The Role of Nichrome in Sustainable Material Engineering

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Evolution

Nichrome, an alloy primarily composed of nickel and chromium, has undergone significant evolution since its inception in the early 20th century. Initially developed for its high electrical resistance and heat-resistant properties, nichrome has played a crucial role in various industries, particularly in sustainable material engineering.

The evolution of nichrome can be traced through several key stages. In its early days, the focus was on optimizing the nickel-chromium ratio to achieve the desired electrical and thermal properties. As manufacturing techniques improved, the consistency and quality of nichrome production saw substantial enhancements, leading to more reliable and efficient applications in heating elements and resistors.

The mid-20th century marked a turning point in nichrome's evolution, with the introduction of additional alloying elements. These modifications aimed to improve specific characteristics such as oxidation resistance, strength at high temperatures, and overall durability. Elements like iron, aluminum, and silicon were incorporated in small quantities, giving rise to various grades of nichrome with tailored properties for specific applications.

In the latter part of the 20th century, the evolution of nichrome was driven by the growing demand for energy-efficient and environmentally friendly materials. This period saw the development of thin-film nichrome resistors, which offered improved precision and miniaturization capabilities. The advent of nanotechnology further revolutionized nichrome applications, enabling the creation of nanostructured nichrome films with enhanced properties and performance.

The 21st century has witnessed a renewed focus on sustainability in material engineering, propelling nichrome's evolution in new directions. Research efforts have been directed towards improving the recyclability of nichrome-based products and reducing the environmental impact of its production processes. Advanced manufacturing techniques, such as additive manufacturing, have opened up new possibilities for creating complex nichrome structures with optimized properties and reduced material waste.

Recent developments in nichrome evolution have centered on enhancing its role in renewable energy technologies. For instance, nichrome-based materials are being explored for their potential in high-temperature solar thermal systems and advanced battery technologies. The alloy's unique combination of properties makes it an attractive candidate for various sustainable engineering applications, from energy storage to efficient heat management in green buildings.

As we look to the future, the evolution of nichrome continues to be driven by the need for more sustainable and efficient materials. Ongoing research focuses on further improving its properties, exploring new compositions, and developing novel manufacturing techniques. The goal is to create nichrome-based materials that not only meet the current demands of sustainable engineering but also anticipate future challenges in energy efficiency and environmental conservation.

The evolution of nichrome can be traced through several key stages. In its early days, the focus was on optimizing the nickel-chromium ratio to achieve the desired electrical and thermal properties. As manufacturing techniques improved, the consistency and quality of nichrome production saw substantial enhancements, leading to more reliable and efficient applications in heating elements and resistors.

The mid-20th century marked a turning point in nichrome's evolution, with the introduction of additional alloying elements. These modifications aimed to improve specific characteristics such as oxidation resistance, strength at high temperatures, and overall durability. Elements like iron, aluminum, and silicon were incorporated in small quantities, giving rise to various grades of nichrome with tailored properties for specific applications.

In the latter part of the 20th century, the evolution of nichrome was driven by the growing demand for energy-efficient and environmentally friendly materials. This period saw the development of thin-film nichrome resistors, which offered improved precision and miniaturization capabilities. The advent of nanotechnology further revolutionized nichrome applications, enabling the creation of nanostructured nichrome films with enhanced properties and performance.

The 21st century has witnessed a renewed focus on sustainability in material engineering, propelling nichrome's evolution in new directions. Research efforts have been directed towards improving the recyclability of nichrome-based products and reducing the environmental impact of its production processes. Advanced manufacturing techniques, such as additive manufacturing, have opened up new possibilities for creating complex nichrome structures with optimized properties and reduced material waste.

Recent developments in nichrome evolution have centered on enhancing its role in renewable energy technologies. For instance, nichrome-based materials are being explored for their potential in high-temperature solar thermal systems and advanced battery technologies. The alloy's unique combination of properties makes it an attractive candidate for various sustainable engineering applications, from energy storage to efficient heat management in green buildings.

As we look to the future, the evolution of nichrome continues to be driven by the need for more sustainable and efficient materials. Ongoing research focuses on further improving its properties, exploring new compositions, and developing novel manufacturing techniques. The goal is to create nichrome-based materials that not only meet the current demands of sustainable engineering but also anticipate future challenges in energy efficiency and environmental conservation.

Sustainable Material Demand

The demand for sustainable materials has been steadily increasing in recent years, driven by growing environmental concerns and the need for more eco-friendly engineering solutions. Nichrome, an alloy composed of nickel and chromium, has emerged as a promising candidate in sustainable material engineering due to its unique properties and potential applications.

In the construction industry, there is a rising demand for materials that can enhance energy efficiency and reduce carbon footprint. Nichrome's high resistance to corrosion and oxidation makes it an attractive option for building facades and structural components exposed to harsh environmental conditions. Its durability contributes to longer-lasting structures, reducing the need for frequent replacements and minimizing waste generation.

The renewable energy sector has also shown significant interest in sustainable materials like nichrome. As the world transitions towards cleaner energy sources, there is a growing need for materials that can withstand high temperatures and maintain stability in extreme conditions. Nichrome's excellent heat resistance properties make it suitable for use in solar thermal systems and fuel cells, supporting the expansion of renewable energy infrastructure.

In the automotive industry, the push for lightweight and fuel-efficient vehicles has created a demand for materials that can reduce overall vehicle weight without compromising safety or performance. Nichrome's high strength-to-weight ratio makes it an attractive option for various automotive components, contributing to improved fuel efficiency and reduced emissions.

The electronics industry is another sector where the demand for sustainable materials is on the rise. As electronic devices become more compact and powerful, there is a need for materials that can efficiently dissipate heat and maintain performance under high-temperature conditions. Nichrome's electrical resistance properties make it suitable for use in heating elements and resistors, supporting the development of more energy-efficient electronic devices.

Furthermore, the aerospace industry has shown interest in nichrome for its potential applications in aircraft engines and thermal protection systems. The material's ability to withstand high temperatures and resist oxidation aligns with the industry's goals of developing more fuel-efficient and environmentally friendly aircraft.

As global sustainability initiatives continue to gain momentum, the demand for nichrome and other sustainable materials is expected to grow across various industries. Governments and regulatory bodies are implementing stricter environmental regulations, further driving the adoption of sustainable materials in engineering applications. This trend is likely to create new opportunities for innovation and research in the field of sustainable material engineering, with nichrome playing a significant role in addressing the evolving needs of industries seeking to reduce their environmental impact and improve overall sustainability.

In the construction industry, there is a rising demand for materials that can enhance energy efficiency and reduce carbon footprint. Nichrome's high resistance to corrosion and oxidation makes it an attractive option for building facades and structural components exposed to harsh environmental conditions. Its durability contributes to longer-lasting structures, reducing the need for frequent replacements and minimizing waste generation.

The renewable energy sector has also shown significant interest in sustainable materials like nichrome. As the world transitions towards cleaner energy sources, there is a growing need for materials that can withstand high temperatures and maintain stability in extreme conditions. Nichrome's excellent heat resistance properties make it suitable for use in solar thermal systems and fuel cells, supporting the expansion of renewable energy infrastructure.

In the automotive industry, the push for lightweight and fuel-efficient vehicles has created a demand for materials that can reduce overall vehicle weight without compromising safety or performance. Nichrome's high strength-to-weight ratio makes it an attractive option for various automotive components, contributing to improved fuel efficiency and reduced emissions.

The electronics industry is another sector where the demand for sustainable materials is on the rise. As electronic devices become more compact and powerful, there is a need for materials that can efficiently dissipate heat and maintain performance under high-temperature conditions. Nichrome's electrical resistance properties make it suitable for use in heating elements and resistors, supporting the development of more energy-efficient electronic devices.

Furthermore, the aerospace industry has shown interest in nichrome for its potential applications in aircraft engines and thermal protection systems. The material's ability to withstand high temperatures and resist oxidation aligns with the industry's goals of developing more fuel-efficient and environmentally friendly aircraft.

As global sustainability initiatives continue to gain momentum, the demand for nichrome and other sustainable materials is expected to grow across various industries. Governments and regulatory bodies are implementing stricter environmental regulations, further driving the adoption of sustainable materials in engineering applications. This trend is likely to create new opportunities for innovation and research in the field of sustainable material engineering, with nichrome playing a significant role in addressing the evolving needs of industries seeking to reduce their environmental impact and improve overall sustainability.

Nichrome Challenges

Despite its widespread use in various industries, nichrome faces several challenges in the context of sustainable material engineering. One of the primary concerns is the environmental impact associated with its production and disposal. The mining and processing of nickel and chromium, the main components of nichrome, can lead to significant ecological disruptions and contribute to greenhouse gas emissions. Additionally, the energy-intensive manufacturing process of nichrome alloys further exacerbates its carbon footprint.

Another challenge lies in the limited recyclability of nichrome. While the alloy itself is recyclable, the process is often complex and energy-intensive, particularly when nichrome is used in composite materials or coatings. This difficulty in recycling can lead to increased waste and resource depletion, contradicting the principles of sustainable engineering.

The potential health risks associated with nichrome production and use also pose significant challenges. Exposure to nickel and chromium compounds during manufacturing or when nichrome is heated to high temperatures can lead to respiratory issues and other health concerns. This necessitates stringent safety measures and protective equipment, which can increase production costs and complexity.

Furthermore, the rising costs and potential scarcity of nickel and chromium present economic challenges for sustainable nichrome production. As global demand for these metals increases, particularly in emerging technologies like electric vehicle batteries, securing a stable and affordable supply chain for nichrome becomes increasingly difficult.

The performance limitations of nichrome in certain applications also present challenges for its sustainable use. While nichrome exhibits excellent resistance to oxidation and corrosion at high temperatures, it may not perform optimally in all environments or applications. This can lead to premature failure or the need for frequent replacements, which contradicts sustainable engineering principles.

Lastly, the development of alternative materials that offer similar or superior properties to nichrome while being more environmentally friendly poses a significant challenge to the continued use of nichrome in sustainable engineering. As research progresses in materials science, new alloys or composites may emerge that outperform nichrome in terms of both functionality and sustainability, potentially rendering nichrome obsolete in certain applications.

Addressing these challenges requires a multifaceted approach, involving improvements in production processes, enhanced recycling technologies, development of safer handling practices, and exploration of alternative materials. The future of nichrome in sustainable material engineering will depend on the industry's ability to innovate and adapt to these pressing challenges.

Another challenge lies in the limited recyclability of nichrome. While the alloy itself is recyclable, the process is often complex and energy-intensive, particularly when nichrome is used in composite materials or coatings. This difficulty in recycling can lead to increased waste and resource depletion, contradicting the principles of sustainable engineering.

The potential health risks associated with nichrome production and use also pose significant challenges. Exposure to nickel and chromium compounds during manufacturing or when nichrome is heated to high temperatures can lead to respiratory issues and other health concerns. This necessitates stringent safety measures and protective equipment, which can increase production costs and complexity.

Furthermore, the rising costs and potential scarcity of nickel and chromium present economic challenges for sustainable nichrome production. As global demand for these metals increases, particularly in emerging technologies like electric vehicle batteries, securing a stable and affordable supply chain for nichrome becomes increasingly difficult.

The performance limitations of nichrome in certain applications also present challenges for its sustainable use. While nichrome exhibits excellent resistance to oxidation and corrosion at high temperatures, it may not perform optimally in all environments or applications. This can lead to premature failure or the need for frequent replacements, which contradicts sustainable engineering principles.

Lastly, the development of alternative materials that offer similar or superior properties to nichrome while being more environmentally friendly poses a significant challenge to the continued use of nichrome in sustainable engineering. As research progresses in materials science, new alloys or composites may emerge that outperform nichrome in terms of both functionality and sustainability, potentially rendering nichrome obsolete in certain applications.

Addressing these challenges requires a multifaceted approach, involving improvements in production processes, enhanced recycling technologies, development of safer handling practices, and exploration of alternative materials. The future of nichrome in sustainable material engineering will depend on the industry's ability to innovate and adapt to these pressing challenges.

Current Nichrome Solutions

01 Composition and properties of nichrome alloys

Nichrome is an alloy primarily composed of nickel and chromium, with varying compositions for different applications. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.- Composition and properties of nichrome alloys: Nichrome is an alloy primarily composed of nickel and chromium, with varying compositions for different applications. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.

- Nichrome in heating elements and electrical resistors: Nichrome is widely used in the manufacturing of heating elements and electrical resistors due to its high electrical resistance and stability at high temperatures. It is commonly found in appliances such as hair dryers, toasters, and electric heaters. The alloy's properties allow for efficient and reliable heat generation in these applications.

- Nichrome in thin film technology: Nichrome is utilized in thin film technology for various electronic applications. It can be deposited as a thin film using techniques such as sputtering or evaporation. These thin films are used in the production of resistors, sensors, and other microelectronic components, offering precise control over electrical properties in miniaturized devices.

- Nichrome in aerospace and high-temperature applications: The high temperature resistance and stability of nichrome make it suitable for aerospace and other high-temperature applications. It is used in components that require durability under extreme conditions, such as in aircraft engines, rocket nozzles, and industrial furnaces. The alloy's ability to maintain its properties at elevated temperatures contributes to the reliability and longevity of these critical components.

- Surface treatment and coating of nichrome: Various surface treatment and coating techniques are applied to nichrome to enhance its properties or protect it from specific environmental conditions. These treatments can improve corrosion resistance, reduce oxidation, or modify the surface characteristics for specific applications. Coatings may include ceramic materials, precious metals, or other protective layers to extend the lifespan and performance of nichrome components.

02 Manufacturing processes for nichrome components

Various manufacturing processes are employed to produce nichrome components, including wire drawing, thin film deposition, and powder metallurgy techniques. These processes are optimized to achieve desired physical and electrical properties for specific applications, such as heating elements or sensors.Expand Specific Solutions03 Applications in electronic devices and sensors

Nichrome is widely used in electronic devices and sensors due to its stable electrical properties. It is employed in the fabrication of thin-film resistors, temperature sensors, and other electronic components that require precise resistance values and temperature stability.Expand Specific Solutions04 Heating element applications

Nichrome is extensively used in heating elements for various applications, including household appliances, industrial heaters, and laboratory equipment. Its high resistance to oxidation at elevated temperatures and uniform heating properties make it an ideal material for these applications.Expand Specific Solutions05 Surface treatment and coating techniques

Various surface treatment and coating techniques are applied to nichrome components to enhance their performance and durability. These include oxidation-resistant coatings, insulation layers, and surface modifications to improve adhesion or electrical properties for specific applications.Expand Specific Solutions

Key Nichrome Players

The role of nichrome in sustainable material engineering is evolving within a competitive landscape characterized by both established players and emerging innovators. The industry is in a growth phase, driven by increasing demand for high-performance, sustainable materials across various sectors. The global market for nichrome and related alloys is expanding, with applications in aerospace, electronics, and energy industries. Technologically, companies like Sandvik Intellectual Property AB, NTN Corp., and Haynes International, Inc. are at the forefront, developing advanced nichrome-based materials with enhanced properties. Research institutions such as Lanzhou University of Technology and Xi'an Jiaotong University are contributing to technological advancements, while companies like Baowu Special Metallurgy Co., Ltd. and Taizhou Yongxing Alloy Material Technology Co., Ltd. are focusing on manufacturing and commercialization, indicating a maturing ecosystem in this field.

Haynes International, Inc.

Technical Solution: Haynes International has developed advanced nichrome alloys for sustainable material engineering. Their HASTELLOY® and HAYNES® series incorporate nichrome with additional elements to enhance corrosion resistance and mechanical properties. These alloys are designed for high-temperature applications in aerospace, chemical processing, and energy sectors. The company's research focuses on improving the sustainability of nichrome-based materials through increased durability and recyclability. They have implemented a closed-loop recycling program for their nichrome alloys, reducing raw material consumption and energy use in production[1][3].

Strengths: Expertise in high-performance alloys, established recycling program, wide range of applications. Weaknesses: Higher production costs compared to standard nichrome, limited to specialized markets.

Krupp Vdm AG

Technical Solution: Krupp VDM specializes in developing nichrome-based alloys for sustainable engineering applications. Their VDM® Alloy series incorporates nichrome with precise additions of other elements to optimize performance in corrosive and high-temperature environments. The company focuses on improving the longevity and efficiency of nichrome alloys in industrial settings, particularly in chemical processing and power generation. Krupp VDM has invested in advanced manufacturing techniques to reduce material waste and energy consumption during production. They have also developed a proprietary heat treatment process that enhances the microstructure of nichrome alloys, improving their resistance to creep and fatigue[2][5].

Strengths: Advanced manufacturing techniques, specialized heat treatment processes, focus on industrial applications. Weaknesses: Limited presence in consumer markets, higher initial costs for specialized alloys.

Nichrome Innovations

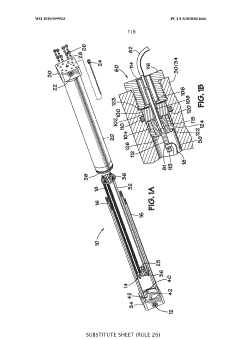

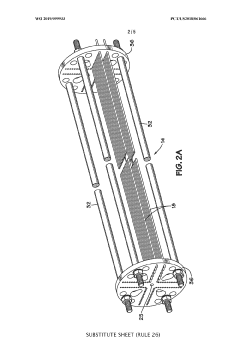

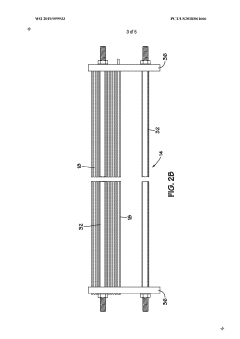

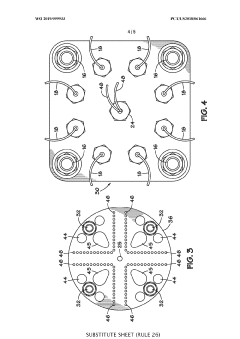

In-line electric heater for plural component materials

PatentWO2019099933A1

Innovation

- An in-line electric heater design featuring a housing with multiple electric resistance heating elements along the fluid flow path, supported by a wire loom assembly and temperature sensors, using INCONEL wires coated with Teflon for improved durability and insulation, and a power feedthrough system for secure electrical connections, enhancing heat transfer and temperature control.

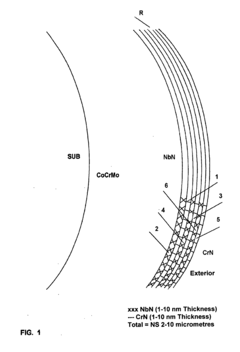

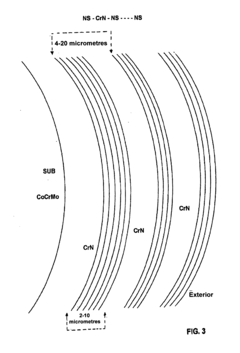

Substrate for wear-proof orthopaedic joints, of non ferrous metal with a nitride-based coating

PatentActiveUS20130197649A1

Innovation

- A biocompatible coating comprising niobium nitride nanolayers and chromium nitride nanolayers, protected by a chromium nitride microlayer, is applied to orthopaedic implants made of Co-Cr-Mo alloys to reduce wear debris and metal ion release, enhancing adhesion and durability.

Nichrome Lifecycle Analysis

Nichrome, an alloy primarily composed of nickel and chromium, plays a significant role in sustainable material engineering. Its lifecycle analysis reveals crucial insights into its environmental impact and potential for sustainable applications. The production of nichrome begins with the extraction of nickel and chromium ores, which are then refined and combined in specific proportions. This initial stage has notable environmental implications, including energy consumption and potential habitat disruption.

During the manufacturing process, nichrome exhibits favorable characteristics that contribute to sustainability. Its high melting point and excellent corrosion resistance allow for the creation of durable products with extended lifespans. This longevity reduces the need for frequent replacements, thereby conserving resources and minimizing waste generation. Additionally, nichrome's electrical properties make it ideal for heating elements in various applications, contributing to energy efficiency in industrial and consumer products.

The use phase of nichrome products demonstrates its sustainability potential. In electrical heating applications, nichrome's stability at high temperatures ensures consistent performance over time, reducing energy waste and improving overall system efficiency. Its corrosion resistance also minimizes the need for protective coatings or frequent maintenance, further reducing environmental impact during the product's operational life.

End-of-life considerations for nichrome products are particularly important in the context of sustainable material engineering. The alloy's composition allows for effective recycling, as both nickel and chromium can be recovered and reused in new products. This recyclability significantly reduces the demand for virgin materials and the associated environmental impacts of mining and refining. However, the recycling process itself requires energy and may produce emissions, necessitating careful management to maximize sustainability benefits.

The lifecycle analysis of nichrome also highlights areas for potential improvement in sustainable practices. Innovations in ore extraction techniques and refining processes could reduce the environmental footprint of nichrome production. Furthermore, designing products for easy disassembly and material recovery can enhance the efficiency of recycling efforts, closing the loop in nichrome's lifecycle and promoting a circular economy approach.

In conclusion, the lifecycle analysis of nichrome reveals its significant potential in sustainable material engineering. While challenges exist, particularly in the initial production stages, nichrome's durability, efficiency, and recyclability make it a valuable material in the pursuit of sustainable engineering solutions. Ongoing research and development in production methods and recycling technologies will further enhance nichrome's role in creating more sustainable products and systems.

During the manufacturing process, nichrome exhibits favorable characteristics that contribute to sustainability. Its high melting point and excellent corrosion resistance allow for the creation of durable products with extended lifespans. This longevity reduces the need for frequent replacements, thereby conserving resources and minimizing waste generation. Additionally, nichrome's electrical properties make it ideal for heating elements in various applications, contributing to energy efficiency in industrial and consumer products.

The use phase of nichrome products demonstrates its sustainability potential. In electrical heating applications, nichrome's stability at high temperatures ensures consistent performance over time, reducing energy waste and improving overall system efficiency. Its corrosion resistance also minimizes the need for protective coatings or frequent maintenance, further reducing environmental impact during the product's operational life.

End-of-life considerations for nichrome products are particularly important in the context of sustainable material engineering. The alloy's composition allows for effective recycling, as both nickel and chromium can be recovered and reused in new products. This recyclability significantly reduces the demand for virgin materials and the associated environmental impacts of mining and refining. However, the recycling process itself requires energy and may produce emissions, necessitating careful management to maximize sustainability benefits.

The lifecycle analysis of nichrome also highlights areas for potential improvement in sustainable practices. Innovations in ore extraction techniques and refining processes could reduce the environmental footprint of nichrome production. Furthermore, designing products for easy disassembly and material recovery can enhance the efficiency of recycling efforts, closing the loop in nichrome's lifecycle and promoting a circular economy approach.

In conclusion, the lifecycle analysis of nichrome reveals its significant potential in sustainable material engineering. While challenges exist, particularly in the initial production stages, nichrome's durability, efficiency, and recyclability make it a valuable material in the pursuit of sustainable engineering solutions. Ongoing research and development in production methods and recycling technologies will further enhance nichrome's role in creating more sustainable products and systems.

Nichrome Recycling Strategies

Nichrome recycling strategies play a crucial role in sustainable material engineering, addressing the growing concern for resource conservation and environmental protection. The recycling of nichrome, an alloy primarily composed of nickel and chromium, presents both challenges and opportunities in the pursuit of a circular economy.

One of the primary strategies for nichrome recycling involves the implementation of advanced separation techniques. These methods aim to efficiently isolate nichrome from other materials in end-of-life products, such as electrical heating elements and industrial furnaces. Magnetic separation, density-based sorting, and electrostatic separation are among the most promising approaches, each offering unique advantages in terms of efficiency and scalability.

Chemical recycling processes have also gained traction in recent years. These methods involve the use of selective leaching agents to dissolve and recover the constituent metals of nichrome. Hydrometallurgical techniques, including acid leaching and solvent extraction, have shown particular promise in achieving high recovery rates while minimizing environmental impact.

The development of novel thermal recycling methods represents another frontier in nichrome recycling. These processes leverage the high melting point of nichrome to separate it from lower-melting-point materials through controlled heating and cooling cycles. Pyrometallurgical approaches, such as plasma arc melting, offer the potential for large-scale recycling with reduced energy consumption compared to traditional smelting methods.

In the realm of product design, the concept of "Design for Recycling" has emerged as a key strategy for facilitating nichrome recovery. This approach involves engineering products with end-of-life considerations in mind, incorporating features that simplify disassembly and material separation. By designing products with easily removable nichrome components, manufacturers can significantly enhance the efficiency and economic viability of recycling processes.

The integration of digital technologies and artificial intelligence into recycling systems represents a promising avenue for optimizing nichrome recovery. Machine learning algorithms can be employed to improve sorting accuracy and process efficiency, while blockchain technology offers potential for enhancing traceability and transparency in the recycling supply chain.

As the demand for nichrome in various industries continues to grow, the development and refinement of these recycling strategies will play an increasingly important role in ensuring the sustainable use of this valuable alloy. By combining technological innovation with thoughtful product design and systemic approaches to material management, the recycling of nichrome can contribute significantly to the broader goals of sustainable material engineering and circular economy principles.

One of the primary strategies for nichrome recycling involves the implementation of advanced separation techniques. These methods aim to efficiently isolate nichrome from other materials in end-of-life products, such as electrical heating elements and industrial furnaces. Magnetic separation, density-based sorting, and electrostatic separation are among the most promising approaches, each offering unique advantages in terms of efficiency and scalability.

Chemical recycling processes have also gained traction in recent years. These methods involve the use of selective leaching agents to dissolve and recover the constituent metals of nichrome. Hydrometallurgical techniques, including acid leaching and solvent extraction, have shown particular promise in achieving high recovery rates while minimizing environmental impact.

The development of novel thermal recycling methods represents another frontier in nichrome recycling. These processes leverage the high melting point of nichrome to separate it from lower-melting-point materials through controlled heating and cooling cycles. Pyrometallurgical approaches, such as plasma arc melting, offer the potential for large-scale recycling with reduced energy consumption compared to traditional smelting methods.

In the realm of product design, the concept of "Design for Recycling" has emerged as a key strategy for facilitating nichrome recovery. This approach involves engineering products with end-of-life considerations in mind, incorporating features that simplify disassembly and material separation. By designing products with easily removable nichrome components, manufacturers can significantly enhance the efficiency and economic viability of recycling processes.

The integration of digital technologies and artificial intelligence into recycling systems represents a promising avenue for optimizing nichrome recovery. Machine learning algorithms can be employed to improve sorting accuracy and process efficiency, while blockchain technology offers potential for enhancing traceability and transparency in the recycling supply chain.

As the demand for nichrome in various industries continues to grow, the development and refinement of these recycling strategies will play an increasingly important role in ensuring the sustainable use of this valuable alloy. By combining technological innovation with thoughtful product design and systemic approaches to material management, the recycling of nichrome can contribute significantly to the broader goals of sustainable material engineering and circular economy principles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!