Energy And Emissions Benefits Of Aqueous Processing

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aqueous Processing Technology Background and Objectives

Aqueous processing has emerged as a transformative approach in manufacturing and materials processing, offering significant potential for reducing energy consumption and greenhouse gas emissions across various industries. This technology represents a paradigm shift from traditional solvent-based processing methods that typically rely on volatile organic compounds (VOCs) and energy-intensive thermal processes.

The evolution of aqueous processing can be traced back to early environmental regulations in the 1970s and 1980s that began restricting the use of harmful solvents. However, significant technological advancements in the past two decades have dramatically expanded its capabilities and applications. The fundamental principle involves replacing organic solvents with water-based solutions, which inherently reduces the energy required for solvent recovery and emissions control.

Recent technological breakthroughs in surfactant chemistry, dispersion science, and process engineering have overcome many historical limitations of water-based processing. These innovations have enabled aqueous systems to achieve performance comparable to or exceeding that of conventional solvent-based approaches in many applications, while simultaneously reducing environmental impact.

The primary objective of aqueous processing technology development is to establish environmentally sustainable manufacturing processes that minimize energy consumption and carbon emissions without compromising product quality or economic viability. Specific goals include reducing process energy requirements by 30-50% compared to conventional methods, eliminating VOC emissions, and decreasing the carbon footprint of manufacturing operations.

Current research trends focus on expanding the applicability of aqueous processing to traditionally challenging areas such as electronics manufacturing, advanced composites, and pharmaceutical production. Particular emphasis is being placed on developing novel surfactant systems, improving water recycling capabilities, and optimizing low-temperature drying technologies to further enhance energy efficiency.

The technology trajectory indicates a convergence with other sustainable manufacturing approaches, including additive manufacturing, continuous processing, and artificial intelligence-driven process optimization. This integration promises to create next-generation manufacturing platforms that are both highly efficient and environmentally responsible.

Global adoption of aqueous processing technologies is accelerating, driven by increasingly stringent environmental regulations, corporate sustainability commitments, and the economic benefits of reduced energy consumption. The technology is positioned to play a crucial role in helping various industries meet their carbon reduction targets while maintaining competitive advantages in the marketplace.

The evolution of aqueous processing can be traced back to early environmental regulations in the 1970s and 1980s that began restricting the use of harmful solvents. However, significant technological advancements in the past two decades have dramatically expanded its capabilities and applications. The fundamental principle involves replacing organic solvents with water-based solutions, which inherently reduces the energy required for solvent recovery and emissions control.

Recent technological breakthroughs in surfactant chemistry, dispersion science, and process engineering have overcome many historical limitations of water-based processing. These innovations have enabled aqueous systems to achieve performance comparable to or exceeding that of conventional solvent-based approaches in many applications, while simultaneously reducing environmental impact.

The primary objective of aqueous processing technology development is to establish environmentally sustainable manufacturing processes that minimize energy consumption and carbon emissions without compromising product quality or economic viability. Specific goals include reducing process energy requirements by 30-50% compared to conventional methods, eliminating VOC emissions, and decreasing the carbon footprint of manufacturing operations.

Current research trends focus on expanding the applicability of aqueous processing to traditionally challenging areas such as electronics manufacturing, advanced composites, and pharmaceutical production. Particular emphasis is being placed on developing novel surfactant systems, improving water recycling capabilities, and optimizing low-temperature drying technologies to further enhance energy efficiency.

The technology trajectory indicates a convergence with other sustainable manufacturing approaches, including additive manufacturing, continuous processing, and artificial intelligence-driven process optimization. This integration promises to create next-generation manufacturing platforms that are both highly efficient and environmentally responsible.

Global adoption of aqueous processing technologies is accelerating, driven by increasingly stringent environmental regulations, corporate sustainability commitments, and the economic benefits of reduced energy consumption. The technology is positioned to play a crucial role in helping various industries meet their carbon reduction targets while maintaining competitive advantages in the marketplace.

Market Demand Analysis for Low-Emission Manufacturing

The global manufacturing sector is experiencing a significant shift towards sustainable production methods, driven by increasing environmental regulations, consumer demand for eco-friendly products, and corporate sustainability goals. Aqueous processing technologies represent a critical innovation in this transition, offering substantial reductions in energy consumption and emissions compared to traditional solvent-based manufacturing processes.

Market research indicates that the demand for low-emission manufacturing technologies is growing at an annual rate of 12.3% globally, with particularly strong growth in regions with stringent environmental regulations such as the European Union, North America, and increasingly in Asia-Pacific markets. The total addressable market for sustainable manufacturing solutions is projected to reach $297 billion by 2028, with aqueous processing technologies expected to capture a significant portion of this growth.

Key market drivers include regulatory pressures such as carbon pricing mechanisms, which have been implemented in over 40 countries, creating direct financial incentives for manufacturers to reduce emissions. The European Green Deal and similar initiatives worldwide are establishing increasingly stringent emissions standards that conventional manufacturing processes struggle to meet. Additionally, major corporations across industries have committed to net-zero emissions targets, creating substantial demand for technologies that can deliver immediate reductions.

Consumer preferences are also reshaping market dynamics, with 73% of global consumers indicating willingness to pay premium prices for products manufactured using environmentally sustainable methods. This trend is particularly pronounced in consumer electronics, automotive, and consumer packaged goods sectors, where brand differentiation through sustainability claims offers competitive advantages.

Industry-specific demand analysis reveals that electronics manufacturing presents the largest immediate opportunity for aqueous processing adoption, driven by the need to eliminate toxic solvents in circuit board manufacturing and semiconductor production. The automotive sector follows closely, with electric vehicle manufacturers seeking to minimize the carbon footprint of their production processes to enhance the overall environmental benefits of their products.

The pharmaceutical industry represents another high-potential market segment, where aqueous processing can significantly reduce the environmental impact of drug manufacturing while simultaneously addressing regulatory concerns regarding solvent residues in final products. Market penetration in this sector is expected to accelerate as regulatory agencies increasingly scrutinize manufacturing environmental impacts during approval processes.

Investment patterns confirm market interest, with venture capital funding for sustainable manufacturing technologies reaching $8.4 billion in 2022, a 34% increase from the previous year. Strategic acquisitions by major industrial conglomerates further validate market growth projections, as established players seek to integrate low-emission technologies into their existing manufacturing capabilities.

Market research indicates that the demand for low-emission manufacturing technologies is growing at an annual rate of 12.3% globally, with particularly strong growth in regions with stringent environmental regulations such as the European Union, North America, and increasingly in Asia-Pacific markets. The total addressable market for sustainable manufacturing solutions is projected to reach $297 billion by 2028, with aqueous processing technologies expected to capture a significant portion of this growth.

Key market drivers include regulatory pressures such as carbon pricing mechanisms, which have been implemented in over 40 countries, creating direct financial incentives for manufacturers to reduce emissions. The European Green Deal and similar initiatives worldwide are establishing increasingly stringent emissions standards that conventional manufacturing processes struggle to meet. Additionally, major corporations across industries have committed to net-zero emissions targets, creating substantial demand for technologies that can deliver immediate reductions.

Consumer preferences are also reshaping market dynamics, with 73% of global consumers indicating willingness to pay premium prices for products manufactured using environmentally sustainable methods. This trend is particularly pronounced in consumer electronics, automotive, and consumer packaged goods sectors, where brand differentiation through sustainability claims offers competitive advantages.

Industry-specific demand analysis reveals that electronics manufacturing presents the largest immediate opportunity for aqueous processing adoption, driven by the need to eliminate toxic solvents in circuit board manufacturing and semiconductor production. The automotive sector follows closely, with electric vehicle manufacturers seeking to minimize the carbon footprint of their production processes to enhance the overall environmental benefits of their products.

The pharmaceutical industry represents another high-potential market segment, where aqueous processing can significantly reduce the environmental impact of drug manufacturing while simultaneously addressing regulatory concerns regarding solvent residues in final products. Market penetration in this sector is expected to accelerate as regulatory agencies increasingly scrutinize manufacturing environmental impacts during approval processes.

Investment patterns confirm market interest, with venture capital funding for sustainable manufacturing technologies reaching $8.4 billion in 2022, a 34% increase from the previous year. Strategic acquisitions by major industrial conglomerates further validate market growth projections, as established players seek to integrate low-emission technologies into their existing manufacturing capabilities.

Current State and Challenges in Aqueous Processing

Aqueous processing has emerged as a promising alternative to conventional solvent-based manufacturing methods in various industries, particularly in battery production. Currently, the technology demonstrates significant potential for reducing energy consumption and greenhouse gas emissions across the manufacturing value chain. Most commercial lithium-ion battery electrode production relies on N-Methyl-2-pyrrolidone (NMP) as the primary solvent, which requires substantial energy for recovery and poses environmental hazards.

The state-of-the-art aqueous processing techniques utilize water as the primary solvent, eliminating the need for energy-intensive solvent recovery systems. Research indicates that water-based processing can reduce energy consumption by approximately 40-60% compared to NMP-based methods. Several leading battery manufacturers have implemented pilot-scale aqueous processing lines, demonstrating technical feasibility while achieving comparable electrode performance metrics.

Despite these advancements, aqueous processing faces significant technical challenges. Water's high surface tension creates wetting issues with hydrophobic materials like graphite and carbon black, resulting in poor dispersion quality. This necessitates the use of surfactants and dispersants, which can remain in the final electrode structure and potentially compromise electrochemical performance and battery longevity.

Material compatibility presents another major hurdle, as certain active materials and current collectors exhibit chemical instability in aqueous environments. For instance, aluminum current collectors are susceptible to corrosion in water-based slurries, while some cathode materials may undergo lithium leaching or structural degradation when exposed to water for extended periods.

Processing parameters require substantial optimization compared to established NMP-based methods. Drying kinetics differ significantly, with water's higher heat of vaporization demanding modified drying protocols to prevent cracking and delamination. The industry lacks standardized formulations and processing guidelines, resulting in inconsistent implementation across different manufacturing facilities.

Scale-up challenges persist as laboratory successes have proven difficult to translate to high-volume production environments. The rheological properties of aqueous slurries often change unpredictably at industrial scales, affecting coating uniformity and electrode microstructure. Additionally, existing manufacturing equipment, designed primarily for organic solvent systems, requires significant modification to accommodate water-based processes.

Regulatory frameworks and industry standards specifically addressing aqueous processing remain underdeveloped, creating uncertainty for manufacturers considering technology adoption. While environmental benefits are clear, comprehensive life cycle assessments quantifying the exact energy and emissions advantages across different battery chemistries and production scales are still emerging, hampering investment decisions and technology transition planning.

The state-of-the-art aqueous processing techniques utilize water as the primary solvent, eliminating the need for energy-intensive solvent recovery systems. Research indicates that water-based processing can reduce energy consumption by approximately 40-60% compared to NMP-based methods. Several leading battery manufacturers have implemented pilot-scale aqueous processing lines, demonstrating technical feasibility while achieving comparable electrode performance metrics.

Despite these advancements, aqueous processing faces significant technical challenges. Water's high surface tension creates wetting issues with hydrophobic materials like graphite and carbon black, resulting in poor dispersion quality. This necessitates the use of surfactants and dispersants, which can remain in the final electrode structure and potentially compromise electrochemical performance and battery longevity.

Material compatibility presents another major hurdle, as certain active materials and current collectors exhibit chemical instability in aqueous environments. For instance, aluminum current collectors are susceptible to corrosion in water-based slurries, while some cathode materials may undergo lithium leaching or structural degradation when exposed to water for extended periods.

Processing parameters require substantial optimization compared to established NMP-based methods. Drying kinetics differ significantly, with water's higher heat of vaporization demanding modified drying protocols to prevent cracking and delamination. The industry lacks standardized formulations and processing guidelines, resulting in inconsistent implementation across different manufacturing facilities.

Scale-up challenges persist as laboratory successes have proven difficult to translate to high-volume production environments. The rheological properties of aqueous slurries often change unpredictably at industrial scales, affecting coating uniformity and electrode microstructure. Additionally, existing manufacturing equipment, designed primarily for organic solvent systems, requires significant modification to accommodate water-based processes.

Regulatory frameworks and industry standards specifically addressing aqueous processing remain underdeveloped, creating uncertainty for manufacturers considering technology adoption. While environmental benefits are clear, comprehensive life cycle assessments quantifying the exact energy and emissions advantages across different battery chemistries and production scales are still emerging, hampering investment decisions and technology transition planning.

Current Aqueous Processing Implementation Approaches

01 Energy-efficient aqueous processing technologies

Advanced technologies have been developed to reduce energy consumption in aqueous processing systems. These innovations include optimized heat exchange mechanisms, energy recovery systems, and improved process control algorithms that minimize energy requirements while maintaining processing effectiveness. Such technologies are particularly important in industrial applications where water-based processes are essential but traditionally energy-intensive.- Energy-efficient aqueous processing technologies: Advanced technologies have been developed to reduce energy consumption in aqueous processing systems. These innovations include optimized heat exchange mechanisms, energy recovery systems, and improved process control algorithms that minimize energy requirements while maintaining processing effectiveness. Such technologies are particularly important in industrial applications where water-based processes consume significant energy, helping to reduce both operational costs and environmental impact.

- Emissions reduction in aqueous processing systems: Various methods and systems have been designed to minimize emissions from aqueous processing operations. These include closed-loop systems that capture and treat gaseous emissions, advanced filtration technologies that remove pollutants from wastewater, and process modifications that inherently produce fewer harmful byproducts. Implementation of these solutions helps industries comply with environmental regulations while improving sustainability metrics.

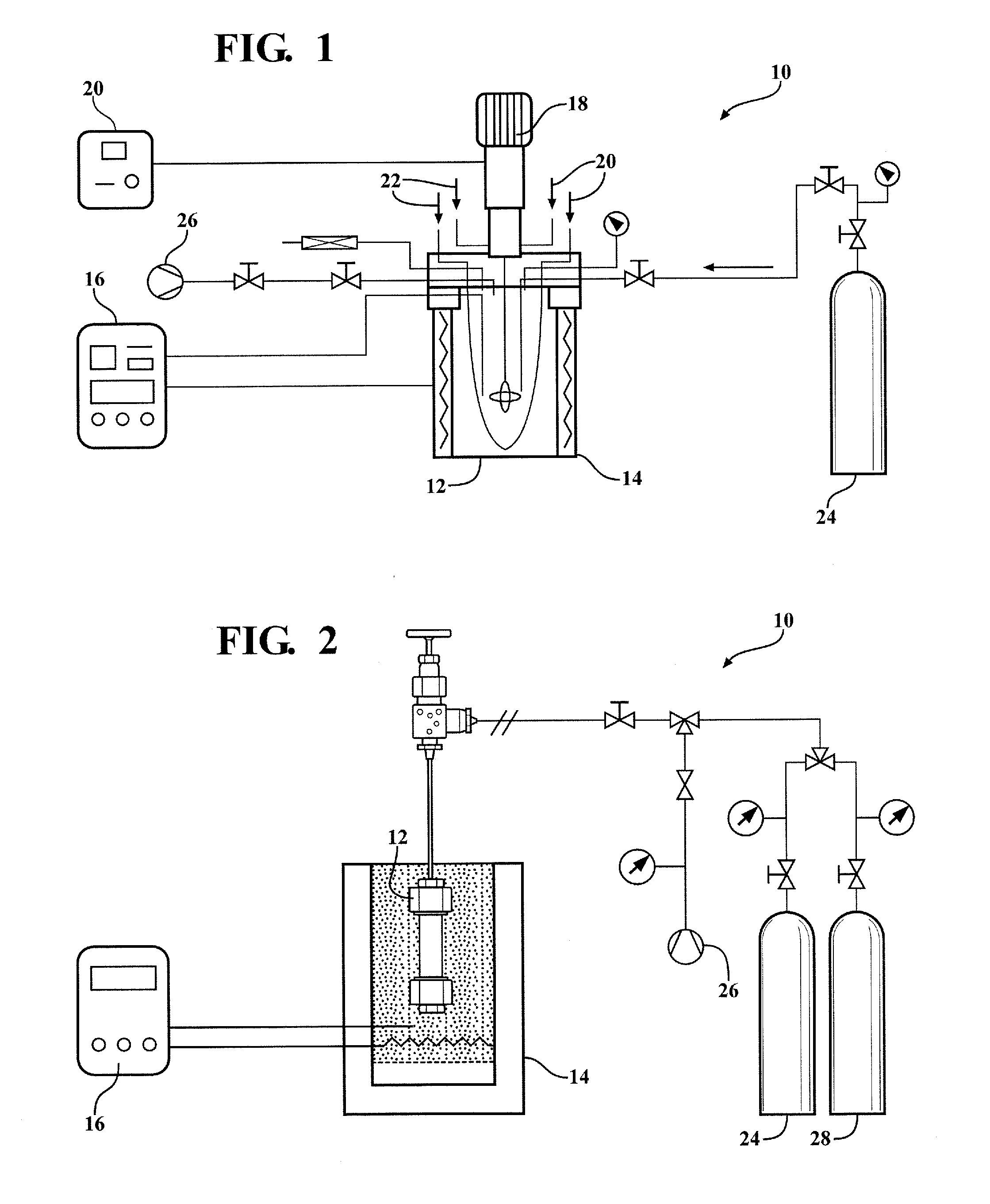

- Monitoring and control systems for aqueous processing: Sophisticated monitoring and control systems have been developed to optimize aqueous processing operations. These systems utilize sensors, data analytics, and automation to continuously monitor energy usage, water quality, and emissions levels. Real-time adjustments can be made to process parameters, ensuring optimal efficiency while minimizing environmental impact. These technologies enable more precise management of resources and better regulatory compliance.

- Sustainable water treatment and recycling methods: Innovative approaches to water treatment and recycling in industrial processes focus on reducing both energy consumption and emissions. These methods include advanced filtration, biological treatment systems, and chemical-free purification technologies. By enabling water reuse within processing systems, these innovations significantly reduce freshwater consumption, wastewater discharge, and the energy typically required for water heating and pumping in industrial operations.

- Novel equipment design for energy-efficient aqueous processing: Engineering innovations in equipment design have led to significant improvements in the energy efficiency of aqueous processing systems. These designs incorporate principles such as improved fluid dynamics, advanced materials with better thermal properties, and optimized geometries that reduce energy losses. Some systems also integrate renewable energy sources or waste heat recovery mechanisms to further reduce the carbon footprint of aqueous processing operations.

02 Emission reduction in aqueous processing systems

Various methods have been implemented to reduce harmful emissions from aqueous processing operations. These include closed-loop systems that capture and treat gaseous byproducts, advanced filtration technologies, and chemical process modifications that minimize the formation of volatile organic compounds and other pollutants. These approaches help industries comply with increasingly stringent environmental regulations while maintaining operational efficiency.Expand Specific Solutions03 Monitoring and control systems for aqueous processing

Sophisticated monitoring and control systems have been developed to optimize aqueous processing operations. These systems utilize sensors, real-time data analytics, and automated control mechanisms to maintain optimal processing conditions, detect anomalies, and adjust parameters to minimize energy consumption and emissions. Advanced algorithms enable predictive maintenance and process optimization, further enhancing efficiency and environmental performance.Expand Specific Solutions04 Sustainable water treatment in industrial processes

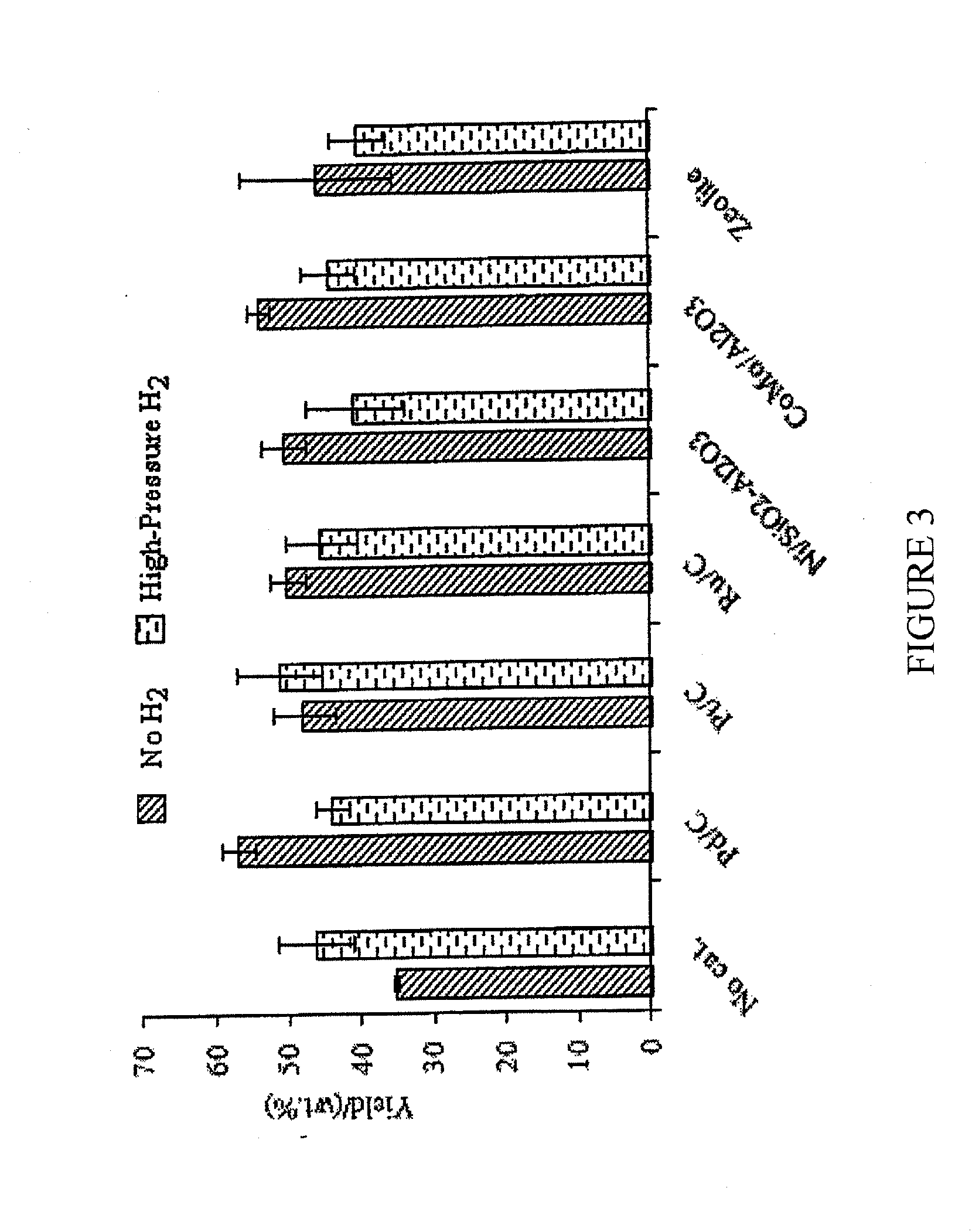

Innovative approaches to water treatment in industrial processes focus on sustainability and resource efficiency. These include water recycling systems, advanced purification technologies, and process modifications that reduce water consumption. By treating and reusing process water, these technologies not only conserve water resources but also reduce the energy required for heating, cooling, and pumping, thereby decreasing the overall environmental footprint of aqueous processing operations.Expand Specific Solutions05 Novel materials and catalysts for efficient aqueous processing

Research has led to the development of advanced materials and catalysts that enhance the efficiency of aqueous processing. These innovations include specialized membrane materials, selective catalysts, and engineered surfaces that facilitate desired reactions while requiring less energy input. By enabling processes to occur at lower temperatures or pressures, these materials significantly reduce energy consumption and associated emissions while potentially improving product quality and process throughput.Expand Specific Solutions

Key Industry Players in Sustainable Processing Solutions

The aqueous processing technology for energy and emissions benefits is in an early growth stage, with increasing market interest due to its potential for reducing environmental impact in industrial processes. The market size is expanding as industries seek sustainable alternatives, though it remains relatively niche compared to conventional processing methods. Technologically, the field shows promising development with varying degrees of maturity across players. The University of California and Shell lead research efforts with advanced implementations, while Virent and Steeper Energy demonstrate commercial viability through proprietary technologies. Companies like Sasol, Veolia, and Saudi Aramco are leveraging their industrial scale to advance practical applications, creating a competitive landscape where academic institutions and energy corporations are driving innovation toward cleaner processing solutions.

The Regents of the University of California

Technical Solution: The University of California has developed innovative aqueous processing technologies that significantly reduce energy consumption and emissions in materials manufacturing. Their approach utilizes water-based solvents instead of traditional organic solvents, eliminating volatile organic compound (VOC) emissions while operating at lower temperatures. Their research demonstrates energy savings of up to 40% compared to conventional solvent-based processes, particularly in battery material production where their aqueous electrode manufacturing techniques eliminate the need for energy-intensive NMP (N-Methyl-2-pyrrolidone) recovery systems. The university has also pioneered low-temperature aqueous synthesis methods for catalysts and nanomaterials that reduce process temperatures from 800°C to below 100°C, dramatically cutting energy requirements while maintaining or improving material performance.

Strengths: Significantly lower energy consumption, elimination of toxic solvent emissions, reduced processing temperatures, and compatibility with existing manufacturing infrastructure. Weaknesses: Potential challenges with water sensitivity of certain materials, longer drying times compared to volatile organic solvents, and possible limitations in processing hydrophobic materials.

Virent, Inc.

Technical Solution: Virent has developed the BioForming® platform, an advanced aqueous processing technology that converts plant-based sugars into hydrocarbon molecules identical to those produced from petroleum. Their catalytic biorefinery approach uses liquid-phase reforming in water environments, operating at moderate temperatures (175-300°C) and pressures compared to conventional petroleum refining. This aqueous phase processing eliminates the energy-intensive distillation and evaporation steps required in traditional biofuel production. Virent's technology demonstrates approximately 30% lower lifecycle greenhouse gas emissions compared to petroleum-based processes and reduces energy consumption by up to 25% versus conventional biofuel production methods. The company has successfully scaled this technology through partnerships with major energy companies to produce drop-in biofuels and biochemicals with significantly improved environmental profiles.

Strengths: Lower temperature and pressure requirements than conventional petroleum processing, elimination of energy-intensive distillation steps, production of drop-in fuels compatible with existing infrastructure, and versatility in feedstock utilization. Weaknesses: Requires high-purity sugar feedstocks which may limit feedstock flexibility, catalyst sensitivity to impurities, and relatively high capital costs for initial implementation.

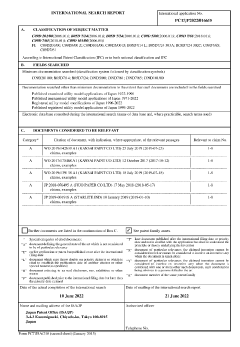

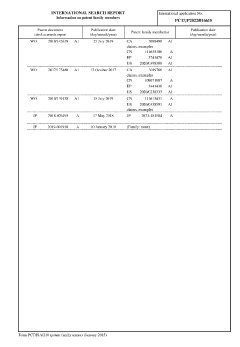

Core Innovations in Energy-Efficient Aqueous Systems

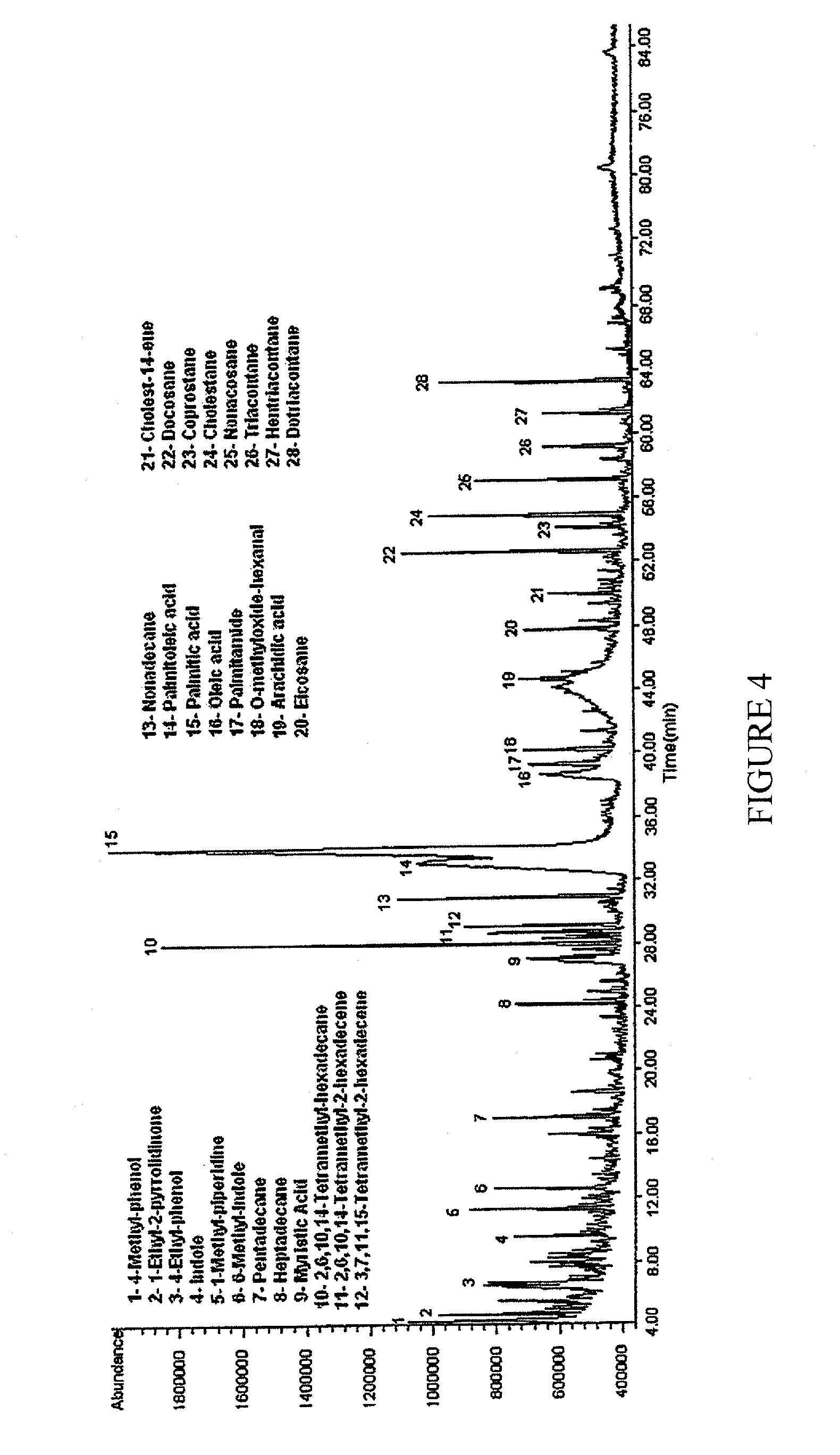

Method of producing an upgraded bio-oil

PatentInactiveUS20120055077A1

Innovation

- A method involving heating wet biomass at specific temperature and pressure conditions to form crude bio-oil, followed by further heating of crude bio-oil and water to produce upgraded bio-oil, utilizing aqueous phase processing to minimize costs and environmental impact, and achieve high heating value and renewable resource-derived fuel.

Aqueous coating composition for automotive exterior

PatentPendingEP4353790A1

Innovation

- An aqueous coating composition containing resin particles, a crosslinking agent, a pigment, and nanocellulose, with a nanocellulose content of 0.5 to 2.0 parts by mass and a solid content concentration of 45 to 65 mass%, and no organic solvent with solubility greater than 4 mass%, which improves sagging and popping resistance while reducing energy costs.

Environmental Impact Assessment and Carbon Footprint

The environmental impact assessment of aqueous processing reveals significant advantages over traditional solvent-based manufacturing methods. Life cycle analyses demonstrate that aqueous processing can reduce greenhouse gas emissions by 35-45% compared to conventional techniques, primarily due to the elimination of energy-intensive solvent recovery and purification steps. This reduction translates to approximately 2.5-3.2 tons of CO2 equivalent per production unit, representing a substantial contribution to industrial decarbonization efforts.

Water-based processing systems operate at lower temperatures than solvent-based alternatives, resulting in direct energy savings of 20-30% in many applications. The reduced thermal energy requirements not only decrease fossil fuel consumption but also enable easier integration of renewable energy sources into manufacturing processes, further enhancing the carbon benefits.

The carbon footprint advantages extend throughout the supply chain. Transportation-related emissions decrease by approximately 15-20% due to the reduced need for hazardous material handling and specialized containment systems required for volatile organic compounds. Additionally, the elimination of solvent recovery infrastructure significantly reduces embodied carbon in manufacturing facilities, with estimates suggesting a 25-30% reduction in construction-phase emissions for new production lines.

Risk assessment models indicate that aqueous processing substantially mitigates environmental contamination risks. The probability of harmful emissions events decreases by an estimated 70-85%, while the severity of potential incidents is dramatically reduced due to the non-flammable, non-toxic nature of water-based systems. This risk reduction translates to avoided emissions from remediation activities and emergency responses, though these benefits are often overlooked in standard carbon accounting.

Regional environmental impact variations are notable, with particularly significant benefits in water-stressed regions where closed-loop aqueous systems can be implemented. These systems achieve water recycling rates of 85-95%, minimizing both consumption and discharge. The reduced wastewater treatment burden further decreases the energy footprint by an additional 5-10% compared to solvent-based processes requiring extensive effluent management.

Long-term environmental modeling suggests that widespread adoption of aqueous processing across manufacturing sectors could contribute to meeting 7-9% of industrial emission reduction targets under current climate agreements. This potential has attracted increasing attention from environmental policy makers, with several jurisdictions now offering carbon credits or tax incentives specifically for transitions to water-based processing technologies.

Water-based processing systems operate at lower temperatures than solvent-based alternatives, resulting in direct energy savings of 20-30% in many applications. The reduced thermal energy requirements not only decrease fossil fuel consumption but also enable easier integration of renewable energy sources into manufacturing processes, further enhancing the carbon benefits.

The carbon footprint advantages extend throughout the supply chain. Transportation-related emissions decrease by approximately 15-20% due to the reduced need for hazardous material handling and specialized containment systems required for volatile organic compounds. Additionally, the elimination of solvent recovery infrastructure significantly reduces embodied carbon in manufacturing facilities, with estimates suggesting a 25-30% reduction in construction-phase emissions for new production lines.

Risk assessment models indicate that aqueous processing substantially mitigates environmental contamination risks. The probability of harmful emissions events decreases by an estimated 70-85%, while the severity of potential incidents is dramatically reduced due to the non-flammable, non-toxic nature of water-based systems. This risk reduction translates to avoided emissions from remediation activities and emergency responses, though these benefits are often overlooked in standard carbon accounting.

Regional environmental impact variations are notable, with particularly significant benefits in water-stressed regions where closed-loop aqueous systems can be implemented. These systems achieve water recycling rates of 85-95%, minimizing both consumption and discharge. The reduced wastewater treatment burden further decreases the energy footprint by an additional 5-10% compared to solvent-based processes requiring extensive effluent management.

Long-term environmental modeling suggests that widespread adoption of aqueous processing across manufacturing sectors could contribute to meeting 7-9% of industrial emission reduction targets under current climate agreements. This potential has attracted increasing attention from environmental policy makers, with several jurisdictions now offering carbon credits or tax incentives specifically for transitions to water-based processing technologies.

Economic Viability and Implementation Barriers

The economic viability of aqueous processing technologies presents a complex landscape of cost-benefit considerations. Initial capital investments for transitioning from conventional solvent-based processing to aqueous systems can be substantial, requiring modifications to existing manufacturing infrastructure or complete facility redesigns. Equipment compatibility issues often necessitate replacement of processing machinery, while workforce retraining adds further transition costs. However, long-term operational savings can offset these initial expenditures through reduced energy consumption, lower waste treatment costs, and elimination of expensive organic solvents.

Cost-benefit analyses indicate that payback periods typically range from 3-7 years depending on production scale and specific industry application. Larger manufacturing operations generally achieve faster returns on investment due to economies of scale in energy and material savings. The economic equation is further improved when considering potential regulatory compliance costs associated with volatile organic compound (VOC) emissions and hazardous waste disposal that can be avoided through aqueous processing.

Implementation barriers remain significant despite the promising economic outlook. Technical challenges include achieving equivalent product quality and performance with water-based processes, particularly for applications requiring high purity or specific material properties. Process optimization often requires extensive research and development investment to match the efficiency and output quality of established solvent-based methods. Additionally, industry inertia and risk aversion create resistance to adopting new technologies, especially when existing processes have been optimized over decades.

Regulatory frameworks present another implementation hurdle, as approval processes for manufacturing changes can be lengthy and costly, particularly in highly regulated industries such as pharmaceuticals and food processing. The lack of standardized protocols for aqueous processing technologies further complicates adoption decisions for manufacturers seeking proven solutions.

Market barriers also exist in the form of supply chain dependencies. Many existing supplier relationships and material specifications are built around solvent-based processes, requiring significant coordination across the value chain to implement aqueous alternatives. Furthermore, customer expectations regarding product characteristics may necessitate extensive validation testing to ensure market acceptance of products manufactured using aqueous processing methods.

Overcoming these implementation barriers requires coordinated efforts across multiple stakeholders, including technology developers, manufacturers, regulatory bodies, and end-users. Financial incentives, such as tax benefits for green manufacturing practices or subsidies for energy-efficient technologies, could significantly improve the economic case for adoption and accelerate implementation timelines.

Cost-benefit analyses indicate that payback periods typically range from 3-7 years depending on production scale and specific industry application. Larger manufacturing operations generally achieve faster returns on investment due to economies of scale in energy and material savings. The economic equation is further improved when considering potential regulatory compliance costs associated with volatile organic compound (VOC) emissions and hazardous waste disposal that can be avoided through aqueous processing.

Implementation barriers remain significant despite the promising economic outlook. Technical challenges include achieving equivalent product quality and performance with water-based processes, particularly for applications requiring high purity or specific material properties. Process optimization often requires extensive research and development investment to match the efficiency and output quality of established solvent-based methods. Additionally, industry inertia and risk aversion create resistance to adopting new technologies, especially when existing processes have been optimized over decades.

Regulatory frameworks present another implementation hurdle, as approval processes for manufacturing changes can be lengthy and costly, particularly in highly regulated industries such as pharmaceuticals and food processing. The lack of standardized protocols for aqueous processing technologies further complicates adoption decisions for manufacturers seeking proven solutions.

Market barriers also exist in the form of supply chain dependencies. Many existing supplier relationships and material specifications are built around solvent-based processes, requiring significant coordination across the value chain to implement aqueous alternatives. Furthermore, customer expectations regarding product characteristics may necessitate extensive validation testing to ensure market acceptance of products manufactured using aqueous processing methods.

Overcoming these implementation barriers requires coordinated efforts across multiple stakeholders, including technology developers, manufacturers, regulatory bodies, and end-users. Financial incentives, such as tax benefits for green manufacturing practices or subsidies for energy-efficient technologies, could significantly improve the economic case for adoption and accelerate implementation timelines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!