In-Line Rheology Sensors For Process Control

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

In-Line Rheology Sensing Technology Background and Objectives

Rheology, the study of flow and deformation of matter, has been a critical aspect of industrial process control since the early 20th century. Traditional rheological measurements were predominantly conducted offline in laboratories, requiring sample extraction and specialized equipment. This approach, while precise, introduced significant time delays and potential sample alterations, limiting real-time process optimization capabilities.

The evolution of in-line rheology sensing technology began in the 1970s with rudimentary flow sensors, progressing significantly in the 1990s with the integration of advanced computational capabilities. The past two decades have witnessed accelerated development driven by miniaturization of sensing elements, improved signal processing algorithms, and the emergence of Industry 4.0 paradigms emphasizing continuous monitoring and adaptive control.

In-line rheology sensors represent a transformative approach to process control across multiple industries including polymer processing, food production, pharmaceutical manufacturing, and oil and gas operations. These sensors enable continuous, real-time measurement of critical rheological parameters such as viscosity, elasticity, yield stress, and thixotropic behavior directly within production lines without process interruption.

The primary technological objective of modern in-line rheology sensing is to achieve high measurement accuracy comparable to laboratory instruments while maintaining robustness under harsh industrial conditions. This includes resistance to temperature fluctuations, pressure variations, chemical exposure, and mechanical vibrations inherent in manufacturing environments.

Secondary objectives include miniaturization for integration into existing process equipment, reduced calibration requirements, extended operational lifespans, and compatibility with digital communication protocols for seamless integration with factory automation systems and data analytics platforms.

A particularly challenging goal is the development of multi-parameter sensing capabilities that can simultaneously measure multiple rheological properties, providing comprehensive material characterization during production. This would enable more sophisticated process control strategies addressing complex material behaviors that influence product quality.

The technological trajectory is increasingly focused on non-invasive measurement techniques that eliminate potential contamination risks and flow disturbances. Ultrasonic, optical, and magnetic resonance methods represent promising avenues for achieving this objective, though each presents unique implementation challenges in industrial settings.

As manufacturing processes become more sophisticated and product quality specifications more stringent, the demand for high-precision in-line rheology sensing continues to grow. The ultimate technological vision is a self-calibrating, multi-parameter rheological monitoring system capable of adaptive response to changing process conditions while providing actionable insights for process optimization and quality control.

The evolution of in-line rheology sensing technology began in the 1970s with rudimentary flow sensors, progressing significantly in the 1990s with the integration of advanced computational capabilities. The past two decades have witnessed accelerated development driven by miniaturization of sensing elements, improved signal processing algorithms, and the emergence of Industry 4.0 paradigms emphasizing continuous monitoring and adaptive control.

In-line rheology sensors represent a transformative approach to process control across multiple industries including polymer processing, food production, pharmaceutical manufacturing, and oil and gas operations. These sensors enable continuous, real-time measurement of critical rheological parameters such as viscosity, elasticity, yield stress, and thixotropic behavior directly within production lines without process interruption.

The primary technological objective of modern in-line rheology sensing is to achieve high measurement accuracy comparable to laboratory instruments while maintaining robustness under harsh industrial conditions. This includes resistance to temperature fluctuations, pressure variations, chemical exposure, and mechanical vibrations inherent in manufacturing environments.

Secondary objectives include miniaturization for integration into existing process equipment, reduced calibration requirements, extended operational lifespans, and compatibility with digital communication protocols for seamless integration with factory automation systems and data analytics platforms.

A particularly challenging goal is the development of multi-parameter sensing capabilities that can simultaneously measure multiple rheological properties, providing comprehensive material characterization during production. This would enable more sophisticated process control strategies addressing complex material behaviors that influence product quality.

The technological trajectory is increasingly focused on non-invasive measurement techniques that eliminate potential contamination risks and flow disturbances. Ultrasonic, optical, and magnetic resonance methods represent promising avenues for achieving this objective, though each presents unique implementation challenges in industrial settings.

As manufacturing processes become more sophisticated and product quality specifications more stringent, the demand for high-precision in-line rheology sensing continues to grow. The ultimate technological vision is a self-calibrating, multi-parameter rheological monitoring system capable of adaptive response to changing process conditions while providing actionable insights for process optimization and quality control.

Market Demand Analysis for Process Control Rheology Sensors

The global market for in-line rheology sensors in process control applications has been experiencing robust growth, driven primarily by increasing demands for real-time quality control and process optimization across multiple industries. Current market assessments value the industrial process control sensors market at approximately $16 billion, with rheology sensors representing a specialized but rapidly growing segment within this broader category.

Manufacturing sectors, particularly polymer processing, food and beverage production, pharmaceutical manufacturing, and petrochemical industries, demonstrate the strongest demand for these sensors. This demand stems from stringent quality requirements, the need for process efficiency, and increasingly complex formulations that require precise rheological monitoring during production.

The food and beverage industry has emerged as a particularly strong growth sector, with manufacturers seeking to maintain consistent product texture and mouthfeel while optimizing production efficiency. Similarly, the pharmaceutical industry's shift toward continuous manufacturing processes has created significant new opportunities for in-line rheology monitoring solutions that can ensure batch-to-batch consistency and regulatory compliance.

Regional analysis reveals that North America and Europe currently dominate the market for advanced rheology sensors, accounting for over 60% of global installations. However, the Asia-Pacific region is witnessing the fastest growth rate, driven by rapid industrialization in China and India, along with increasing adoption of automation technologies across manufacturing sectors.

Key market drivers include the growing emphasis on process analytical technology (PAT), increasing regulatory requirements for product consistency, and the broader industrial trend toward Industry 4.0 implementation. The potential for cost savings through reduced waste, improved energy efficiency, and decreased production downtime provides compelling economic justification for investment in these technologies.

Customer surveys indicate that end-users prioritize measurement accuracy, reliability in harsh industrial environments, and seamless integration with existing control systems when selecting rheology sensors. There is also growing demand for sensors that can perform multiparameter measurements, combining rheological properties with other physical characteristics such as temperature, pressure, or chemical composition.

Market forecasts project a compound annual growth rate of 7.8% for in-line rheology sensors over the next five years, outpacing the broader process control instrumentation market. This growth trajectory is supported by technological advancements in sensor miniaturization, wireless connectivity, and improved data analytics capabilities that enhance the value proposition of these devices.

Manufacturing sectors, particularly polymer processing, food and beverage production, pharmaceutical manufacturing, and petrochemical industries, demonstrate the strongest demand for these sensors. This demand stems from stringent quality requirements, the need for process efficiency, and increasingly complex formulations that require precise rheological monitoring during production.

The food and beverage industry has emerged as a particularly strong growth sector, with manufacturers seeking to maintain consistent product texture and mouthfeel while optimizing production efficiency. Similarly, the pharmaceutical industry's shift toward continuous manufacturing processes has created significant new opportunities for in-line rheology monitoring solutions that can ensure batch-to-batch consistency and regulatory compliance.

Regional analysis reveals that North America and Europe currently dominate the market for advanced rheology sensors, accounting for over 60% of global installations. However, the Asia-Pacific region is witnessing the fastest growth rate, driven by rapid industrialization in China and India, along with increasing adoption of automation technologies across manufacturing sectors.

Key market drivers include the growing emphasis on process analytical technology (PAT), increasing regulatory requirements for product consistency, and the broader industrial trend toward Industry 4.0 implementation. The potential for cost savings through reduced waste, improved energy efficiency, and decreased production downtime provides compelling economic justification for investment in these technologies.

Customer surveys indicate that end-users prioritize measurement accuracy, reliability in harsh industrial environments, and seamless integration with existing control systems when selecting rheology sensors. There is also growing demand for sensors that can perform multiparameter measurements, combining rheological properties with other physical characteristics such as temperature, pressure, or chemical composition.

Market forecasts project a compound annual growth rate of 7.8% for in-line rheology sensors over the next five years, outpacing the broader process control instrumentation market. This growth trajectory is supported by technological advancements in sensor miniaturization, wireless connectivity, and improved data analytics capabilities that enhance the value proposition of these devices.

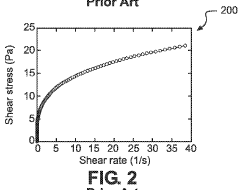

Current State and Challenges in Rheological Measurement Technology

Rheological measurement technology has evolved significantly over the past decades, transitioning from laboratory-based testing to in-line process monitoring capabilities. Traditional rheological measurements typically involved sample extraction and offline analysis using rotational rheometers or viscometers, which provided high accuracy but lacked real-time feedback for process control. Current state-of-the-art in-line rheology sensors employ various technologies including ultrasonic, vibrational, rotational, and optical methods to provide continuous monitoring of fluid properties during manufacturing processes.

Despite advancements, significant challenges persist in rheological measurement technology. One primary limitation is the trade-off between measurement accuracy and robustness in industrial environments. Many existing in-line sensors struggle to maintain calibration stability when exposed to harsh processing conditions including temperature fluctuations, pressure variations, and chemical exposure. This often necessitates frequent recalibration, reducing operational efficiency and increasing maintenance costs.

Another critical challenge is the limited measurement range of individual sensor technologies. Most current sensors excel at measuring either low or high viscosity ranges but rarely both. This constraint often requires manufacturers to deploy multiple sensor types across different process stages, increasing complexity and cost. Additionally, many sensors exhibit material-specific responses, requiring extensive calibration for each formulation, which becomes particularly problematic for manufacturers handling diverse product portfolios.

Data interpretation presents another significant hurdle. Raw sensor outputs frequently require complex algorithms to translate into meaningful rheological parameters. The relationship between measured properties and actual rheological behavior is often non-linear and dependent on multiple variables, making accurate interpretation challenging, especially for non-Newtonian fluids that exhibit time-dependent behaviors such as thixotropy or rheopexy.

Miniaturization and integration challenges also limit widespread adoption. Many current technologies remain bulky or require specific installation configurations that are incompatible with existing process equipment. This physical constraint often necessitates significant process redesign to accommodate sensor integration, increasing implementation costs and complexity.

Standardization issues further complicate the landscape. Unlike laboratory rheometry, which benefits from established testing protocols and standards, in-line rheological measurement lacks unified calibration methods and performance metrics. This absence of standardization makes technology comparison difficult and slows industry-wide adoption as manufacturers struggle to evaluate competing solutions against consistent benchmarks.

Despite advancements, significant challenges persist in rheological measurement technology. One primary limitation is the trade-off between measurement accuracy and robustness in industrial environments. Many existing in-line sensors struggle to maintain calibration stability when exposed to harsh processing conditions including temperature fluctuations, pressure variations, and chemical exposure. This often necessitates frequent recalibration, reducing operational efficiency and increasing maintenance costs.

Another critical challenge is the limited measurement range of individual sensor technologies. Most current sensors excel at measuring either low or high viscosity ranges but rarely both. This constraint often requires manufacturers to deploy multiple sensor types across different process stages, increasing complexity and cost. Additionally, many sensors exhibit material-specific responses, requiring extensive calibration for each formulation, which becomes particularly problematic for manufacturers handling diverse product portfolios.

Data interpretation presents another significant hurdle. Raw sensor outputs frequently require complex algorithms to translate into meaningful rheological parameters. The relationship between measured properties and actual rheological behavior is often non-linear and dependent on multiple variables, making accurate interpretation challenging, especially for non-Newtonian fluids that exhibit time-dependent behaviors such as thixotropy or rheopexy.

Miniaturization and integration challenges also limit widespread adoption. Many current technologies remain bulky or require specific installation configurations that are incompatible with existing process equipment. This physical constraint often necessitates significant process redesign to accommodate sensor integration, increasing implementation costs and complexity.

Standardization issues further complicate the landscape. Unlike laboratory rheometry, which benefits from established testing protocols and standards, in-line rheological measurement lacks unified calibration methods and performance metrics. This absence of standardization makes technology comparison difficult and slows industry-wide adoption as manufacturers struggle to evaluate competing solutions against consistent benchmarks.

Current Technical Solutions for In-Line Rheological Monitoring

01 In-line rheology sensors for medical applications

In-line rheology sensors are used in medical applications to monitor and analyze the rheological properties of bodily fluids in real-time. These sensors can be integrated into medical devices to provide continuous monitoring of blood viscosity, flow characteristics, and other rheological parameters. This technology enables better diagnosis and treatment of various medical conditions by providing immediate feedback on fluid properties within the body.- In-line rheology sensors for medical applications: In-line rheology sensors are utilized in medical applications to monitor and analyze the rheological properties of bodily fluids in real-time. These sensors can be integrated into medical devices for continuous monitoring of blood viscosity, flow characteristics, and other rheological parameters. The technology enables early detection of abnormalities and assists in diagnosis and treatment decisions. These sensors typically employ various measurement principles including ultrasound, optical methods, or mechanical sensing to provide accurate rheological data in clinical settings.

- Optical-based in-line rheology measurement systems: Optical technologies are employed in in-line rheology sensors to measure fluid properties without disrupting flow. These systems utilize various optical principles such as laser diffraction, image analysis, and light scattering to determine rheological parameters. The sensors can detect changes in viscosity, elasticity, and flow behavior by analyzing how light interacts with the fluid. Optical-based systems offer advantages including non-invasive measurement, high sensitivity, and the ability to work with transparent or semi-transparent materials in real-time processing environments.

- In-line rheology monitoring for polymer processing: In-line rheology sensors specifically designed for polymer processing applications enable real-time monitoring of material properties during manufacturing. These sensors can be integrated into extrusion lines, injection molding systems, or other polymer processing equipment to provide immediate feedback on melt viscosity, elasticity, and flow behavior. The technology allows for process optimization, quality control, and reduction of waste by detecting variations in material properties before they affect the final product. Various sensing technologies including pressure differential measurements, vibration analysis, and specialized probes are employed in these systems.

- Microfluidic rheology sensing technologies: Microfluidic platforms incorporate miniaturized rheology sensors for precise measurement of fluid properties in small sample volumes. These technologies utilize microchannels, MEMS (Micro-Electro-Mechanical Systems), and specialized sensing elements to determine rheological parameters with high accuracy. The compact nature of these systems makes them suitable for portable devices, lab-on-chip applications, and situations where sample conservation is critical. Microfluidic rheology sensors can detect subtle changes in viscosity, elasticity, and other flow properties at microscale levels, providing valuable data for research and industrial applications.

- Data processing systems for in-line rheology measurements: Advanced data processing systems are essential components of in-line rheology sensing technologies. These systems employ specialized algorithms, signal processing techniques, and computational models to convert raw sensor data into meaningful rheological parameters. Real-time analysis capabilities allow for immediate detection of property changes and process deviations. Many systems incorporate machine learning and artificial intelligence to improve measurement accuracy and enable predictive capabilities. The data processing components can be integrated with process control systems to enable automated adjustments based on rheological measurements, enhancing manufacturing efficiency and product consistency.

02 Optical-based in-line rheology measurement systems

Optical technologies are employed in in-line rheology sensors to measure fluid properties without disrupting flow. These systems use various optical principles including light scattering, image processing, and spectroscopic analysis to determine rheological parameters such as viscosity, elasticity, and flow behavior. The non-invasive nature of optical measurements makes them particularly valuable for continuous process monitoring in industrial applications where maintaining sterility or flow integrity is critical.Expand Specific Solutions03 In-line rheology monitoring for polymer processing

Specialized in-line rheology sensors are designed for polymer processing applications to monitor material properties during extrusion, injection molding, and other manufacturing processes. These sensors provide real-time data on melt viscosity, elasticity, and flow behavior, allowing for immediate process adjustments to maintain product quality. The technology enables manufacturers to optimize processing conditions, reduce waste, and ensure consistent product properties.Expand Specific Solutions04 Advanced sensor integration and data processing techniques

Modern in-line rheology sensors incorporate advanced data processing algorithms and integration techniques to improve measurement accuracy and reliability. These systems often combine multiple sensing modalities and employ machine learning or artificial intelligence to interpret complex rheological data. The integration of these sensors with process control systems enables automated adjustments based on real-time rheological measurements, enhancing manufacturing efficiency and product consistency.Expand Specific Solutions05 Novel materials and fabrication methods for rheology sensors

Innovative materials and fabrication techniques are being developed to create more sensitive and robust in-line rheology sensors. These advances include the use of nanomaterials, MEMS technology, and specialized coatings that enhance sensor performance in challenging environments. New fabrication methods enable miniaturization of sensors for applications where space is limited, while also improving durability for use in harsh industrial conditions with extreme temperatures, pressures, or corrosive media.Expand Specific Solutions

Key Industry Players in Rheology Sensor Manufacturing

The in-line rheology sensors market is currently in a growth phase, characterized by increasing adoption across process industries seeking real-time quality control and efficiency improvements. The global market size is estimated to be expanding at a CAGR of 7-9%, driven by demand in oil and gas, chemical processing, and pharmaceutical sectors. From a technological maturity perspective, the landscape shows varied development stages with established players like Halliburton Energy Services and Emerson's Rosemount offering commercial solutions for specific applications, while specialized companies such as Rheonics and Lenterra are advancing innovative sensor technologies. Academic institutions including the University of Birmingham and Zhejiang University are contributing fundamental research, while industrial giants like Schlumberger, Bayer, and Novozymes are integrating these technologies into their process control systems, indicating growing market acceptance despite remaining technical challenges in harsh operating environments.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed advanced in-line rheology monitoring systems specifically designed for oil and gas applications, particularly for drilling fluids and cement slurries. Their Real-Time Rheology (RTR) system employs multiple sensing technologies including ultrasonic wave propagation and mechanical impedance measurements to continuously monitor fluid properties during drilling operations. The system can detect changes in viscosity, yield stress, and thixotropic behavior under varying temperature and pressure conditions that simulate downhole environments. Halliburton's technology incorporates machine learning algorithms that analyze rheological data patterns to predict potential issues before they occur, allowing for proactive adjustment of fluid properties. Their sensors are designed to withstand extreme conditions with operating capabilities at temperatures up to 175°C and pressures exceeding 20,000 psi, making them suitable for deepwater and HPHT (High Pressure High Temperature) applications.

Strengths: Specifically engineered for extreme oilfield conditions; integrated predictive analytics capabilities; robust design for high reliability in critical operations; seamless integration with existing drilling fluid management systems. Weaknesses: Highly specialized for oil and gas applications with limited crossover to other industries; significant capital investment required; complex calibration procedures needed for different fluid systems.

Malvern Panalytical Ltd.

Technical Solution: Malvern Panalytical offers sophisticated in-line rheology measurement solutions based on multiple technologies including laser diffraction, dynamic light scattering, and ultrasonic attenuation. Their Insitec system provides real-time particle characterization that correlates with rheological properties, while their Kinexus rheometer technology has been adapted for in-line process applications. Malvern's systems employ non-contact optical techniques that can measure through sight glasses or sapphire windows, eliminating the need for direct contact with process fluids in many applications. Their technology incorporates advanced algorithms that translate measured parameters into rheological properties using established correlations and material models. Malvern's systems feature self-diagnostic capabilities that continuously verify measurement accuracy and can automatically compensate for process variations such as temperature fluctuations, flow rate changes, and air bubbles. The company has developed industry-specific calibration protocols for pharmaceuticals, food processing, and chemical manufacturing to ensure accurate rheological characterization across diverse material types.

Strengths: Exceptional measurement precision; versatile application across multiple industries; non-contact measurement options reduce contamination risks; comprehensive data analysis software with industry-specific models. Weaknesses: Higher complexity requiring specialized knowledge for optimal implementation; some solutions require periodic maintenance of optical components; challenging implementation in highly opaque or extremely viscous materials.

Core Patents and Innovations in Rheology Sensor Technology

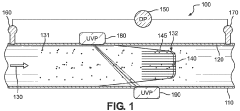

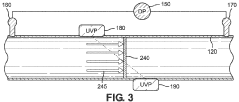

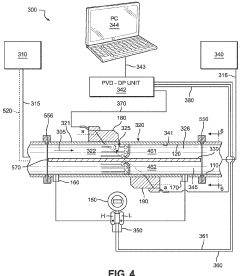

System and method for determining in-line rheology measurement of slipping flow of fluid

PatentWO2024039500A1

Innovation

- A measurement system that includes an additional shearing surface within the pipe, allowing for the detection and quantification of shear stress using UVP-PD technology, disrupting the plug flow condition and enabling the construction of an in-process rheogram by generating a non-zero shear rate zone with a radial velocity gradient.

Expert-system-based rheology

PatentActiveEP2329248A2

Innovation

- A rheometer equipped with a mobile and fixed part, vertical and rotary actuators, material and process parameter storage, and rheometry logic that assists users in selecting appropriate geometries, test parameters, and control sequences, allowing for user-friendly setup and execution of rheological tests, even for inexperienced users, and storing sample history for precise measurements.

Integration Strategies with Industrial IoT Systems

The integration of In-Line Rheology Sensors with Industrial IoT systems represents a critical advancement in modern manufacturing environments. These sensors, which provide real-time data on material flow properties, must be seamlessly incorporated into broader IoT ecosystems to maximize their value. Effective integration strategies typically begin with standardized communication protocols such as OPC UA, MQTT, or AMQP, which enable rheology sensors to communicate efficiently with existing industrial networks while maintaining data integrity and security.

Data management frameworks form another essential component of successful integration. Time-series databases like InfluxDB or Prometheus are particularly well-suited for handling the continuous streams of rheological measurements, while edge computing devices can perform preliminary data processing to reduce bandwidth requirements and enable faster response times. This distributed architecture helps balance the need for real-time process control with broader data analytics capabilities.

Security considerations must be paramount when connecting rheology sensors to IoT networks. Implementation of end-to-end encryption, secure boot mechanisms, and regular firmware updates helps protect sensitive production data and prevent unauthorized access. Additionally, network segmentation techniques can isolate critical control systems from potential vulnerabilities in the broader IoT environment.

Scalability represents another key challenge in integration strategies. Cloud-based platforms such as AWS IoT, Microsoft Azure IoT, or Google Cloud IoT provide flexible infrastructure that can accommodate growing numbers of sensors and increasing data volumes. These platforms typically offer built-in analytics capabilities that can be leveraged to extract meaningful insights from rheological measurements across multiple production lines or facilities.

Digital twin technology offers particularly promising integration opportunities for rheology sensors. By creating virtual representations of physical production processes, manufacturers can simulate the effects of rheological variations on product quality and process efficiency. This enables predictive maintenance strategies and optimization of process parameters without disrupting actual production.

Integration with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems completes the value chain by connecting shop floor rheological data with broader business processes. This vertical integration enables more responsive supply chain management and production planning based on real-time material property information, ultimately driving improved operational efficiency and product quality.

Data management frameworks form another essential component of successful integration. Time-series databases like InfluxDB or Prometheus are particularly well-suited for handling the continuous streams of rheological measurements, while edge computing devices can perform preliminary data processing to reduce bandwidth requirements and enable faster response times. This distributed architecture helps balance the need for real-time process control with broader data analytics capabilities.

Security considerations must be paramount when connecting rheology sensors to IoT networks. Implementation of end-to-end encryption, secure boot mechanisms, and regular firmware updates helps protect sensitive production data and prevent unauthorized access. Additionally, network segmentation techniques can isolate critical control systems from potential vulnerabilities in the broader IoT environment.

Scalability represents another key challenge in integration strategies. Cloud-based platforms such as AWS IoT, Microsoft Azure IoT, or Google Cloud IoT provide flexible infrastructure that can accommodate growing numbers of sensors and increasing data volumes. These platforms typically offer built-in analytics capabilities that can be leveraged to extract meaningful insights from rheological measurements across multiple production lines or facilities.

Digital twin technology offers particularly promising integration opportunities for rheology sensors. By creating virtual representations of physical production processes, manufacturers can simulate the effects of rheological variations on product quality and process efficiency. This enables predictive maintenance strategies and optimization of process parameters without disrupting actual production.

Integration with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems completes the value chain by connecting shop floor rheological data with broader business processes. This vertical integration enables more responsive supply chain management and production planning based on real-time material property information, ultimately driving improved operational efficiency and product quality.

Calibration and Validation Methodologies for Rheology Sensors

Effective calibration and validation methodologies are critical for ensuring the accuracy and reliability of in-line rheology sensors in industrial process control applications. These methodologies must address the unique challenges posed by continuous measurement in dynamic production environments, where conditions can vary significantly from laboratory settings.

The calibration process for rheology sensors typically begins with primary calibration using certified reference materials (CRMs) that exhibit well-characterized rheological properties across relevant temperature and shear rate ranges. This establishes the baseline response of the sensor against known standards. For polymer processing applications, polystyrene and polyethylene standards with certified molecular weight distributions are commonly employed, while in food processing, standardized solutions of hydrocolloids such as xanthan gum provide reliable calibration references.

Secondary calibration procedures involve comparative measurements between the in-line sensor and laboratory instruments under controlled conditions. This cross-validation approach helps identify systematic errors and establishes correlation factors that can be applied to real-time measurements. Modern calibration protocols increasingly incorporate multivariate statistical techniques to account for the complex interdependencies between rheological parameters and process variables.

Validation methodologies extend beyond initial calibration to ensure ongoing measurement integrity. Periodic validation checks using process samples analyzed both in-line and through laboratory testing help quantify measurement drift and maintain accuracy over time. Statistical process control (SPC) techniques, including control charts for viscosity measurements, enable continuous monitoring of sensor performance and early detection of calibration shifts.

For critical applications, redundant measurement systems may be deployed, where multiple sensors using different measurement principles monitor the same process stream. This approach provides cross-validation capabilities and increases system reliability through measurement redundancy. The implementation of automated validation routines that periodically introduce reference materials into the process stream without disrupting production represents an advanced validation strategy gaining traction in continuous manufacturing environments.

Digital twin technology is emerging as a powerful tool for sensor validation, where real-time measurements are continuously compared against physics-based models of the process. Significant deviations between measured and predicted rheological properties trigger alerts for potential sensor issues or process anomalies, enabling proactive maintenance and calibration interventions.

Documentation and traceability form the foundation of robust calibration and validation protocols. Comprehensive records of calibration procedures, reference materials, environmental conditions, and validation results establish an audit trail that supports regulatory compliance and facilitates troubleshooting when measurement discrepancies arise.

The calibration process for rheology sensors typically begins with primary calibration using certified reference materials (CRMs) that exhibit well-characterized rheological properties across relevant temperature and shear rate ranges. This establishes the baseline response of the sensor against known standards. For polymer processing applications, polystyrene and polyethylene standards with certified molecular weight distributions are commonly employed, while in food processing, standardized solutions of hydrocolloids such as xanthan gum provide reliable calibration references.

Secondary calibration procedures involve comparative measurements between the in-line sensor and laboratory instruments under controlled conditions. This cross-validation approach helps identify systematic errors and establishes correlation factors that can be applied to real-time measurements. Modern calibration protocols increasingly incorporate multivariate statistical techniques to account for the complex interdependencies between rheological parameters and process variables.

Validation methodologies extend beyond initial calibration to ensure ongoing measurement integrity. Periodic validation checks using process samples analyzed both in-line and through laboratory testing help quantify measurement drift and maintain accuracy over time. Statistical process control (SPC) techniques, including control charts for viscosity measurements, enable continuous monitoring of sensor performance and early detection of calibration shifts.

For critical applications, redundant measurement systems may be deployed, where multiple sensors using different measurement principles monitor the same process stream. This approach provides cross-validation capabilities and increases system reliability through measurement redundancy. The implementation of automated validation routines that periodically introduce reference materials into the process stream without disrupting production represents an advanced validation strategy gaining traction in continuous manufacturing environments.

Digital twin technology is emerging as a powerful tool for sensor validation, where real-time measurements are continuously compared against physics-based models of the process. Significant deviations between measured and predicted rheological properties trigger alerts for potential sensor issues or process anomalies, enabling proactive maintenance and calibration interventions.

Documentation and traceability form the foundation of robust calibration and validation protocols. Comprehensive records of calibration procedures, reference materials, environmental conditions, and validation results establish an audit trail that supports regulatory compliance and facilitates troubleshooting when measurement discrepancies arise.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!