Rheology Control Strategies For High-Throughput Slurries

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Slurry Rheology Background and Objectives

Rheology control in slurries has evolved significantly over the past several decades, transitioning from empirical approaches to scientifically-driven methodologies. Initially, slurry rheology management relied heavily on trial-and-error techniques with limited understanding of underlying physical mechanisms. The 1950s marked the beginning of systematic studies in this field, with researchers establishing fundamental relationships between particle characteristics and flow behaviors.

The evolution accelerated in the 1980s and 1990s with the development of advanced rheometers and computational fluid dynamics, enabling more precise characterization and prediction of slurry behavior. Recent technological advancements have further refined our understanding of complex rheological phenomena in high-solids content suspensions, particularly in high-throughput applications where processing speed and efficiency are paramount.

High-throughput slurry processing presents unique rheological challenges across multiple industries including semiconductor manufacturing, ceramic production, pharmaceutical formulation, and mining operations. These applications demand precise control over flow properties to maintain production efficiency while ensuring product quality. The ability to manipulate viscosity, yield stress, and thixotropic recovery becomes increasingly critical as throughput requirements intensify.

Current technological trends point toward more sophisticated rheology modifiers, in-line monitoring systems, and predictive modeling approaches. The integration of machine learning algorithms with rheological data is emerging as a powerful tool for optimizing slurry formulations and processing parameters in real-time, representing a significant shift from traditional methodologies.

The primary objectives of rheology control in high-throughput slurries include achieving consistent flow properties across varying processing conditions, preventing sedimentation and phase separation during high-speed operations, minimizing energy consumption while maintaining throughput targets, and ensuring uniform particle distribution in final products. These objectives must be balanced against economic considerations and specific application requirements.

This technical research aims to comprehensively evaluate existing rheology control strategies for high-throughput slurries, identify technological gaps in current approaches, and explore innovative solutions that can address emerging challenges. The investigation will focus particularly on advanced additive technologies, novel processing equipment designs, and integrated monitoring systems that enable precise rheological manipulation under demanding production conditions.

By establishing a clear understanding of the historical context, current capabilities, and future directions in slurry rheology control, this research seeks to provide actionable insights for technology development roadmaps and strategic investment decisions in high-throughput processing applications.

The evolution accelerated in the 1980s and 1990s with the development of advanced rheometers and computational fluid dynamics, enabling more precise characterization and prediction of slurry behavior. Recent technological advancements have further refined our understanding of complex rheological phenomena in high-solids content suspensions, particularly in high-throughput applications where processing speed and efficiency are paramount.

High-throughput slurry processing presents unique rheological challenges across multiple industries including semiconductor manufacturing, ceramic production, pharmaceutical formulation, and mining operations. These applications demand precise control over flow properties to maintain production efficiency while ensuring product quality. The ability to manipulate viscosity, yield stress, and thixotropic recovery becomes increasingly critical as throughput requirements intensify.

Current technological trends point toward more sophisticated rheology modifiers, in-line monitoring systems, and predictive modeling approaches. The integration of machine learning algorithms with rheological data is emerging as a powerful tool for optimizing slurry formulations and processing parameters in real-time, representing a significant shift from traditional methodologies.

The primary objectives of rheology control in high-throughput slurries include achieving consistent flow properties across varying processing conditions, preventing sedimentation and phase separation during high-speed operations, minimizing energy consumption while maintaining throughput targets, and ensuring uniform particle distribution in final products. These objectives must be balanced against economic considerations and specific application requirements.

This technical research aims to comprehensively evaluate existing rheology control strategies for high-throughput slurries, identify technological gaps in current approaches, and explore innovative solutions that can address emerging challenges. The investigation will focus particularly on advanced additive technologies, novel processing equipment designs, and integrated monitoring systems that enable precise rheological manipulation under demanding production conditions.

By establishing a clear understanding of the historical context, current capabilities, and future directions in slurry rheology control, this research seeks to provide actionable insights for technology development roadmaps and strategic investment decisions in high-throughput processing applications.

Industrial Demand Analysis for High-Throughput Slurries

The global market for high-throughput slurries has experienced significant growth in recent years, driven primarily by expanding applications in semiconductor manufacturing, chemical processing, mining operations, and advanced materials production. These industries increasingly demand slurries capable of maintaining consistent rheological properties while being processed at higher volumes and speeds.

In the semiconductor sector, chemical mechanical planarization (CMP) processes require precisely controlled slurries for wafer polishing, with market analysts reporting annual growth rates exceeding 7% as chip manufacturers pursue more advanced node technologies. The push toward smaller feature sizes in semiconductor fabrication has intensified the need for slurries with exceptional stability and performance characteristics even at accelerated processing rates.

The mining industry represents another substantial market segment, where high-throughput mineral processing operations depend on slurry systems for efficient material transport and separation. Mining companies are actively seeking rheology control solutions that can reduce water consumption while maintaining optimal flow properties, particularly as environmental regulations become more stringent worldwide.

Chemical processing industries have demonstrated growing demand for advanced rheology control technologies that enable faster production rates without compromising product quality. Specialty chemical manufacturers report that improvements in slurry handling can reduce production cycle times by up to 30%, representing significant operational cost savings.

The construction materials sector, particularly cement and concrete production, has emerged as a rapidly expanding market for high-throughput slurry technologies. With global construction activity projected to increase substantially over the next decade, manufacturers are investing in advanced rheological control systems to meet production demands while maintaining product consistency.

Energy sector applications, including oil and gas drilling operations and emerging carbon capture technologies, represent growing market opportunities. These applications often involve processing abrasive or challenging slurries under extreme conditions, creating demand for sophisticated rheology control strategies that can function reliably at high throughput rates.

Customer requirements across these industries consistently emphasize several key performance attributes: stability under high shear conditions, predictable flow behavior, resistance to settling or phase separation, and compatibility with existing processing equipment. Additionally, there is growing market pressure for environmentally sustainable formulations that reduce water usage and minimize chemical additives.

Market forecasts indicate that the global high-throughput slurry processing equipment market will continue its upward trajectory, with particularly strong growth in Asia-Pacific regions where manufacturing capacity expansion is occurring most rapidly. This regional growth is creating new opportunities for technology providers who can deliver effective rheology control solutions adapted to local manufacturing conditions and requirements.

In the semiconductor sector, chemical mechanical planarization (CMP) processes require precisely controlled slurries for wafer polishing, with market analysts reporting annual growth rates exceeding 7% as chip manufacturers pursue more advanced node technologies. The push toward smaller feature sizes in semiconductor fabrication has intensified the need for slurries with exceptional stability and performance characteristics even at accelerated processing rates.

The mining industry represents another substantial market segment, where high-throughput mineral processing operations depend on slurry systems for efficient material transport and separation. Mining companies are actively seeking rheology control solutions that can reduce water consumption while maintaining optimal flow properties, particularly as environmental regulations become more stringent worldwide.

Chemical processing industries have demonstrated growing demand for advanced rheology control technologies that enable faster production rates without compromising product quality. Specialty chemical manufacturers report that improvements in slurry handling can reduce production cycle times by up to 30%, representing significant operational cost savings.

The construction materials sector, particularly cement and concrete production, has emerged as a rapidly expanding market for high-throughput slurry technologies. With global construction activity projected to increase substantially over the next decade, manufacturers are investing in advanced rheological control systems to meet production demands while maintaining product consistency.

Energy sector applications, including oil and gas drilling operations and emerging carbon capture technologies, represent growing market opportunities. These applications often involve processing abrasive or challenging slurries under extreme conditions, creating demand for sophisticated rheology control strategies that can function reliably at high throughput rates.

Customer requirements across these industries consistently emphasize several key performance attributes: stability under high shear conditions, predictable flow behavior, resistance to settling or phase separation, and compatibility with existing processing equipment. Additionally, there is growing market pressure for environmentally sustainable formulations that reduce water usage and minimize chemical additives.

Market forecasts indicate that the global high-throughput slurry processing equipment market will continue its upward trajectory, with particularly strong growth in Asia-Pacific regions where manufacturing capacity expansion is occurring most rapidly. This regional growth is creating new opportunities for technology providers who can deliver effective rheology control solutions adapted to local manufacturing conditions and requirements.

Current Rheology Control Challenges and Limitations

Despite significant advancements in rheology control for high-throughput slurries, several persistent challenges continue to impede optimal performance in industrial applications. The primary limitation remains the inherent complexity of non-Newtonian fluid behavior under varying process conditions. Slurries typically exhibit time-dependent properties, including thixotropy and rheopexy, which are difficult to predict and control in real-time production environments.

Temperature sensitivity presents another substantial challenge, as viscosity profiles can change dramatically with even minor temperature fluctuations. This is particularly problematic in continuous processing systems where maintaining thermal uniformity throughout large volumes is technically difficult and energy-intensive. The resulting viscosity gradients can lead to inconsistent flow patterns and product quality issues.

Particle sedimentation and aggregation continue to plague high-throughput operations, especially during process interruptions or low-shear conditions. Current stabilization technologies often fail to maintain homogeneity over extended periods without compromising other rheological properties. The trade-off between stability and processability remains a significant limitation in formulation design.

Scale-up challenges represent perhaps the most significant barrier to implementing laboratory-developed rheology control strategies in industrial settings. Rheological behaviors observed in small-scale testing frequently fail to translate predictably to production-scale equipment due to differences in shear history, residence time distributions, and equipment geometry. This scale-dependency undermines the reliability of pilot studies and increases development costs.

Measurement and monitoring limitations further complicate rheology control efforts. Current inline rheometry technologies often lack the sensitivity, accuracy, or response time needed for effective real-time control in high-throughput environments. The gap between laboratory characterization capabilities and practical process monitoring options creates significant blind spots in quality control systems.

Formulation constraints also impose limitations, as many effective rheology modifiers introduce unwanted side effects in final products or downstream processes. The chemical compatibility requirements of modern formulations often restrict the range of available rheological additives, forcing compromises between flow properties and other performance attributes.

Regulatory and sustainability considerations have emerged as increasingly important limitations. Traditional rheology modifiers face growing scrutiny regarding environmental persistence, biodegradability, and toxicological profiles. The transition toward more sustainable alternatives frequently involves accepting reduced performance or higher costs, creating difficult trade-offs for manufacturers.

Temperature sensitivity presents another substantial challenge, as viscosity profiles can change dramatically with even minor temperature fluctuations. This is particularly problematic in continuous processing systems where maintaining thermal uniformity throughout large volumes is technically difficult and energy-intensive. The resulting viscosity gradients can lead to inconsistent flow patterns and product quality issues.

Particle sedimentation and aggregation continue to plague high-throughput operations, especially during process interruptions or low-shear conditions. Current stabilization technologies often fail to maintain homogeneity over extended periods without compromising other rheological properties. The trade-off between stability and processability remains a significant limitation in formulation design.

Scale-up challenges represent perhaps the most significant barrier to implementing laboratory-developed rheology control strategies in industrial settings. Rheological behaviors observed in small-scale testing frequently fail to translate predictably to production-scale equipment due to differences in shear history, residence time distributions, and equipment geometry. This scale-dependency undermines the reliability of pilot studies and increases development costs.

Measurement and monitoring limitations further complicate rheology control efforts. Current inline rheometry technologies often lack the sensitivity, accuracy, or response time needed for effective real-time control in high-throughput environments. The gap between laboratory characterization capabilities and practical process monitoring options creates significant blind spots in quality control systems.

Formulation constraints also impose limitations, as many effective rheology modifiers introduce unwanted side effects in final products or downstream processes. The chemical compatibility requirements of modern formulations often restrict the range of available rheological additives, forcing compromises between flow properties and other performance attributes.

Regulatory and sustainability considerations have emerged as increasingly important limitations. Traditional rheology modifiers face growing scrutiny regarding environmental persistence, biodegradability, and toxicological profiles. The transition toward more sustainable alternatives frequently involves accepting reduced performance or higher costs, creating difficult trade-offs for manufacturers.

Current Rheological Modification Techniques

01 Rheological modifiers for slurry control

Various additives can be incorporated into slurries to modify their rheological properties. These modifiers help control viscosity, flow behavior, and stability of the slurry systems. Common rheological modifiers include polymers, surfactants, and dispersants that can be tailored to specific slurry compositions. These additives enable precise control of slurry behavior during processing, transportation, and application, which is critical for industrial operations.- Rheological modifiers for slurry control: Various additives can be incorporated into slurries to modify their rheological properties. These modifiers help control viscosity, flow behavior, and stability of the slurry systems. Common rheological modifiers include polymers, surfactants, and dispersants that can adjust yield stress, thixotropy, and shear-thinning characteristics. These additives are crucial for maintaining optimal flow properties during processing, transportation, and application of slurries in various industrial settings.

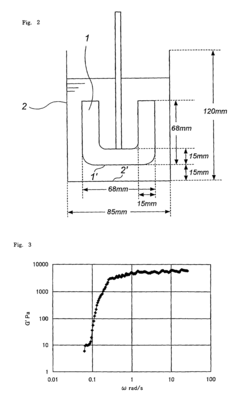

- Measurement techniques for slurry rheology: Advanced techniques and instruments are employed to accurately measure and characterize the rheological properties of slurries. These include rheometers, viscometers, and specialized testing equipment that can determine parameters such as viscosity, yield stress, and flow behavior under different conditions. Real-time monitoring systems allow for continuous assessment of slurry properties during processing. These measurement techniques are essential for quality control, process optimization, and ensuring consistent performance of slurry-based products.

- Temperature and pressure effects on slurry rheology: The rheological behavior of slurries is significantly influenced by temperature and pressure conditions. Changes in temperature can alter viscosity, while pressure variations affect flow characteristics and particle interactions within the slurry. Understanding these relationships is crucial for predicting slurry behavior in various processing environments. Formulations can be designed to maintain consistent rheological properties across a range of operating conditions, ensuring reliable performance in applications from mining to construction and manufacturing.

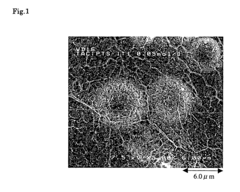

- Particle size distribution impact on slurry flow: The distribution of particle sizes within a slurry significantly affects its rheological properties. Controlling particle size distribution can optimize flow behavior, stability, and processing characteristics. Finer particles typically increase viscosity and yield stress, while broader distributions may improve packing efficiency and reduce water requirements. Techniques for manipulating particle size distribution include grinding, classification, and selective aggregation, allowing for tailored slurry properties suited to specific applications in ceramics, mining, and construction industries.

- Stabilization of slurries for improved rheological performance: Various methods are employed to stabilize slurries and enhance their rheological performance over time. These include the addition of dispersants, surfactants, and pH modifiers that prevent particle agglomeration and sedimentation. Stabilized slurries maintain consistent flow properties during storage and application, reducing the need for constant agitation or remixing. Advanced stabilization techniques can extend the usable life of slurries while ensuring predictable rheological behavior in diverse applications from pharmaceutical formulations to construction materials.

02 Measurement techniques for slurry rheology

Advanced techniques and instruments are employed to measure and characterize the rheological properties of slurries. These include viscometers, rheometers, and specialized testing equipment that can determine parameters such as yield stress, thixotropy, and flow curves. Real-time monitoring systems allow for continuous assessment of slurry behavior under various conditions, enabling process optimization and quality control in industrial applications.Expand Specific Solutions03 Temperature and pressure effects on slurry rheology

Temperature and pressure significantly influence the rheological behavior of slurries. As temperature increases, viscosity typically decreases, affecting flow characteristics and stability. Pressure changes can alter particle interactions and fluid dynamics within the slurry. Understanding these effects is crucial for designing slurry systems that maintain desired rheological properties across varying environmental conditions, particularly in applications involving extreme temperatures or pressure gradients.Expand Specific Solutions04 Particle size distribution impact on slurry rheology

The distribution of particle sizes within a slurry significantly affects its rheological properties. Slurries with uniform particle sizes typically exhibit different flow behaviors compared to those with varied particle dimensions. Controlling particle size distribution can optimize packing density, reduce viscosity at high solid loadings, and improve overall stability. This aspect is particularly important in ceramic processing, mining operations, and construction materials where specific flow characteristics are required.Expand Specific Solutions05 Computational modeling of slurry rheology

Advanced computational methods are employed to model and predict the rheological behavior of complex slurry systems. These models incorporate factors such as particle interactions, fluid dynamics, and chemical effects to simulate slurry behavior under various conditions. Machine learning algorithms and computational fluid dynamics (CFD) approaches enable more accurate predictions of slurry performance, reducing the need for extensive experimental testing and facilitating the design of optimized slurry formulations for specific applications.Expand Specific Solutions

Leading Companies in Slurry Processing Industry

The rheology control market for high-throughput slurries is currently in a growth phase, with increasing demand across oil and gas, chemical processing, and energy storage sectors. The global market size is estimated to exceed $5 billion, driven by industrial efficiency requirements and sustainability initiatives. Technology maturity varies significantly across applications, with established players like Halliburton Energy Services and Schlumberger Technologies dominating in oilfield services, while ExxonMobil and Chevron lead in research innovation. Chemical specialists including Ecolab, GCP Applied Technologies, and Arr-Maz offer specialized formulations. Emerging applications in battery manufacturing are being advanced by LG Energy Solution and Samsung SDI, focusing on next-generation slurry technologies for improved energy storage performance.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed advanced rheology control systems specifically for high-throughput oil and gas drilling slurries. Their technology incorporates smart polymer additives that respond to changing downhole conditions, maintaining optimal flow properties under varying temperature and pressure environments. The company's proprietary BARADRIL-N® system utilizes specially engineered polymers that provide superior suspension capabilities while maintaining pumpability at high throughput rates[1]. Additionally, Halliburton has implemented real-time rheology monitoring systems that allow for continuous adjustment of slurry properties during operations, using sensors that measure viscosity, yield point, and gel strength to automatically trigger chemical adjustments when parameters deviate from optimal ranges[3]. Their technology also includes shear-thinning additives that reduce viscosity under high shear conditions at the pump while maintaining stability at low shear conditions downhole.

Strengths: Exceptional performance in extreme temperature and pressure environments; real-time monitoring capabilities allow for immediate adjustments; extensive field testing across diverse geological formations. Weaknesses: Higher cost compared to conventional systems; requires specialized equipment for implementation; some formulations have limited shelf life in certain climate conditions.

Exxonmobil Upstream Research Co.

Technical Solution: ExxonMobil has pioneered rheology control strategies for high-throughput slurries through their Rheology Modification Technology (RMT) platform. This comprehensive approach combines computational fluid dynamics modeling with advanced chemical formulations to predict and control slurry behavior across various processing conditions. Their system employs proprietary viscoelastic surfactants that create reversible molecular networks, providing exceptional stability during high-throughput operations while maintaining the ability to break down under controlled conditions[2]. ExxonMobil's technology incorporates temperature-responsive polymers that automatically adjust viscosity profiles as operational conditions change, maintaining optimal flow characteristics throughout the process chain. Additionally, they've developed nano-engineered particles that serve as rheology modifiers, creating steric barriers between suspended solids to prevent agglomeration even at high solid loadings of up to 70% by weight[4]. Their integrated approach also includes specialized mixing equipment designed to ensure homogeneous distribution of additives throughout large-volume slurries.

Strengths: Exceptional stability at high solid loadings; predictive modeling capabilities reduce operational failures; adaptable to wide range of temperature conditions; compatible with existing infrastructure. Weaknesses: Requires significant computational resources for modeling complex systems; higher initial implementation costs; some formulations contain proprietary components with limited availability.

Key Patents and Innovations in Slurry Flow Control

Slurry rheology modifier

PatentInactiveUS7374699B2

Innovation

- A slurry rheology modifier comprising two different water-soluble low-molecular compounds (A) and (B) that form an association product network when mixed, providing enhanced viscosity and segregation resistance without delaying coagulation, even in high water/powder ratios or when contacting an aqueous phase.

Rheology modifier

PatentActiveUS20070290160A1

Innovation

- A powdery rheology modifier is developed using an anionic aromatic compound and a cationic surfactant, combined with an inorganic powder of high specific surface area, forming an aggregate structure that significantly increases viscosity when mixed, and is produced through a method involving mixing with an inorganic powder to enhance powderization and handling.

Environmental Impact of Slurry Processing Methods

The environmental impact of slurry processing methods has become increasingly significant as industrial operations scale up to meet growing global demands. High-throughput slurry processing, while economically advantageous, presents substantial environmental challenges that require careful consideration and mitigation strategies. The rheological control methods employed in these processes directly influence their environmental footprint across multiple dimensions.

Water consumption represents one of the most pressing environmental concerns in slurry processing. Traditional rheology control often relies on dilution techniques that necessitate large volumes of fresh water, contributing to water scarcity issues in many regions. Advanced rheological modifiers that maintain optimal flow properties at higher solid concentrations can reduce water requirements by 20-30%, significantly decreasing the overall water footprint of these operations.

Energy utilization patterns in high-throughput slurry processing are directly linked to rheological properties. Poorly controlled slurries typically require greater pumping energy and more intensive mixing operations, resulting in elevated carbon emissions. Recent studies indicate that optimized rheology control strategies can reduce energy consumption by up to 25% in large-scale operations, with corresponding reductions in greenhouse gas emissions.

Chemical additives used for rheology modification present another environmental consideration. Traditional dispersants and flocculants may contain environmentally persistent compounds that resist biodegradation. The industry trend toward bio-based rheology modifiers derived from renewable resources represents a significant advancement in reducing the ecological impact of slurry processing. These bio-derived alternatives have demonstrated comparable performance while reducing environmental persistence by 40-60% compared to conventional options.

Waste generation and disposal challenges are magnified in high-throughput operations. Inefficient rheology control often leads to increased waste volumes and more frequent equipment cleaning cycles, generating additional wastewater streams. Optimized rheological properties can improve process efficiency, reducing waste generation by 15-35% depending on the specific application and processing conditions.

Land disturbance associated with tailings and waste storage represents a significant environmental concern, particularly in mining operations utilizing slurry processing. Advanced rheology control enabling higher solids content can substantially reduce the footprint of tailings impoundments, decreasing land disturbance by up to 50% in some applications while simultaneously reducing the risk of containment failures.

Regulatory frameworks worldwide are increasingly focusing on the environmental impacts of industrial processes, with slurry handling receiving particular attention due to its high resource intensity. Companies implementing advanced rheology control strategies not only achieve operational benefits but also position themselves advantageously for compliance with evolving environmental regulations and sustainability certifications.

Water consumption represents one of the most pressing environmental concerns in slurry processing. Traditional rheology control often relies on dilution techniques that necessitate large volumes of fresh water, contributing to water scarcity issues in many regions. Advanced rheological modifiers that maintain optimal flow properties at higher solid concentrations can reduce water requirements by 20-30%, significantly decreasing the overall water footprint of these operations.

Energy utilization patterns in high-throughput slurry processing are directly linked to rheological properties. Poorly controlled slurries typically require greater pumping energy and more intensive mixing operations, resulting in elevated carbon emissions. Recent studies indicate that optimized rheology control strategies can reduce energy consumption by up to 25% in large-scale operations, with corresponding reductions in greenhouse gas emissions.

Chemical additives used for rheology modification present another environmental consideration. Traditional dispersants and flocculants may contain environmentally persistent compounds that resist biodegradation. The industry trend toward bio-based rheology modifiers derived from renewable resources represents a significant advancement in reducing the ecological impact of slurry processing. These bio-derived alternatives have demonstrated comparable performance while reducing environmental persistence by 40-60% compared to conventional options.

Waste generation and disposal challenges are magnified in high-throughput operations. Inefficient rheology control often leads to increased waste volumes and more frequent equipment cleaning cycles, generating additional wastewater streams. Optimized rheological properties can improve process efficiency, reducing waste generation by 15-35% depending on the specific application and processing conditions.

Land disturbance associated with tailings and waste storage represents a significant environmental concern, particularly in mining operations utilizing slurry processing. Advanced rheology control enabling higher solids content can substantially reduce the footprint of tailings impoundments, decreasing land disturbance by up to 50% in some applications while simultaneously reducing the risk of containment failures.

Regulatory frameworks worldwide are increasingly focusing on the environmental impacts of industrial processes, with slurry handling receiving particular attention due to its high resource intensity. Companies implementing advanced rheology control strategies not only achieve operational benefits but also position themselves advantageously for compliance with evolving environmental regulations and sustainability certifications.

Scale-up Considerations for Industrial Implementation

Scaling up rheology control strategies from laboratory to industrial scale presents significant challenges that require careful consideration of multiple factors. The transition from small-scale testing to full production environments introduces variables that can dramatically affect slurry behavior and processing efficiency. Equipment design becomes a critical factor, as industrial-scale mixers, pumps, and processing vessels create different shear profiles compared to laboratory equipment. These differences can fundamentally alter the rheological properties of high-throughput slurries, necessitating adjustments to formulations and processing parameters.

Process parameters require systematic scaling methodologies to maintain consistent rheological properties. Temperature gradients, which are more pronounced in large vessels, can create localized variations in viscosity and flow behavior. Similarly, mixing time and energy input must be carefully calibrated to ensure homogeneity without excessive shear degradation of rheology modifiers. The development of scale-up correlations based on dimensionless numbers such as Reynolds and Péclet numbers provides valuable frameworks for predicting behavior across different scales.

Material handling systems represent another crucial consideration in industrial implementation. Continuous processing systems require different rheology control strategies compared to batch operations, particularly regarding the stability of rheological properties over extended production runs. Pumping systems must be designed to accommodate the non-Newtonian behavior of many high-throughput slurries, with particular attention to yield stress and thixotropic recovery times that affect restart capabilities after process interruptions.

Quality control methodologies must evolve with scale-up to ensure consistent rheological properties throughout production. In-line rheometry and real-time monitoring systems become essential for detecting deviations from target specifications and enabling prompt corrective actions. Statistical process control approaches help identify the critical process parameters that most significantly impact rheological properties at industrial scale.

Economic considerations ultimately determine the viability of rheology control strategies in industrial settings. The cost-effectiveness of rheology modifiers must be evaluated at production scale, where even small percentage reductions in additive concentrations can yield substantial cost savings. Additionally, energy consumption related to pumping and mixing high-viscosity slurries represents a significant operational expense that can be optimized through rheology control. The development of robust scale-up protocols that address these considerations enables successful technology transfer from laboratory innovation to industrial implementation, ensuring consistent product quality while maximizing operational efficiency.

Process parameters require systematic scaling methodologies to maintain consistent rheological properties. Temperature gradients, which are more pronounced in large vessels, can create localized variations in viscosity and flow behavior. Similarly, mixing time and energy input must be carefully calibrated to ensure homogeneity without excessive shear degradation of rheology modifiers. The development of scale-up correlations based on dimensionless numbers such as Reynolds and Péclet numbers provides valuable frameworks for predicting behavior across different scales.

Material handling systems represent another crucial consideration in industrial implementation. Continuous processing systems require different rheology control strategies compared to batch operations, particularly regarding the stability of rheological properties over extended production runs. Pumping systems must be designed to accommodate the non-Newtonian behavior of many high-throughput slurries, with particular attention to yield stress and thixotropic recovery times that affect restart capabilities after process interruptions.

Quality control methodologies must evolve with scale-up to ensure consistent rheological properties throughout production. In-line rheometry and real-time monitoring systems become essential for detecting deviations from target specifications and enabling prompt corrective actions. Statistical process control approaches help identify the critical process parameters that most significantly impact rheological properties at industrial scale.

Economic considerations ultimately determine the viability of rheology control strategies in industrial settings. The cost-effectiveness of rheology modifiers must be evaluated at production scale, where even small percentage reductions in additive concentrations can yield substantial cost savings. Additionally, energy consumption related to pumping and mixing high-viscosity slurries represents a significant operational expense that can be optimized through rheology control. The development of robust scale-up protocols that address these considerations enables successful technology transfer from laboratory innovation to industrial implementation, ensuring consistent product quality while maximizing operational efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!