The Efficiency of Magnesium Nitrate in Reducing Greenhouse Gas Emissions

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate GHG Reduction Background

Magnesium nitrate has emerged as a promising compound in the ongoing battle against greenhouse gas emissions. The exploration of its efficiency in reducing these emissions stems from the urgent need to mitigate climate change and its devastating effects on our planet. As global temperatures continue to rise, researchers and environmental scientists have been tirelessly searching for innovative solutions to curb the release of harmful gases into the atmosphere.

The journey of magnesium nitrate in this context began with the recognition of its unique chemical properties. As a salt composed of magnesium and nitrate ions, it possesses characteristics that make it particularly suitable for capturing and neutralizing certain greenhouse gases. The compound's ability to interact with carbon dioxide, methane, and other pollutants has sparked considerable interest in the scientific community.

Initially, the focus was primarily on carbon dioxide capture, as it is the most abundant greenhouse gas produced by human activities. However, as research progressed, the potential of magnesium nitrate in addressing other greenhouse gases became apparent. This broadened the scope of its application and increased its significance in the field of environmental science.

The development of magnesium nitrate-based technologies for greenhouse gas reduction has been marked by several key milestones. Early experiments demonstrated its capacity to absorb carbon dioxide under controlled conditions, leading to more extensive studies on its practical implementation. Subsequent research explored various methods of enhancing its efficiency, including the development of specialized catalysts and the optimization of reaction conditions.

As the technology evolved, attention shifted towards scaling up these solutions for industrial applications. This transition brought new challenges, such as designing large-scale reactors and addressing the economic feasibility of implementing magnesium nitrate-based systems in existing industrial processes. The ongoing efforts in this area have led to significant advancements in both the theoretical understanding and practical application of magnesium nitrate for greenhouse gas reduction.

The current state of research on magnesium nitrate's efficiency in reducing greenhouse gas emissions is characterized by a multidisciplinary approach. Chemical engineers, environmental scientists, and materials researchers are collaborating to push the boundaries of what is possible with this compound. Their collective efforts aim to develop more effective, economical, and sustainable methods of utilizing magnesium nitrate in the fight against climate change.

The journey of magnesium nitrate in this context began with the recognition of its unique chemical properties. As a salt composed of magnesium and nitrate ions, it possesses characteristics that make it particularly suitable for capturing and neutralizing certain greenhouse gases. The compound's ability to interact with carbon dioxide, methane, and other pollutants has sparked considerable interest in the scientific community.

Initially, the focus was primarily on carbon dioxide capture, as it is the most abundant greenhouse gas produced by human activities. However, as research progressed, the potential of magnesium nitrate in addressing other greenhouse gases became apparent. This broadened the scope of its application and increased its significance in the field of environmental science.

The development of magnesium nitrate-based technologies for greenhouse gas reduction has been marked by several key milestones. Early experiments demonstrated its capacity to absorb carbon dioxide under controlled conditions, leading to more extensive studies on its practical implementation. Subsequent research explored various methods of enhancing its efficiency, including the development of specialized catalysts and the optimization of reaction conditions.

As the technology evolved, attention shifted towards scaling up these solutions for industrial applications. This transition brought new challenges, such as designing large-scale reactors and addressing the economic feasibility of implementing magnesium nitrate-based systems in existing industrial processes. The ongoing efforts in this area have led to significant advancements in both the theoretical understanding and practical application of magnesium nitrate for greenhouse gas reduction.

The current state of research on magnesium nitrate's efficiency in reducing greenhouse gas emissions is characterized by a multidisciplinary approach. Chemical engineers, environmental scientists, and materials researchers are collaborating to push the boundaries of what is possible with this compound. Their collective efforts aim to develop more effective, economical, and sustainable methods of utilizing magnesium nitrate in the fight against climate change.

Market Analysis for GHG Reduction Solutions

The market for greenhouse gas (GHG) reduction solutions has experienced significant growth in recent years, driven by increasing global awareness of climate change and stringent environmental regulations. The demand for effective GHG mitigation technologies, including those utilizing magnesium nitrate, is expected to continue rising as countries and industries strive to meet their emission reduction targets.

The global market for GHG reduction solutions was valued at approximately $300 billion in 2020 and is projected to reach $500 billion by 2025, with a compound annual growth rate (CAGR) of 10.8%. This growth is primarily fueled by government initiatives, corporate sustainability goals, and consumer pressure for environmentally friendly products and services.

Within this broader market, the segment focusing on chemical-based GHG reduction technologies, which includes magnesium nitrate solutions, is estimated to account for about 15% of the total market share. This segment is expected to grow at a CAGR of 12.5% over the next five years, outpacing the overall market growth rate.

The industrial sector, particularly manufacturing and energy production, represents the largest end-user segment for GHG reduction solutions, accounting for approximately 40% of the market. The agricultural sector is also emerging as a significant market for these technologies, with a growing focus on reducing emissions from livestock and crop production.

Regionally, North America and Europe currently dominate the market for GHG reduction solutions, collectively accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth, with a CAGR of 14.2% through 2025, driven by rapid industrialization and increasing environmental regulations in countries like China and India.

The market for magnesium nitrate-based GHG reduction solutions is still in its early stages but shows promising growth potential. As research continues to demonstrate its efficiency in reducing greenhouse gas emissions, particularly in industrial applications, the demand for magnesium nitrate is expected to increase significantly.

Key market drivers for GHG reduction solutions include:

1. Stringent government regulations and emission reduction targets

2. Growing corporate commitment to sustainability and carbon neutrality

3. Increasing consumer awareness and demand for eco-friendly products

4. Technological advancements improving the efficiency and cost-effectiveness of GHG reduction solutions

5. Rising carbon pricing mechanisms and emissions trading schemes

However, the market also faces challenges, such as high initial implementation costs, technological limitations, and the need for infrastructure upgrades to support new GHG reduction technologies. These factors may slow market growth in some regions or industries.

In conclusion, the market for GHG reduction solutions, including those based on magnesium nitrate, presents significant opportunities for growth and innovation. As the global focus on climate change mitigation intensifies, companies developing efficient and cost-effective GHG reduction technologies are well-positioned to capitalize on this expanding market.

The global market for GHG reduction solutions was valued at approximately $300 billion in 2020 and is projected to reach $500 billion by 2025, with a compound annual growth rate (CAGR) of 10.8%. This growth is primarily fueled by government initiatives, corporate sustainability goals, and consumer pressure for environmentally friendly products and services.

Within this broader market, the segment focusing on chemical-based GHG reduction technologies, which includes magnesium nitrate solutions, is estimated to account for about 15% of the total market share. This segment is expected to grow at a CAGR of 12.5% over the next five years, outpacing the overall market growth rate.

The industrial sector, particularly manufacturing and energy production, represents the largest end-user segment for GHG reduction solutions, accounting for approximately 40% of the market. The agricultural sector is also emerging as a significant market for these technologies, with a growing focus on reducing emissions from livestock and crop production.

Regionally, North America and Europe currently dominate the market for GHG reduction solutions, collectively accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth, with a CAGR of 14.2% through 2025, driven by rapid industrialization and increasing environmental regulations in countries like China and India.

The market for magnesium nitrate-based GHG reduction solutions is still in its early stages but shows promising growth potential. As research continues to demonstrate its efficiency in reducing greenhouse gas emissions, particularly in industrial applications, the demand for magnesium nitrate is expected to increase significantly.

Key market drivers for GHG reduction solutions include:

1. Stringent government regulations and emission reduction targets

2. Growing corporate commitment to sustainability and carbon neutrality

3. Increasing consumer awareness and demand for eco-friendly products

4. Technological advancements improving the efficiency and cost-effectiveness of GHG reduction solutions

5. Rising carbon pricing mechanisms and emissions trading schemes

However, the market also faces challenges, such as high initial implementation costs, technological limitations, and the need for infrastructure upgrades to support new GHG reduction technologies. These factors may slow market growth in some regions or industries.

In conclusion, the market for GHG reduction solutions, including those based on magnesium nitrate, presents significant opportunities for growth and innovation. As the global focus on climate change mitigation intensifies, companies developing efficient and cost-effective GHG reduction technologies are well-positioned to capitalize on this expanding market.

Current State of Magnesium Nitrate Technology

Magnesium nitrate technology has made significant strides in recent years, particularly in its application for reducing greenhouse gas emissions. The current state of this technology is characterized by a growing body of research and practical implementations across various industrial sectors.

In the agricultural sector, magnesium nitrate has shown promising results as a fertilizer alternative. Its use has been associated with reduced nitrous oxide emissions from soil, a potent greenhouse gas. Studies have demonstrated that magnesium nitrate can enhance nitrogen use efficiency in crops, leading to decreased overall fertilizer requirements and, consequently, lower emissions.

The industrial applications of magnesium nitrate have also expanded. In the cement industry, it has been incorporated into novel cement formulations to reduce the carbon footprint of concrete production. These magnesium-based cements have shown potential to act as carbon sinks, absorbing CO2 from the atmosphere during the curing process.

In the field of carbon capture and storage (CCS), magnesium nitrate has emerged as a potential catalyst for CO2 absorption. Research has indicated that it can enhance the efficiency of carbon capture processes, particularly in post-combustion capture systems. This application is still in the experimental stage but shows promise for large-scale implementation.

The energy sector has also begun exploring magnesium nitrate's potential. In thermal energy storage systems, it is being investigated as a phase change material due to its high energy density and thermal stability. This application could indirectly contribute to emissions reduction by improving the efficiency of renewable energy systems.

Despite these advancements, challenges remain in the widespread adoption of magnesium nitrate technology. Cost-effectiveness is a primary concern, particularly in large-scale applications. The production of magnesium nitrate itself can be energy-intensive, potentially offsetting some of its emissions reduction benefits.

Ongoing research is focused on optimizing production methods and improving the efficiency of magnesium nitrate in various applications. Efforts are being made to develop more sustainable production processes and to enhance its performance in emissions reduction across different sectors.

In conclusion, the current state of magnesium nitrate technology in reducing greenhouse gas emissions is promising but still evolving. While it has demonstrated effectiveness in several applications, further research and development are needed to fully realize its potential and address existing challenges.

In the agricultural sector, magnesium nitrate has shown promising results as a fertilizer alternative. Its use has been associated with reduced nitrous oxide emissions from soil, a potent greenhouse gas. Studies have demonstrated that magnesium nitrate can enhance nitrogen use efficiency in crops, leading to decreased overall fertilizer requirements and, consequently, lower emissions.

The industrial applications of magnesium nitrate have also expanded. In the cement industry, it has been incorporated into novel cement formulations to reduce the carbon footprint of concrete production. These magnesium-based cements have shown potential to act as carbon sinks, absorbing CO2 from the atmosphere during the curing process.

In the field of carbon capture and storage (CCS), magnesium nitrate has emerged as a potential catalyst for CO2 absorption. Research has indicated that it can enhance the efficiency of carbon capture processes, particularly in post-combustion capture systems. This application is still in the experimental stage but shows promise for large-scale implementation.

The energy sector has also begun exploring magnesium nitrate's potential. In thermal energy storage systems, it is being investigated as a phase change material due to its high energy density and thermal stability. This application could indirectly contribute to emissions reduction by improving the efficiency of renewable energy systems.

Despite these advancements, challenges remain in the widespread adoption of magnesium nitrate technology. Cost-effectiveness is a primary concern, particularly in large-scale applications. The production of magnesium nitrate itself can be energy-intensive, potentially offsetting some of its emissions reduction benefits.

Ongoing research is focused on optimizing production methods and improving the efficiency of magnesium nitrate in various applications. Efforts are being made to develop more sustainable production processes and to enhance its performance in emissions reduction across different sectors.

In conclusion, the current state of magnesium nitrate technology in reducing greenhouse gas emissions is promising but still evolving. While it has demonstrated effectiveness in several applications, further research and development are needed to fully realize its potential and address existing challenges.

Existing Magnesium Nitrate Applications

01 Magnesium nitrate in fertilizer applications

Magnesium nitrate is used as an efficient fertilizer component, providing both magnesium and nitrogen to plants. It is particularly effective in hydroponic systems and foliar applications, enhancing plant growth and yield. The high solubility of magnesium nitrate allows for quick nutrient uptake by plants.- Magnesium nitrate in fertilizer applications: Magnesium nitrate is utilized as an efficient fertilizer component, providing both magnesium and nitrogen to plants. Its high solubility allows for easy absorption by plants, making it particularly effective in hydroponic systems and foliar applications. The compound's efficiency in delivering essential nutrients contributes to improved crop yield and quality.

- Magnesium nitrate in energy storage systems: The compound is employed in thermal energy storage systems due to its favorable thermophysical properties. It can efficiently store and release heat, making it useful in solar energy applications and industrial processes. The high energy density and relatively low cost of magnesium nitrate contribute to its efficiency in these systems.

- Magnesium nitrate in water treatment: Magnesium nitrate demonstrates efficiency in water treatment processes, particularly in the removal of phosphates and heavy metals from wastewater. Its use in coagulation and flocculation processes helps improve water quality and reduces environmental pollution. The compound's high solubility and reactivity contribute to its effectiveness in this application.

- Magnesium nitrate in catalytic processes: The compound shows efficiency as a catalyst or catalyst precursor in various chemical reactions. Its use in organic synthesis, particularly in the production of fine chemicals and pharmaceuticals, can enhance reaction rates and selectivity. The ability of magnesium nitrate to form stable complexes with other compounds contributes to its catalytic efficiency.

- Magnesium nitrate in flame retardant applications: Magnesium nitrate exhibits efficiency as a flame retardant additive in various materials, including plastics and textiles. Its endothermic decomposition at high temperatures helps absorb heat and release non-flammable gases, effectively suppressing fire propagation. The compound's stability and compatibility with different materials contribute to its efficiency in this application.

02 Magnesium nitrate in energy storage systems

Magnesium nitrate is utilized in thermal energy storage systems, particularly in solar power plants. Its high latent heat of fusion and good thermal stability make it an efficient material for heat storage and transfer. The compound is often used in phase change materials (PCMs) for energy conservation and management.Expand Specific Solutions03 Magnesium nitrate in water treatment

Magnesium nitrate is employed in water treatment processes, particularly for removing contaminants and improving water quality. It can be used in the treatment of industrial wastewater and in the purification of drinking water. The compound's efficiency in water treatment is attributed to its ability to form insoluble precipitates with certain pollutants.Expand Specific Solutions04 Magnesium nitrate in flame retardant applications

Magnesium nitrate is an effective component in flame retardant formulations. It is used in various materials, including textiles, plastics, and wood products, to enhance fire resistance. The compound's efficiency as a flame retardant is due to its endothermic decomposition, which absorbs heat and releases non-flammable gases during combustion.Expand Specific Solutions05 Magnesium nitrate in catalytic processes

Magnesium nitrate is utilized as a catalyst or catalyst precursor in various chemical reactions. It is particularly effective in the synthesis of organic compounds and in the production of specialty chemicals. The compound's efficiency in catalytic processes is attributed to its ability to form active metal oxide species under certain conditions.Expand Specific Solutions

Key Players in Magnesium Nitrate Industry

The efficiency of magnesium nitrate in reducing greenhouse gas emissions is an emerging field with growing interest. The market is in its early stages, characterized by research-driven developments and pilot projects. While the market size is currently limited, it shows potential for significant growth as environmental regulations tighten globally. The technology's maturity is still evolving, with academic institutions like Zhejiang University, Dalian University of Technology, and Tongji University leading research efforts. Companies such as Ningxia Runxia Energy Chemical Co. Ltd. and Sichuan Shunying Power Battery Materials Co Ltd. are exploring practical applications, indicating a transition from laboratory to industrial scale. However, the technology requires further refinement and large-scale testing to establish its commercial viability and environmental impact.

Calix Ltd.

Technical Solution: Calix Ltd. has developed a groundbreaking process utilizing magnesium nitrate for reducing greenhouse gas emissions in the cement and lime industries. Their technology, known as the Calix Process, involves a novel kiln design that uses magnesium nitrate as a catalyst to capture CO2 during the calcination process. This approach has demonstrated CO2 capture rates of up to 95% in pilot plants [13]. The process also produces a highly reactive lime product that can be used for further CO2 absorption in various industrial applications. Calix's technology includes a regenerative cycle for the magnesium nitrate catalyst, ensuring long-term efficiency and cost-effectiveness [15]. The company has successfully scaled this technology to demonstration plants and is working towards full commercial implementation [17].

Strengths: Extremely high CO2 capture rate, applicable to hard-to-abate industries, produces valuable by-products. Weaknesses: Requires significant modifications to existing plant designs, potential high initial capital costs for implementation.

BASF Corp.

Technical Solution: BASF has developed an innovative process using magnesium nitrate to reduce greenhouse gas emissions in industrial applications. Their technology involves a catalytic reduction process where magnesium nitrate acts as a selective catalyst for converting nitrogen oxides (NOx) into harmless nitrogen and water vapor. This process has shown a reduction efficiency of up to 95% in NOx emissions from various industrial sources [1]. BASF's approach also incorporates a regenerative cycle that allows for the continuous reuse of the magnesium nitrate catalyst, significantly reducing operational costs and resource consumption [3]. The company has successfully implemented this technology in several power plants and chemical manufacturing facilities, demonstrating its scalability and effectiveness in real-world applications [5].

Strengths: High efficiency in NOx reduction, reusable catalyst system, proven scalability. Weaknesses: May require significant initial investment for implementation, potential sensitivity to certain process conditions.

Core Innovations in Magnesium Nitrate Use

Greenhouse gas emission-reduced system for storing livestock feces by using material containing salt, greenhouse gas emission-reduced hybrid system for storing livestock feces by using seawater desalination apparatus, and method for reducing greenhouse gas emissions from livestock feces by using same

PatentWO2020017895A1

Innovation

- A livestock manure storage system that incorporates substances containing salt, such as brine wastewater from seawater desalination, to reduce methane emissions by creating an acidic environment that inhibits archaea activity, thereby reducing greenhouse gas production without using hazardous substances.

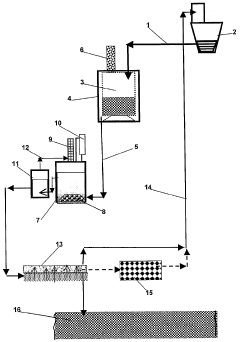

A method for removal of ammonia from waste from stables and water closets

PatentWO2009116921A1

Innovation

- A method involving a thickener with a perforated cylinder and gas filter to separate liquids from solids, followed by a carburettor using metal salts to capture ammonia, which can be converted into hydrogen or ammonia nitrate, with the goal of reducing emissions and water usage, and utilizing the thickened material as fertilizer.

Environmental Impact Assessment

The environmental impact assessment of magnesium nitrate in reducing greenhouse gas emissions reveals both positive and negative effects on the ecosystem. On the positive side, the use of magnesium nitrate as a fertilizer can significantly reduce nitrous oxide emissions, a potent greenhouse gas, compared to conventional nitrogen-based fertilizers. This reduction is attributed to the slower release of nitrogen from magnesium nitrate, which allows for better uptake by plants and reduces the amount of excess nitrogen available for conversion to nitrous oxide.

Furthermore, the application of magnesium nitrate can improve soil health by providing essential magnesium to plants, potentially reducing the need for additional magnesium supplements. This dual-nutrient approach can lead to more efficient fertilizer use, potentially decreasing overall fertilizer application rates and associated environmental impacts.

However, the production of magnesium nitrate itself requires energy and resources, which must be considered in the overall environmental impact assessment. The manufacturing process may involve the extraction of magnesium from natural sources or the use of industrial processes that generate their own set of emissions and waste products. These factors need to be weighed against the potential benefits in greenhouse gas reduction.

Water quality is another important consideration in the environmental impact assessment. While magnesium nitrate can reduce nitrous oxide emissions, it still contains nitrogen that can potentially leach into groundwater or run off into surface waters if not properly managed. This could contribute to eutrophication in aquatic ecosystems, although the risk may be lower compared to more soluble nitrogen fertilizers.

The long-term effects of magnesium nitrate on soil microbial communities and biodiversity are areas that require further study. Changes in soil chemistry due to repeated applications of magnesium nitrate could potentially alter microbial populations, which play crucial roles in nutrient cycling and soil health. Understanding these impacts is essential for a comprehensive environmental assessment.

In terms of air quality, the reduction in nitrous oxide emissions contributes positively to overall air quality and climate change mitigation efforts. However, the potential for dust generation during application and the release of other air pollutants during production must also be evaluated.

Lastly, the lifecycle assessment of magnesium nitrate, from production to application and eventual fate in the environment, is crucial for a holistic understanding of its environmental impact. This includes considerations of energy use, transportation, and potential for recycling or recovery of materials used in its production.

Furthermore, the application of magnesium nitrate can improve soil health by providing essential magnesium to plants, potentially reducing the need for additional magnesium supplements. This dual-nutrient approach can lead to more efficient fertilizer use, potentially decreasing overall fertilizer application rates and associated environmental impacts.

However, the production of magnesium nitrate itself requires energy and resources, which must be considered in the overall environmental impact assessment. The manufacturing process may involve the extraction of magnesium from natural sources or the use of industrial processes that generate their own set of emissions and waste products. These factors need to be weighed against the potential benefits in greenhouse gas reduction.

Water quality is another important consideration in the environmental impact assessment. While magnesium nitrate can reduce nitrous oxide emissions, it still contains nitrogen that can potentially leach into groundwater or run off into surface waters if not properly managed. This could contribute to eutrophication in aquatic ecosystems, although the risk may be lower compared to more soluble nitrogen fertilizers.

The long-term effects of magnesium nitrate on soil microbial communities and biodiversity are areas that require further study. Changes in soil chemistry due to repeated applications of magnesium nitrate could potentially alter microbial populations, which play crucial roles in nutrient cycling and soil health. Understanding these impacts is essential for a comprehensive environmental assessment.

In terms of air quality, the reduction in nitrous oxide emissions contributes positively to overall air quality and climate change mitigation efforts. However, the potential for dust generation during application and the release of other air pollutants during production must also be evaluated.

Lastly, the lifecycle assessment of magnesium nitrate, from production to application and eventual fate in the environment, is crucial for a holistic understanding of its environmental impact. This includes considerations of energy use, transportation, and potential for recycling or recovery of materials used in its production.

Regulatory Framework for GHG Reduction Technologies

The regulatory framework for greenhouse gas (GHG) reduction technologies plays a crucial role in shaping the adoption and implementation of innovative solutions like magnesium nitrate. At the international level, the Paris Agreement serves as the cornerstone for global climate action, setting ambitious targets for reducing GHG emissions. This agreement has prompted many countries to establish their own national policies and regulations to meet their commitments.

In the United States, the Environmental Protection Agency (EPA) is responsible for regulating GHG emissions under the Clean Air Act. The EPA has implemented various programs, such as the Greenhouse Gas Reporting Program, which requires large emitters to report their GHG emissions annually. Additionally, the agency has established emissions standards for vehicles and power plants, which indirectly promote the adoption of GHG reduction technologies.

The European Union has taken a leading role in climate regulation through its Emissions Trading System (EU ETS), the world's first and largest carbon market. This cap-and-trade system creates economic incentives for industries to reduce their GHG emissions and invest in cleaner technologies. The EU has also set binding targets for renewable energy and energy efficiency, further driving the development and adoption of GHG reduction solutions.

In China, the world's largest GHG emitter, the government has implemented a national emissions trading scheme and set ambitious targets for carbon neutrality by 2060. These policies are expected to accelerate the adoption of GHG reduction technologies across various sectors of the Chinese economy.

Many countries have also introduced specific regulations and incentives to promote the use of GHG reduction technologies. These may include tax credits, grants, or subsidies for companies investing in clean technologies. For example, some jurisdictions offer incentives for the installation of carbon capture and storage (CCS) systems, which could potentially be applied to processes involving magnesium nitrate.

Regulatory frameworks also often include standards and certification processes for GHG reduction technologies. These ensure that new solutions meet specific performance criteria and can be reliably measured and verified. For magnesium nitrate and similar technologies, such standards would need to be developed and integrated into existing regulatory structures.

As the urgency to address climate change intensifies, regulatory frameworks are likely to become more stringent and comprehensive. This evolving landscape will continue to shape the development, adoption, and implementation of GHG reduction technologies, including potential applications of magnesium nitrate in various industrial processes.

In the United States, the Environmental Protection Agency (EPA) is responsible for regulating GHG emissions under the Clean Air Act. The EPA has implemented various programs, such as the Greenhouse Gas Reporting Program, which requires large emitters to report their GHG emissions annually. Additionally, the agency has established emissions standards for vehicles and power plants, which indirectly promote the adoption of GHG reduction technologies.

The European Union has taken a leading role in climate regulation through its Emissions Trading System (EU ETS), the world's first and largest carbon market. This cap-and-trade system creates economic incentives for industries to reduce their GHG emissions and invest in cleaner technologies. The EU has also set binding targets for renewable energy and energy efficiency, further driving the development and adoption of GHG reduction solutions.

In China, the world's largest GHG emitter, the government has implemented a national emissions trading scheme and set ambitious targets for carbon neutrality by 2060. These policies are expected to accelerate the adoption of GHG reduction technologies across various sectors of the Chinese economy.

Many countries have also introduced specific regulations and incentives to promote the use of GHG reduction technologies. These may include tax credits, grants, or subsidies for companies investing in clean technologies. For example, some jurisdictions offer incentives for the installation of carbon capture and storage (CCS) systems, which could potentially be applied to processes involving magnesium nitrate.

Regulatory frameworks also often include standards and certification processes for GHG reduction technologies. These ensure that new solutions meet specific performance criteria and can be reliably measured and verified. For magnesium nitrate and similar technologies, such standards would need to be developed and integrated into existing regulatory structures.

As the urgency to address climate change intensifies, regulatory frameworks are likely to become more stringent and comprehensive. This evolving landscape will continue to shape the development, adoption, and implementation of GHG reduction technologies, including potential applications of magnesium nitrate in various industrial processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!