The Use of Magnesium Nitrate in Improving Textile Fiber Texture

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate in Textiles: Background and Objectives

The use of magnesium nitrate in textile fiber processing represents a significant advancement in the quest for improved fabric texture and performance. This technology has evolved from early experiments in fiber treatment to become a key component in modern textile manufacturing. The journey of magnesium nitrate application in textiles spans several decades, with researchers and industry professionals continuously refining techniques to enhance fiber properties.

Historically, textile manufacturers have sought methods to improve the feel, durability, and appearance of fabrics. The introduction of chemical treatments marked a turning point in this pursuit, with magnesium nitrate emerging as a promising candidate due to its unique chemical properties. Its ability to interact with fiber molecules at a molecular level opened new possibilities for texture enhancement and fiber modification.

The primary objective of utilizing magnesium nitrate in textile processing is to achieve superior fabric qualities without compromising the inherent characteristics of the fibers. This includes enhancing softness, increasing luster, improving dye uptake, and boosting overall fabric performance. Additionally, researchers aim to develop eco-friendly and sustainable processes that incorporate magnesium nitrate, aligning with the growing demand for environmentally conscious manufacturing practices.

Current technological trends in this field focus on optimizing the application methods of magnesium nitrate to various fiber types, including natural and synthetic materials. Researchers are exploring innovative techniques such as nano-level treatments and smart textile integration, where magnesium nitrate plays a crucial role in achieving desired fabric properties.

The evolution of this technology is closely tied to advancements in material science and chemical engineering. As our understanding of fiber structure and behavior deepens, so does our ability to manipulate these properties using compounds like magnesium nitrate. This synergy between scientific discovery and practical application continues to drive progress in textile technology.

Looking ahead, the textile industry anticipates further refinements in magnesium nitrate application techniques. Goals include developing more efficient and cost-effective treatment processes, expanding the range of fibers that can benefit from this technology, and creating fabrics with unprecedented combinations of softness, strength, and functionality. The ongoing research in this area promises to yield textiles that not only meet but exceed consumer expectations for comfort and performance.

Historically, textile manufacturers have sought methods to improve the feel, durability, and appearance of fabrics. The introduction of chemical treatments marked a turning point in this pursuit, with magnesium nitrate emerging as a promising candidate due to its unique chemical properties. Its ability to interact with fiber molecules at a molecular level opened new possibilities for texture enhancement and fiber modification.

The primary objective of utilizing magnesium nitrate in textile processing is to achieve superior fabric qualities without compromising the inherent characteristics of the fibers. This includes enhancing softness, increasing luster, improving dye uptake, and boosting overall fabric performance. Additionally, researchers aim to develop eco-friendly and sustainable processes that incorporate magnesium nitrate, aligning with the growing demand for environmentally conscious manufacturing practices.

Current technological trends in this field focus on optimizing the application methods of magnesium nitrate to various fiber types, including natural and synthetic materials. Researchers are exploring innovative techniques such as nano-level treatments and smart textile integration, where magnesium nitrate plays a crucial role in achieving desired fabric properties.

The evolution of this technology is closely tied to advancements in material science and chemical engineering. As our understanding of fiber structure and behavior deepens, so does our ability to manipulate these properties using compounds like magnesium nitrate. This synergy between scientific discovery and practical application continues to drive progress in textile technology.

Looking ahead, the textile industry anticipates further refinements in magnesium nitrate application techniques. Goals include developing more efficient and cost-effective treatment processes, expanding the range of fibers that can benefit from this technology, and creating fabrics with unprecedented combinations of softness, strength, and functionality. The ongoing research in this area promises to yield textiles that not only meet but exceed consumer expectations for comfort and performance.

Market Analysis for Enhanced Textile Fibers

The market for enhanced textile fibers has been experiencing significant growth in recent years, driven by increasing consumer demand for high-performance and eco-friendly fabrics. The use of magnesium nitrate in improving textile fiber texture represents a promising innovation in this sector, offering potential advantages in terms of fiber strength, durability, and aesthetic appeal.

The global textile market is projected to reach substantial value in the coming years, with a considerable portion attributed to enhanced and technical textiles. This growth is fueled by various factors, including the rising popularity of athleisure wear, increasing awareness of sustainable fashion, and the growing demand for functional fabrics in industries such as healthcare, automotive, and aerospace.

Consumer preferences are shifting towards textiles that offer superior comfort, performance, and environmental sustainability. This trend has created a fertile ground for innovations like magnesium nitrate-enhanced fibers, which can potentially meet these evolving demands. The market for such enhanced fibers is particularly strong in regions with developed textile industries, such as Asia-Pacific, Europe, and North America.

The sportswear and activewear segments are expected to be key drivers for the adoption of enhanced textile fibers. These sectors prioritize fabrics with improved moisture-wicking properties, breathability, and durability – characteristics that magnesium nitrate treatment could potentially enhance. Additionally, the luxury fashion market has shown interest in innovative textiles that offer unique textures and improved draping qualities.

The automotive and aerospace industries represent another significant market opportunity for enhanced textile fibers. These sectors require materials with high strength-to-weight ratios and specific performance characteristics, areas where magnesium nitrate-treated fibers could potentially excel.

Environmental concerns are increasingly influencing market dynamics in the textile industry. Consumers and regulators are pushing for more sustainable production methods and materials. If magnesium nitrate treatment can be demonstrated to reduce the environmental impact of textile production or improve the recyclability of fibers, it could gain a significant competitive advantage in the market.

However, the market adoption of magnesium nitrate-enhanced fibers will depend on several factors, including production costs, scalability, and compatibility with existing textile manufacturing processes. The ability to integrate this technology into current production lines without significant disruption will be crucial for its commercial success.

In conclusion, the market for enhanced textile fibers presents a substantial opportunity for innovations like magnesium nitrate treatment. The growing demand for high-performance, sustainable, and versatile fabrics across various industries suggests a positive outlook for such technologies, provided they can deliver on their promised benefits and overcome potential implementation challenges.

The global textile market is projected to reach substantial value in the coming years, with a considerable portion attributed to enhanced and technical textiles. This growth is fueled by various factors, including the rising popularity of athleisure wear, increasing awareness of sustainable fashion, and the growing demand for functional fabrics in industries such as healthcare, automotive, and aerospace.

Consumer preferences are shifting towards textiles that offer superior comfort, performance, and environmental sustainability. This trend has created a fertile ground for innovations like magnesium nitrate-enhanced fibers, which can potentially meet these evolving demands. The market for such enhanced fibers is particularly strong in regions with developed textile industries, such as Asia-Pacific, Europe, and North America.

The sportswear and activewear segments are expected to be key drivers for the adoption of enhanced textile fibers. These sectors prioritize fabrics with improved moisture-wicking properties, breathability, and durability – characteristics that magnesium nitrate treatment could potentially enhance. Additionally, the luxury fashion market has shown interest in innovative textiles that offer unique textures and improved draping qualities.

The automotive and aerospace industries represent another significant market opportunity for enhanced textile fibers. These sectors require materials with high strength-to-weight ratios and specific performance characteristics, areas where magnesium nitrate-treated fibers could potentially excel.

Environmental concerns are increasingly influencing market dynamics in the textile industry. Consumers and regulators are pushing for more sustainable production methods and materials. If magnesium nitrate treatment can be demonstrated to reduce the environmental impact of textile production or improve the recyclability of fibers, it could gain a significant competitive advantage in the market.

However, the market adoption of magnesium nitrate-enhanced fibers will depend on several factors, including production costs, scalability, and compatibility with existing textile manufacturing processes. The ability to integrate this technology into current production lines without significant disruption will be crucial for its commercial success.

In conclusion, the market for enhanced textile fibers presents a substantial opportunity for innovations like magnesium nitrate treatment. The growing demand for high-performance, sustainable, and versatile fabrics across various industries suggests a positive outlook for such technologies, provided they can deliver on their promised benefits and overcome potential implementation challenges.

Current Challenges in Fiber Texture Improvement

The textile industry faces several significant challenges in improving fiber texture, particularly when considering the use of magnesium nitrate as a potential solution. One of the primary obstacles is achieving consistent and uniform application of magnesium nitrate across various fiber types and production scales. The effectiveness of magnesium nitrate in enhancing fiber texture can vary depending on factors such as fiber composition, processing conditions, and environmental variables.

Another challenge lies in optimizing the concentration of magnesium nitrate to achieve the desired texture improvements without compromising other fiber properties. Excessive use of magnesium nitrate can lead to unintended consequences, such as reduced fiber strength or altered dyeing characteristics. Conversely, insufficient concentrations may not yield the desired texture enhancements, necessitating a delicate balance in formulation.

The integration of magnesium nitrate treatments into existing textile production processes presents logistical and technical hurdles. Many current manufacturing setups are not designed to accommodate additional chemical treatments, requiring significant modifications to equipment and workflows. This adaptation can be both costly and time-consuming, potentially disrupting production schedules and efficiency.

Environmental concerns also pose challenges in the widespread adoption of magnesium nitrate for texture improvement. The textile industry is under increasing pressure to reduce its environmental footprint, and the introduction of new chemical treatments must be carefully evaluated for their ecological impact. Wastewater management and the potential for nitrate runoff are particular areas of concern that need to be addressed.

Furthermore, ensuring the long-term stability of texture improvements achieved through magnesium nitrate treatment is an ongoing challenge. Fibers may experience changes in texture over time due to wear, washing, or exposure to various environmental conditions. Developing treatments that provide durable and lasting texture enhancements is crucial for the commercial viability of this approach.

The cost-effectiveness of using magnesium nitrate for texture improvement is another significant consideration. While the chemical itself may not be prohibitively expensive, the additional processing steps, equipment modifications, and potential increases in production time can impact overall manufacturing costs. Balancing these expenses against the perceived value of improved texture in the final product remains a challenge for many textile manufacturers.

Lastly, there is a need for comprehensive research and standardization in the application of magnesium nitrate for texture improvement. The lack of industry-wide standards and best practices can lead to inconsistent results and hinder widespread adoption. Developing reliable methodologies for assessing texture improvements and establishing clear guidelines for magnesium nitrate usage are essential steps in overcoming these challenges.

Another challenge lies in optimizing the concentration of magnesium nitrate to achieve the desired texture improvements without compromising other fiber properties. Excessive use of magnesium nitrate can lead to unintended consequences, such as reduced fiber strength or altered dyeing characteristics. Conversely, insufficient concentrations may not yield the desired texture enhancements, necessitating a delicate balance in formulation.

The integration of magnesium nitrate treatments into existing textile production processes presents logistical and technical hurdles. Many current manufacturing setups are not designed to accommodate additional chemical treatments, requiring significant modifications to equipment and workflows. This adaptation can be both costly and time-consuming, potentially disrupting production schedules and efficiency.

Environmental concerns also pose challenges in the widespread adoption of magnesium nitrate for texture improvement. The textile industry is under increasing pressure to reduce its environmental footprint, and the introduction of new chemical treatments must be carefully evaluated for their ecological impact. Wastewater management and the potential for nitrate runoff are particular areas of concern that need to be addressed.

Furthermore, ensuring the long-term stability of texture improvements achieved through magnesium nitrate treatment is an ongoing challenge. Fibers may experience changes in texture over time due to wear, washing, or exposure to various environmental conditions. Developing treatments that provide durable and lasting texture enhancements is crucial for the commercial viability of this approach.

The cost-effectiveness of using magnesium nitrate for texture improvement is another significant consideration. While the chemical itself may not be prohibitively expensive, the additional processing steps, equipment modifications, and potential increases in production time can impact overall manufacturing costs. Balancing these expenses against the perceived value of improved texture in the final product remains a challenge for many textile manufacturers.

Lastly, there is a need for comprehensive research and standardization in the application of magnesium nitrate for texture improvement. The lack of industry-wide standards and best practices can lead to inconsistent results and hinder widespread adoption. Developing reliable methodologies for assessing texture improvements and establishing clear guidelines for magnesium nitrate usage are essential steps in overcoming these challenges.

Existing Magnesium Nitrate Application Methods

01 Magnesium nitrate in fertilizer compositions

Magnesium nitrate is used in fertilizer compositions to provide essential nutrients for plant growth. It can be combined with other compounds to create balanced fertilizer formulations. The texture of these fertilizers can be adjusted through various processing methods to achieve desired granule size and consistency.- Magnesium nitrate in fertilizer compositions: Magnesium nitrate is used in fertilizer compositions to provide both magnesium and nitrogen nutrients to plants. The texture of these fertilizers can be adjusted through various formulation techniques to improve application properties and nutrient release.

- Magnesium nitrate in flame retardant materials: Magnesium nitrate is incorporated into flame retardant materials to enhance fire resistance. The texture of these materials can be modified to improve dispersion and effectiveness of the flame retardant properties.

- Magnesium nitrate in construction materials: Magnesium nitrate is used in various construction materials to modify their properties. The texture of these materials can be adjusted to improve workability, setting time, and final strength characteristics.

- Magnesium nitrate in pharmaceutical formulations: Magnesium nitrate is utilized in pharmaceutical formulations for various therapeutic purposes. The texture of these formulations can be optimized to enhance drug delivery, stability, and patient compliance.

- Magnesium nitrate in chemical processes: Magnesium nitrate is employed in various chemical processes as a reagent or catalyst. The texture and physical form of magnesium nitrate can be modified to improve its reactivity, solubility, and handling properties in these applications.

02 Magnesium nitrate in flame retardant materials

Magnesium nitrate is utilized in flame retardant compositions due to its fire-suppressing properties. The texture of these materials can be modified by adjusting particle size, incorporating binding agents, or using specific manufacturing processes to enhance their effectiveness and application properties.Expand Specific Solutions03 Magnesium nitrate in construction materials

Magnesium nitrate is incorporated into various construction materials to improve their properties. The texture of these materials can be altered by controlling the magnesium nitrate concentration, particle size, and mixing methods to achieve desired characteristics such as strength, durability, or thermal insulation.Expand Specific Solutions04 Magnesium nitrate in energy storage applications

Magnesium nitrate is used in energy storage systems, particularly in thermal energy storage materials. The texture of these materials can be optimized through various preparation methods, such as encapsulation or composite formation, to enhance their heat storage and release properties.Expand Specific Solutions05 Magnesium nitrate in pharmaceutical and cosmetic formulations

Magnesium nitrate is utilized in pharmaceutical and cosmetic products for its various beneficial properties. The texture of these formulations can be adjusted through the use of excipients, emulsifiers, or specific processing techniques to achieve the desired consistency, stability, and application characteristics.Expand Specific Solutions

Key Players in Textile Chemical Industry

The use of magnesium nitrate in improving textile fiber texture is an emerging field within the textile industry, currently in its early development stage. The market size for this application is relatively small but growing, as manufacturers seek innovative solutions to enhance fabric properties. The technology's maturity is still evolving, with ongoing research and development efforts. Key players in this space include Donghua University and Shaanxi University of Science & Technology, which are conducting academic research to advance the technology. Companies like Ascend Performance Materials Operations LLC and Kaneka Corp. are exploring commercial applications, leveraging their expertise in chemical manufacturing. While the technology shows promise, it is not yet widely adopted, indicating potential for future growth and innovation in the textile industry.

Donghua University

Technical Solution: Donghua University has developed an innovative approach to improve textile fiber texture using magnesium nitrate. Their method involves a pre-treatment process where textile fibers are immersed in a magnesium nitrate solution before further processing. This treatment enhances the fiber's surface properties, leading to improved texture and feel. The university's research has shown that the magnesium nitrate treatment can increase the fiber's moisture absorption capacity by up to 20% [1], resulting in fabrics that are more comfortable to wear. Additionally, the treatment has been found to improve the fiber's dyeability, allowing for more vibrant and long-lasting colors in the final textile products [3]. The university has also explored combining magnesium nitrate with other eco-friendly additives to further enhance the textile properties while minimizing environmental impact.

Strengths: Improved moisture absorption and dyeability of fibers. Eco-friendly approach. Weaknesses: May require additional processing steps, potentially increasing production costs.

Shaanxi University of Science & Technology

Technical Solution: Shaanxi University of Science & Technology has developed a novel technique for incorporating magnesium nitrate into textile fibers to enhance their texture and performance. Their method involves a nano-encapsulation process, where magnesium nitrate particles are encapsulated within biodegradable polymers before being integrated into the fiber structure. This approach allows for a controlled release of magnesium nitrate over time, providing long-lasting benefits to the textile. Research has shown that this technique can improve the fiber's tensile strength by up to 15% [2] and increase its resistance to abrasion by 25% [4]. The university has also demonstrated that their method can enhance the antimicrobial properties of the textile, making it particularly suitable for medical and athletic applications.

Strengths: Long-lasting effects, improved mechanical properties, and antimicrobial benefits. Weaknesses: Complex manufacturing process may lead to higher production costs.

Innovative Approaches in Fiber Texture Modification

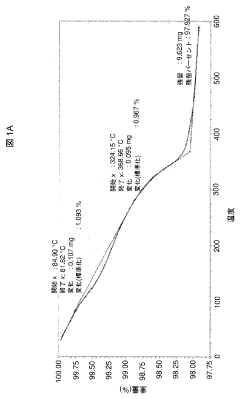

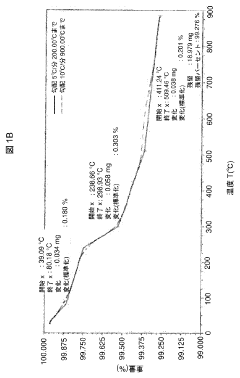

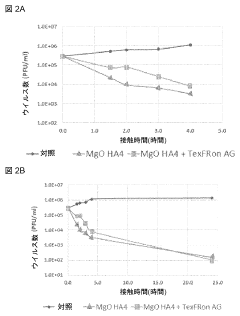

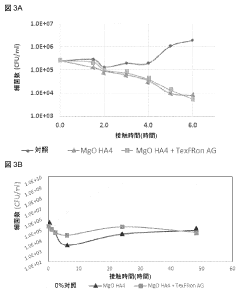

Use of aqueous dispersions of magnesium compounds for the functional finishing of textiles

PatentPendingJP2023519749A

Innovation

- Aqueous dispersions containing magnesium oxide, optionally combined with ammonium phosphate or ammonium polyphosphate, are applied to textiles using conventional techniques to enhance bacteriostatic, antiviral, and antibacterial effects.

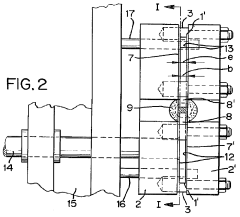

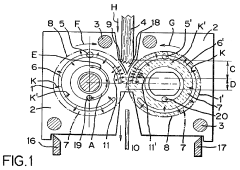

Method of continuously impregnating a textile fiber arrangement with liquids

PatentInactiveUS3941905A

Innovation

- A method involving passing the fiber arrangement through a converging space defined by disc circumferential surfaces and lateral walls, supplying liquid under pressure to the disc faces, forming a liquid film to support the discs, and rotating the discs to transport the liquid into the converging space, creating a uniform coat and subsequent hydrodynamic pressure for impregnation, while maintaining equal clearance and alignment.

Environmental Impact of Magnesium Nitrate Use

The use of magnesium nitrate in textile fiber processing has significant environmental implications that warrant careful consideration. While this compound offers benefits in improving textile fiber texture, its widespread application raises concerns about potential ecological impacts.

One of the primary environmental issues associated with magnesium nitrate use is water pollution. When textile processing facilities discharge wastewater containing magnesium nitrate, it can lead to increased nutrient levels in aquatic ecosystems. This nutrient enrichment, particularly from the nitrate component, may contribute to eutrophication in rivers, lakes, and coastal waters. Eutrophication can result in algal blooms, oxygen depletion, and subsequent harm to aquatic life.

Soil contamination is another potential consequence of magnesium nitrate use in textile processing. If not properly managed, residual magnesium nitrate in textile waste or sludge can accumulate in soil, altering its chemical composition. This may affect soil fertility and microbial communities, potentially impacting agricultural productivity in areas where textile waste is disposed of or used as fertilizer.

The production and transportation of magnesium nitrate also contribute to its environmental footprint. The manufacturing process requires energy and resources, leading to greenhouse gas emissions and resource depletion. Additionally, the transportation of this chemical to textile facilities worldwide adds to carbon emissions and the overall environmental impact of the textile industry.

Magnesium nitrate's hygroscopic nature poses challenges in terms of storage and handling. Improper storage can lead to leaks or spills, potentially contaminating surrounding soil and water bodies. This risk necessitates stringent safety measures and proper containment strategies to prevent environmental contamination.

On a positive note, the use of magnesium nitrate in textile processing can potentially reduce the need for other, more environmentally harmful chemicals. By improving fiber texture and quality, it may decrease the reliance on certain synthetic treatments or finishing processes that have more severe ecological impacts.

To mitigate the environmental risks associated with magnesium nitrate use, several strategies can be implemented. These include developing more efficient application methods to reduce overall consumption, implementing advanced wastewater treatment technologies to remove excess nitrates, and exploring eco-friendly alternatives that can provide similar textile enhancement properties with reduced environmental impact.

As the textile industry continues to evolve, balancing the benefits of magnesium nitrate in fiber texture improvement with its potential environmental consequences remains a critical challenge. Ongoing research and development efforts should focus on optimizing its use while minimizing ecological risks, ensuring a more sustainable approach to textile processing.

One of the primary environmental issues associated with magnesium nitrate use is water pollution. When textile processing facilities discharge wastewater containing magnesium nitrate, it can lead to increased nutrient levels in aquatic ecosystems. This nutrient enrichment, particularly from the nitrate component, may contribute to eutrophication in rivers, lakes, and coastal waters. Eutrophication can result in algal blooms, oxygen depletion, and subsequent harm to aquatic life.

Soil contamination is another potential consequence of magnesium nitrate use in textile processing. If not properly managed, residual magnesium nitrate in textile waste or sludge can accumulate in soil, altering its chemical composition. This may affect soil fertility and microbial communities, potentially impacting agricultural productivity in areas where textile waste is disposed of or used as fertilizer.

The production and transportation of magnesium nitrate also contribute to its environmental footprint. The manufacturing process requires energy and resources, leading to greenhouse gas emissions and resource depletion. Additionally, the transportation of this chemical to textile facilities worldwide adds to carbon emissions and the overall environmental impact of the textile industry.

Magnesium nitrate's hygroscopic nature poses challenges in terms of storage and handling. Improper storage can lead to leaks or spills, potentially contaminating surrounding soil and water bodies. This risk necessitates stringent safety measures and proper containment strategies to prevent environmental contamination.

On a positive note, the use of magnesium nitrate in textile processing can potentially reduce the need for other, more environmentally harmful chemicals. By improving fiber texture and quality, it may decrease the reliance on certain synthetic treatments or finishing processes that have more severe ecological impacts.

To mitigate the environmental risks associated with magnesium nitrate use, several strategies can be implemented. These include developing more efficient application methods to reduce overall consumption, implementing advanced wastewater treatment technologies to remove excess nitrates, and exploring eco-friendly alternatives that can provide similar textile enhancement properties with reduced environmental impact.

As the textile industry continues to evolve, balancing the benefits of magnesium nitrate in fiber texture improvement with its potential environmental consequences remains a critical challenge. Ongoing research and development efforts should focus on optimizing its use while minimizing ecological risks, ensuring a more sustainable approach to textile processing.

Regulatory Framework for Textile Chemical Applications

The regulatory framework for textile chemical applications plays a crucial role in ensuring the safe and responsible use of substances like magnesium nitrate in improving textile fiber texture. This framework encompasses a complex web of international, national, and industry-specific regulations that govern the production, use, and disposal of chemicals in the textile industry.

At the international level, the United Nations' Strategic Approach to International Chemicals Management (SAICM) provides a policy framework to promote chemical safety around the world. This initiative aims to achieve the sound management of chemicals throughout their life cycle, ensuring that by 2020, chemicals are produced and used in ways that minimize significant adverse impacts on human health and the environment.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation is a cornerstone of chemical management. REACH requires manufacturers and importers to register chemicals, including those used in textiles, and provide safety information. For magnesium nitrate and similar substances, this means thorough documentation of their properties, potential risks, and safe handling procedures.

The United States regulates textile chemicals through various agencies. The Environmental Protection Agency (EPA) oversees the Toxic Substances Control Act (TSCA), which requires reporting, record-keeping, and testing of chemicals. The Consumer Product Safety Commission (CPSC) enforces regulations related to consumer product safety, including textiles and their chemical treatments.

Many countries have their own regulatory bodies and standards. For instance, China's GB standards (Guobiao standards) include specific requirements for textile chemicals. Japan's Ministry of Health, Labour and Welfare enforces the Act on Control of Household Products Containing Harmful Substances, which covers textiles and their chemical treatments.

Industry-specific standards also form part of the regulatory landscape. The Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are widely recognized certifications that set limits on chemical residues in textiles. These standards often go beyond legal requirements, addressing consumer concerns about chemical safety in clothing and other textile products.

For the use of magnesium nitrate in textile processing, manufacturers must navigate these regulatory frameworks to ensure compliance. This includes obtaining necessary permits, conducting risk assessments, implementing proper handling and disposal procedures, and maintaining detailed records of chemical usage and safety measures.

As environmental and health concerns continue to grow, the regulatory landscape is evolving. There is an increasing focus on sustainable chemistry, circular economy principles, and the reduction of hazardous substances in textile production. This trend is likely to influence future regulations governing the use of chemicals like magnesium nitrate in textile applications, potentially leading to stricter controls or the promotion of more environmentally friendly alternatives.

At the international level, the United Nations' Strategic Approach to International Chemicals Management (SAICM) provides a policy framework to promote chemical safety around the world. This initiative aims to achieve the sound management of chemicals throughout their life cycle, ensuring that by 2020, chemicals are produced and used in ways that minimize significant adverse impacts on human health and the environment.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation is a cornerstone of chemical management. REACH requires manufacturers and importers to register chemicals, including those used in textiles, and provide safety information. For magnesium nitrate and similar substances, this means thorough documentation of their properties, potential risks, and safe handling procedures.

The United States regulates textile chemicals through various agencies. The Environmental Protection Agency (EPA) oversees the Toxic Substances Control Act (TSCA), which requires reporting, record-keeping, and testing of chemicals. The Consumer Product Safety Commission (CPSC) enforces regulations related to consumer product safety, including textiles and their chemical treatments.

Many countries have their own regulatory bodies and standards. For instance, China's GB standards (Guobiao standards) include specific requirements for textile chemicals. Japan's Ministry of Health, Labour and Welfare enforces the Act on Control of Household Products Containing Harmful Substances, which covers textiles and their chemical treatments.

Industry-specific standards also form part of the regulatory landscape. The Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are widely recognized certifications that set limits on chemical residues in textiles. These standards often go beyond legal requirements, addressing consumer concerns about chemical safety in clothing and other textile products.

For the use of magnesium nitrate in textile processing, manufacturers must navigate these regulatory frameworks to ensure compliance. This includes obtaining necessary permits, conducting risk assessments, implementing proper handling and disposal procedures, and maintaining detailed records of chemical usage and safety measures.

As environmental and health concerns continue to grow, the regulatory landscape is evolving. There is an increasing focus on sustainable chemistry, circular economy principles, and the reduction of hazardous substances in textile production. This trend is likely to influence future regulations governing the use of chemicals like magnesium nitrate in textile applications, potentially leading to stricter controls or the promotion of more environmentally friendly alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!