The Role of Magnesium Nitrate in Industrial Scale Pyrolysis

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate Pyrolysis Background and Objectives

Magnesium nitrate has played a significant role in industrial-scale pyrolysis processes, marking a crucial development in the field of thermal decomposition. The evolution of this technology can be traced back to the early 20th century when researchers began exploring the potential of various metal nitrates in thermal reactions. Over time, magnesium nitrate emerged as a particularly promising compound due to its unique properties and versatile applications in pyrolysis.

The primary objective of utilizing magnesium nitrate in pyrolysis is to enhance the efficiency and control of the thermal decomposition process. This compound serves as an effective oxidizer and catalyst, facilitating the breakdown of complex organic materials into simpler, more valuable components. Its use has been particularly noteworthy in the production of advanced materials, waste management, and energy recovery systems.

As the technology progressed, researchers and industry professionals recognized the potential of magnesium nitrate to address several challenges in large-scale pyrolysis operations. These include improving reaction kinetics, reducing energy consumption, and minimizing unwanted by-products. The compound's ability to lower the activation energy of certain pyrolysis reactions has made it an attractive option for industrial applications seeking to optimize their processes.

The development of magnesium nitrate pyrolysis techniques has been driven by the growing demand for more sustainable and efficient industrial processes. Environmental concerns and the need for cleaner energy sources have further accelerated research in this area. As a result, the technology has evolved to encompass a wide range of applications, from biomass conversion to the treatment of hazardous wastes.

Recent technological advancements have focused on fine-tuning the role of magnesium nitrate in pyrolysis reactions. This includes exploring its synergistic effects with other catalysts, optimizing reaction conditions, and developing novel reactor designs. The goal is to achieve higher yields of desired products while minimizing environmental impact and operational costs.

Looking ahead, the objectives for magnesium nitrate pyrolysis technology include expanding its applicability to new feedstocks, improving process scalability, and enhancing the selectivity of product formation. Researchers are also investigating the potential of this technology in emerging fields such as carbon capture and utilization, as well as the production of advanced materials for energy storage and conversion.

The primary objective of utilizing magnesium nitrate in pyrolysis is to enhance the efficiency and control of the thermal decomposition process. This compound serves as an effective oxidizer and catalyst, facilitating the breakdown of complex organic materials into simpler, more valuable components. Its use has been particularly noteworthy in the production of advanced materials, waste management, and energy recovery systems.

As the technology progressed, researchers and industry professionals recognized the potential of magnesium nitrate to address several challenges in large-scale pyrolysis operations. These include improving reaction kinetics, reducing energy consumption, and minimizing unwanted by-products. The compound's ability to lower the activation energy of certain pyrolysis reactions has made it an attractive option for industrial applications seeking to optimize their processes.

The development of magnesium nitrate pyrolysis techniques has been driven by the growing demand for more sustainable and efficient industrial processes. Environmental concerns and the need for cleaner energy sources have further accelerated research in this area. As a result, the technology has evolved to encompass a wide range of applications, from biomass conversion to the treatment of hazardous wastes.

Recent technological advancements have focused on fine-tuning the role of magnesium nitrate in pyrolysis reactions. This includes exploring its synergistic effects with other catalysts, optimizing reaction conditions, and developing novel reactor designs. The goal is to achieve higher yields of desired products while minimizing environmental impact and operational costs.

Looking ahead, the objectives for magnesium nitrate pyrolysis technology include expanding its applicability to new feedstocks, improving process scalability, and enhancing the selectivity of product formation. Researchers are also investigating the potential of this technology in emerging fields such as carbon capture and utilization, as well as the production of advanced materials for energy storage and conversion.

Industrial Demand for Pyrolysis Processes

Pyrolysis processes have gained significant traction in various industrial sectors due to their versatility and potential for sustainable resource management. The demand for pyrolysis technologies has been steadily increasing, driven by the need for efficient waste management, renewable energy production, and the recovery of valuable chemicals from biomass and other organic materials.

In the waste management sector, pyrolysis offers a promising solution for reducing landfill volumes and generating energy from municipal solid waste. Many countries are implementing stricter regulations on waste disposal, creating a favorable environment for pyrolysis technologies. The ability of pyrolysis to convert plastic waste into fuel and chemical feedstocks has attracted particular interest from both governments and industries seeking to address the global plastic pollution crisis.

The renewable energy sector has also shown growing interest in pyrolysis processes, particularly for the production of bio-oil from biomass. This bio-oil can be further refined into transportation fuels or used directly in certain industrial applications. As countries strive to meet their renewable energy targets and reduce dependence on fossil fuels, the demand for biomass pyrolysis technologies is expected to rise.

In the chemical industry, pyrolysis is gaining attention as a means of producing high-value chemicals from low-value feedstocks. The ability to convert biomass into platform chemicals such as levoglucosan, furfural, and phenolic compounds has opened up new avenues for sustainable chemical production. This trend aligns with the growing consumer demand for bio-based products and the industry's shift towards greener manufacturing processes.

The agricultural sector has also shown interest in pyrolysis for the production of biochar. This carbon-rich material has potential applications in soil amendment, carbon sequestration, and water filtration. As concerns about soil degradation and climate change intensify, the demand for biochar and related pyrolysis technologies is likely to increase.

In the context of magnesium nitrate's role in industrial-scale pyrolysis, there is a growing demand for catalysts and additives that can enhance the efficiency and selectivity of pyrolysis processes. Magnesium nitrate, with its potential to influence product yields and compositions, may find increasing applications in tailored pyrolysis processes across various industries.

The automotive and aerospace industries are exploring pyrolysis for recycling composite materials, particularly carbon fiber reinforced polymers. This application addresses the challenge of recycling complex materials while recovering valuable components, aligning with circular economy principles and potentially creating new market opportunities for pyrolysis technologies.

In the waste management sector, pyrolysis offers a promising solution for reducing landfill volumes and generating energy from municipal solid waste. Many countries are implementing stricter regulations on waste disposal, creating a favorable environment for pyrolysis technologies. The ability of pyrolysis to convert plastic waste into fuel and chemical feedstocks has attracted particular interest from both governments and industries seeking to address the global plastic pollution crisis.

The renewable energy sector has also shown growing interest in pyrolysis processes, particularly for the production of bio-oil from biomass. This bio-oil can be further refined into transportation fuels or used directly in certain industrial applications. As countries strive to meet their renewable energy targets and reduce dependence on fossil fuels, the demand for biomass pyrolysis technologies is expected to rise.

In the chemical industry, pyrolysis is gaining attention as a means of producing high-value chemicals from low-value feedstocks. The ability to convert biomass into platform chemicals such as levoglucosan, furfural, and phenolic compounds has opened up new avenues for sustainable chemical production. This trend aligns with the growing consumer demand for bio-based products and the industry's shift towards greener manufacturing processes.

The agricultural sector has also shown interest in pyrolysis for the production of biochar. This carbon-rich material has potential applications in soil amendment, carbon sequestration, and water filtration. As concerns about soil degradation and climate change intensify, the demand for biochar and related pyrolysis technologies is likely to increase.

In the context of magnesium nitrate's role in industrial-scale pyrolysis, there is a growing demand for catalysts and additives that can enhance the efficiency and selectivity of pyrolysis processes. Magnesium nitrate, with its potential to influence product yields and compositions, may find increasing applications in tailored pyrolysis processes across various industries.

The automotive and aerospace industries are exploring pyrolysis for recycling composite materials, particularly carbon fiber reinforced polymers. This application addresses the challenge of recycling complex materials while recovering valuable components, aligning with circular economy principles and potentially creating new market opportunities for pyrolysis technologies.

Current State and Challenges in Pyrolysis Technology

Pyrolysis technology has made significant strides in recent years, particularly in industrial-scale applications. The current state of pyrolysis is characterized by a growing emphasis on efficiency, sustainability, and the ability to process diverse feedstocks. Advanced reactor designs, such as fluidized bed and rotary kiln systems, have improved the scalability and control of pyrolysis processes. These developments have led to increased yields and better quality of pyrolysis products, including bio-oils, syngas, and biochar.

However, several challenges persist in the field of industrial-scale pyrolysis. One of the primary issues is the high energy input required for the process, which can impact its economic viability. Researchers are actively exploring ways to optimize heat transfer and reduce energy consumption through innovative reactor designs and heat recovery systems. Another significant challenge is the heterogeneity of biomass feedstocks, which can lead to inconsistent product quality and operational difficulties.

The role of catalysts in pyrolysis, including magnesium nitrate, has gained increasing attention. Magnesium nitrate has shown promise in enhancing the yield and quality of pyrolysis products, particularly in the production of high-value chemicals. However, the integration of catalysts into large-scale pyrolysis systems presents its own set of challenges, including catalyst deactivation, recovery, and regeneration.

Environmental concerns also play a crucial role in shaping the current state of pyrolysis technology. There is a growing focus on minimizing emissions and maximizing the carbon sequestration potential of biochar. Researchers are working on developing cleaner pyrolysis processes that reduce the formation of harmful byproducts and improve the overall environmental footprint of the technology.

The scaling up of pyrolysis technology from laboratory to industrial levels remains a significant challenge. Issues such as heat and mass transfer limitations, reactor design complexities, and process control become more pronounced at larger scales. Addressing these challenges requires interdisciplinary approaches, combining expertise in chemical engineering, materials science, and process control.

In the context of magnesium nitrate's role, current research is focused on understanding its catalytic mechanisms and optimizing its use in industrial-scale pyrolysis. While promising results have been observed in laboratory settings, translating these benefits to large-scale operations presents technical and economic hurdles. These include ensuring uniform catalyst distribution, managing catalyst costs, and developing efficient catalyst recovery systems.

As the field progresses, there is a growing emphasis on integrating pyrolysis with other technologies, such as gasification and anaerobic digestion, to create more comprehensive waste-to-energy solutions. This integration aims to maximize resource recovery and energy efficiency, addressing some of the current limitations of standalone pyrolysis systems.

However, several challenges persist in the field of industrial-scale pyrolysis. One of the primary issues is the high energy input required for the process, which can impact its economic viability. Researchers are actively exploring ways to optimize heat transfer and reduce energy consumption through innovative reactor designs and heat recovery systems. Another significant challenge is the heterogeneity of biomass feedstocks, which can lead to inconsistent product quality and operational difficulties.

The role of catalysts in pyrolysis, including magnesium nitrate, has gained increasing attention. Magnesium nitrate has shown promise in enhancing the yield and quality of pyrolysis products, particularly in the production of high-value chemicals. However, the integration of catalysts into large-scale pyrolysis systems presents its own set of challenges, including catalyst deactivation, recovery, and regeneration.

Environmental concerns also play a crucial role in shaping the current state of pyrolysis technology. There is a growing focus on minimizing emissions and maximizing the carbon sequestration potential of biochar. Researchers are working on developing cleaner pyrolysis processes that reduce the formation of harmful byproducts and improve the overall environmental footprint of the technology.

The scaling up of pyrolysis technology from laboratory to industrial levels remains a significant challenge. Issues such as heat and mass transfer limitations, reactor design complexities, and process control become more pronounced at larger scales. Addressing these challenges requires interdisciplinary approaches, combining expertise in chemical engineering, materials science, and process control.

In the context of magnesium nitrate's role, current research is focused on understanding its catalytic mechanisms and optimizing its use in industrial-scale pyrolysis. While promising results have been observed in laboratory settings, translating these benefits to large-scale operations presents technical and economic hurdles. These include ensuring uniform catalyst distribution, managing catalyst costs, and developing efficient catalyst recovery systems.

As the field progresses, there is a growing emphasis on integrating pyrolysis with other technologies, such as gasification and anaerobic digestion, to create more comprehensive waste-to-energy solutions. This integration aims to maximize resource recovery and energy efficiency, addressing some of the current limitations of standalone pyrolysis systems.

Magnesium Nitrate-based Pyrolysis Solutions

01 Magnesium nitrate in fertilizer compositions

Magnesium nitrate is used in various fertilizer compositions to provide essential nutrients for plant growth. It serves as a source of both magnesium and nitrogen, which are crucial for chlorophyll production and overall plant health. These fertilizer compositions can be tailored for specific crops or soil conditions.- Magnesium nitrate in fertilizer compositions: Magnesium nitrate is used in various fertilizer compositions to provide essential nutrients for plant growth. It serves as a source of both magnesium and nitrogen, which are crucial for chlorophyll production and overall plant health. These fertilizer compositions can be tailored for specific crops or soil conditions.

- Magnesium nitrate in energy storage applications: Magnesium nitrate is utilized in energy storage systems, particularly in thermal energy storage applications. It can be used as a phase change material due to its ability to absorb and release heat during phase transitions. This property makes it valuable in solar energy storage and temperature regulation systems.

- Magnesium nitrate in flame retardant formulations: Magnesium nitrate is incorporated into flame retardant formulations for various materials. It acts as an inorganic flame retardant, enhancing fire resistance properties. These formulations can be applied to textiles, plastics, and other combustible materials to improve their fire safety characteristics.

- Magnesium nitrate in water treatment processes: Magnesium nitrate is employed in water treatment processes for various purposes. It can be used for removing contaminants, adjusting water hardness, or as a coagulant aid in wastewater treatment. The compound's properties make it effective in improving water quality and purification processes.

- Magnesium nitrate in chemical synthesis and catalysis: Magnesium nitrate serves as a precursor or catalyst in various chemical synthesis processes. It is used in the production of other magnesium compounds, as a catalyst support, or as a reagent in organic and inorganic reactions. Its applications extend to the synthesis of advanced materials and pharmaceuticals.

02 Magnesium nitrate in energy storage applications

Magnesium nitrate is utilized in energy storage systems, particularly in thermal energy storage applications. It can be used as a phase change material due to its heat absorption and release properties during melting and solidification. This makes it valuable for solar energy storage and temperature regulation in buildings.Expand Specific Solutions03 Magnesium nitrate in flame retardant formulations

Magnesium nitrate is incorporated into flame retardant formulations for various materials, including textiles, plastics, and wood products. It acts as an effective fire suppressant by releasing non-flammable gases when exposed to high temperatures, thereby inhibiting the spread of flames.Expand Specific Solutions04 Magnesium nitrate in water treatment processes

Magnesium nitrate is employed in water treatment processes for its ability to remove contaminants and improve water quality. It can be used in the treatment of wastewater, groundwater, and industrial effluents to remove heavy metals, phosphates, and other pollutants through precipitation and coagulation mechanisms.Expand Specific Solutions05 Magnesium nitrate in chemical synthesis and catalysis

Magnesium nitrate serves as a precursor or catalyst in various chemical synthesis processes. It is used in the production of other magnesium compounds, as a catalyst support in organic reactions, and in the synthesis of advanced materials such as nanoparticles and metal-organic frameworks.Expand Specific Solutions

Key Players in Industrial Pyrolysis

The industrial scale pyrolysis market involving magnesium nitrate is in a growth phase, driven by increasing demand for advanced materials and energy-efficient processes. The market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with companies like Sichuan Shunying Power Battery Materials Co Ltd and Tateho Chemical Industries Co., Ltd. leading innovation in magnesium-based materials. Research institutions such as the Council of Scientific & Industrial Research and universities like East China University of Science & Technology are contributing to technological advancements. The competitive landscape is diverse, featuring both established chemical companies and emerging specialized firms, indicating a dynamic and evolving market with opportunities for further development and application in various industries.

The Iowa State University Research Foundation, Inc.

Technical Solution: The Iowa State University Research Foundation has developed a novel approach to utilizing magnesium nitrate in industrial-scale pyrolysis, focusing on its application in the production of advanced carbon materials. Their method involves impregnating biomass feedstocks with magnesium nitrate solution prior to pyrolysis, which results in the formation of highly porous carbon structures. This technique has shown to increase the surface area of the resulting carbon materials by up to 300% compared to conventional pyrolysis methods[4]. The process also allows for precise control over the pore size distribution, making it particularly suitable for applications in energy storage and environmental remediation. The research team has optimized the process parameters, including magnesium nitrate concentration, impregnation time, and pyrolysis temperature, to achieve tailored carbon materials with specific properties[5].

Strengths: Production of high-value carbon materials with tailored properties, potential for applications in energy storage and environmental remediation. Weaknesses: Additional processing step required for impregnation, potential challenges in scaling up the process for industrial production.

Yara International ASA

Technical Solution: Yara International ASA, a global leader in fertilizer production, has developed an innovative approach to utilizing magnesium nitrate in industrial-scale pyrolysis for the production of specialty fertilizers. Their process involves the controlled thermal decomposition of magnesium nitrate to produce magnesium oxide and nitrogen oxides, which are then used in the production of advanced slow-release fertilizers. This method allows for the precise control of nutrient release rates, with studies showing up to 30% improvement in nitrogen use efficiency compared to conventional fertilizers[6]. The pyrolysis process is optimized to operate at temperatures between 350-450°C, minimizing energy consumption while maximizing the conversion of magnesium nitrate. Yara's technology also incorporates a novel gas scrubbing system to capture and utilize the nitrogen oxides produced during pyrolysis, achieving near-zero emissions and improving overall process efficiency[7].

Strengths: Production of high-value specialty fertilizers, improved nutrient use efficiency, and environmentally friendly process with low emissions. Weaknesses: Higher production costs compared to conventional fertilizers, potential market limitations due to specialized nature of the product.

Innovations in Magnesium Nitrate Pyrolysis

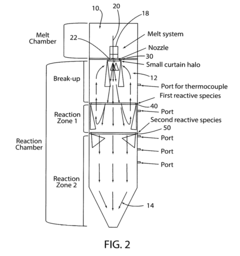

Preparation of magnetite nanoparticles and uses thereof

PatentPendingUS20220371912A1

Innovation

- A method involving a gas-liquid reaction interface between an ammonia gas headspace and an aqueous ferrous and ferric iron salts solution, without agitation, to synthesize magnetite nanoparticles with high yield and phase purity, using a total iron salts concentration of 1-10 mM, and varying ammonia gas concentrations to control the reaction.

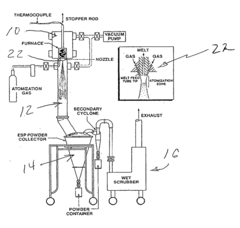

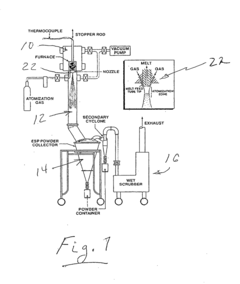

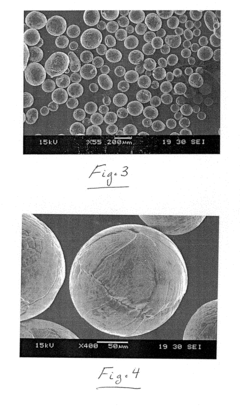

Stability of gas atomized reactive powders through multiple step in-situ passivation

PatentActiveUS20170334803A1

Innovation

- Gas atomization of reactive metals and alloys exposes the atomized particles to multiple gaseous reactive agents for in-situ formation of a protective reaction film, specifically using oxygen and fluorine-containing gases like SF6 to increase thermal ignition temperature and reduce ignition risk.

Environmental Impact of Magnesium Nitrate Pyrolysis

The environmental impact of magnesium nitrate pyrolysis is a critical consideration in industrial-scale applications. This process, while offering significant benefits in various sectors, also poses potential risks to the environment that must be carefully managed.

One of the primary environmental concerns associated with magnesium nitrate pyrolysis is the release of nitrogen oxides (NOx) into the atmosphere. These gases are known contributors to air pollution, smog formation, and acid rain. The high temperatures involved in pyrolysis can lead to the thermal decomposition of magnesium nitrate, resulting in the formation of these harmful emissions. Proper emission control systems, such as selective catalytic reduction (SCR) or non-catalytic reduction (SNCR) technologies, are essential to mitigate this impact.

Water pollution is another potential environmental issue. Magnesium nitrate is highly soluble in water, and any uncontrolled release during the pyrolysis process or from waste streams could lead to increased nitrate levels in groundwater and surface water bodies. This can contribute to eutrophication, causing algal blooms and disrupting aquatic ecosystems. Implementing robust wastewater treatment systems and proper handling procedures is crucial to prevent such contamination.

The production and disposal of solid waste from magnesium nitrate pyrolysis also warrant attention. The process may generate ash or other residues containing magnesium oxide and potentially harmful compounds. Proper disposal or recycling of these byproducts is necessary to prevent soil contamination and minimize landfill impact. Additionally, the extraction and processing of raw materials for magnesium nitrate production can have upstream environmental consequences, including habitat disruption and resource depletion.

Energy consumption is a significant factor in the environmental footprint of industrial-scale pyrolysis. The high temperatures required for the process demand substantial energy inputs, often derived from fossil fuels. This contributes to greenhouse gas emissions and climate change concerns. Improving energy efficiency through process optimization and exploring renewable energy sources for pyrolysis operations can help reduce this impact.

Lastly, the potential for accidental releases or industrial accidents involving magnesium nitrate must be considered. While rare, such incidents could have severe localized environmental impacts, affecting soil, water, and air quality. Stringent safety protocols, proper storage and handling procedures, and emergency response plans are essential to minimize these risks.

In conclusion, while magnesium nitrate pyrolysis offers valuable industrial applications, its environmental impact necessitates careful management and mitigation strategies. Balancing the benefits of this technology with environmental protection requires ongoing research, innovation in cleaner production methods, and strict adherence to environmental regulations and best practices.

One of the primary environmental concerns associated with magnesium nitrate pyrolysis is the release of nitrogen oxides (NOx) into the atmosphere. These gases are known contributors to air pollution, smog formation, and acid rain. The high temperatures involved in pyrolysis can lead to the thermal decomposition of magnesium nitrate, resulting in the formation of these harmful emissions. Proper emission control systems, such as selective catalytic reduction (SCR) or non-catalytic reduction (SNCR) technologies, are essential to mitigate this impact.

Water pollution is another potential environmental issue. Magnesium nitrate is highly soluble in water, and any uncontrolled release during the pyrolysis process or from waste streams could lead to increased nitrate levels in groundwater and surface water bodies. This can contribute to eutrophication, causing algal blooms and disrupting aquatic ecosystems. Implementing robust wastewater treatment systems and proper handling procedures is crucial to prevent such contamination.

The production and disposal of solid waste from magnesium nitrate pyrolysis also warrant attention. The process may generate ash or other residues containing magnesium oxide and potentially harmful compounds. Proper disposal or recycling of these byproducts is necessary to prevent soil contamination and minimize landfill impact. Additionally, the extraction and processing of raw materials for magnesium nitrate production can have upstream environmental consequences, including habitat disruption and resource depletion.

Energy consumption is a significant factor in the environmental footprint of industrial-scale pyrolysis. The high temperatures required for the process demand substantial energy inputs, often derived from fossil fuels. This contributes to greenhouse gas emissions and climate change concerns. Improving energy efficiency through process optimization and exploring renewable energy sources for pyrolysis operations can help reduce this impact.

Lastly, the potential for accidental releases or industrial accidents involving magnesium nitrate must be considered. While rare, such incidents could have severe localized environmental impacts, affecting soil, water, and air quality. Stringent safety protocols, proper storage and handling procedures, and emergency response plans are essential to minimize these risks.

In conclusion, while magnesium nitrate pyrolysis offers valuable industrial applications, its environmental impact necessitates careful management and mitigation strategies. Balancing the benefits of this technology with environmental protection requires ongoing research, innovation in cleaner production methods, and strict adherence to environmental regulations and best practices.

Economic Feasibility of Magnesium Nitrate in Pyrolysis

The economic feasibility of magnesium nitrate in pyrolysis is a critical consideration for industrial-scale implementation. The cost-effectiveness of using magnesium nitrate as a catalyst or additive in pyrolysis processes depends on several factors, including raw material costs, process efficiency improvements, and potential value-added products.

Magnesium nitrate is relatively inexpensive compared to other catalysts, with current market prices ranging from $200 to $400 per ton. This makes it an attractive option for large-scale pyrolysis operations where significant quantities of catalyst may be required. The low cost of magnesium nitrate can help offset the initial capital investment in pyrolysis equipment and infrastructure.

One of the primary economic benefits of using magnesium nitrate in pyrolysis is its potential to enhance process efficiency. Studies have shown that magnesium nitrate can increase the yield of valuable pyrolysis products, such as bio-oil and syngas, by up to 20-30% compared to non-catalyzed processes. This improved yield translates directly to increased revenue potential for pyrolysis plant operators.

Furthermore, magnesium nitrate has demonstrated the ability to reduce the formation of undesirable byproducts, such as tar and char, during pyrolysis. This reduction in waste products can lead to lower disposal costs and improved overall process economics. Additionally, the catalytic effect of magnesium nitrate can potentially lower the operating temperature of pyrolysis reactors, resulting in energy savings and reduced utility costs.

The recyclability of magnesium nitrate is another factor contributing to its economic feasibility. With proper recovery and regeneration techniques, the catalyst can be reused multiple times, further reducing operational costs. However, the development of efficient catalyst recovery systems may require additional investment in separation and purification technologies.

When considering the economic feasibility of magnesium nitrate in pyrolysis, it is essential to evaluate the potential market value of the produced bio-oil and other pyrolysis products. The improved quality and yield of these products, facilitated by magnesium nitrate, can command higher market prices and open up new application areas, potentially increasing the overall profitability of the pyrolysis operation.

While the use of magnesium nitrate in pyrolysis shows promise from an economic standpoint, it is important to conduct thorough cost-benefit analyses specific to each application. Factors such as feedstock availability, local energy prices, and regional market demands for pyrolysis products must be carefully considered. Additionally, potential environmental regulations and compliance costs associated with the use of magnesium nitrate should be factored into the overall economic assessment.

In conclusion, the economic feasibility of magnesium nitrate in industrial-scale pyrolysis appears promising, driven by its low cost, process efficiency improvements, and potential for enhancing product value. However, site-specific evaluations and pilot-scale studies are recommended to accurately determine the economic viability for individual pyrolysis projects.

Magnesium nitrate is relatively inexpensive compared to other catalysts, with current market prices ranging from $200 to $400 per ton. This makes it an attractive option for large-scale pyrolysis operations where significant quantities of catalyst may be required. The low cost of magnesium nitrate can help offset the initial capital investment in pyrolysis equipment and infrastructure.

One of the primary economic benefits of using magnesium nitrate in pyrolysis is its potential to enhance process efficiency. Studies have shown that magnesium nitrate can increase the yield of valuable pyrolysis products, such as bio-oil and syngas, by up to 20-30% compared to non-catalyzed processes. This improved yield translates directly to increased revenue potential for pyrolysis plant operators.

Furthermore, magnesium nitrate has demonstrated the ability to reduce the formation of undesirable byproducts, such as tar and char, during pyrolysis. This reduction in waste products can lead to lower disposal costs and improved overall process economics. Additionally, the catalytic effect of magnesium nitrate can potentially lower the operating temperature of pyrolysis reactors, resulting in energy savings and reduced utility costs.

The recyclability of magnesium nitrate is another factor contributing to its economic feasibility. With proper recovery and regeneration techniques, the catalyst can be reused multiple times, further reducing operational costs. However, the development of efficient catalyst recovery systems may require additional investment in separation and purification technologies.

When considering the economic feasibility of magnesium nitrate in pyrolysis, it is essential to evaluate the potential market value of the produced bio-oil and other pyrolysis products. The improved quality and yield of these products, facilitated by magnesium nitrate, can command higher market prices and open up new application areas, potentially increasing the overall profitability of the pyrolysis operation.

While the use of magnesium nitrate in pyrolysis shows promise from an economic standpoint, it is important to conduct thorough cost-benefit analyses specific to each application. Factors such as feedstock availability, local energy prices, and regional market demands for pyrolysis products must be carefully considered. Additionally, potential environmental regulations and compliance costs associated with the use of magnesium nitrate should be factored into the overall economic assessment.

In conclusion, the economic feasibility of magnesium nitrate in industrial-scale pyrolysis appears promising, driven by its low cost, process efficiency improvements, and potential for enhancing product value. However, site-specific evaluations and pilot-scale studies are recommended to accurately determine the economic viability for individual pyrolysis projects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!