Techniques for Carboxylic Acid-Based Antioxidant Production

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carboxylic Antioxidant Evolution and Objectives

Carboxylic acid-based antioxidants have emerged as a crucial class of compounds in various industries, particularly in food preservation, cosmetics, and pharmaceuticals. The evolution of these antioxidants can be traced back to the early 20th century when scientists first recognized the role of oxidative stress in cellular damage and aging processes.

Initially, research focused on naturally occurring antioxidants such as ascorbic acid (vitamin C) and tocopherols (vitamin E). However, as the demand for more potent and stable antioxidants grew, attention shifted towards synthetic alternatives. The 1950s and 1960s saw significant advancements in the development of carboxylic acid-based antioxidants, with the introduction of compounds like butylated hydroxyanisole (BHA) and butylated hydroxytoluene (BHT).

The subsequent decades witnessed a surge in research aimed at understanding the mechanisms of antioxidant action and developing more efficient production techniques. This period also saw an increased emphasis on the safety and regulatory aspects of antioxidant use, leading to the exploration of novel carboxylic acid derivatives with improved toxicological profiles.

In recent years, the focus has shifted towards sustainable and eco-friendly production methods for carboxylic acid-based antioxidants. This trend is driven by growing consumer demand for natural and clean-label products, as well as stricter environmental regulations. Consequently, researchers are exploring bio-based feedstocks and green chemistry approaches to synthesize these compounds.

The current objectives in the field of carboxylic acid-based antioxidant production are multifaceted. Firstly, there is a push to develop more efficient and cost-effective synthesis routes, utilizing advanced catalytic systems and process intensification techniques. Secondly, researchers aim to enhance the stability and efficacy of these antioxidants under various environmental conditions, expanding their applicability across different industries.

Another key objective is to design multifunctional carboxylic acid-based antioxidants that can simultaneously address multiple aspects of oxidative stress and provide additional benefits such as antimicrobial activity. This approach aims to create value-added products that can meet the complex demands of modern applications.

Furthermore, there is a growing interest in understanding the synergistic effects between different carboxylic acid-based antioxidants and other bioactive compounds. This knowledge can lead to the development of optimized antioxidant blends with enhanced performance and broader spectrum of activity.

Lastly, as regulatory scrutiny intensifies, a critical objective is to ensure the safety and biocompatibility of newly developed carboxylic acid-based antioxidants. This involves comprehensive toxicological studies and the exploration of natural alternatives that can match or exceed the performance of synthetic compounds while meeting stringent safety standards.

Initially, research focused on naturally occurring antioxidants such as ascorbic acid (vitamin C) and tocopherols (vitamin E). However, as the demand for more potent and stable antioxidants grew, attention shifted towards synthetic alternatives. The 1950s and 1960s saw significant advancements in the development of carboxylic acid-based antioxidants, with the introduction of compounds like butylated hydroxyanisole (BHA) and butylated hydroxytoluene (BHT).

The subsequent decades witnessed a surge in research aimed at understanding the mechanisms of antioxidant action and developing more efficient production techniques. This period also saw an increased emphasis on the safety and regulatory aspects of antioxidant use, leading to the exploration of novel carboxylic acid derivatives with improved toxicological profiles.

In recent years, the focus has shifted towards sustainable and eco-friendly production methods for carboxylic acid-based antioxidants. This trend is driven by growing consumer demand for natural and clean-label products, as well as stricter environmental regulations. Consequently, researchers are exploring bio-based feedstocks and green chemistry approaches to synthesize these compounds.

The current objectives in the field of carboxylic acid-based antioxidant production are multifaceted. Firstly, there is a push to develop more efficient and cost-effective synthesis routes, utilizing advanced catalytic systems and process intensification techniques. Secondly, researchers aim to enhance the stability and efficacy of these antioxidants under various environmental conditions, expanding their applicability across different industries.

Another key objective is to design multifunctional carboxylic acid-based antioxidants that can simultaneously address multiple aspects of oxidative stress and provide additional benefits such as antimicrobial activity. This approach aims to create value-added products that can meet the complex demands of modern applications.

Furthermore, there is a growing interest in understanding the synergistic effects between different carboxylic acid-based antioxidants and other bioactive compounds. This knowledge can lead to the development of optimized antioxidant blends with enhanced performance and broader spectrum of activity.

Lastly, as regulatory scrutiny intensifies, a critical objective is to ensure the safety and biocompatibility of newly developed carboxylic acid-based antioxidants. This involves comprehensive toxicological studies and the exploration of natural alternatives that can match or exceed the performance of synthetic compounds while meeting stringent safety standards.

Market Analysis for Carboxylic Acid Antioxidants

The global market for carboxylic acid-based antioxidants has experienced significant growth in recent years, driven by increasing demand across various industries. These antioxidants play a crucial role in preserving the quality and extending the shelf life of products in sectors such as food and beverages, pharmaceuticals, cosmetics, and industrial applications.

In the food and beverage industry, carboxylic acid antioxidants are widely used to prevent rancidity and maintain product freshness. The growing consumer awareness of food safety and the preference for clean-label products have fueled the demand for natural antioxidants derived from carboxylic acids. This trend is particularly evident in developed markets where consumers are willing to pay a premium for products with natural preservatives.

The pharmaceutical sector represents another significant market for carboxylic acid antioxidants. These compounds are utilized in drug formulations to enhance stability and prevent oxidation of active ingredients. With the expanding pharmaceutical industry, especially in emerging economies, the demand for high-quality antioxidants is expected to rise steadily.

Cosmetics and personal care products also contribute substantially to the market growth of carboxylic acid antioxidants. These compounds are incorporated into skincare formulations to protect against free radical damage and maintain product integrity. The increasing consumer focus on anti-aging and natural skincare solutions has bolstered the demand for antioxidants in this sector.

Industrial applications, including plastics, rubber, and lubricants, form another significant market segment for carboxylic acid antioxidants. These compounds help prevent degradation and extend the lifespan of materials exposed to harsh environmental conditions. The growing automotive and construction industries in developing countries are expected to drive demand in this sector.

Geographically, North America and Europe currently dominate the carboxylic acid antioxidant market due to stringent regulations on food safety and increasing consumer awareness. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, propelled by rapid industrialization, changing dietary habits, and increasing disposable incomes.

Key market players in the carboxylic acid antioxidant industry include BASF SE, Eastman Chemical Company, Koninklijke DSM N.V., and Archer Daniels Midland Company. These companies are focusing on research and development to introduce innovative products and expand their market share. Strategic partnerships and mergers are also common strategies employed to strengthen market positions and broaden product portfolios.

In the food and beverage industry, carboxylic acid antioxidants are widely used to prevent rancidity and maintain product freshness. The growing consumer awareness of food safety and the preference for clean-label products have fueled the demand for natural antioxidants derived from carboxylic acids. This trend is particularly evident in developed markets where consumers are willing to pay a premium for products with natural preservatives.

The pharmaceutical sector represents another significant market for carboxylic acid antioxidants. These compounds are utilized in drug formulations to enhance stability and prevent oxidation of active ingredients. With the expanding pharmaceutical industry, especially in emerging economies, the demand for high-quality antioxidants is expected to rise steadily.

Cosmetics and personal care products also contribute substantially to the market growth of carboxylic acid antioxidants. These compounds are incorporated into skincare formulations to protect against free radical damage and maintain product integrity. The increasing consumer focus on anti-aging and natural skincare solutions has bolstered the demand for antioxidants in this sector.

Industrial applications, including plastics, rubber, and lubricants, form another significant market segment for carboxylic acid antioxidants. These compounds help prevent degradation and extend the lifespan of materials exposed to harsh environmental conditions. The growing automotive and construction industries in developing countries are expected to drive demand in this sector.

Geographically, North America and Europe currently dominate the carboxylic acid antioxidant market due to stringent regulations on food safety and increasing consumer awareness. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, propelled by rapid industrialization, changing dietary habits, and increasing disposable incomes.

Key market players in the carboxylic acid antioxidant industry include BASF SE, Eastman Chemical Company, Koninklijke DSM N.V., and Archer Daniels Midland Company. These companies are focusing on research and development to introduce innovative products and expand their market share. Strategic partnerships and mergers are also common strategies employed to strengthen market positions and broaden product portfolios.

Current Challenges in Antioxidant Synthesis

The synthesis of carboxylic acid-based antioxidants faces several significant challenges in the current landscape. One of the primary obstacles is the complexity of the chemical reactions involved. These reactions often require multiple steps, precise control of reaction conditions, and the use of expensive catalysts or reagents. This complexity not only increases production costs but also makes it difficult to scale up production for industrial applications.

Another major challenge is the environmental impact of traditional synthesis methods. Many conventional processes for producing carboxylic acid-based antioxidants involve the use of toxic solvents, generate substantial waste, and consume significant energy. This has led to increasing pressure from regulatory bodies and consumers for more sustainable production methods, pushing researchers to explore greener alternatives.

The purity and stability of the final product present additional hurdles. Carboxylic acid-based antioxidants are often sensitive to environmental factors such as light, heat, and oxygen. Ensuring high purity and maintaining stability during production, storage, and application is crucial for product efficacy but can be technically challenging and costly to achieve consistently.

Yield optimization remains a persistent issue in antioxidant synthesis. Current methods often result in relatively low yields, which impacts the economic viability of production. Improving reaction efficiency and reducing side product formation are ongoing areas of research, with scientists exploring novel catalysts and reaction conditions to enhance yield.

The development of selective synthesis routes poses another significant challenge. Many desirable carboxylic acid-based antioxidants have complex structures with multiple functional groups. Achieving high selectivity in the formation of specific isomers or derivatives while minimizing unwanted by-products requires sophisticated synthetic strategies and often involves intricate purification processes.

Lastly, the regulatory landscape presents a formidable challenge for the development and commercialization of new antioxidant compounds. Stringent safety and efficacy requirements, particularly for antioxidants intended for use in food, pharmaceuticals, or cosmetics, necessitate extensive testing and documentation. This regulatory burden can significantly extend development timelines and increase costs, potentially deterring innovation in the field.

Another major challenge is the environmental impact of traditional synthesis methods. Many conventional processes for producing carboxylic acid-based antioxidants involve the use of toxic solvents, generate substantial waste, and consume significant energy. This has led to increasing pressure from regulatory bodies and consumers for more sustainable production methods, pushing researchers to explore greener alternatives.

The purity and stability of the final product present additional hurdles. Carboxylic acid-based antioxidants are often sensitive to environmental factors such as light, heat, and oxygen. Ensuring high purity and maintaining stability during production, storage, and application is crucial for product efficacy but can be technically challenging and costly to achieve consistently.

Yield optimization remains a persistent issue in antioxidant synthesis. Current methods often result in relatively low yields, which impacts the economic viability of production. Improving reaction efficiency and reducing side product formation are ongoing areas of research, with scientists exploring novel catalysts and reaction conditions to enhance yield.

The development of selective synthesis routes poses another significant challenge. Many desirable carboxylic acid-based antioxidants have complex structures with multiple functional groups. Achieving high selectivity in the formation of specific isomers or derivatives while minimizing unwanted by-products requires sophisticated synthetic strategies and often involves intricate purification processes.

Lastly, the regulatory landscape presents a formidable challenge for the development and commercialization of new antioxidant compounds. Stringent safety and efficacy requirements, particularly for antioxidants intended for use in food, pharmaceuticals, or cosmetics, necessitate extensive testing and documentation. This regulatory burden can significantly extend development timelines and increase costs, potentially deterring innovation in the field.

Existing Carboxylic Acid Antioxidant Techniques

01 Synthesis methods for carboxylic acid-based antioxidants

Various synthesis methods are employed to produce carboxylic acid-based antioxidants. These methods may involve oxidation reactions, catalytic processes, or the use of specific precursors to form the desired antioxidant compounds. The synthesis routes are designed to optimize yield, purity, and efficiency in the production of these valuable antioxidants.- Synthesis methods for carboxylic acid-based antioxidants: Various synthesis methods are employed to produce carboxylic acid-based antioxidants. These methods may involve oxidation reactions, catalytic processes, or the use of specific precursors to form the desired antioxidant compounds. The synthesis routes are designed to optimize yield, purity, and efficiency in the production of these valuable antioxidants.

- Purification and isolation techniques: After synthesis, carboxylic acid-based antioxidants require purification and isolation. Techniques such as crystallization, distillation, chromatography, and extraction are commonly used to separate the desired antioxidants from reaction mixtures and impurities. These processes are crucial for obtaining high-quality antioxidants suitable for various applications.

- Production of specific carboxylic acid antioxidants: The production of specific carboxylic acid-based antioxidants, such as ascorbic acid derivatives or phenolic acids, involves tailored processes. These may include specialized reaction conditions, specific catalysts, or unique precursor materials to achieve the desired antioxidant structure and properties.

- Industrial scale-up and process optimization: Scaling up the production of carboxylic acid-based antioxidants from laboratory to industrial scale requires careful process optimization. This involves considerations such as reactor design, heat transfer, mixing efficiency, and process control to ensure consistent quality and yield in large-scale production.

- Formulation and stabilization of antioxidants: The formulation of carboxylic acid-based antioxidants into stable products is crucial for their effectiveness and shelf life. This may involve the use of stabilizers, encapsulation techniques, or specific delivery systems to protect the antioxidants from degradation and enhance their performance in various applications.

02 Purification and isolation techniques

After synthesis, carboxylic acid-based antioxidants require purification and isolation. Techniques such as crystallization, distillation, and chromatography are commonly used to separate the desired antioxidants from byproducts and unreacted starting materials. These processes ensure the production of high-quality antioxidants suitable for various applications.Expand Specific Solutions03 Production of specific carboxylic acid-based antioxidants

The production of specific carboxylic acid-based antioxidants, such as ascorbic acid derivatives or phenolic acids, involves tailored synthesis routes and specialized processing conditions. These antioxidants may have unique properties or applications that require specific production methods to achieve the desired molecular structure and functionality.Expand Specific Solutions04 Scale-up and industrial production processes

Scaling up the production of carboxylic acid-based antioxidants from laboratory to industrial scale requires careful process optimization. This involves designing efficient reactor systems, implementing continuous flow processes, and developing strategies for heat and mass transfer on a larger scale. Industrial production processes aim to maximize yield and minimize costs while maintaining product quality.Expand Specific Solutions05 Green chemistry approaches in antioxidant production

Green chemistry principles are increasingly applied in the production of carboxylic acid-based antioxidants. This involves using environmentally friendly solvents, catalysts, and reagents, as well as developing more energy-efficient processes. These approaches aim to reduce the environmental impact of antioxidant production while maintaining or improving product quality and yield.Expand Specific Solutions

Key Industry Players and Competitors

The competitive landscape for techniques in carboxylic acid-based antioxidant production is characterized by a mature market with established players and ongoing research. The industry is in a growth phase, driven by increasing demand for antioxidants in various sectors. Market size is substantial, with major chemical and pharmaceutical companies like Eastman Chemical, Evonik, and Mitsubishi Gas Chemical actively involved. Technological maturity is high, with continuous innovations from both industry leaders and academic institutions such as the University of Science & Technology of China and King Saud University. Companies like Clariant and Ajinomoto are also contributing to advancements in this field, indicating a competitive and dynamic environment for carboxylic acid-based antioxidant production techniques.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced techniques for carboxylic acid-based antioxidant production, focusing on improving the efficiency and sustainability of the process. Their approach involves a novel catalytic oxidation method that utilizes a proprietary metal-organic framework (MOF) catalyst[1]. This catalyst enhances the selective oxidation of primary alcohols to carboxylic acids under mild conditions, reducing energy consumption and improving yield. Additionally, Sinopec has implemented a continuous flow reactor system that allows for better control of reaction parameters and increased production capacity[3]. The company has also invested in green chemistry principles, incorporating bio-based feedstocks and solvent recycling techniques to minimize environmental impact[5].

Strengths: High efficiency, improved selectivity, and reduced environmental impact. Weaknesses: Potential high initial investment costs and dependency on specific catalysts.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has pioneered a sustainable approach to carboxylic acid-based antioxidant production through their proprietary "GEM Technology" (Green Enzymatic Manufacturing)[2]. This process utilizes biocatalysts, specifically engineered enzymes, to catalyze the oxidation of alcohols to carboxylic acids under ambient conditions. The enzymatic approach significantly reduces energy requirements and eliminates the need for heavy metal catalysts. Eastman has also developed a novel purification technique that combines membrane separation and crystallization, enhancing the purity of the final product while reducing solvent usage[4]. Furthermore, the company has implemented a closed-loop system for recycling reaction media and recovering unreacted substrates, improving overall process efficiency and reducing waste[6].

Strengths: Environmentally friendly, high product purity, and reduced energy consumption. Weaknesses: Potential scalability challenges and sensitivity of enzymes to process conditions.

Innovative Patents in Antioxidant Synthesis

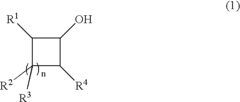

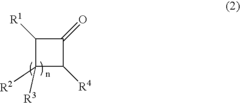

Method for producing carboxylic acid

PatentInactiveUS20050215817A1

Innovation

- A method involving a heterogeneous solution system where oily alicyclic alcohols or ketones react with aqueous hydrogen peroxide in the presence of a catalyst from Group 6 of the Periodic Table, such as chromium, molybdenum, or tungsten, under mild conditions, eliminating the need for polar solvents and simplifying the reaction process.

Method for producing carboxylic acid

PatentInactiveIN237CHENP2005A

Innovation

- A method involving a heterogeneous solution system where oily alicyclic alcohols or ketones react with aqueous hydrogen peroxide in the presence of a catalyst from Group 6 of the Periodic Table, such as chromium, molybdenum, or tungsten, under mild conditions, eliminating the need for polar solvents and simplifying the reaction process.

Environmental Impact of Antioxidant Manufacturing

The production of carboxylic acid-based antioxidants has significant environmental implications that must be carefully considered. These manufacturing processes often involve the use of various chemicals and solvents, which can potentially lead to environmental contamination if not properly managed.

One of the primary environmental concerns is the generation of waste products during the synthesis of antioxidants. These may include unreacted starting materials, byproducts, and spent solvents. Proper waste management and disposal protocols are essential to minimize the release of these substances into the environment. Many manufacturers are implementing advanced waste treatment systems to reduce the environmental impact of their operations.

Water usage and wastewater management are also critical factors in antioxidant production. The synthesis processes often require substantial amounts of water for reactions, cooling, and cleaning. Implementing water recycling and treatment systems can significantly reduce the overall water footprint of manufacturing facilities. Additionally, ensuring that wastewater is properly treated before discharge is crucial to prevent contamination of local water bodies.

Air emissions are another important aspect to consider. Volatile organic compounds (VOCs) and other airborne pollutants may be released during various stages of production. Installing efficient air filtration and scrubbing systems can help mitigate these emissions and improve air quality in and around manufacturing facilities.

Energy consumption is a significant contributor to the environmental impact of antioxidant production. The processes often require high temperatures and pressures, leading to substantial energy use. Implementing energy-efficient technologies and exploring renewable energy sources can help reduce the carbon footprint associated with manufacturing operations.

The sourcing of raw materials for antioxidant production also has environmental implications. Sustainable sourcing practices and the use of renewable feedstocks can help minimize the ecological impact of resource extraction and transportation. Some manufacturers are exploring bio-based alternatives to traditional petrochemical-derived starting materials.

Life cycle assessment (LCA) studies have become increasingly important in evaluating the overall environmental impact of antioxidant production. These assessments consider all stages of the product lifecycle, from raw material extraction to end-of-life disposal. LCA results can guide manufacturers in identifying areas for improvement and implementing more sustainable practices throughout the production chain.

As environmental regulations become more stringent globally, antioxidant manufacturers are increasingly focusing on developing greener production methods. This includes exploring alternative synthesis routes that use less harmful reagents, implementing catalytic processes that improve reaction efficiency, and designing closed-loop systems that minimize waste generation and resource consumption.

One of the primary environmental concerns is the generation of waste products during the synthesis of antioxidants. These may include unreacted starting materials, byproducts, and spent solvents. Proper waste management and disposal protocols are essential to minimize the release of these substances into the environment. Many manufacturers are implementing advanced waste treatment systems to reduce the environmental impact of their operations.

Water usage and wastewater management are also critical factors in antioxidant production. The synthesis processes often require substantial amounts of water for reactions, cooling, and cleaning. Implementing water recycling and treatment systems can significantly reduce the overall water footprint of manufacturing facilities. Additionally, ensuring that wastewater is properly treated before discharge is crucial to prevent contamination of local water bodies.

Air emissions are another important aspect to consider. Volatile organic compounds (VOCs) and other airborne pollutants may be released during various stages of production. Installing efficient air filtration and scrubbing systems can help mitigate these emissions and improve air quality in and around manufacturing facilities.

Energy consumption is a significant contributor to the environmental impact of antioxidant production. The processes often require high temperatures and pressures, leading to substantial energy use. Implementing energy-efficient technologies and exploring renewable energy sources can help reduce the carbon footprint associated with manufacturing operations.

The sourcing of raw materials for antioxidant production also has environmental implications. Sustainable sourcing practices and the use of renewable feedstocks can help minimize the ecological impact of resource extraction and transportation. Some manufacturers are exploring bio-based alternatives to traditional petrochemical-derived starting materials.

Life cycle assessment (LCA) studies have become increasingly important in evaluating the overall environmental impact of antioxidant production. These assessments consider all stages of the product lifecycle, from raw material extraction to end-of-life disposal. LCA results can guide manufacturers in identifying areas for improvement and implementing more sustainable practices throughout the production chain.

As environmental regulations become more stringent globally, antioxidant manufacturers are increasingly focusing on developing greener production methods. This includes exploring alternative synthesis routes that use less harmful reagents, implementing catalytic processes that improve reaction efficiency, and designing closed-loop systems that minimize waste generation and resource consumption.

Regulatory Framework for Food Additives

The regulatory framework for food additives plays a crucial role in ensuring the safety and quality of carboxylic acid-based antioxidants used in food production. In the United States, the Food and Drug Administration (FDA) oversees the approval and regulation of food additives, including antioxidants. The FDA's regulatory process involves rigorous safety assessments and evaluations of scientific data before granting approval for use in food products.

The European Union (EU) has its own regulatory system for food additives, managed by the European Food Safety Authority (EFSA). The EFSA conducts comprehensive risk assessments and provides scientific opinions on the safety of food additives, including carboxylic acid-based antioxidants. The EU maintains a positive list of approved food additives, each assigned a unique E-number for easy identification.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) is responsible for regulating food additives. The Japanese regulatory system includes a list of approved additives and specific usage guidelines. Manufacturers must adhere to these regulations when producing and using carboxylic acid-based antioxidants in food products for the Japanese market.

International organizations, such as the Joint FAO/WHO Expert Committee on Food Additives (JECFA), provide scientific advice and risk assessments on food additives to global regulatory bodies. JECFA's evaluations often serve as a reference for national regulatory agencies when developing their own policies and guidelines.

Many countries have adopted the Codex Alimentarius international food standards, which include guidelines for the use of food additives. These standards help harmonize regulations across different regions and facilitate international trade in food products containing approved additives.

Regulatory frameworks typically require manufacturers to demonstrate the safety and efficacy of carboxylic acid-based antioxidants through extensive toxicological studies and stability tests. Additionally, regulations often specify maximum permitted levels of these additives in various food categories to ensure consumer safety.

Labeling requirements for food products containing carboxylic acid-based antioxidants vary by region but generally mandate the disclosure of additives on product packaging. This transparency allows consumers to make informed choices about the foods they consume.

As scientific knowledge advances and new research emerges, regulatory frameworks for food additives are subject to periodic review and updates. This ongoing process ensures that regulations remain current with the latest scientific evidence and continue to prioritize public health and safety in the use of carboxylic acid-based antioxidants and other food additives.

The European Union (EU) has its own regulatory system for food additives, managed by the European Food Safety Authority (EFSA). The EFSA conducts comprehensive risk assessments and provides scientific opinions on the safety of food additives, including carboxylic acid-based antioxidants. The EU maintains a positive list of approved food additives, each assigned a unique E-number for easy identification.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) is responsible for regulating food additives. The Japanese regulatory system includes a list of approved additives and specific usage guidelines. Manufacturers must adhere to these regulations when producing and using carboxylic acid-based antioxidants in food products for the Japanese market.

International organizations, such as the Joint FAO/WHO Expert Committee on Food Additives (JECFA), provide scientific advice and risk assessments on food additives to global regulatory bodies. JECFA's evaluations often serve as a reference for national regulatory agencies when developing their own policies and guidelines.

Many countries have adopted the Codex Alimentarius international food standards, which include guidelines for the use of food additives. These standards help harmonize regulations across different regions and facilitate international trade in food products containing approved additives.

Regulatory frameworks typically require manufacturers to demonstrate the safety and efficacy of carboxylic acid-based antioxidants through extensive toxicological studies and stability tests. Additionally, regulations often specify maximum permitted levels of these additives in various food categories to ensure consumer safety.

Labeling requirements for food products containing carboxylic acid-based antioxidants vary by region but generally mandate the disclosure of additives on product packaging. This transparency allows consumers to make informed choices about the foods they consume.

As scientific knowledge advances and new research emerges, regulatory frameworks for food additives are subject to periodic review and updates. This ongoing process ensures that regulations remain current with the latest scientific evidence and continue to prioritize public health and safety in the use of carboxylic acid-based antioxidants and other food additives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!