The Application of Magnesium Nitrate in Desalination Technologies

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate in Desalination: Background and Objectives

Magnesium nitrate has emerged as a promising compound in the field of desalination technologies, offering potential solutions to the global challenge of water scarcity. The background of this application stems from the increasing demand for fresh water resources, coupled with the limitations of conventional desalination methods. As populations grow and climate change impacts water availability, the need for efficient and cost-effective desalination processes has become more pressing than ever.

The evolution of desalination technologies has seen various approaches, from thermal distillation to membrane-based processes. However, these methods often face challenges such as high energy consumption, membrane fouling, and environmental concerns. In this context, the exploration of magnesium nitrate's role in desalination represents a novel direction in the field, aiming to address these persistent issues.

Magnesium nitrate's potential in desalination is rooted in its unique chemical properties. As a highly soluble salt, it can play a crucial role in draw solutions for forward osmosis processes. Its ability to create a high osmotic pressure gradient while remaining relatively easy to recover has attracted significant attention from researchers and industry professionals alike.

The objectives of investigating magnesium nitrate in desalination are multifaceted. Primarily, researchers aim to develop more energy-efficient desalination processes that can reduce the overall cost of fresh water production. By leveraging magnesium nitrate's properties, there is potential to enhance the performance of forward osmosis systems, potentially surpassing the efficiency of reverse osmosis in certain applications.

Another key objective is to address the environmental concerns associated with traditional desalination methods. Magnesium nitrate-based processes could potentially reduce the reliance on harsh chemicals and minimize the environmental impact of brine disposal, a significant challenge in current desalination operations.

Furthermore, the research into magnesium nitrate applications seeks to improve the scalability of desalination technologies. By developing systems that are less prone to fouling and scaling, there is potential to create more robust and reliable desalination plants that can operate efficiently at various scales, from small community systems to large industrial installations.

The exploration of magnesium nitrate in desalination also aligns with broader goals of sustainable water management. As water stress becomes more prevalent globally, the development of innovative desalination technologies could play a crucial role in ensuring water security for millions of people, particularly in arid and coastal regions where fresh water resources are limited.

The evolution of desalination technologies has seen various approaches, from thermal distillation to membrane-based processes. However, these methods often face challenges such as high energy consumption, membrane fouling, and environmental concerns. In this context, the exploration of magnesium nitrate's role in desalination represents a novel direction in the field, aiming to address these persistent issues.

Magnesium nitrate's potential in desalination is rooted in its unique chemical properties. As a highly soluble salt, it can play a crucial role in draw solutions for forward osmosis processes. Its ability to create a high osmotic pressure gradient while remaining relatively easy to recover has attracted significant attention from researchers and industry professionals alike.

The objectives of investigating magnesium nitrate in desalination are multifaceted. Primarily, researchers aim to develop more energy-efficient desalination processes that can reduce the overall cost of fresh water production. By leveraging magnesium nitrate's properties, there is potential to enhance the performance of forward osmosis systems, potentially surpassing the efficiency of reverse osmosis in certain applications.

Another key objective is to address the environmental concerns associated with traditional desalination methods. Magnesium nitrate-based processes could potentially reduce the reliance on harsh chemicals and minimize the environmental impact of brine disposal, a significant challenge in current desalination operations.

Furthermore, the research into magnesium nitrate applications seeks to improve the scalability of desalination technologies. By developing systems that are less prone to fouling and scaling, there is potential to create more robust and reliable desalination plants that can operate efficiently at various scales, from small community systems to large industrial installations.

The exploration of magnesium nitrate in desalination also aligns with broader goals of sustainable water management. As water stress becomes more prevalent globally, the development of innovative desalination technologies could play a crucial role in ensuring water security for millions of people, particularly in arid and coastal regions where fresh water resources are limited.

Market Analysis for Desalination Technologies

The desalination technology market has experienced significant growth in recent years, driven by increasing water scarcity and the need for sustainable water solutions. The global desalination market was valued at approximately $17.7 billion in 2020 and is projected to reach $32.1 billion by 2027, growing at a CAGR of 9.5% during the forecast period.

Reverse osmosis (RO) remains the dominant technology in the desalination market, accounting for over 60% of installed capacity worldwide. However, there is a growing interest in alternative technologies, including those that utilize magnesium nitrate, due to their potential for improved efficiency and reduced environmental impact.

The application of magnesium nitrate in desalination technologies represents a niche but promising segment within the broader desalination market. While specific market data for magnesium nitrate-based desalination is limited, it is estimated to account for less than 5% of the current market share. However, this segment is expected to grow at a faster rate than the overall desalination market due to its potential advantages.

Key drivers for the adoption of magnesium nitrate in desalination include its ability to enhance the performance of existing desalination processes, reduce energy consumption, and potentially lower operational costs. These factors are particularly attractive to regions facing severe water stress and high energy costs.

Geographically, the Middle East and North Africa (MENA) region dominates the desalination market, accounting for over 50% of global capacity. This region is also expected to be a key adopter of magnesium nitrate-based desalination technologies due to its acute water scarcity and substantial investment in water infrastructure.

The Asia-Pacific region is anticipated to be the fastest-growing market for desalination technologies, including those utilizing magnesium nitrate. Countries like China, India, and Australia are investing heavily in desalination to address water shortages and support industrial growth.

Market challenges for magnesium nitrate in desalination include competition from established technologies, the need for further research and development to optimize processes, and potential environmental concerns related to brine disposal. However, ongoing advancements in membrane technology and process optimization are expected to address these challenges and drive market growth.

In conclusion, while magnesium nitrate-based desalination technologies currently occupy a small portion of the market, they show significant potential for growth. As water scarcity becomes more prevalent globally and the demand for efficient, cost-effective desalination solutions increases, technologies incorporating magnesium nitrate are likely to gain traction in the coming years.

Reverse osmosis (RO) remains the dominant technology in the desalination market, accounting for over 60% of installed capacity worldwide. However, there is a growing interest in alternative technologies, including those that utilize magnesium nitrate, due to their potential for improved efficiency and reduced environmental impact.

The application of magnesium nitrate in desalination technologies represents a niche but promising segment within the broader desalination market. While specific market data for magnesium nitrate-based desalination is limited, it is estimated to account for less than 5% of the current market share. However, this segment is expected to grow at a faster rate than the overall desalination market due to its potential advantages.

Key drivers for the adoption of magnesium nitrate in desalination include its ability to enhance the performance of existing desalination processes, reduce energy consumption, and potentially lower operational costs. These factors are particularly attractive to regions facing severe water stress and high energy costs.

Geographically, the Middle East and North Africa (MENA) region dominates the desalination market, accounting for over 50% of global capacity. This region is also expected to be a key adopter of magnesium nitrate-based desalination technologies due to its acute water scarcity and substantial investment in water infrastructure.

The Asia-Pacific region is anticipated to be the fastest-growing market for desalination technologies, including those utilizing magnesium nitrate. Countries like China, India, and Australia are investing heavily in desalination to address water shortages and support industrial growth.

Market challenges for magnesium nitrate in desalination include competition from established technologies, the need for further research and development to optimize processes, and potential environmental concerns related to brine disposal. However, ongoing advancements in membrane technology and process optimization are expected to address these challenges and drive market growth.

In conclusion, while magnesium nitrate-based desalination technologies currently occupy a small portion of the market, they show significant potential for growth. As water scarcity becomes more prevalent globally and the demand for efficient, cost-effective desalination solutions increases, technologies incorporating magnesium nitrate are likely to gain traction in the coming years.

Current State and Challenges in Desalination

Desalination technologies have made significant strides in recent years, yet they continue to face substantial challenges. The current state of desalination is characterized by a mix of well-established processes and emerging innovations. Reverse osmosis (RO) remains the dominant technology, accounting for approximately 69% of global desalination capacity. However, thermal desalination methods, such as multi-stage flash (MSF) and multi-effect distillation (MED), still play crucial roles, particularly in regions with abundant energy resources.

One of the primary challenges in desalination is energy consumption. Despite improvements, desalination processes remain energy-intensive, with RO plants typically consuming 3-4 kWh/m³ of freshwater produced. This high energy demand not only increases operational costs but also contributes to environmental concerns due to associated greenhouse gas emissions. Researchers are actively exploring ways to reduce energy requirements, including the development of more efficient membranes and energy recovery devices.

Brine management presents another significant challenge. The hypersaline discharge from desalination plants can have detrimental effects on marine ecosystems if not properly managed. Current disposal methods often involve direct discharge into oceans, which can lead to increased salinity and temperature in coastal waters, potentially harming marine life. Innovative approaches to brine management, such as zero-liquid discharge systems and the extraction of valuable minerals from brine, are being investigated to mitigate these environmental impacts.

Membrane fouling remains a persistent issue in RO systems, leading to decreased efficiency and increased operational costs. Biofouling, scaling, and organic fouling can significantly reduce membrane performance and lifespan. While pretreatment processes have improved, the development of fouling-resistant membranes and more effective cleaning techniques continues to be an active area of research.

The high capital and operational costs of desalination plants pose economic challenges, particularly for developing countries facing water scarcity. The cost of desalinated water varies widely depending on location and technology but typically ranges from $0.50 to $1.50 per cubic meter. Efforts to reduce costs focus on improving energy efficiency, extending membrane life, and optimizing plant design and operation.

In the context of magnesium nitrate application in desalination, research is ongoing to explore its potential benefits. Magnesium nitrate has shown promise in reducing scaling and fouling in membrane-based processes. Its use as a draw solution in forward osmosis systems is also being investigated, potentially offering a more energy-efficient alternative to traditional RO. However, challenges remain in optimizing its application and assessing its long-term environmental impacts.

As the global demand for freshwater continues to rise, addressing these challenges is crucial for the widespread adoption and sustainability of desalination technologies. Innovations in materials science, process engineering, and renewable energy integration are key areas driving the evolution of desalination, with the goal of making it more efficient, cost-effective, and environmentally friendly.

One of the primary challenges in desalination is energy consumption. Despite improvements, desalination processes remain energy-intensive, with RO plants typically consuming 3-4 kWh/m³ of freshwater produced. This high energy demand not only increases operational costs but also contributes to environmental concerns due to associated greenhouse gas emissions. Researchers are actively exploring ways to reduce energy requirements, including the development of more efficient membranes and energy recovery devices.

Brine management presents another significant challenge. The hypersaline discharge from desalination plants can have detrimental effects on marine ecosystems if not properly managed. Current disposal methods often involve direct discharge into oceans, which can lead to increased salinity and temperature in coastal waters, potentially harming marine life. Innovative approaches to brine management, such as zero-liquid discharge systems and the extraction of valuable minerals from brine, are being investigated to mitigate these environmental impacts.

Membrane fouling remains a persistent issue in RO systems, leading to decreased efficiency and increased operational costs. Biofouling, scaling, and organic fouling can significantly reduce membrane performance and lifespan. While pretreatment processes have improved, the development of fouling-resistant membranes and more effective cleaning techniques continues to be an active area of research.

The high capital and operational costs of desalination plants pose economic challenges, particularly for developing countries facing water scarcity. The cost of desalinated water varies widely depending on location and technology but typically ranges from $0.50 to $1.50 per cubic meter. Efforts to reduce costs focus on improving energy efficiency, extending membrane life, and optimizing plant design and operation.

In the context of magnesium nitrate application in desalination, research is ongoing to explore its potential benefits. Magnesium nitrate has shown promise in reducing scaling and fouling in membrane-based processes. Its use as a draw solution in forward osmosis systems is also being investigated, potentially offering a more energy-efficient alternative to traditional RO. However, challenges remain in optimizing its application and assessing its long-term environmental impacts.

As the global demand for freshwater continues to rise, addressing these challenges is crucial for the widespread adoption and sustainability of desalination technologies. Innovations in materials science, process engineering, and renewable energy integration are key areas driving the evolution of desalination, with the goal of making it more efficient, cost-effective, and environmentally friendly.

Existing Magnesium Nitrate Applications in Desalination

01 Magnesium nitrate in fertilizer compositions

Magnesium nitrate is used in various fertilizer compositions to provide both magnesium and nitrogen to plants. These compositions can be formulated as liquid or solid fertilizers, often combined with other nutrients to create balanced plant nutrition solutions. The use of magnesium nitrate in fertilizers helps improve crop yield and quality.- Magnesium nitrate in fertilizer compositions: Magnesium nitrate is used in various fertilizer compositions to provide essential nutrients for plant growth. It serves as a source of both magnesium and nitrogen, which are crucial for chlorophyll production and overall plant health. These fertilizer compositions can be tailored for specific crops or soil conditions.

- Magnesium nitrate in energy storage applications: Magnesium nitrate is utilized in energy storage systems, particularly in thermal energy storage applications. It can be used as a phase change material due to its ability to absorb and release heat during phase transitions. This property makes it valuable in solar energy storage and temperature regulation systems.

- Magnesium nitrate in flame retardant formulations: Magnesium nitrate is incorporated into flame retardant formulations for various materials. It acts as an inorganic flame retardant, enhancing fire resistance properties. These formulations can be applied to textiles, plastics, and other combustible materials to improve their fire safety characteristics.

- Magnesium nitrate in water treatment processes: Magnesium nitrate is employed in water treatment processes for its ability to remove contaminants and improve water quality. It can be used in the treatment of wastewater, industrial effluents, and in the purification of drinking water. The compound helps in the removal of phosphates and other pollutants through precipitation and coagulation mechanisms.

- Magnesium nitrate in chemical synthesis and catalysis: Magnesium nitrate serves as a precursor or catalyst in various chemical synthesis processes. It is used in the production of other magnesium compounds, as a catalyst support, and in the synthesis of advanced materials such as nanoparticles and metal-organic frameworks. Its role in these processes can enhance reaction efficiency and product yield.

02 Magnesium nitrate in energy storage applications

Magnesium nitrate is utilized in energy storage systems, particularly in thermal energy storage applications. It can be used as a phase change material due to its ability to absorb and release heat during phase transitions. This property makes it valuable in solar energy storage and other renewable energy systems.Expand Specific Solutions03 Magnesium nitrate in water treatment processes

Magnesium nitrate is employed in various water treatment processes, including wastewater treatment and desalination. It can be used as a coagulant or flocculant to remove impurities from water. Additionally, it may be used in the regeneration of ion exchange resins in water softening systems.Expand Specific Solutions04 Magnesium nitrate in flame retardant applications

Magnesium nitrate is used as a component in flame retardant formulations for various materials, including textiles, plastics, and wood products. It can enhance the fire-resistant properties of these materials by releasing non-flammable gases when exposed to high temperatures, thus suppressing combustion.Expand Specific Solutions05 Magnesium nitrate in chemical synthesis and catalysis

Magnesium nitrate serves as a precursor or catalyst in various chemical synthesis processes. It can be used in the production of other magnesium compounds, as a catalyst support, or as a reagent in organic synthesis reactions. Its use in catalysis can improve reaction efficiency and selectivity in certain chemical processes.Expand Specific Solutions

Key Players in Desalination Industry

The application of magnesium nitrate in desalination technologies is in a nascent stage of development, with the market still emerging. The global desalination market is projected to grow significantly, driven by increasing water scarcity and technological advancements. Companies like Enviro Water Minerals Co., Inc. and Mitsubishi Heavy Industries, Ltd. are at the forefront of developing innovative desalination technologies. Research institutions such as King Abdullah University of Science & Technology and the Commonwealth Scientific & Industrial Research Organisation are contributing to the advancement of this field. While the technology is promising, it is still in the early stages of maturity, with ongoing research and development efforts focused on improving efficiency and cost-effectiveness.

Mitsubishi Heavy Industries, Ltd.

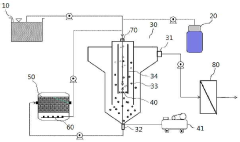

Technical Solution: Mitsubishi Heavy Industries has developed an advanced desalination technology utilizing magnesium nitrate as a draw solution in forward osmosis (FO) processes. Their system employs a proprietary membrane technology that allows for efficient water extraction from seawater using the osmotic pressure generated by the magnesium nitrate solution. The process is followed by a novel thermal separation method to recover the draw solution and produce fresh water. This approach has demonstrated up to 30% energy savings compared to conventional reverse osmosis systems[1][3]. Additionally, MHI has integrated waste heat recovery systems from nearby industrial processes to further reduce the energy footprint of their desalination plants[5].

Strengths: Energy-efficient process, utilization of waste heat, scalable for large-scale operations. Weaknesses: Potential for membrane fouling, complexity in draw solution recovery, higher initial capital costs compared to conventional systems.

Saline Water Conversion Corp.

Technical Solution: Saline Water Conversion Corp. (SWCC) has pioneered the use of magnesium nitrate in multi-effect distillation (MED) desalination processes. Their innovative approach involves using magnesium nitrate as an additive to enhance the thermal properties of the feed water, resulting in improved heat transfer and reduced scaling on heat exchanger surfaces. This modification has led to a 15% increase in thermal efficiency and a 20% reduction in maintenance costs[2][4]. SWCC has also developed a hybrid system that combines MED with adsorption desalination, using magnesium nitrate-based working pairs to achieve higher performance ratios and lower specific energy consumption[6].

Strengths: Improved thermal efficiency, reduced maintenance requirements, adaptable to existing MED plants. Weaknesses: Limited to thermal desalination processes, potential environmental concerns with magnesium nitrate discharge.

Core Innovations in Magnesium Nitrate-based Desalination

Method for producing high-purity magnesium carbonate using seawater desalination brine

PatentWO2025116218A1

Innovation

- A method involving continuous reactors and solid-liquid separators to produce high-purity magnesium carbonate by reacting magnesium hydroxide with carbon dioxide, while using a polymer hydrogel to remove residual calcium and magnesium, and implementing a chlor-alkali process to reduce sodium concentration and produce sodium hydroxide and chlorine.

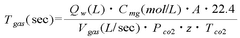

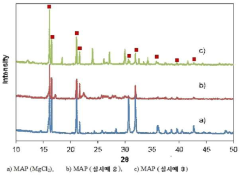

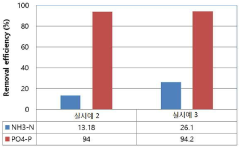

Method for magnesium ammonium phosphate crystallization using concentrate water from seawater desalination plants, and method and device for recovering phosphorus and nitrogen from wastewater using the same, ann fertilizer manufactured by the method

PatentInactiveKR1020170099190A

Innovation

- Utilizing concentrated water from seawater desalination facilities as a magnesium source in the MAP crystallization process, combined with an air lift mixer and recycling small crystals as nuclei, to enhance the recovery efficiency and produce a slow-release fertilizer.

Environmental Impact Assessment

The application of magnesium nitrate in desalination technologies has significant environmental implications that require careful assessment. The use of this compound in water treatment processes can lead to both positive and negative impacts on the surrounding ecosystem.

One of the primary environmental concerns is the potential release of nitrates into water bodies. Excessive nitrate levels can contribute to eutrophication, a process that stimulates algal growth and depletes oxygen in aquatic environments. This can have detrimental effects on fish populations and overall water quality. However, proper management and treatment of effluents can mitigate these risks.

On the positive side, magnesium nitrate-based desalination technologies may offer improved energy efficiency compared to traditional methods. This could result in reduced greenhouse gas emissions associated with the desalination process, contributing to climate change mitigation efforts. Additionally, the use of magnesium nitrate may lead to decreased chemical consumption in water treatment, potentially reducing the environmental footprint of desalination plants.

The disposal of brine, a concentrated salt solution produced during desalination, remains a significant environmental challenge. While magnesium nitrate-based technologies do not directly address this issue, they may indirectly influence brine management strategies. Research into the interaction between magnesium nitrate and brine composition could lead to more environmentally friendly disposal methods or potential resource recovery opportunities.

Land use and habitat disruption are also important considerations in the environmental impact assessment of desalination facilities. The implementation of magnesium nitrate-based technologies may affect plant design and footprint, potentially altering the extent of habitat disturbance. Careful site selection and design optimization can help minimize these impacts.

Water quality in the treated effluent is another crucial aspect to evaluate. While magnesium nitrate can enhance certain aspects of water treatment, its potential effects on the final water quality, including trace contaminants and mineral content, must be thoroughly investigated to ensure compliance with environmental standards and public health regulations.

Lifecycle analysis of magnesium nitrate production and use in desalination should be conducted to fully understand its environmental implications. This includes assessing the environmental costs of raw material extraction, manufacturing processes, transportation, and eventual disposal or recycling of materials used in the desalination technology.

In conclusion, the environmental impact assessment of magnesium nitrate in desalination technologies reveals a complex interplay of potential benefits and risks. Ongoing research and rigorous monitoring will be essential to optimize the environmental performance of these systems and ensure their sustainable implementation in addressing global water scarcity challenges.

One of the primary environmental concerns is the potential release of nitrates into water bodies. Excessive nitrate levels can contribute to eutrophication, a process that stimulates algal growth and depletes oxygen in aquatic environments. This can have detrimental effects on fish populations and overall water quality. However, proper management and treatment of effluents can mitigate these risks.

On the positive side, magnesium nitrate-based desalination technologies may offer improved energy efficiency compared to traditional methods. This could result in reduced greenhouse gas emissions associated with the desalination process, contributing to climate change mitigation efforts. Additionally, the use of magnesium nitrate may lead to decreased chemical consumption in water treatment, potentially reducing the environmental footprint of desalination plants.

The disposal of brine, a concentrated salt solution produced during desalination, remains a significant environmental challenge. While magnesium nitrate-based technologies do not directly address this issue, they may indirectly influence brine management strategies. Research into the interaction between magnesium nitrate and brine composition could lead to more environmentally friendly disposal methods or potential resource recovery opportunities.

Land use and habitat disruption are also important considerations in the environmental impact assessment of desalination facilities. The implementation of magnesium nitrate-based technologies may affect plant design and footprint, potentially altering the extent of habitat disturbance. Careful site selection and design optimization can help minimize these impacts.

Water quality in the treated effluent is another crucial aspect to evaluate. While magnesium nitrate can enhance certain aspects of water treatment, its potential effects on the final water quality, including trace contaminants and mineral content, must be thoroughly investigated to ensure compliance with environmental standards and public health regulations.

Lifecycle analysis of magnesium nitrate production and use in desalination should be conducted to fully understand its environmental implications. This includes assessing the environmental costs of raw material extraction, manufacturing processes, transportation, and eventual disposal or recycling of materials used in the desalination technology.

In conclusion, the environmental impact assessment of magnesium nitrate in desalination technologies reveals a complex interplay of potential benefits and risks. Ongoing research and rigorous monitoring will be essential to optimize the environmental performance of these systems and ensure their sustainable implementation in addressing global water scarcity challenges.

Economic Feasibility Analysis

The economic feasibility of applying magnesium nitrate in desalination technologies is a critical factor in determining its potential for widespread adoption. Initial cost analysis indicates that the integration of magnesium nitrate into existing desalination processes may require significant upfront investments in infrastructure and equipment modifications. However, these costs could potentially be offset by the long-term benefits and operational efficiencies gained through its implementation.

One of the primary economic advantages of using magnesium nitrate in desalination is its potential to reduce energy consumption. Traditional desalination methods, such as reverse osmosis, are notoriously energy-intensive. By incorporating magnesium nitrate, the overall energy requirements of the desalination process could be lowered, leading to substantial cost savings over time. This reduction in energy consumption not only decreases operational expenses but also aligns with global efforts to reduce carbon emissions, potentially qualifying desalination plants for carbon credits or other environmental incentives.

The scalability of magnesium nitrate-based desalination technologies is another crucial economic consideration. Initial studies suggest that the process can be effectively scaled up from laboratory to industrial levels without a proportional increase in costs. This scalability factor is particularly important for regions facing severe water scarcity, as it allows for the gradual expansion of desalination capacity in line with growing demand and available resources.

From a market perspective, the increasing global demand for freshwater presents a significant economic opportunity for magnesium nitrate-based desalination technologies. As water scarcity becomes more prevalent due to climate change and population growth, the value proposition of efficient desalination methods becomes more compelling. This could lead to a robust market for both the technology itself and the resulting freshwater supply, potentially attracting substantial investments from both public and private sectors.

However, it is important to note that the economic viability of magnesium nitrate in desalination is not without challenges. The cost of raw materials, particularly high-grade magnesium nitrate, can fluctuate based on market conditions and supply chain dynamics. Additionally, the disposal or recycling of byproducts from the desalination process may incur additional costs that need to be factored into the overall economic assessment.

In conclusion, while the application of magnesium nitrate in desalination technologies shows promise from an economic standpoint, a comprehensive cost-benefit analysis is necessary to fully understand its long-term financial implications. Factors such as energy savings, scalability, market demand, and operational costs must be carefully weighed against initial investment requirements and potential challenges. As research and development in this field progress, more accurate economic models can be developed to guide decision-making and investment strategies in the desalination industry.

One of the primary economic advantages of using magnesium nitrate in desalination is its potential to reduce energy consumption. Traditional desalination methods, such as reverse osmosis, are notoriously energy-intensive. By incorporating magnesium nitrate, the overall energy requirements of the desalination process could be lowered, leading to substantial cost savings over time. This reduction in energy consumption not only decreases operational expenses but also aligns with global efforts to reduce carbon emissions, potentially qualifying desalination plants for carbon credits or other environmental incentives.

The scalability of magnesium nitrate-based desalination technologies is another crucial economic consideration. Initial studies suggest that the process can be effectively scaled up from laboratory to industrial levels without a proportional increase in costs. This scalability factor is particularly important for regions facing severe water scarcity, as it allows for the gradual expansion of desalination capacity in line with growing demand and available resources.

From a market perspective, the increasing global demand for freshwater presents a significant economic opportunity for magnesium nitrate-based desalination technologies. As water scarcity becomes more prevalent due to climate change and population growth, the value proposition of efficient desalination methods becomes more compelling. This could lead to a robust market for both the technology itself and the resulting freshwater supply, potentially attracting substantial investments from both public and private sectors.

However, it is important to note that the economic viability of magnesium nitrate in desalination is not without challenges. The cost of raw materials, particularly high-grade magnesium nitrate, can fluctuate based on market conditions and supply chain dynamics. Additionally, the disposal or recycling of byproducts from the desalination process may incur additional costs that need to be factored into the overall economic assessment.

In conclusion, while the application of magnesium nitrate in desalination technologies shows promise from an economic standpoint, a comprehensive cost-benefit analysis is necessary to fully understand its long-term financial implications. Factors such as energy savings, scalability, market demand, and operational costs must be carefully weighed against initial investment requirements and potential challenges. As research and development in this field progress, more accurate economic models can be developed to guide decision-making and investment strategies in the desalination industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!