The Synergy between AI and Piezoelectric Sensors

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AI-Piezo Synergy Background and Objectives

The synergy between Artificial Intelligence (AI) and piezoelectric sensors represents a cutting-edge technological convergence with immense potential for revolutionizing various industries. This fusion combines the sensing capabilities of piezoelectric materials with the analytical power of AI, creating a symbiotic relationship that enhances both technologies.

Piezoelectric sensors, known for their ability to convert mechanical stress into electrical signals, have been widely used in diverse applications for decades. These sensors excel in measuring pressure, acceleration, and vibration, making them invaluable in fields such as automotive, aerospace, and healthcare. However, the traditional use of piezoelectric sensors has been limited by the complexity of signal interpretation and the need for specialized expertise to extract meaningful insights from the data they generate.

The integration of AI with piezoelectric sensors marks a significant leap forward in addressing these limitations. AI algorithms, particularly machine learning and deep learning techniques, can process and analyze the vast amounts of data generated by piezoelectric sensors in real-time. This capability allows for more accurate interpretation of sensor outputs, enabling the detection of subtle patterns and anomalies that might be imperceptible to human analysts or traditional data processing methods.

The evolution of this technological synergy has been driven by advancements in both AI and materials science. As AI algorithms have become more sophisticated and computationally efficient, they have opened up new possibilities for real-time data analysis and decision-making. Concurrently, improvements in piezoelectric materials and sensor design have led to enhanced sensitivity and reliability, providing AI systems with higher quality input data.

The primary objective of this technological convergence is to create intelligent sensing systems that can autonomously monitor, analyze, and respond to physical phenomena with unprecedented accuracy and speed. This goal encompasses several key aims, including enhancing predictive maintenance capabilities in industrial settings, improving structural health monitoring in civil engineering, and advancing medical diagnostics through more sensitive and intelligent biosensors.

Looking ahead, the synergy between AI and piezoelectric sensors is expected to drive innovation across multiple sectors. In manufacturing, it could lead to smarter production lines with real-time quality control and predictive maintenance. In healthcare, it may enable more accurate and less invasive diagnostic tools. In environmental monitoring, it could facilitate more precise tracking of seismic activity and structural integrity in buildings and infrastructure.

As this field continues to evolve, researchers and engineers are focusing on overcoming challenges such as improving the energy efficiency of AI-enabled sensor systems, enhancing the robustness of AI algorithms in noisy environments, and developing standardized protocols for integrating AI with existing sensor networks. The ultimate aim is to create a seamless interface between the physical and digital worlds, where intelligent sensors can provide actionable insights and automate complex decision-making processes across a wide range of applications.

Piezoelectric sensors, known for their ability to convert mechanical stress into electrical signals, have been widely used in diverse applications for decades. These sensors excel in measuring pressure, acceleration, and vibration, making them invaluable in fields such as automotive, aerospace, and healthcare. However, the traditional use of piezoelectric sensors has been limited by the complexity of signal interpretation and the need for specialized expertise to extract meaningful insights from the data they generate.

The integration of AI with piezoelectric sensors marks a significant leap forward in addressing these limitations. AI algorithms, particularly machine learning and deep learning techniques, can process and analyze the vast amounts of data generated by piezoelectric sensors in real-time. This capability allows for more accurate interpretation of sensor outputs, enabling the detection of subtle patterns and anomalies that might be imperceptible to human analysts or traditional data processing methods.

The evolution of this technological synergy has been driven by advancements in both AI and materials science. As AI algorithms have become more sophisticated and computationally efficient, they have opened up new possibilities for real-time data analysis and decision-making. Concurrently, improvements in piezoelectric materials and sensor design have led to enhanced sensitivity and reliability, providing AI systems with higher quality input data.

The primary objective of this technological convergence is to create intelligent sensing systems that can autonomously monitor, analyze, and respond to physical phenomena with unprecedented accuracy and speed. This goal encompasses several key aims, including enhancing predictive maintenance capabilities in industrial settings, improving structural health monitoring in civil engineering, and advancing medical diagnostics through more sensitive and intelligent biosensors.

Looking ahead, the synergy between AI and piezoelectric sensors is expected to drive innovation across multiple sectors. In manufacturing, it could lead to smarter production lines with real-time quality control and predictive maintenance. In healthcare, it may enable more accurate and less invasive diagnostic tools. In environmental monitoring, it could facilitate more precise tracking of seismic activity and structural integrity in buildings and infrastructure.

As this field continues to evolve, researchers and engineers are focusing on overcoming challenges such as improving the energy efficiency of AI-enabled sensor systems, enhancing the robustness of AI algorithms in noisy environments, and developing standardized protocols for integrating AI with existing sensor networks. The ultimate aim is to create a seamless interface between the physical and digital worlds, where intelligent sensors can provide actionable insights and automate complex decision-making processes across a wide range of applications.

Market Demand Analysis for AI-Enhanced Piezo Sensors

The market demand for AI-enhanced piezoelectric sensors is experiencing significant growth, driven by the increasing need for advanced sensing technologies across various industries. This synergy between artificial intelligence and piezoelectric sensors is creating new opportunities and applications, particularly in sectors such as healthcare, automotive, industrial automation, and consumer electronics.

In the healthcare industry, there is a growing demand for AI-enhanced piezoelectric sensors in medical devices and diagnostic equipment. These sensors can provide more accurate and real-time data for patient monitoring, enabling early detection of health issues and improved treatment outcomes. The integration of AI algorithms allows for more sophisticated analysis of sensor data, leading to better predictive capabilities and personalized healthcare solutions.

The automotive sector is another key driver of market demand for AI-enhanced piezoelectric sensors. With the rise of autonomous vehicles and advanced driver assistance systems (ADAS), there is an increasing need for high-precision sensors that can provide reliable data for vehicle control and safety features. AI-enhanced piezoelectric sensors offer improved accuracy and responsiveness, making them ideal for applications such as tire pressure monitoring, engine management, and collision avoidance systems.

In industrial automation, the demand for AI-enhanced piezoelectric sensors is being fueled by the ongoing digital transformation and the adoption of Industry 4.0 principles. These sensors play a crucial role in predictive maintenance, quality control, and process optimization. By combining piezoelectric sensing technology with AI algorithms, manufacturers can achieve higher levels of efficiency, reduce downtime, and improve overall productivity.

The consumer electronics market is also showing increased interest in AI-enhanced piezoelectric sensors. These sensors are being integrated into smartphones, wearables, and smart home devices to enable new features and improve user experiences. For example, AI-enhanced piezoelectric sensors can be used for gesture recognition, haptic feedback, and energy harvesting applications in consumer devices.

Market analysts project substantial growth in the AI-enhanced piezoelectric sensor market over the next five years. The increasing adoption of Internet of Things (IoT) devices and the growing demand for smart sensors are expected to be major contributors to this growth. Additionally, the development of new materials and manufacturing techniques is likely to drive down costs and improve the performance of these sensors, further expanding their market potential.

However, challenges such as data privacy concerns, the need for standardization, and the complexity of integrating AI algorithms with sensor hardware may impact market growth. Despite these challenges, the overall outlook for AI-enhanced piezoelectric sensors remains positive, with ongoing research and development efforts aimed at addressing these issues and unlocking new applications across various industries.

In the healthcare industry, there is a growing demand for AI-enhanced piezoelectric sensors in medical devices and diagnostic equipment. These sensors can provide more accurate and real-time data for patient monitoring, enabling early detection of health issues and improved treatment outcomes. The integration of AI algorithms allows for more sophisticated analysis of sensor data, leading to better predictive capabilities and personalized healthcare solutions.

The automotive sector is another key driver of market demand for AI-enhanced piezoelectric sensors. With the rise of autonomous vehicles and advanced driver assistance systems (ADAS), there is an increasing need for high-precision sensors that can provide reliable data for vehicle control and safety features. AI-enhanced piezoelectric sensors offer improved accuracy and responsiveness, making them ideal for applications such as tire pressure monitoring, engine management, and collision avoidance systems.

In industrial automation, the demand for AI-enhanced piezoelectric sensors is being fueled by the ongoing digital transformation and the adoption of Industry 4.0 principles. These sensors play a crucial role in predictive maintenance, quality control, and process optimization. By combining piezoelectric sensing technology with AI algorithms, manufacturers can achieve higher levels of efficiency, reduce downtime, and improve overall productivity.

The consumer electronics market is also showing increased interest in AI-enhanced piezoelectric sensors. These sensors are being integrated into smartphones, wearables, and smart home devices to enable new features and improve user experiences. For example, AI-enhanced piezoelectric sensors can be used for gesture recognition, haptic feedback, and energy harvesting applications in consumer devices.

Market analysts project substantial growth in the AI-enhanced piezoelectric sensor market over the next five years. The increasing adoption of Internet of Things (IoT) devices and the growing demand for smart sensors are expected to be major contributors to this growth. Additionally, the development of new materials and manufacturing techniques is likely to drive down costs and improve the performance of these sensors, further expanding their market potential.

However, challenges such as data privacy concerns, the need for standardization, and the complexity of integrating AI algorithms with sensor hardware may impact market growth. Despite these challenges, the overall outlook for AI-enhanced piezoelectric sensors remains positive, with ongoing research and development efforts aimed at addressing these issues and unlocking new applications across various industries.

Current AI-Piezo Integration Challenges

The integration of AI and piezoelectric sensors faces several significant challenges that hinder the full realization of their synergistic potential. One primary obstacle is the complexity of data interpretation from piezoelectric sensors. These sensors generate vast amounts of high-frequency data, often containing noise and artifacts. AI algorithms must be sophisticated enough to accurately process and interpret this complex data stream in real-time, distinguishing meaningful signals from background noise.

Another challenge lies in the miniaturization and power efficiency of integrated AI-piezo systems. Piezoelectric sensors are often deployed in space-constrained environments or as part of IoT devices, necessitating compact AI processing units. However, advanced AI algorithms typically require substantial computational resources, creating a tension between system size and performance capabilities. Developing energy-efficient AI architectures that can operate effectively within these constraints remains a significant hurdle.

The diversity of piezoelectric sensor applications also presents a challenge for AI integration. Different use cases, from structural health monitoring to medical diagnostics, require tailored AI models and algorithms. Creating versatile AI systems that can adapt to various piezoelectric sensor applications while maintaining high accuracy and reliability is a complex task that demands extensive research and development efforts.

Calibration and standardization pose additional challenges. Piezoelectric sensors can exhibit variations in performance due to environmental factors or manufacturing differences. AI systems need to account for these variations and maintain consistent performance across different sensor units and operating conditions. Developing robust calibration methods and standardized protocols for AI-piezo systems is crucial for widespread adoption and interoperability.

The need for explainable AI in critical applications utilizing piezoelectric sensors is another significant challenge. In fields such as healthcare or structural safety, decisions made by AI based on piezoelectric sensor data must be transparent and interpretable. Developing AI models that not only provide accurate results but also offer clear explanations for their decisions is an ongoing area of research and development.

Lastly, the integration of AI with piezoelectric sensors faces challenges in terms of data security and privacy. Many applications of this technology involve sensitive information, such as personal health data or industrial process details. Ensuring the security of data transmission and processing while maintaining the real-time performance required for many piezoelectric sensor applications is a complex balancing act that requires innovative solutions in both hardware and software design.

Another challenge lies in the miniaturization and power efficiency of integrated AI-piezo systems. Piezoelectric sensors are often deployed in space-constrained environments or as part of IoT devices, necessitating compact AI processing units. However, advanced AI algorithms typically require substantial computational resources, creating a tension between system size and performance capabilities. Developing energy-efficient AI architectures that can operate effectively within these constraints remains a significant hurdle.

The diversity of piezoelectric sensor applications also presents a challenge for AI integration. Different use cases, from structural health monitoring to medical diagnostics, require tailored AI models and algorithms. Creating versatile AI systems that can adapt to various piezoelectric sensor applications while maintaining high accuracy and reliability is a complex task that demands extensive research and development efforts.

Calibration and standardization pose additional challenges. Piezoelectric sensors can exhibit variations in performance due to environmental factors or manufacturing differences. AI systems need to account for these variations and maintain consistent performance across different sensor units and operating conditions. Developing robust calibration methods and standardized protocols for AI-piezo systems is crucial for widespread adoption and interoperability.

The need for explainable AI in critical applications utilizing piezoelectric sensors is another significant challenge. In fields such as healthcare or structural safety, decisions made by AI based on piezoelectric sensor data must be transparent and interpretable. Developing AI models that not only provide accurate results but also offer clear explanations for their decisions is an ongoing area of research and development.

Lastly, the integration of AI with piezoelectric sensors faces challenges in terms of data security and privacy. Many applications of this technology involve sensitive information, such as personal health data or industrial process details. Ensuring the security of data transmission and processing while maintaining the real-time performance required for many piezoelectric sensor applications is a complex balancing act that requires innovative solutions in both hardware and software design.

Existing AI-Piezo Synergy Solutions

01 AI-enhanced piezoelectric sensor systems

Integration of artificial intelligence with piezoelectric sensor technology to improve sensing capabilities, data analysis, and decision-making processes. This combination enables more accurate and intelligent monitoring of various physical parameters, enhancing the overall performance and adaptability of sensor systems.- AI-enhanced piezoelectric sensor systems: Integration of artificial intelligence with piezoelectric sensor technology to improve sensing capabilities, data analysis, and decision-making processes. This combination enhances the accuracy and efficiency of sensor systems in various applications.

- Machine learning for piezoelectric signal processing: Application of machine learning algorithms to process and interpret signals from piezoelectric sensors, enabling more sophisticated pattern recognition and anomaly detection in sensor data streams.

- AI-driven piezoelectric energy harvesting optimization: Utilization of AI techniques to optimize the energy harvesting capabilities of piezoelectric devices, improving efficiency and power output for self-powered sensor applications.

- Intelligent piezoelectric sensor networks: Development of smart sensor networks using piezoelectric technology and AI, enabling distributed sensing, collaborative data analysis, and adaptive system responses in complex environments.

- AI-based fault detection and predictive maintenance: Implementation of AI algorithms for real-time fault detection and predictive maintenance in systems utilizing piezoelectric sensors, enhancing reliability and reducing downtime in industrial applications.

02 Machine learning for piezoelectric signal processing

Application of machine learning algorithms to process and interpret signals from piezoelectric sensors. This approach enhances signal quality, reduces noise, and enables more sophisticated pattern recognition and anomaly detection in sensor data.Expand Specific Solutions03 AI-driven piezoelectric energy harvesting

Utilization of artificial intelligence to optimize energy harvesting from piezoelectric materials. AI algorithms can adapt to changing environmental conditions and user behavior to maximize energy generation and storage efficiency in piezoelectric-based energy harvesting systems.Expand Specific Solutions04 Smart piezoelectric sensor networks

Development of interconnected networks of piezoelectric sensors enhanced by AI for distributed sensing applications. These networks can self-organize, communicate, and collaboratively process data to provide comprehensive monitoring solutions for large-scale systems or environments.Expand Specific Solutions05 AI-assisted piezoelectric material design

Application of artificial intelligence in the design and optimization of piezoelectric materials. AI algorithms can predict material properties, suggest novel compositions, and optimize structural designs to enhance the performance of piezoelectric sensors for specific applications.Expand Specific Solutions

Key Players in AI-Piezo Sensor Industry

The synergy between AI and piezoelectric sensors is in an early growth stage, with a rapidly expanding market driven by increasing demand for smart and IoT devices. The global market size is projected to reach billions of dollars by 2025. While the technology is still evolving, several key players are making significant advancements. Companies like Murata Manufacturing, BOE Technology, and Jabil are leading in sensor development, while tech giants such as Texas Instruments and Honeywell are integrating AI capabilities. Research institutions like Chongqing University and the Industrial Technology Research Institute are contributing to technological breakthroughs, indicating a collaborative ecosystem that's pushing the boundaries of this emerging field.

Murata Manufacturing Co. Ltd.

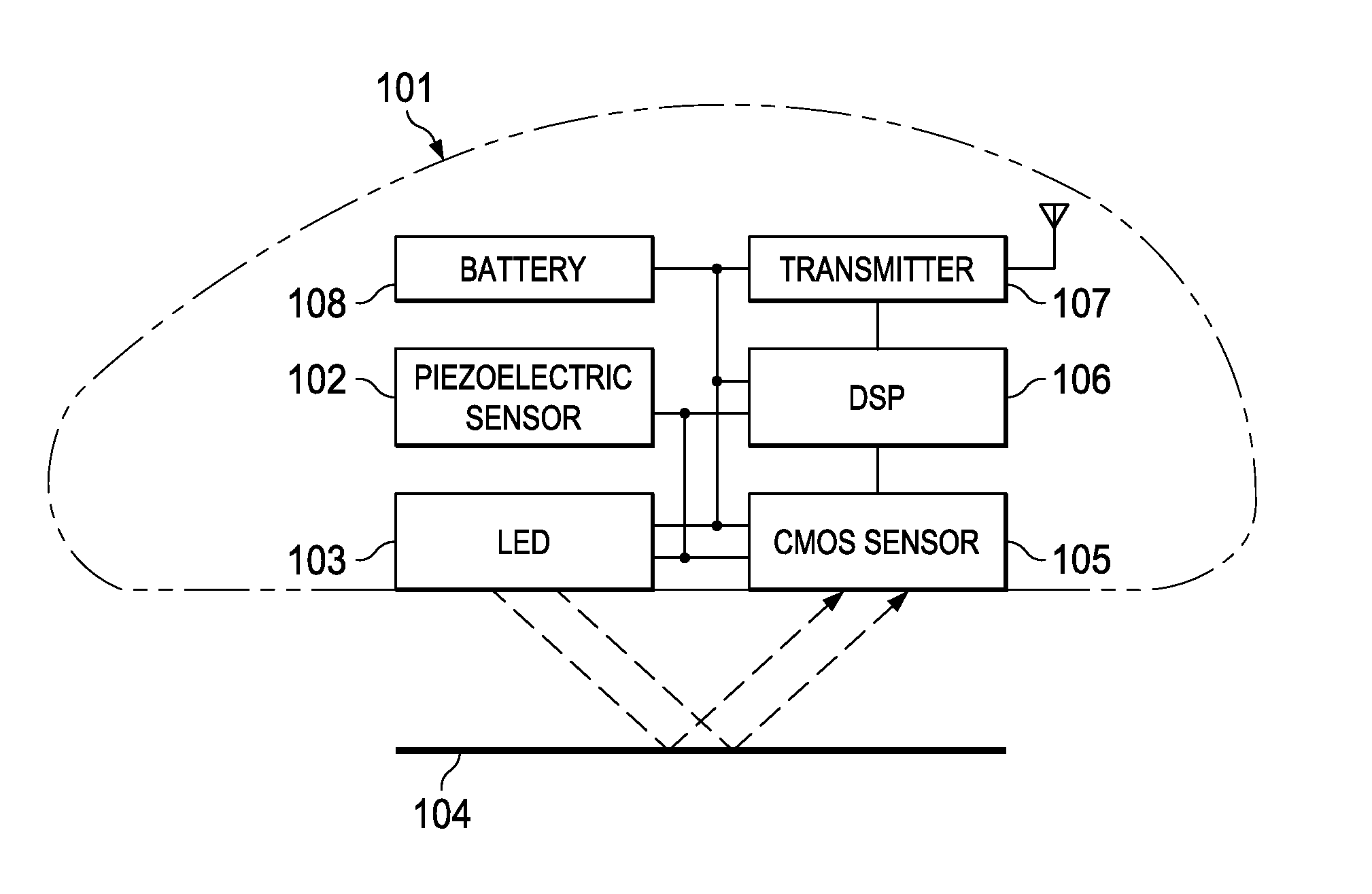

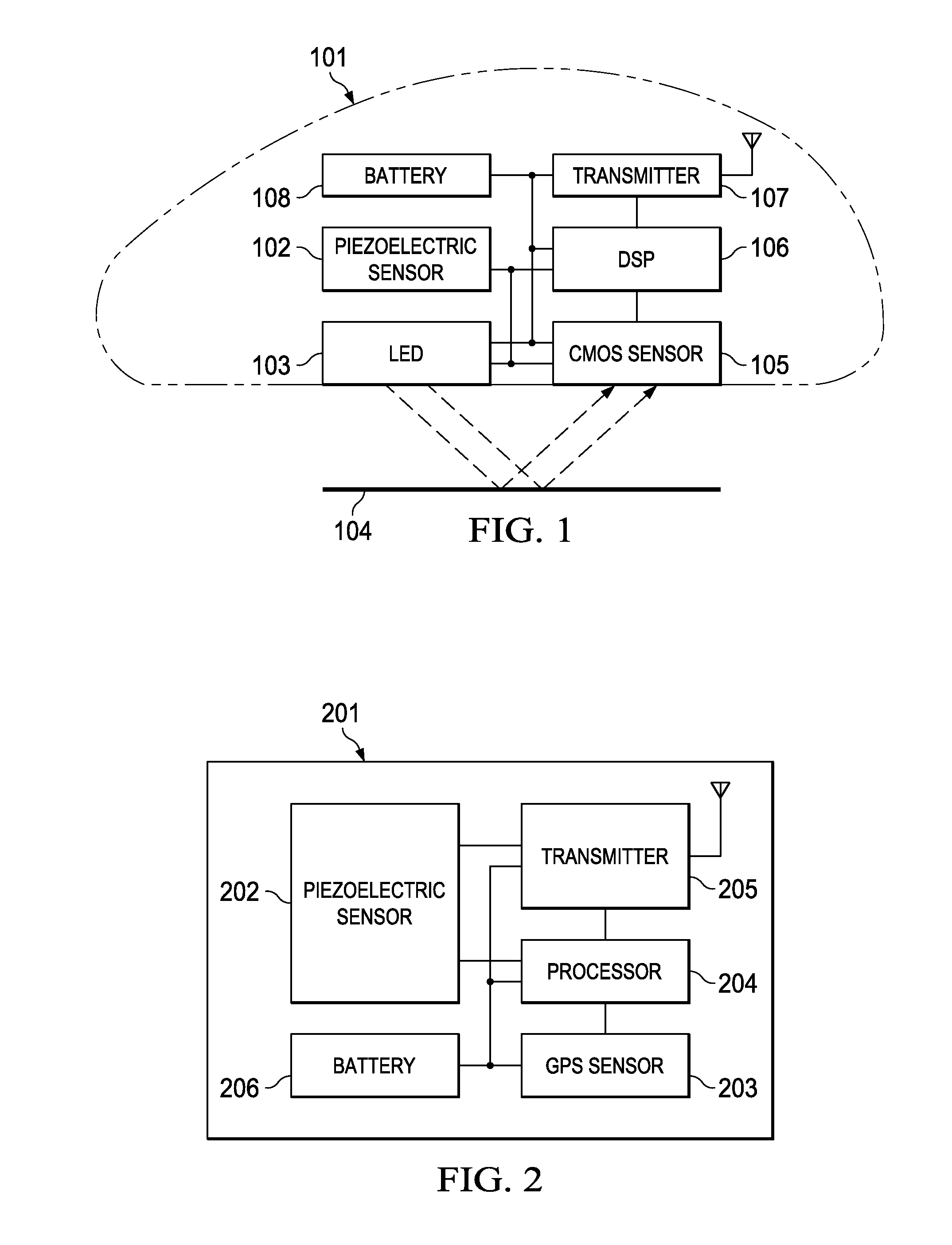

Technical Solution: Murata has developed an AI-enhanced piezoelectric sensor system that combines their expertise in piezoelectric materials with advanced machine learning algorithms. Their approach involves integrating miniaturized piezoelectric sensors with edge AI processors to enable real-time data analysis and decision-making. The system uses a neural network trained on vast amounts of vibration and pressure data to accurately detect and classify various physical phenomena[1]. Murata's solution also incorporates adaptive filtering techniques to reduce noise and improve signal quality, enhancing the overall sensitivity and reliability of the piezoelectric sensors[3]. This synergy between AI and piezoelectric technology allows for more precise and context-aware sensing in applications such as structural health monitoring, predictive maintenance, and human-machine interfaces[5].

Strengths: Industry-leading expertise in piezoelectric materials, extensive sensor manufacturing capabilities, and strong AI integration. Weaknesses: Potential high costs for implementation and need for specialized knowledge to maintain and update the AI models.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an advanced AI-driven piezoelectric sensor platform for industrial and aerospace applications. Their system combines high-performance piezoelectric sensors with sophisticated AI algorithms to enable predictive maintenance and enhanced safety features. Honeywell's approach utilizes a hybrid AI model that combines traditional physics-based models with machine learning techniques, allowing for more accurate predictions and anomaly detection[12]. The platform incorporates a distributed sensor network architecture, where data from multiple piezoelectric sensors is aggregated and analyzed using edge computing devices. Honeywell has also developed specialized AI models for specific industrial processes, such as turbine monitoring and structural health assessment in aircraft. These models are designed to detect subtle changes in vibration patterns and stress distributions, enabling early identification of potential failures and optimizing maintenance schedules[14].

Strengths: Extensive experience in aerospace and industrial control systems, strong focus on safety-critical applications, and robust data security measures. Weaknesses: Solutions may be complex and costly to implement, potentially limiting adoption in smaller-scale operations.

Core AI-Piezo Integration Innovations

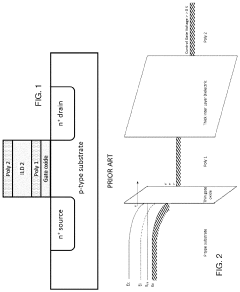

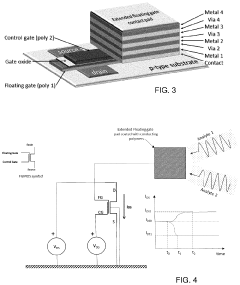

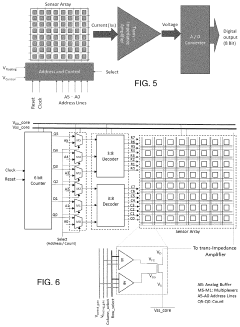

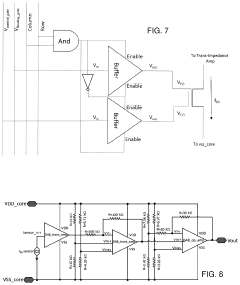

Floating Gate MOS Based Olfactory Sensor System

PatentInactiveUS20220276197A1

Innovation

- A Floating Gate Metal Oxide Semiconductor (FGMOS) transistor with a novel extension pad structure for electrodeposition of conducting polymers, allowing for a small, inexpensive, and programmable olfactory sensor platform using CMOS technology, featuring an array of sensors with chemically diverse polymer coatings for enhanced analyte detection.

Activity Sensing Using Piezoelectric Sensors for Ultra Low Power Operation of Devices with Significant Inactivity Time

PatentInactiveUS20120274564A1

Innovation

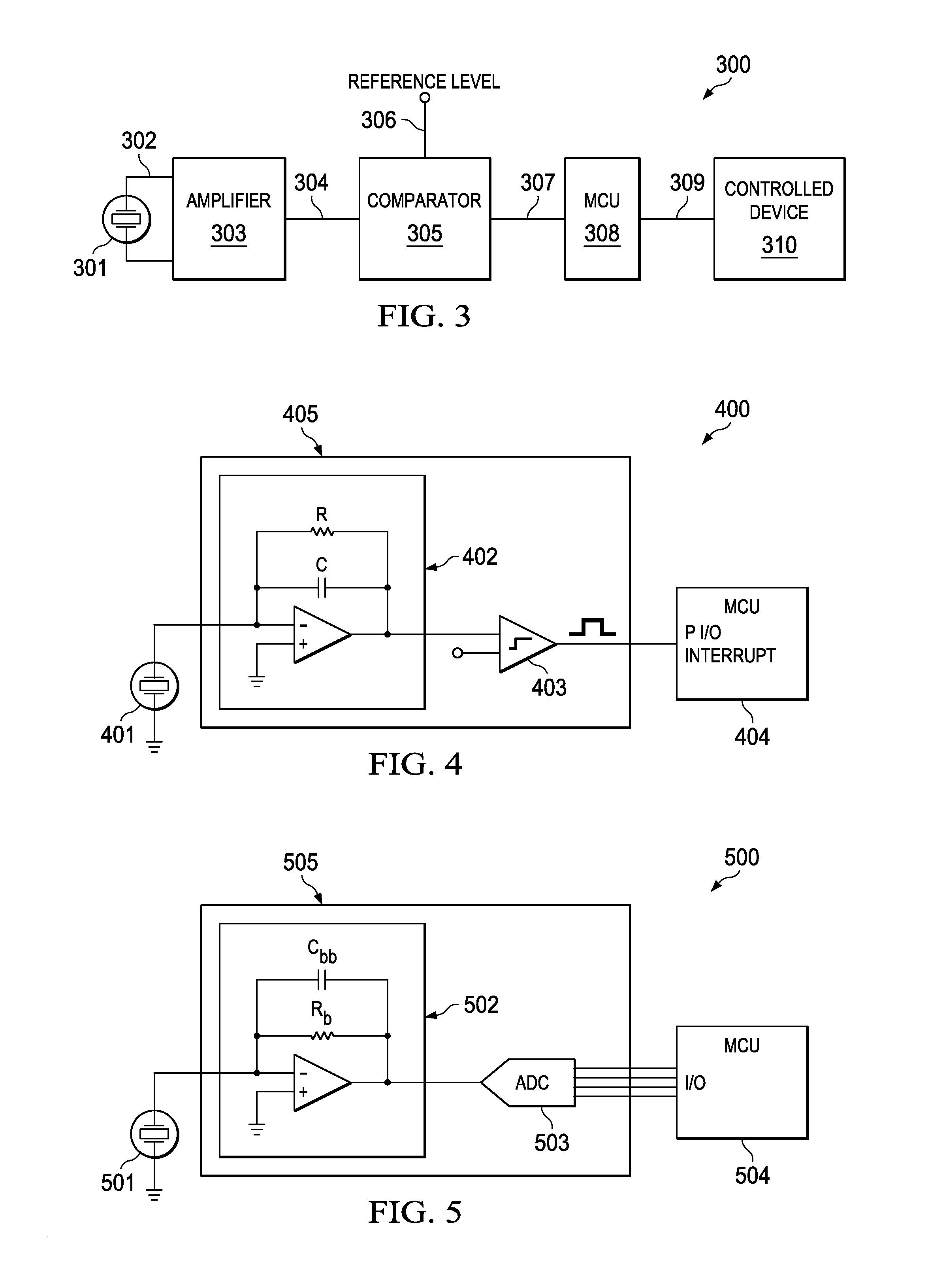

- The use of piezoelectric sensors to detect activity at very low power levels, allowing devices to enter a sleep mode until actual movement is detected, significantly reducing power consumption and extending battery life.

AI-Piezo Data Privacy and Security

The integration of AI and piezoelectric sensors brings significant advancements in data collection and analysis, but it also introduces new challenges in data privacy and security. As these systems become more prevalent in various applications, from healthcare to industrial monitoring, protecting sensitive information becomes paramount.

One of the primary concerns is the potential for unauthorized access to the vast amounts of data collected by piezoelectric sensors. These sensors can capture intricate details about physical movements, vibrations, and pressure changes, which may include personal or proprietary information. AI algorithms processing this data could potentially extract sensitive insights, making data protection crucial.

Encryption plays a vital role in securing AI-piezo systems. Advanced encryption techniques must be implemented at multiple levels, including data transmission, storage, and processing. End-to-end encryption ensures that data remains protected from the point of collection to its final analysis, reducing the risk of interception or tampering.

Access control mechanisms are essential to maintain data integrity and confidentiality. Implementing robust authentication protocols and role-based access control helps ensure that only authorized personnel can interact with the AI-piezo system and its data. This is particularly important in scenarios where multiple stakeholders may have varying levels of access rights.

Data anonymization techniques are crucial when dealing with personal or sensitive information. AI algorithms can be designed to work with anonymized data sets, reducing the risk of individual identification while still allowing for meaningful analysis. Techniques such as differential privacy can be employed to add controlled noise to the data, further protecting individual privacy.

The use of federated learning in AI-piezo systems offers a promising approach to privacy preservation. This technique allows AI models to be trained on distributed datasets without the need to centralize sensitive information. By keeping data localized and only sharing model updates, federated learning significantly reduces the risk of data breaches.

Continuous monitoring and auditing of AI-piezo systems are necessary to detect and respond to potential security threats. Implementing intrusion detection systems and regularly conducting security assessments can help identify vulnerabilities and ensure compliance with data protection regulations.

As AI and piezoelectric sensor technologies continue to evolve, so too must the strategies for data privacy and security. Ongoing research and development in areas such as homomorphic encryption and secure multi-party computation will be crucial in addressing emerging challenges and maintaining trust in these powerful systems.

One of the primary concerns is the potential for unauthorized access to the vast amounts of data collected by piezoelectric sensors. These sensors can capture intricate details about physical movements, vibrations, and pressure changes, which may include personal or proprietary information. AI algorithms processing this data could potentially extract sensitive insights, making data protection crucial.

Encryption plays a vital role in securing AI-piezo systems. Advanced encryption techniques must be implemented at multiple levels, including data transmission, storage, and processing. End-to-end encryption ensures that data remains protected from the point of collection to its final analysis, reducing the risk of interception or tampering.

Access control mechanisms are essential to maintain data integrity and confidentiality. Implementing robust authentication protocols and role-based access control helps ensure that only authorized personnel can interact with the AI-piezo system and its data. This is particularly important in scenarios where multiple stakeholders may have varying levels of access rights.

Data anonymization techniques are crucial when dealing with personal or sensitive information. AI algorithms can be designed to work with anonymized data sets, reducing the risk of individual identification while still allowing for meaningful analysis. Techniques such as differential privacy can be employed to add controlled noise to the data, further protecting individual privacy.

The use of federated learning in AI-piezo systems offers a promising approach to privacy preservation. This technique allows AI models to be trained on distributed datasets without the need to centralize sensitive information. By keeping data localized and only sharing model updates, federated learning significantly reduces the risk of data breaches.

Continuous monitoring and auditing of AI-piezo systems are necessary to detect and respond to potential security threats. Implementing intrusion detection systems and regularly conducting security assessments can help identify vulnerabilities and ensure compliance with data protection regulations.

As AI and piezoelectric sensor technologies continue to evolve, so too must the strategies for data privacy and security. Ongoing research and development in areas such as homomorphic encryption and secure multi-party computation will be crucial in addressing emerging challenges and maintaining trust in these powerful systems.

Standardization of AI-Piezo Technologies

The standardization of AI-Piezo technologies is a critical step towards ensuring interoperability, reliability, and widespread adoption of these innovative systems. As the integration of artificial intelligence and piezoelectric sensors continues to evolve, establishing common protocols and guidelines becomes increasingly important for industry-wide implementation and scalability.

One of the primary areas requiring standardization is data formats and communication protocols. Piezoelectric sensors generate vast amounts of data, which must be processed and analyzed by AI algorithms. Developing standardized data structures and transmission protocols will facilitate seamless integration between different sensor types and AI platforms, enabling more efficient data exchange and analysis across various applications and industries.

Calibration and performance metrics represent another crucial aspect of standardization. Establishing uniform methods for calibrating AI-Piezo systems and evaluating their performance will allow for meaningful comparisons between different solutions and ensure consistent quality across implementations. This includes defining standard test procedures, benchmark datasets, and performance indicators specific to AI-enhanced piezoelectric sensing applications.

Security and privacy considerations must also be addressed through standardization efforts. As AI-Piezo technologies often involve sensitive data collection and analysis, developing standardized security protocols and privacy guidelines is essential. This may include encryption standards for data transmission, access control mechanisms, and guidelines for data anonymization and retention.

Interoperability standards are vital for creating an ecosystem of compatible AI-Piezo technologies. Defining standard interfaces and APIs will enable different components of these systems to work together seamlessly, regardless of the manufacturer or specific implementation. This will foster innovation and competition while ensuring that end-users can easily integrate various AI-Piezo solutions into their existing infrastructure.

Ethical considerations and responsible AI practices should also be incorporated into the standardization process. Developing guidelines for transparency, explainability, and fairness in AI algorithms used in conjunction with piezoelectric sensors will help build trust and ensure responsible deployment of these technologies across various applications, from healthcare to industrial monitoring.

As the field of AI-Piezo technologies continues to advance, ongoing collaboration between industry stakeholders, research institutions, and regulatory bodies will be crucial for developing and maintaining effective standards. Regular reviews and updates to these standards will be necessary to keep pace with technological advancements and emerging challenges in this rapidly evolving field.

One of the primary areas requiring standardization is data formats and communication protocols. Piezoelectric sensors generate vast amounts of data, which must be processed and analyzed by AI algorithms. Developing standardized data structures and transmission protocols will facilitate seamless integration between different sensor types and AI platforms, enabling more efficient data exchange and analysis across various applications and industries.

Calibration and performance metrics represent another crucial aspect of standardization. Establishing uniform methods for calibrating AI-Piezo systems and evaluating their performance will allow for meaningful comparisons between different solutions and ensure consistent quality across implementations. This includes defining standard test procedures, benchmark datasets, and performance indicators specific to AI-enhanced piezoelectric sensing applications.

Security and privacy considerations must also be addressed through standardization efforts. As AI-Piezo technologies often involve sensitive data collection and analysis, developing standardized security protocols and privacy guidelines is essential. This may include encryption standards for data transmission, access control mechanisms, and guidelines for data anonymization and retention.

Interoperability standards are vital for creating an ecosystem of compatible AI-Piezo technologies. Defining standard interfaces and APIs will enable different components of these systems to work together seamlessly, regardless of the manufacturer or specific implementation. This will foster innovation and competition while ensuring that end-users can easily integrate various AI-Piezo solutions into their existing infrastructure.

Ethical considerations and responsible AI practices should also be incorporated into the standardization process. Developing guidelines for transparency, explainability, and fairness in AI algorithms used in conjunction with piezoelectric sensors will help build trust and ensure responsible deployment of these technologies across various applications, from healthcare to industrial monitoring.

As the field of AI-Piezo technologies continues to advance, ongoing collaboration between industry stakeholders, research institutions, and regulatory bodies will be crucial for developing and maintaining effective standards. Regular reviews and updates to these standards will be necessary to keep pace with technological advancements and emerging challenges in this rapidly evolving field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!