes with compromised adhesion, non-uniform particle distribution, and ultimately reduced electrochemical performance compared to NMP-based counterparts.

The rheological properties of green electrode slurries present another significant challenge. Aqueous binders like carboxymethyl cellulose (CMC) and styrene-butadiene rubber (SBR) exhibit complex viscoelastic behaviors that differ substantially from PVDF in NMP systems. This difference complicates the optimization of mixing protocols and coating parameters, often leading to inconsistent electrode quality and manufacturing defects.

Surface tension mismatches between green solvents and current collector materials frequently cause coating defects such as dewetting, orange peel effects, and uneven thickness distribution. These issues become particularly pronounced at higher production speeds, creating a significant barrier to industrial-scale implementation of green electrode formulations.

The drying process for water-based electrodes requires careful control to prevent cracking and delamination. The higher surface tension of water compared to organic solvents creates stronger capillary forces during evaporation, which can disrupt the electrode microstructure. This often necessitates slower drying rates and more complex drying protocols, reducing production throughput.

Shelf stability represents another critical challenge, as green formulations typically demonstrate shorter viable processing windows before rheological properties change significantly. This instability complicates quality control and increases manufacturing variability, particularly in large-scale production environments.

From a performance perspective, electrodes produced with green formulations often exhibit higher interfacial resistance, reduced rate capability, and shorter cycle life compared to conventional formulations. These performance gaps are particularly evident in high-energy density applications where electrode thickness exceeds 100 μm, creating a significant barrier to adoption in premium battery applications.

The transition to green electrode formulations also requires substantial modifications to existing manufacturing infrastructure, including different mixing equipment, coating technologies, and drying systems. This capital investment requirement, coupled with process revalidation needs, creates significant economic barriers to widespread industry adoption despite the clear environmental benefits.

Water-based formulations represent the most environmentally friendly alternative but struggle with fundamental issues including poor wetting of active materials, slower drying rates, and increased energy consumption during processing. These formulations often result in electrodes with compromised adhesion, non-uniform particle distribution, and ultimately reduced electrochemical performance compared to NMP-based counterparts.

The rheological properties of green electrode slurries present another significant challenge. Aqueous binders like carboxymethyl cellulose (CMC) and styrene-butadiene rubber (SBR) exhibit complex viscoelastic behaviors that differ substantially from PVDF in NMP systems. This difference complicates the optimization of mixing protocols and coating parameters, often leading to inconsistent electrode quality and manufacturing defects.

Surface tension mismatches between green solvents and current collector materials frequently cause coating defects such as dewetting, orange peel effects, and uneven thickness distribution. These issues become particularly pronounced at higher production speeds, creating a significant barrier to industrial-scale implementation of green electrode formulations.

The drying process for water-based electrodes requires careful control to prevent cracking and delamination. The higher surface tension of water compared to organic solvents creates stronger capillary forces during evaporation, which can disrupt the electrode microstructure. This often necessitates slower drying rates and more complex drying protocols, reducing production throughput.

Shelf stability represents another critical challenge, as green formulations typically demonstrate shorter viable processing windows before rheological properties change significantly. This instability complicates quality control and increases manufacturing variability, particularly in large-scale production environments.

From a performance perspective, electrodes produced with green formulations often exhibit higher interfacial resistance, reduced rate capability, and shorter cycle life compared to conventional formulations. These performance gaps are particularly evident in high-energy density applications where electrode thickness exceeds 100 μm, creating a significant barrier to adoption in premium battery applications.

The transition to green electrode formulations also requires substantial modifications to existing manufacturing infrastructure, including different mixing equipment, coating technologies, and drying systems. This capital investment requirement, coupled with process revalidation needs, creates significant economic barriers to widespread industry adoption despite the clear environmental benefits.

Current QbD Methodologies for Electrode Formulation

01 Environmentally friendly electrode materials

Green electrode formulations focus on using environmentally friendly materials that reduce toxic components while maintaining performance. These approaches incorporate sustainable raw materials, biodegradable components, and reduced heavy metal content. The QbD approach ensures these green materials meet performance requirements through systematic design and testing, optimizing both environmental impact and electrode functionality.- Environmentally friendly electrode materials: Green electrode formulations focus on using environmentally friendly materials that reduce toxic components while maintaining performance. These approaches incorporate sustainable raw materials, biodegradable components, and reduced heavy metal content. The Quality by Design methodology ensures these green materials meet performance standards through systematic development and testing, optimizing both environmental impact and electrode functionality.

- QbD framework for electrode manufacturing: The Quality by Design framework applied to electrode manufacturing involves identifying critical quality attributes, establishing design space parameters, and implementing process analytical technology. This systematic approach enables manufacturers to develop robust electrode formulations with consistent quality while minimizing environmental impact. The framework includes risk assessment, design of experiments, and continuous monitoring to ensure green electrodes meet both performance and sustainability requirements.

- Sustainable binders and conductive additives: Green electrode formulations incorporate sustainable binders and conductive additives derived from renewable sources. These components replace traditional petroleum-based materials with bio-based alternatives such as cellulose derivatives, chitosan, alginate, and conductive polymers from sustainable sources. The QbD approach optimizes these materials for proper electrode cohesion, conductivity, and environmental compatibility while ensuring consistent manufacturing quality.

- Water-based processing techniques: Water-based processing techniques for electrode formulation eliminate or reduce the use of toxic organic solvents. These green methods utilize aqueous dispersions and water-soluble binders to create electrode slurries. The QbD approach identifies critical process parameters for water-based systems, including mixing conditions, drying protocols, and coating techniques that ensure consistent electrode quality while significantly reducing environmental impact and workplace hazards.

- Recycled and recovered electrode materials: Green electrode formulations incorporate recycled and recovered materials from end-of-life batteries and electronic waste. The QbD methodology establishes protocols for processing these recovered materials to ensure consistent quality despite variability in recycled feedstock. This approach includes purification techniques, particle size control, and composition adjustments to maintain electrode performance while promoting circular economy principles and reducing the demand for virgin raw materials.

02 QbD methodology for electrode manufacturing

Quality by Design principles applied to electrode formulation involve systematic identification of critical quality attributes and process parameters. This methodology establishes design spaces that ensure consistent electrode performance while minimizing environmental impact. The approach includes risk assessment, design of experiments, and process analytical technology to develop robust manufacturing processes that yield green electrodes with predictable quality characteristics.Expand Specific Solutions03 Water-based electrode formulations

Water-based electrode formulations represent a significant advancement in green electrode technology by replacing organic solvents with aqueous systems. These formulations reduce volatile organic compound emissions and health hazards associated with traditional electrode manufacturing. The QbD approach optimizes water-based binder systems, dispersants, and processing conditions to achieve electrode performance comparable to conventional solvent-based systems while significantly reducing environmental footprint.Expand Specific Solutions04 Sustainable binders and additives

Green electrode formulations incorporate sustainable binders and additives derived from renewable resources. These include biopolymers, plant-based dispersants, and naturally occurring conductive additives that replace petroleum-based components. The QbD framework guides the selection and optimization of these materials to ensure they provide adequate adhesion, conductivity, and stability while reducing environmental impact throughout the electrode lifecycle.Expand Specific Solutions05 Energy-efficient electrode processing techniques

Energy-efficient processing techniques for green electrode formulation focus on reducing the carbon footprint of manufacturing operations. These approaches include low-temperature curing methods, solvent-free processing, and advanced drying technologies that minimize energy consumption. The QbD methodology optimizes these processes by identifying critical process parameters that balance energy efficiency with electrode performance, ensuring sustainable manufacturing without compromising quality.Expand Specific Solutions

Leading Companies in Green Battery Technology

The Quality by Design (QbD) approach for green electrode formulation is currently in a growth phase, with an estimated market size of $3-5 billion and expanding at 15-20% annually. The competitive landscape features established materials companies like LG Chem, DuPont, and Cabot Corporation developing sustainable electrode technologies alongside specialized players such as Nanoco Technologies focusing on nanomaterials. Major electronics manufacturers including Huawei, BOE Technology, and TCL are integrating these technologies into consumer products. The technology maturity varies significantly, with companies like 3M and Sumitomo Electric demonstrating advanced commercial applications, while university research partners (MIT, University of Toronto, University of California) continue to drive fundamental innovation in environmentally friendly electrode materials and manufacturing processes.

LG Chem Ltd.

Technical Solution: LG Chem has developed a comprehensive QbD approach for green electrode formulation that integrates statistical design of experiments (DoE) with machine learning algorithms to optimize electrode manufacturing processes. Their system utilizes water-based binders instead of traditional NMP (N-Methyl-2-pyrrolidone) solvents, significantly reducing toxic emissions and waste. The company has implemented a systematic risk assessment framework that identifies critical material attributes (CMAs) and critical process parameters (CPPs) affecting electrode performance. Their green electrode formulation incorporates bio-derived polymeric binders and utilizes aqueous processing techniques that reduce energy consumption by approximately 40% compared to conventional methods. LG Chem's QbD platform enables real-time monitoring of electrode coating uniformity, porosity, and adhesion strength, allowing for continuous process verification and adjustment to maintain consistent quality while minimizing environmental impact.

Strengths: Advanced integration of AI/ML with manufacturing processes enables precise control over electrode properties while maintaining environmental standards. Their water-based processing significantly reduces hazardous waste. Weaknesses: The water-based systems may still face challenges with certain active materials that are sensitive to moisture, potentially limiting application with some high-energy cathode materials.

BYD Co., Ltd.

Technical Solution: BYD has pioneered a QbD framework specifically for green electrode manufacturing that focuses on eliminating toxic solvents and heavy metals from the production process. Their approach incorporates a closed-loop water recycling system that recovers over 95% of process water, dramatically reducing wastewater discharge. BYD's electrode formulation utilizes plant-derived cellulose as a structural additive and employs low-temperature drying techniques that reduce energy consumption by up to 30%. The company has developed a comprehensive design space mapping methodology that correlates green material properties with electrode performance metrics, enabling predictive quality control. Their manufacturing process incorporates in-line optical and electrochemical characterization tools that provide immediate feedback on electrode quality parameters, allowing for real-time process adjustments to maintain optimal performance while adhering to green chemistry principles. BYD's QbD system also includes life cycle assessment tools that quantify the environmental impact reduction achieved through their green formulation approach.

Strengths: Exceptional integration of water recycling systems with electrode manufacturing creates a nearly closed-loop production system. Their cellulose-based additives provide renewable alternatives to synthetic polymers. Weaknesses: The plant-derived materials may introduce batch-to-batch variability that requires more sophisticated quality control systems compared to synthetic alternatives.

Key Technical Innovations in Green Electrode Materials

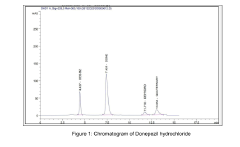

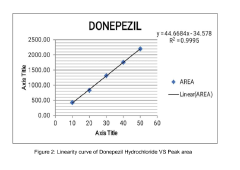

A quality by design (QBD) approach for validating HPLC method for donepezil hydrochloride

PatentPendingIN202321077115A

Innovation

- A Quality by Design (QbD) approach for validating the HPLC method for donepezil hydrochloride and its related substances, utilizing a mobile phase of methanol: 0.1% orthophosphoric acid in a 51.9:48.1 ratio, a flow rate of 0.85 mL/min, detection at 228.7 nm, and an injection volume of 20 μL, with validation parameters including linearity, precision, robustness, accuracy, limit of detection, and limit of quantitation, as per ICH Q2(R1) standards.

Environmental Impact Assessment Framework

The Environmental Impact Assessment Framework for Quality by Design (QbD) in green electrode formulation represents a systematic approach to evaluating and minimizing the ecological footprint throughout the electrode development lifecycle. This framework integrates environmental considerations directly into the QbD methodology, ensuring that sustainability becomes a critical quality attribute rather than an afterthought.

The framework consists of four interconnected assessment phases that align with the electrode formulation process. The first phase involves raw material evaluation, where each component is analyzed for resource depletion potential, extraction impacts, and renewable content percentage. This assessment utilizes standardized metrics such as the Environmental Priority Strategies (EPS) system and Material Circularity Indicators (MCI) to quantify environmental burden.

Process impact analysis forms the second phase, focusing on energy consumption, waste generation, and emissions during electrode manufacturing. This includes comprehensive Life Cycle Assessment (LCA) methodologies specifically adapted for battery production environments. The framework incorporates real-time monitoring systems that track key environmental parameters throughout the formulation process, enabling immediate adjustments to minimize ecological impact.

The third phase addresses end-of-life considerations, evaluating recyclability potential, biodegradability of components, and recovery efficiency of critical materials. This assessment utilizes the Circular Economy Assessment Protocol (CEAP) to quantify the electrode's alignment with closed-loop principles and identifies opportunities for design modifications that enhance material recovery.

Performance-impact correlation represents the final phase, establishing mathematical relationships between environmental metrics and electrode performance parameters. This enables formulators to optimize both sustainability and functionality simultaneously through multi-objective optimization algorithms. The framework employs sensitivity analysis to identify which formulation variables most significantly influence environmental outcomes.

Implementation of this assessment framework requires cross-functional collaboration between formulation scientists, environmental engineers, and quality assurance specialists. The framework provides standardized documentation templates and decision matrices to facilitate consistent application across different electrode development projects. Additionally, it establishes threshold values for key environmental indicators that trigger design review when exceeded.

By integrating this environmental impact assessment framework into the QbD approach for green electrode formulation, manufacturers can systematically reduce ecological footprint while maintaining performance standards. This proactive methodology transforms sustainability from a regulatory compliance issue into a fundamental design parameter that drives innovation in electrode technology.

The framework consists of four interconnected assessment phases that align with the electrode formulation process. The first phase involves raw material evaluation, where each component is analyzed for resource depletion potential, extraction impacts, and renewable content percentage. This assessment utilizes standardized metrics such as the Environmental Priority Strategies (EPS) system and Material Circularity Indicators (MCI) to quantify environmental burden.

Process impact analysis forms the second phase, focusing on energy consumption, waste generation, and emissions during electrode manufacturing. This includes comprehensive Life Cycle Assessment (LCA) methodologies specifically adapted for battery production environments. The framework incorporates real-time monitoring systems that track key environmental parameters throughout the formulation process, enabling immediate adjustments to minimize ecological impact.

The third phase addresses end-of-life considerations, evaluating recyclability potential, biodegradability of components, and recovery efficiency of critical materials. This assessment utilizes the Circular Economy Assessment Protocol (CEAP) to quantify the electrode's alignment with closed-loop principles and identifies opportunities for design modifications that enhance material recovery.

Performance-impact correlation represents the final phase, establishing mathematical relationships between environmental metrics and electrode performance parameters. This enables formulators to optimize both sustainability and functionality simultaneously through multi-objective optimization algorithms. The framework employs sensitivity analysis to identify which formulation variables most significantly influence environmental outcomes.

Implementation of this assessment framework requires cross-functional collaboration between formulation scientists, environmental engineers, and quality assurance specialists. The framework provides standardized documentation templates and decision matrices to facilitate consistent application across different electrode development projects. Additionally, it establishes threshold values for key environmental indicators that trigger design review when exceeded.

By integrating this environmental impact assessment framework into the QbD approach for green electrode formulation, manufacturers can systematically reduce ecological footprint while maintaining performance standards. This proactive methodology transforms sustainability from a regulatory compliance issue into a fundamental design parameter that drives innovation in electrode technology.

Regulatory Compliance for Green Battery Production

Regulatory compliance for green battery production has become increasingly stringent as governments worldwide prioritize environmental sustainability. The implementation of Quality by Design (QbD) principles in green electrode formulation must align with these evolving regulatory frameworks to ensure market access and operational legitimacy.

The European Union leads with its comprehensive Battery Directive (2006/66/EC) and the newer Batteries Regulation, which specifically addresses sustainable battery production. These regulations mandate reduced use of hazardous substances, minimum recycled content requirements, and carbon footprint declarations for batteries. Manufacturers implementing QbD for green electrode formulation must document how their design choices actively reduce environmental impact to meet these standards.

In North America, the U.S. Environmental Protection Agency's regulations under the Resource Conservation and Recovery Act (RCRA) govern battery production waste management. Additionally, California's Proposition 65 requires warnings for products containing chemicals known to cause cancer or reproductive harm, directly impacting electrode formulation decisions. QbD approaches must incorporate these regulatory considerations from the earliest design phases.

Asian markets present varying regulatory landscapes. China's RoHS (Restriction of Hazardous Substances) regulations and recent policies promoting new energy vehicles have established strict standards for battery production. Japan's recycling laws require manufacturers to consider end-of-life management during product design, reinforcing the need for QbD approaches that consider the entire product lifecycle.

International standards such as ISO 14001 (Environmental Management Systems) and ISO 50001 (Energy Management) provide frameworks that complement regulatory requirements. Battery manufacturers implementing QbD for green electrode formulation increasingly pursue certification to these standards to demonstrate compliance and commitment to environmental stewardship.

Emerging regulations are focusing on supply chain transparency and ethical sourcing of battery materials. The EU's proposed Battery Passport system will require detailed documentation of material origins and environmental impacts throughout the supply chain. QbD methodologies must therefore incorporate traceability mechanisms to satisfy these forthcoming requirements.

Compliance strategies for green electrode formulation should include regular regulatory horizon scanning, proactive engagement with regulatory bodies during development phases, and implementation of robust documentation systems that capture environmental performance metrics throughout the QbD process. This approach not only ensures compliance but positions manufacturers advantageously as regulations continue to evolve toward greater environmental protection.

The European Union leads with its comprehensive Battery Directive (2006/66/EC) and the newer Batteries Regulation, which specifically addresses sustainable battery production. These regulations mandate reduced use of hazardous substances, minimum recycled content requirements, and carbon footprint declarations for batteries. Manufacturers implementing QbD for green electrode formulation must document how their design choices actively reduce environmental impact to meet these standards.

In North America, the U.S. Environmental Protection Agency's regulations under the Resource Conservation and Recovery Act (RCRA) govern battery production waste management. Additionally, California's Proposition 65 requires warnings for products containing chemicals known to cause cancer or reproductive harm, directly impacting electrode formulation decisions. QbD approaches must incorporate these regulatory considerations from the earliest design phases.

Asian markets present varying regulatory landscapes. China's RoHS (Restriction of Hazardous Substances) regulations and recent policies promoting new energy vehicles have established strict standards for battery production. Japan's recycling laws require manufacturers to consider end-of-life management during product design, reinforcing the need for QbD approaches that consider the entire product lifecycle.

International standards such as ISO 14001 (Environmental Management Systems) and ISO 50001 (Energy Management) provide frameworks that complement regulatory requirements. Battery manufacturers implementing QbD for green electrode formulation increasingly pursue certification to these standards to demonstrate compliance and commitment to environmental stewardship.

Emerging regulations are focusing on supply chain transparency and ethical sourcing of battery materials. The EU's proposed Battery Passport system will require detailed documentation of material origins and environmental impacts throughout the supply chain. QbD methodologies must therefore incorporate traceability mechanisms to satisfy these forthcoming requirements.

Compliance strategies for green electrode formulation should include regular regulatory horizon scanning, proactive engagement with regulatory bodies during development phases, and implementation of robust documentation systems that capture environmental performance metrics throughout the QbD process. This approach not only ensures compliance but positions manufacturers advantageously as regulations continue to evolve toward greater environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!